Title Page

-

SWMS No

-

Conducted on

-

Prepared by

-

Location

My Company Details

-

Business Name:

-

Business Address:

-

Business Contact:

-

ABN:

-

Phone No:

SWMS APPROVAL

-

SWMS APPROVED BY: (Employer/PCBU/Director/Owner)

-

Date:

-

Name and Signature of person responsible for ensuring compliance with SWMS:

-

Person/s Responsible for Reviewing the SWMS:

-

SWMS amendments must be approved by

Person

-

Name and Signature:

-

ALL PERSONS INVOLVED IN TASK MUST HAVE THIS SWMS COMMUNICATED TO THEM PRIOR TO WORK COMMENCING:

- Daily Tool Box Talks will be undertaken to identify, control and communicate additional site hazards.

- Work must cease immediately if incident or near miss occurs. SWMS must be amended in consultation with relevant persons.

- Amendments must be approved by nominated persons and communicated to all affected workers before work resumes.

- SWMS must be made available for inspection or review as required by WHS legislation.

- Record of SWMS must be kept as required by WHS legislation (until job is complete or for 2 years if involved in a notifiable incident).

Relevant Workers

Relevant workers must be consulted in the development, approval and communication of this SWMS.

-

Workers to be consulted:

Worker

-

Name and Signature:

-

Job Title:

Part 1: Principal Contractor Details

Principal Contractor details

-

The builder or the organisation you are working for.

-

Principal Contractor Company Name:

-

Project Name:

-

Job Address:

-

Project Manager Name and Signature:

-

Date SWMS provided to Principal Contractor:

High Risk Construction Work & PPE

SWMS Scope

-

SWMS Scope: This SWMS covers the use of a floor grinder/polisher on an indoor concrete floor using the HTC Superfloor system.

-

Document #: 10060

High Risk Construction Work

-

This work activity involves the following "High Risk Construction Work"

-

Confined Space

-

Mobile Plan

-

Demolition

-

Asbestos

-

Using explosives

-

Diving work

-

Artificial extremes of temperature

-

Tilt up or pre-cast concrete

-

Pressurised gas distribution mains or piping chemical, fuel or refrigerant lines energised electrical installations or services

-

Structures or buildings involving structural alterations or repairs that require temporary support to prevent collapse

-

Involves a risk of a person falling more than 2m, including work on telecommunications towers

-

Working at depths greater than 1.5 Metres, including tunnels or mines

-

Work in an area that may have a contaminated or flammable atmosphere

-

Work carried out adjacent to a road, railway or shipping lane, traffic corridor

-

In or near water or other liquid that involves risk of drowning

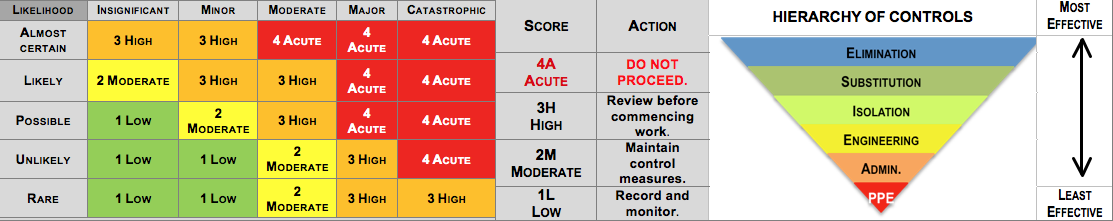

Risk Assessment Matrix & Controls

Personal Protective Equipment (PPE)

-

Ensure all PPE meets relevant Australian Standards. Inspect and replace PPE as needed.

-

Foot Protection

-

Hearing Protection

-

High Visibility

-

Head Protection

-

Eye Protection

-

Face Protection

-

Hand Protection

-

Breathing Protection

-

Protective Clothing

-

Fall Arrest

-

Sun Protection: Broad brimmed hat, UV rated clothing, SPF 30+ sunscreen, tinted safety glasses with adequate UV protection

-

Rings, watches, jewellery that may become entangled in machines must not be worn. Long and loose hair must be tied back.

Planning & Preparation

Potential Hazard

-

Lack of consultation with potential outcomes for personal injury, property damage &/or environmental incident.

-

Risk-Rating (IR) before control measures have been put in place

Control Measures to Reduce Risk

-

Liaise with Principal Contractor to establish the following on-site systems and procedures are in place and take note of:

· Health and Safety rules

· Induction for all workers – site specific and toolbox meetings

· Supervisory arrangements

· Communication arrangements

· All relevant workers are appraised for required competencies & for any pre-existing medical conditions if working in remote or isolated locations.

· PPE required

· Site plans – showing no go zones for pedestrians

· Traffic Management Plan

· Exclusion Zones

· Risk Assessments

· SWMS and JSA’s

· Injury reporting procedures

· Hazard reporting procedures. -

Risk-Rating (RR) after control measures have been put in place<br>

Potential Hazard

-

Personal Injury from delay in emergency assistance to remote workers

-

Risk-Rating (IR) before control measures have been put in place

Control Measures to Reduce Risk

-

A ‘Buddy’ system is utilised for high-risk tasks undertaken in remote locations or working in isolation.

A procedure is developed and in place for regular contact with people working remotely or in isolation, The procedure should identify:

· Travel itineraries, locations, scheduled contact persons and times

· Sufficient supplies of water, food, fuel & supplies needed

· An emergency response

· Appropriate Vehicles

· Safety equipment including first aid. -

Risk-Rating (RR) after control measures have been put in place<br>

-

Person responsible to implement control measures:

Attain Hot Work Permit from responsible person

Potential Hazard

-

Fire

-

Risk-Rating (IR) before control measures have been put in place

Control Measures to Reduce Risk

-

· Ensure completed Hot Work Permit available at site

· Follow safety precautions on Hot Work Permit

· Note: Do not conduct work that is not listed on Hot Work Permit. If other Hot Works are required, obtain Hot Work Permit for that task before commencement. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Training & Capabilities

Potential Hazard

-

Lack of training or the assessment of capability may lead to personal injury, property damage &/or environmental incident.

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Ensure all persons entering site have a General Construction Induction Card (white card)

Ensure all relevant workers have undertaken training and/or received instruction in the use of control measures. Include:

· Reporting procedures for incidents

· Correct use of equipment including selecting, fitting, use, care of and maintenance

· Correct use of all tools used

· Use of supervision where required (e.g. new starters or new equipment)

· Ensure supervisors, foremen etc. are suitably experienced in the type work to be conducted

· All workers are trained in this SWMS.

All relevant workers involved in the use of a grinder must be suitably trained and deemed competent to operate the grinder. Training of operators must include:

· Review of operating manual

· Comprehensive operating instructions

· Location of guard

· Adjustment of guard

· Removal of guard for maintenance work including restrictions on who may do the work

· Actions, including who and how to notify, if a guard is found removed or missing

· Practical instructions on how to replace discs. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Assess onsite conditions

Potential Hazard

-

Lack of a clear assessment may lead to personal injury, property damage &/or environmental incident.

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Assess conditions at site on arrival. Ensure:

· Ensure site-specific induction is undertaken (include location of amenities, first aid facilities, emergency plans and evacuation points, incident reporting, communication, contact persons etc.)

· Assess mobile phone reception’ (alternative emergency communications procedures in place if no reception available)

· Work site is exactly as detailed in Terms of Agreement or contract

· Suitable weather conditions (do not work outside in low visibility, heavy rain, high winds etc.)

· Suitable access for all equipment required

· Suitable space for operation of equipment

· Suitable lighting, including night-works (include flood lighting and operator head lamps as applicable)

· Take note of mobile plant movement

Conduct site inspection to identify potential hazards such as:

· Lighting

· Ventilation

· Dust

· Check that work area is not in close proximity to other hazards (mobile plant, vehicles, hot works, spray painting, demolition works etc.)

· Assess what you are working on – avoid breathing dust - check for asbestos, lead, crystalline silica (found in concrete, granite and stone)

· Check that sparks do not enter flammable storage areas

· Temperature etc.

· Exposed electrical switchboards/power points

· Duration of manual handling tasks (such as working with arms above shoulder height).

If there is a presence of lead and/or asbestos, for this task, ensure there are separate, dedicated SWMS and that all workers/employees have relevant training and licensing. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Work area setup

Potential Hazard

-

Other workers / public safety

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· The area of operations is clearly defined by barricades and warning signs

· Check that near-by workers are not exposed to hazards that arise when using tools

· Keep bystanders away while operating the grinder, set up exclusion zones. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Contact with mobile plant or passing vehicle

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Check constantly for changing hazards while working and monitor work position at all times.

Ensure:

· High visibility clothing worn at all times

· Do not stand behind reversing vehicles

· Allow sufficient distance from plant during operation (allow sufficient room for equipment failure – such as arm/boom failure or plant rollover)

· No work is conducted in established “no go zones” for pedestrians

· Alertness at all times. Listen for:

· Reversing alarms/beepers

· Calls from Plant Operators

· Safety/warning signs, Spotters, traffic barriers etc. must be obeyed as required

· Work positions should be in clear sight of plant operators

· Follow traffic management plan requirements.

Note: Some traffic management plans may say that pedestrians have right-of-way. Never assume this. Make visual and verbal contact with plant operator as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Fire

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Ensure:

· Ensure no ignition sources in area

· Note: Ignition sources include pilot lights, stoves, heaters, cigarettes, matches/lighters, grinding, welding, power points, lighting, light switches, radio transmitters, mobile phones etc.

· Ensure Fire Protection Equipment is available (such as foam, dry powder, CO2, or sand. Do not use water as toxic vapour can be released). -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Struck by debris

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Clear work area of loose items that may be projected.

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Eye health

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· An eye wash station is available in the area of use.

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Muscular stress / musculoskeletal disorder (MSD)

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Ensure equipment is delivered as close to work area as possible

· Depending upon size / awkwardness of grinding unit & associated equipment ensure that a second person is available to assist or use appropriate mechanical aids (e.g. trolleys)

· Lifting/transport equipment suitable for floor grinder (unit weighs approx 380kgs. Lifting should be undertaken via pallet/fork/skid combination – not via persons – such as team-lifts)

· There is adequate space to carry out the activity to reduce congestion and manual handling risks

· Adequate lighting is provided at the work area. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Hazardous atmosphere

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Ensure an industrial vacuum is used with HEPA filter (High Efficiency Particulate Air).

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Slips, trips & falls on the same level

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Ensure:

· Sufficient lighting

· All trip hazards / obstructions removed from work area

· No pits, voids or holes

· Do not drape leads over body or work piece or any metal surface

· Keep power leads up off the ground and out of the way. Pendulum plugs preferred. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Exposure to silica dust

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Always operate grinder in well-ventilated area.

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Work adjacent to road & public safety<br>

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Park working vehicle allocated parking to avoid travelling across roads when delivery working equipment

· If setting up roadside – comply with local laws and permits.

Ensure:

· Compliance with relevant local government requirements such as road or footpath closure

· Barricades or screens are positioned and maintained at a distance from the work to avoid injury to pedestrians and collision by vehicles

· Warning signs are displayed including the lighting of signs where necessary

· Provide adequate lighting to ensure the work areas and access ways are well lit

· If artificial lighting is used, ensure it does not create excessive glare or shadows

· That wheelchair access past the operations is available at all times. (The slope of an access ramp should not exceed 1 in 8, where the ramp is less than 3m in length or 1 in 14 for longer ramps). -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Property damage<br>Fire / explosion <br>

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Ensure equipment is not placed in areas where they may be run over, damaged or exposed to water (unless rated for wet environments). Keep power leads up off the ground and out of the way

· Inspect the floor and remove any objects sticking up that might get fastened and damage the machine. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Contact with electricity<br>

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· All work areas have been scanned for electric cables

· Suspend all electric cables safely above floor or ground level

· All power tools and leads are Tested and Tagged and are current

· Safety switches (RCD’s) are provided

· Pre-inspect equipment

· If equipment is damaged, do not use

· Take out of service, apply Lock-out/tag-out (LOTO) procedures and inform supervisor immediately. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Contact with haz. Chem. / substances<br>

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Ensure current Material/Safety Data Sheets (M/SDS) for HTC cleaning agents, cure and dyes are obtained for all hazardous chemicals/substances and accessible on site.

-

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Grinding & polishing

Potential Hazard

-

Entrapment

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Inspect floor grinder. Ensure:

· Operating labels undamaged and legible

· Handles clear of grease, oil, dirt

· Head locks/shear pins are tight and secured

· All guards/motor housing undamaged

· Suitable grinding wheels as instructed by manufacturer

· Each grinding head has same diamond type, number of diamonds and height

· Emergency stop in place, undamaged and functional

· Shroud undamaged and joining at front. Adjusted to ensure good seal with floor

· Shroud totally encloses exhaust entry point for hose

· Hoses undamaged and adequately secured.

Ensure:

· Machine in “off” position before plugging into power

· Cord is positioned behind unit before starting

· Discs are correctly fastened – let unit idle in a safe position for approx. 30 seconds

· If excessive vibration occurs – turn off immediately and do not use

· Place unit on floor surface carefully, hold with two hands. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Contact with rotating parts

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Ensure safety boots and gloves are worn

· Guards are fitted where provided

· Always ensure that the grinder is switched off and power isolated before pre-start check, adjusting, changing set-ups or repairing

· The disc is in good working condition and is free from crack and deterioration.

Stay alert – concentrate on what you are doing at all times

You must keep all body parts free of moving parts

Never plug in before ensuring the switch is in the “off” position to avoid accidental starting.

NOTE: Always turn off the machine when not in use. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Fire / explosion

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· DO NOT operate the machine in explosive atmospheres (i.e. presence of flammable liquids, gases or dust)

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Contact with electricity (electric units)

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Place any leads on lead stands (also to prevent electrical hazards)

· Use caution making wet cuts with electrical equipment. Check hose connections regularly and do not use more water pressure than required. If drill becomes wet stop using immediately.

Ensure:

· Isolate from power before cleaning or making adjustments

· Keep electric cord away from heat, oil, sharp edges or moving parts

· Replace damaged cords immediately

· Never carry electrical tools by power cord

· Do not use power cord to pull equipment from power socket

· Unplug tool when not in use

· Check for damage or faults regularly during operation. Examples, if excessive vibration occurs, stop using immediately

Do not use electrical grinder in rain or wet conditions

Do not abuse the cord, never use the cord to carry the grinder or pull the plug from the outlet

Do not Drill inverted holes (cutting the underside of a slab, floor or overhang) using an electric drill unless the drill is modified with a water collection ring – Consider us hydraulically driven equipment for this task. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Exposure to silica dust

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Use of remote control is preferred to reduce dust

· Ensure the dust collection bag is fitted properly to the machine

· Wear eye and respirator protection as required:

· Respiratory Protection:

· Persons are deemed medically fit to wear

· Issued to individuals

· Fit testing is conducted by competent person

· Complete facial seal (no facial hair)

· Correct cartridge for contaminant (see SDS for flammable vapour / concrete dust)

· Wear disposable or washable protective clothing:

· Vacuum the dust from the clothes or change before into clean clothes before leaving the worksite

· Wash hands before eating, drinking, smoking or applying cosmetics in areas where crystalline silica is present. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Slips, trips & falls on the same level

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Place any leads on lead stands (also to prevent electrical hazards)

· Remove rubble an slurry clear from work area and maintain housekeeping

· Power cord does not pose a tripping hazard to operator (pendulum plugs preferred)

· A method of collecting residue from the cutting or drilling operations should be put in place in order to prevent surfaces becoming a slip hazard

· Be vigilant in relation to build up / presence of slurry in work area to reduce slip / trip risks. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Noise

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Ensure hearing protection is worn, ensure it is:

· Worn by all persons throughout the period of exposure to noise

· Suitable for the type of working environment and the work tasks

· Comfortable and correctly fitting for the worker

· Regularly inspected and maintained to ensure it remains in good, clean condition. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Contact with hot surfaces

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Discs can be hot. Wear gloves when handling/changing discs and follow manufacturer’s instructions.

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Heat stress

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Ensure:

· Suitable protective clothing

· Sun brim on hard hat

· Safety glasses - UV Rated

· Use 30+ sunscreen on exposed skin areas

· Adequate drinking water

· Access to shade during breaks

· Adequate breaks

· Check weather conditions – do not work in extreme weather. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Muscular stress / MSD / occupational vibration or white finger syndrome

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Use of remote control is preferred to reduce vibration and manual handling risks

· Ensure shock absorbing gloves are worn

· Set handle to hip-height

· Take regular rest breaks and stretch out if bending for long periods

· Consider job rotation to avoid excessive bending/reaching

· Avoid over reaching, keep proper footing and balance at all times

· Avoid any twisting, awkward positions and side-bending

· Do not use excessive force when operating the grinder -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Impregnating and / or protecting concrete

Potential Hazard

-

Environment

-

Risk-Rating (IR) before control measures have been put in place

Control Measures to Reduce Risk

-

· Applying concrete HTC cure products reduce dust when working and living environment.

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Working with HTC products and / or finishes such as epoxy products

-

Risk-Rating (IR) before control measures have been put in place

Control Measures to Reduce Risk

-

· Chemicals:

· Minimum quantities are bought on site

· Original containers used. If other containers are used, ensure they are designed for storing flammables

· Containers in good condition, labelled, and stored safely (out of direct sunlight, within manufacturer’s specifications)

· Respirator cartridge correct for type of vapour

· Respiratory Protection:

· Persons are deemed medically fit to wear

· Issued to individuals

· Fit testing is conducted by competent person

· Complete facial seal (no facial hair)

· Correct cartridge for contaminant (see SDS for flammable vapour and concrete dust)

· Coveralls:

· Good quality (can not be easily torn)

· Leg cuffs are not tucked into boots

· Long sleeves /long pants

· Gloves:

· PVC (undamaged, no holes)

· Footwear:

· Lace-less safety boots or gumboots

· Inspect all parts before and after use, including:

· Filters

· Seals

· Valves

· Ensure filter and respirator are compatible

· Replace filters if damaged, when resistance increases and as per manufacturer’s instructions. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Spills

-

Risk-Rating (IR) before control measures have been put in place

Control Measures to Reduce Risk

-

Ensure spill containment kit available at site. Include:

· Non-combustible absorbent materials

· Prevent entry into sewers, watercourses, basements or confined areas.

Wash spillages into an effluent treatment plant or proceed as follows:

· Contain and collect spillage with non-combustible, absorbent material e.g. sand, earth, vermiculite or diatomaceous earth and place in container for disposal according to local regulations

· Use spark-proof tools and explosion-proof equipment

· Dispose of via a licensed waste disposal contractor

· Contaminated absorbent material may pose the same hazard as the spilt product. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Slips trips and falls

-

Risk-Rating (IR) before control measures have been put in place

Control Measures to Reduce Risk

-

· Ensure to wear non-slip foot protection

· Start at the farthest point from the exit, work toward the exit doorway, avoiding slippery surface

· Clean up spills immediately

· Do not leave materials and equipment in walk/pathways -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Hazardous manual tasks

-

Risk-Rating (IR) before control measures have been put in place

Control Measures to Reduce Risk

-

Ensure equipment is suitable for task. E.g.:

· Light-weight equipment (with adjustable handle and long-handled)

· Long handled tools with swiveling heads.

Ensure:

· Work in a small section to avoid overreaching

· Relevant workers are not required to work in awkward positions when exerting force, or for more than 30 minutes at a time, or 2 hours over entire shift

· Extend handle to apply chemical under furniture etc., to avoid bending, reaching and kneeling. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Site specific hazards

-

Have you identified any further hazards on the job site?

Job Step

-

What job step does this hazard relate to?

-

Potential Hazard

-

Risk-Rating (IR) before control measures have been put in place<br>

Control Measures to Reduce Risk

-

Control measures used to reduce risk

-

Risk-Rating (RR) after control measures have been put in place.

-

Person responsible to implement control measures:

On completion

Potential Hazard

-

Slips, trips, falls causing injury

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Clean up tools and secure into working vehicle

· Clean work area of off-cuts

· Sweep up all dust (avoid the use of compressed air) and /or empty extraction bags. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Cuts / lacerations

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Discs are removed and stored in a safe, dry place.

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Contact with electricity

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Disconnect power tool/extension leads from power point before winding up, so that you don’t get a shock if the lead is damaged

· Inspect leads and power equipment for damage

· If safe to do so, remove isolation locks/tags and test appliance for function. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Contamination of waterways

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Clean up and dispose any slurry

· Dispose of waste material and dust to skips/bins provided. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Public safety

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· If acceptable, remove/ add barricades, contact supervisor and return as agreed.

-

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Emergency Response

-

Emergency Response - CALL 000 IMMEDIATELY.

-

If work is to be conducted on a construction site (or a site controlled by another Employer / PCBU) follow the site-specific Emergency Management Plan. Ensure:

· Adequate numbers of first aid trained staff are on site when working at heights occurs

· First aiders are trained and competent in managing injuries associated with demolition until emergency services arrive

· All rescue equipment is in good condition, available for use and in close proximity to the work site. -

Ensure workers have access to:

· First aid kit/supplies

· First Aid trained personnel familiar with Resuscitation and emergency response for electric shock

· M/SDS

· Communication devices (check mobile phones will have service in area)

· Suitable fire protection equipment.

Part 2: Relevant Legislation & Codes of Practice

Relevant Legislation:

-

Note: Retain only the legislation references applicable to your state of operation for this SWMS.

-

Commonwealth, NSW, QLD, ACT

-

· Work Health and Safety Act 2011

· Work Health and Safety Regulations 2011 -

Northern Territory

-

· Work Health and Safety (National Uniform Legislation) Act 2011

· Work Health and Safety (National Uniform Legislation) Regulations 2011 -

SA, Tasmania

-

· Work Health and Safety Act 2012

· Work Health and Safety Regulations 2012 -

Victoria

-

· Occupational Health & Safety Act 2004

· Occupational Health & Safety Regulations 2007 -

Western Australia

-

· Occupational Safety & Health Act 1984

· Occupational Safety & Health Regulations 1996 -

Codes of Practice:

Codes of Practice

-

Commonwealth, NSW, QLD, ACT, NT, SA, Tas.

-

Safe Work Australia (2011):

· Construction Work

· First Aid in the Workplace

· Managing the Risk of Falls at Workplaces

· Managing the Risk of Plant in the Workplace

· Managing Noise and Preventing Hearing Loss in the Workplace

· How to Manage Work Health and Safety Risks

· Hazardous Manual Tasks

· Managing Risks of Hazardous Chemicals

· Managing Electrical Risks in the Workplace

· Managing the Work Environment and Facilities

·WHS Consultation, Cooperation & Coordination -

Victoria

-

WorkSafe Victoria

(1990): No. 13: Building and Construction Workplaces

(2000): No. 25: Manual Handling

(1995): No. 19: Plant

(1998): No. 23: Plant (Amendment No. 1)

(2004): No. 29: Prevention of Falls in Housing Construction

(2000): No. 24: Hazardous Substances

Compliance Codes: WorkSafe Victoria (2008):

Compliance Code:

· Communicating OHS Across Languages

· First Aid in the Workplace

· Prevention of Falls in General Construction

· Workplace Amenities and Work Environment

Reference Documents

-

Have you referred to any documents?

-

References referred to:

Training, Permits, Tools, Supervisory Arrangements

Training and Licences Required For Workers Undertaking This Task. Select those relevant

-

Are any training or licences required to complete this task?

-

Licence to Perform High Risk Work (operating certain plant, equipment)

-

Licence details

-

Photo of relevant licences

-

TAFE or other recognised training organisation

-

Licence details

-

Photo of relevant licences

-

Construction Induction Card (or equivalent)

-

Licence details

-

Photo of relevant licences

-

PPE

-

Licence details

-

Photo of relevant licences

-

Traffic Management Plan

-

Plan Details

-

Relevant photos

-

Other

-

Licences/training

Licences / Training

-

Licence details

-

Photo of relevant licences

Plant/Tools/Equipment Required For The Job

-

Plant / Tools / Equipment are required to complete this job:

-

Plant / tools / equipment required:

Equipment / Tools / Plant

-

Make & Model

-

Plant/macinery photo

Details of Supervisory Arrangements for Workers Undertaking This Task:

-

Supervisory arrangements for this task:

- Suitably qualified supervisors for job

- Direct on-site supervision

- Remote site - communication systems / schedule

- Audits

- Spot Checks etc

- Reporting Systems

- Not applicable

- Other

-

List other licences/training relevant

Licences / Training

-

Enter relevant information

Details of Regulatory Permits / Licenses / Engineering Details / Certificates / Work Cover Approvals:

-

Are there any Regulatory Permits / Licenses / Engineering Details / Certificates / Work Cover Approvals?

-

Applicable permits / licenses etc

- Local Council Permits

- Authorisation to work

- Confined Space Permit

- Building Approvals

- EPA Approvals / Permits

- Plant to be registered with State Authority

- PPE to comply with relevant Australian Standards

- Other

- Not applicable

-

Item

Licences / Training

-

Item Details

-

Take a photo of relevant licenses / permits where possible

Part 3: Worker / Employee Sign Off

Overall Risk Rating After Controls

-

Select Risk Rating

Worker Sign-off

-

This SWMS has been developed in consultation and cooperation with employee/workers and relevant Employer/Persons Conducting Business or Undertaking (PCBU). I have read the above SWMS and I understand its contents. I confirm that I have the skills and training, including relevant certification to conduct the task as described. I agree to comply with safety requirements within this SWMS including risk control measures, safe work instructions and Personal Protective Equipment described.

Employee

-

Employee/Worker Name and Signature:

-

Job Role/Position

-

Employer/PCBU/Supervisor:

Review & Monitor

-

To ensure controls are implemented and monitored effectively:

• Toolbox /pre-work meetings will be undertaken

• Relevant persons will be consulted on hazards and contents of SWMS, work plans and other applicable information

• Control measures will be monitored throughout works:

o Spot checks

o Consultation

o Scheduled audits

• Corrective actions will be recorded and rectified in a timely manner SWMS will be reviewed and updated accordingly (in consultation with relevant persons) -

Ensure all controls are reviewed as per the following:

• If controls fail to reduce risk adequately

• When changes to the workplace or work activity occur that create new / different risks where controls may no longer be effective

• New hazards identified

• After an incident involving work activities relevant to this SWMS

• During consultation with relevant persons indicate review is needed

• A Health and Safety Representative (HSR) requests a review in line with the requirements of the legislation. -

Review Number

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

Name & Initials

-

Date