Title Page

-

Prepared by:

-

Location:

-

Date:

-

Task/Activity:

-

Brief Description of Task/Activity

-

Document Number:

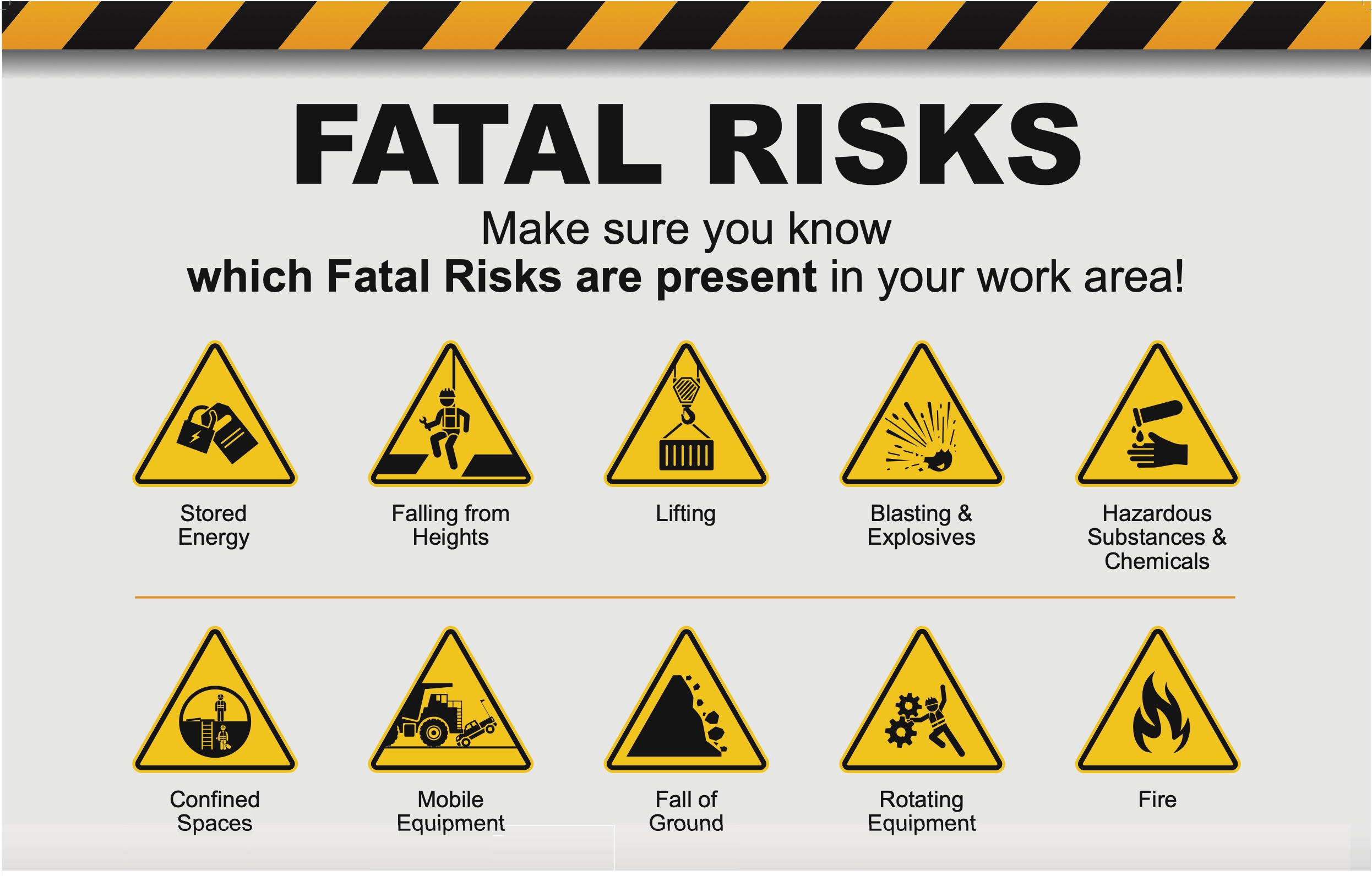

Fatal Risk Control

-

Make sure you know which Fatal Risks are present in your work area!

-

If any fatal risk controls are not effectively implemented or maintained the task/activity should be stopped immediately and the related risks needs to be re assessed by a competent person.

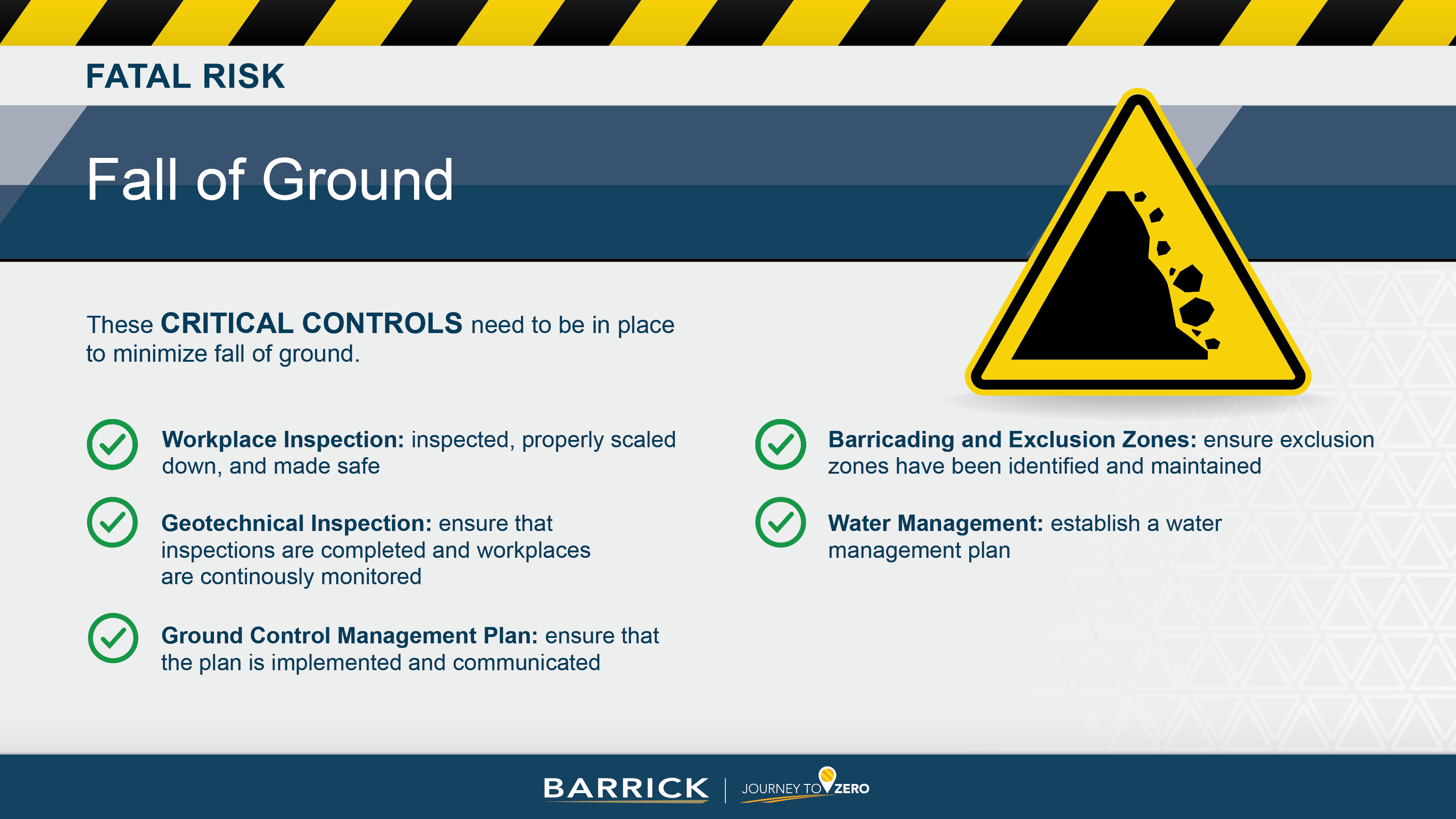

Fall of Ground - Surface

-

These CRITICAL CONTROLS needs to be in place to minimize fall of ground.

-

Does the activity present Surface fall of ground risks.

Competency

-

Has the worker been trained and authorized, and does the worker understand the components of Fall of Ground activity?

-

Is the worker familiar with the FRA and critical controls?

Ground Control

-

Have identified ground control hazards and mitigations been communicated from geotechnical to supervisors and frontline operations in between shifts?

-

Are the highwalls scaled and free of debris, and are the catch benches adequate?

-

Are team members maintaining loading faces at a safe working height/angle and are not positioning themselves between mining equipment and the face?

-

Is there a barrier (e.g., berm or jersey barriers) in place to stop people and mobile equipment from entering areas where material can fall from a high wall/excavation?

-

Is the highwall/stockpile built and maintained to plan design?

-

Are team members entering restricted areas without permission? (e.g., base and crest of highwalls/stockpiles, benches, mining faces, dumps and blasting areas)

-

Is the surface water control installed and maintained according to design and clear of obstructions? (e.g., storm water drains)

Barriers/Barricades and Exclusion Zones

-

Are restricted areas demarcated and signed? Is employee entry prohibited without authorization?

-

Are employees not entering equipment swing radius or blind spots unless positive communication is established, equipment is shut down and any blades/buckets/rippers/etc. are lowered to the ground? Are barriers/barricades and exclusion zones being communicated and maintained?

Engineered Support System & Geotechnical Inspection and Monitoring Systems

-

Do installed trenching controls meet or exceed Excavation and Trenching Standard requirements? (e.g., shoring, sloping, benching designs, or hydro excavating)

-

Is a ground disturbance/dig permit at the work site and filled out correctly?

-

Is there functioning ground displacement detection equipment in place for all areas of the pit wall where there is a risk of failure?

Uncontrolled Ground Movement Procedures

-

Do the employees understand the emergency procedures? (e.g., seismic, primary/secondary escape)

Fall of Ground - Underground

-

Does the activity present Underground fall of ground risks.

Competency

-

Has the worker been trained and authorized, and does the worker understand the components of Fall of Ground activity?

-

Is the worker familiar with the FRA and critical controls?

Ground Control

-

Have identified ground control hazards and mitigations been communicated from geotechnical to supervisors and frontline operations in between shifts?

-

Is an adequate length scaling bar immediately available to workers?

-

Does it appear that scaling/sounding has been conducted in the active work area?

-

Is there a barrier in place to stop people and occupied mobile equipment from entering areas where ground fall hazards exist?

-

Are employees working in supported ground?

Barriers/Barricades and Exclusion Zones

-

Are restricted areas demarcated and signed?

-

Are employees not entering equipment blind spots unless positive communication is established, equipment is shut down, brake set and any blades/buckets/etc. are lowered to the ground?

-

Is there a barrier or barricade and sign in place to prevent employees from entering areas where material can fall?

Engineered Support System

-

Has the correct ground support been installed per the site’s Ground Control Management Plan?

-

Is shotcrete/paste/backfill being installed in compliance with the Ground Control Management Plan?

-

Is there a ground support testing program in place and to standard? (e.g., pull testing)

Geotechnical Inspection and Monitoring Systems

-

Is the work being performed within the design limits? (e.g., cut sheets)

-

If design variances are noted, have controls been implemented to mitigate the hazard?

Emergency Procedures

-

Do the employees understand the emergency procedures? (e.g., seismic, primary/secondary escape, and refuge locations)

-

Are up-to-date escape and evacuation maps available and communicated?

-

When was the last drill and what had we learn from it?

Sign off

-

Person Conducted Fatal Risk Critical Control Verification.