Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

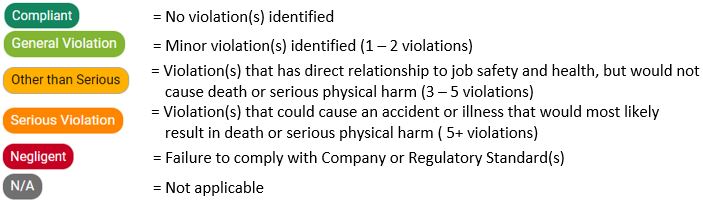

Inspection Response Key

Parking Lot

-

Does the outside parking lot look clean (landscaping, signs, parking lot)?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are there any slip/fall hazardous on the main walkways customers use?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Does the location have the proper gun poster posted outside? (If applicable)

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

Office

-

Does the facility have the required permits, logs, and license's for review upon request?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Does the location have a recordkeeping box? Does it have the proper tabs (Haz Manifests, VOC reporting, non-SKU training certificates, tire disposal receipts, etc? Does the location have Hazardous Waste Manifest or Bill of Lading(s) available for review?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Does the GM have the Safety Programs Binder?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is the GM familiar with workers comp protocols? Does the GM have access to the Nurse Case Triage number? Do they have easy access to the medical authorization form? Do they know how to access injury reporting (in TX do they know they only have until the next business day to report)?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Employer provides proper P.P.E? (i.e. hearing protectors, glasses/goggles, dust mask, respirators, gloves, etc.) to all employees and requires use when working around hazards.

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there a safety glasses container leading into the body shop?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Does the safey glasses container have safety glasses for guests?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an "Employees only" sign

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are there any electrical issues in the office? (exposed wires, missing electrical outlet covers)

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are there any trip hazards? (extension cords and phone wires running through the floor)

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

How is the overall housekeeping in the office?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

Break Room/FOS

-

Are the Labor Law Posters posted?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an emergency contacts list posted?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Shop has a first aid kit on site, is fully stocked, and all employees know the location of both?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Shop has an upoened Bloodborne Pathogen kit?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are all outlets GFI approved and in good working condition? (No broken grounders in outlet, no broken or missing covers)

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Breaker Boxes are properly labeled and have 3 feet of clearance in front of them?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

Fire Protection

-

All fire extinguishers are properly charged, inspected monthly and documented on the attached tag?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

All fire extinguishers have proper signage clearing marking their location and have 3 square feet of clearance around their location?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are the fire risers accessible?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Does the riser have a current certification sticker?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

Body Department

-

Are technicians utilizing the proper PPE (Safety Glasses, Gloves, Welding Mask, Respirators, Knee pads/mats)?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are technicians storing respirators properly? Kept in a sealed container when not in use?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are respirators inspected, cleaned, and/or replaced as part of routine maintenance and documented for proof of maintenance?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an emergency evacuation route map visible in the Body Dept?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an eyewash station(s) in in the Body Dept? Is it clean and in working order, has 3' clearance around it?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an SDS poster visible in the Body Dept? All employees have been trained on HCS and know who to contact in case of an emergency?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are razor blades being disposed of properly in the Body Dept?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Do the body techs have welding blankets readily available?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there a Class D extinguisher located in the Body department?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

All grinders have protective guard and have no more than 1/8 inch clearance from grinding stone or wheel?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

All secondary container bottles have secondary container labels attached?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Compressed gas cylinders are stored at least 20 feet away from any source of heat, elevators, stairs and aisle ways? The area is will ventilated?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

All guards on air compressors are present and in good condition?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are the floor jacks properly marked with maximum load capacity?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are the overhead storage racks marked with maximum load capacity?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Extension cords are in good condition with no exposed wires, spliced or taped cords?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are there any electrical issues in the body department? (exposed wires, missing electrical outlet covers)

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

What is the overall condition of housekeeping for the Body Dept?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

Paint Department

-

Are technicians utilizing the proper PPE (Safety Glasses, Gloves, Welding Mask, Respirators, Knee pads/mats)?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are technicians storing respirators properly? Kept in a sealed container when not in use?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are respirators inspected, cleaned, and/or replaced as part of routine maintenance and documented for proof of maintenance?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an emergency evacuation route map visible in the Paint Dept?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an eyewash station(s) in in the Paint Dept? Is it clean and in working order, has 3' clearance around it?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an SDS poster visible in the Paint Dept? All employees have been trained on HCS and know who to contact in case of an emergency?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are razor blades being disposed of properly in the Paint Dept?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is the gun washer in clean, working order?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an eyewash station near the gun washer?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Mixing room door kept closed when not in use?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an eyewash station in the mixing room?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

All paint/solvent containers are/capped when not in use?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Mixing room is properly ventilated?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Mixing room has explosion proof lighting, walls and a spill containment lip?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Exhaust vents are not obstructed and start automatically when door is closed?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is the mixing room free of electronics? i.e. Phone chargers, mini fridges, plug in fans, etc.

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Spray booth filters are maintained and are on a change-out schedule as per manufacturer's recommendation?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Filter change-out log posted or available for viewing?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

All secondary container bottles have secondary container labels attached?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

All flammables in 5 gallon or larger containers grounded? Are they on spill containment pallets?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is the paint waste properly disposed of? Is the funnel clean, closed when not in use?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are aerosol cans properly disposed of? Labeled appropriately?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are used absorbent wipers properly disposed of? Labeled appropriately?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Painting is being conducted in approved booth and prep station per EPA NESHAP 6H rule?

-

Paint booth is functioning properly and in good condition?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are the sprinkler heads covered to protect from over spray?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Extension cords are in good condition with no exposed wires, or spliced or taped cords?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are there any electrical issues in the paint department? (exposed wires, missing electrical outlet covers)

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

What is the overall housekeeping of the paint department?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

Mechanic Area

-

Is the used oil properly disposed of? Labeled appropriately?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is the used antifreeze properly disposed of? Labeled appropriately?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are oily used absorbents properly disposed of? Labeled appropriately?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are the used oil filters properly disposed of? Labeled appropriately?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an emergency evacuation route map visible in the Mechanic Shop?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an eyewash station(s) in in the Mechanic Shop? Is it clean and in working order, has 3' clearance around it?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an SDS poster visible in the Mechanic Shop? All employees have been trained on HCS and know who to contact in case of an emergency?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Does someone in the shop have an EPA609 certification?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Have the lifts been inspected within the last 12 months? (Any lift that raises above 3 feet)

-

Extension cords are in good condition with no exposed wires, or spliced or taped cords?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are there any electrical issues in the Mechanic Shop? (exposed wires, missing electrical outlet covers)

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

What is the overall condition of housekeeping for the Mechanic shop?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

Forklift

-

Does the site operate a forklift?

-

Does the location have a certified forklift operator operating the equipment?

-

Is the forklift on a regular scheduled maintenance plan?

Detail Area

-

Are steps being taken to eliminate slips and falls in the Detail area?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Ladders are in good condition and secured to the walls properly with chains or proper ladder mounts?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Were teammates smoking in the shop?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an eyewash station(s) in or within 10 seconds of the Detail Area? Is it clean and in working order, has 3' clearance around it?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is there an SDS poster visible in the Detail Area? All employees have been trained on HCS and know who to contact in case of an emergency?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are flammables stored safely and away from combustibles?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

All secondary container bottles have secondary container labels attached?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Extension cords are in good condition with no exposed wires, or spliced or taped cords?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Are there any electrical issues in the Detail area? (exposed wires, missing electrical outlet covers)

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

Shop Exterior

-

Are scrap tires laced and not stacked or situated on a tire rack?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is the exterior of the shop free of debris and compliant with storm water practices?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

-

Is the waste in the dumpster compliant withlocal, state, and federal reguations?

- Compliant

- General Violation

- Other than Serious

- Serious Violation

- Negligent

- N/A

Signature

-

Add signature