Information

-

Audit Title

-

Area/Block

-

Conducted on

-

Prepared by

-

Location

-

Personnel involved in the inspection.

-

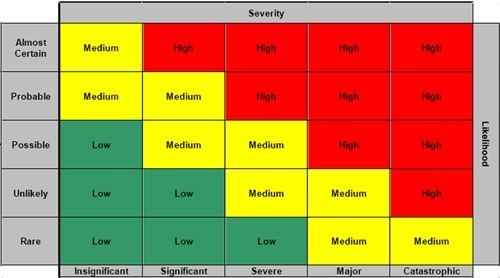

Risk Matrix

-

If something has failed the standard please report as follows:

1) Determine the risk factor (Insignificant, Minor, Moderate, Major, Catastrophic)

2) Start with room number or describe the area - (outside main entrance L Block)

3) List the hazard

4) List any specific controls

5) Action the hazard to a person

example:

Area is clean, tidy and well kept, (stores, desks, bathrooms, kitchens, etc.)

Minor Risk

L18 (or HR Kitchen) slippery floor - rubber mat ? - Neil A (or Facilities)

1. Facilities

-

Area is clean, tidy and well kept (stores, desks, kitchens, etc.)<br>

-

Check floor surfaces need to be even, slip resistant and free from trip hazards.<br>

-

Bathroom, toilet facilities clean and functional.

-

Lighting is adequate. <br>(check dark corners and storage areas)<br>(Also check for too much light?) If unsure report it and we can do a test. <br>

-

There is adequate ventilation (stores, desks, bathrooms, kitchens, etc.)<br>

-

Walls, windows, doors and furniture is in good condition.<br>

2. Emergency Procedures

-

Written evacuation procedures and exits displayed and up to date.

-

Randomly select a portable fire extinguisher and check the service plate (must be within 6 months)<br>

-

Check all Emergency equipment signage. Must be clearly visible.

-

Lockable emergency exit doors/gates should always be able to be opened from the inside.

(Never pad locked or key locked from the inside) -

Check emergency escape routes and exits, these should be clear (Not locked or blocked in any way)<br><br>

-

Any workers that work isolated? (Remote alone work)<br>

-

Are there procedures in place for isolated workers? (ask manager)<br>(Isolated workers must have a means of communication available to call for help and procedures for regular contact)

3. First Aid Facilities

-

There are appropriate first aid and emergency facilities in the near vicinity and workers' are aware of them.

-

Kits are clearly signed, stocked and contents are in-date.

-

Names and contacts of first aiders displayed and up to date.

4. Manual Handling

-

Adequate storage area provided.

-

Storage designed to minimize lifting problems I.e. heavy objects not stored on upper racks.

-

Where applicable manual handling Standard Operating Procedures (SOP) are available.

-

Ask personnel in inspection area if they are trained in manual handling.<br>

-

Trolleys or mechanical hoists are available and are being considered for heavy items or loads.

-

1) Must be an industrial ladder that complies with Australian Standard/New Zealand, AS/NZS 1892, that’s suited for the required task.<br>2) Must have manufacturer’s recommendations on safe use. <br>3) Must have inspection tag on it <br>

-

Workers have been asked for safer ways to do the job.

-

Step ladders or safe steps are available to access light items stored on high shelves.<br>

-

Are manual tasks that may cause injury identified ?<br> <br>

-

Injuries can be the result of gradual wear and tear from frequent or prolonged tasks, or sudden damage from a single lift of something very heavy or awkward.

-

Indicate the hazard factor associated with manual handing tasks in the area ?

5. Slips and Trips

-

Material left in walkways or corridors is one of the most common causes of internal trips in the workplace.

External traffic and ground surfaces are the most common cause of an injury from slips trips and falls. -

Mobile warning signs are available and erected near spills.

-

There are special provisions for slip resistance in wet areas.

-

Guard rails and slip resistance are provided on ramps and stairs.

-

Walkways are free of hazards, such as electrical leads.

-

Emergency Evacuation routes and walkways are free of hazards and easily accessible?<br>(Follow the most common evacuation route to assembly point check for hazards and keep access for disabled people in mind)<br><br>

6. Electrical Safety

-

Facilities maintain a maintenance program that includes testing of equipment and switchboards. A record of relevant test data can be requested, if needed. All power points (GPO's) are RCD protected.

-

Randomly select electrical equipment and check their tag to be current or in date. <br>

-

Is there a mobile RCD device in the inspection area?

-

Do the users know how to test it ? (Ask them to show you)<br>

-

Has it been tested and tagged ? (tag must be in date)<br>

-

Flexable cord, plugs ad extension leads are in good condition and have either moulded or transparent type plugs.

-

Power points are suitable for the location and are positioned safely.

-

Power boards are used. (not double adapters).

-

Faulty equipment is tagged out. (Tag and tags is available).

7. Chemical Aspects

-

A hazardous material is an umbrella term used to describe:

Dangerous goods - they are classified on the basis of immediate physical or chemical effects such as fire, explosion, corrosion and poisoning that may affect property, people or the environment (e.g. petrol, pool chlorine, and some pesticides).

Hazardous substances - they are classified only on the basis of health effects - both medium and long term - particularly in relation to workplaces. -

Any hazardous materials/substances in the inspection area?<br>

-

MSDS (not older older than 5 years) are available for workers reference and included in the hazardous substances register.

-

There is an up to date easy to find and read list/register summary of all chemicals used.

-

A risk assessment has been completed for all chemicals and harmful substances stored and used at the workplace.

-

Actions have been take to control risks. For example , an investigation has been doe to find out whether an alternative safer chemical is available.

-

Decanted containers are labeled with name, risk and safety instructions.

-

Original containers have the manufacturer's label.

-

Chemicals stored according to compatibility and bundled i.e. in flammable or corrosive cabinets.

-

Are minimal amounts of corrosives stored, and/or used?

-

Only flammables stored in flammable liquid cabinet?

-

Are the warning signs on the cabinet legible? (e.g. DG Class 3 diamond, no smoking, no ignition sources).

8. Personal Protective Equipment

-

Instruction and information on PPE are available. (Poster on PPE Cabinet)

-

PPE store available well maintained and in good order.

-

Signage of PPE requirements displayed on equipment.

9. Noise

-

Are hearing protection required in the area?

-

do people need to raise voices to speak with someone one metre away?

Are there very loud mashinery / tools ?

Are there any hearing signs?

If any answer yes, hearing protection is required. -

Control measures have been put in place to reduce the risk of injury as a result of noise, including the provision of personal hearing protection.

-

Are workers trained in fitting, use, selection, maintenance, replacement and storage of hearing protectors?<br>

-

Workers have received information and training in relation to noise at the workplace.

10. Machinery and Plant

-

Records are kept of maintenance, alterations and inspections.

-

Keys are not left behind in unattended mobile plant.

-

Are SOP's and warming signs clearly visible?

-

Manufacturer's manuals and operator instructions are readily available.

-

Inspection re records are made and kept in relation to plant.

-

Work area is organized for the safety of the mobile plant operator and pedestrians. (Safe walkways on floor?)

-

Pre-start safety check of mobile plant is carried out in accordance to Manufactures instructions

-

Mobile plant is in good working order. (Seat, lights, steering, controls, horn, tyres, gas cylinder, warning signs, brakes, mast, chains, hoses, counterweight, control labels).

-

Seatbelt and rollover protection is provided wherer required.

-

Emergency stops tested andc are working.

-

Welding screens available, maintained and in good condition.

14. Guarding

-

Operators and maintenance personnel properly trained, familiar with the operation and set up of machinery and able to demonstrate safety features.

-

Where fixed guards are provided, they prevent operation of the machinery when open, the guards are prevented from opening while the machinery is in operation.

-

Where a presence sensing system is used, it operates as intended and stops the machinery when the light beams or sensors are interrupted.

-

Guards protect against hazards to the rear and sides of machinery.

-

Pre-operational checks are conducted to ensure safety features are in working order.

-

Warning signs and decals clearly visible.

-

Where it is not practical to provide guarding and people are required to operate or pass close to dangerous moving parts, a safe system of work in place to reduce risk.

-

Manufacturer's manuals are available for operators.

15. Welding Safety

-

Are staff appropriately trained and inducted in the dangers of performing welding tasks?

-

Are students appropriately supervised by a competent person when welding?

-

Is there adequate ventilation for welding tasks?

-

Are there appropriate warning signs in welding areas?

-

Are mobile welding screens available.

-

To prevent flashbacks on Oxy-acetylene welding sets, flashback arrestors must be installed on the outlets of both regulators, and torch inlets.

-

Are ventilation systems working adequately?

16. Compressed Gas

-

Cylinders contents are identified and appropriately secured.

-

Cylinders are stored according to dangerous goods class and empty cylinders are separated from full ones.

-

Gas lines are free of leaks, kinks, wear & tear.

17. AED (Automated External Defibrillator) on site? Check the following.

-

Defibrillator alarmed cabinet in Albany security code: 1234 enter.

-

Is the AED clean, undamaged in its carry case and cabinet?

-

Gloves, prep razor, scissors, towel and CPR mask must be in the cabinet clean and available?

-

All electrode packages sealed and within the expiration date?

-

Are the battery within expiration date?

-

Ready light located on the right top corner of the machine?

Other Hazards

-

Other hazards

-

Hazard

-

Hazard

-

Hazard

Please sign and email the report to the OSH Coordinator.

-

Select date

-

Add signature