Title Page

-

Site conducted

-

Conducted on

-

Document Number

-

Prepared by

-

Shift

Call Sign

-

Hour Meter - Rotation Pack

-

Hour Meter - Thrust Pack

-

Hour Meter - Lube motor time

Untitled Page

-

Type of service done

- 250h

- 500h

- 1000h

- 2500h

- 4500h

- 5000h

- 14000h

- each month

- every 3 months

- every 6 months

- every year

- every second year

-

Inspection of fire fighting equipment

-

Technician Comments / Actions Taken

-

Is the register available and up to date?

-

Annual inspection of fire extinguishers and fire fighting equipment systems has been carried out by an authorised party

-

Technician Comments / Actions Taken

-

Is the register available and up to date?

-

Have all certificates been uploaded and available to MDA and client?

-

Condition check on external cooling systems

-

Technician Comments / Actions Taken

-

Inspection and lubrication of hatches and locks (Lubrication with grease gun or brush)

-

Technician Comments / Actions Taken

-

Is the register available and up to date?

-

Visual inspection of all signs

-

Technician Comments / Actions Taken

-

Is the register available and up to date?

-

Inspection and lubrication of turnbuckles (step 1)

-

Inspection and lubrication of turnbuckles (step 2)

-

Inspection and lubrication of turnbuckles

-

Technician Comments / Actions Taken

-

Drive train - Check Tightening - Chuck Bolts

-

Technician Comments / Actions Taken

-

Drive train - Inspection - Measuring play in pilot and main bearings

-

Technician Comments / Actions Taken

-

Drive Train - Check components and replace seals

-

Technician Comments / Actions Taken

-

Drive train - Inspection and cracking indication of floatbox

-

Technician Comments / Actions Taken

-

Replacement of lower bailing pipe seals

-

Technician Comments / Actions Taken

-

Replacement of wearing parts (semi wrench)

-

Technician Comments / Actions Taken

-

Inspection and control tightening of pipe loader

-

Technician Comments / Actions Taken

-

Drive pack - visual inspection - tank cleaning

-

Technician Comments / Actions Taken

-

Thrust pack - visual inspection - tank cleaning

-

Technician Comments / Actions Taken

-

Visual check of pressure relief and flow valves

-

Technician Comments / Actions Taken

-

Visual inspection of hydraulic hoses and couplings

-

Technician Comments / Actions Taken

-

Check of accumulator pressure

-

Technician Comments / Actions Taken

-

Cleaning of drive pack coolant strainer

-

Technician Comments / Actions Taken

-

Cleaning of thrust pack coolant strainer

-

Technician Comments / Actions Taken

-

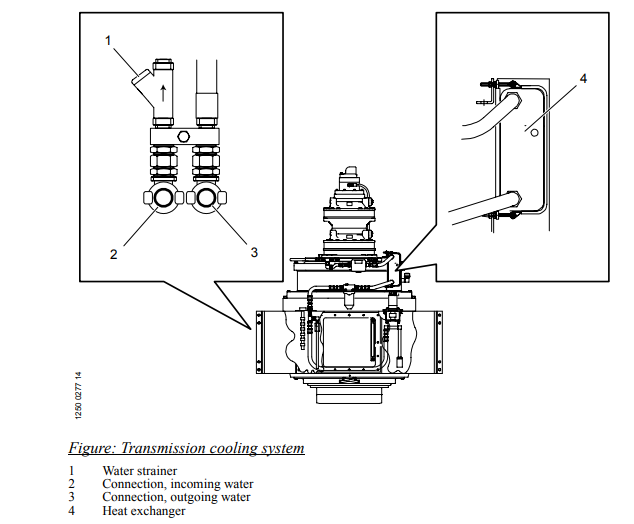

Cleaning of gearbox coolant strainer

-

Technician Comments / Actions Taken

-

Inspection of hydraulic accumulator has been carried out by certified company every 2 years

-

Technician Comments / Actions Taken

-

Swivel, replace upper pipe seals

-

Technician Comments / Actions Taken

-

Drive train - Check Tightening - Output hub

-

Technician Comments / Actions Taken

-

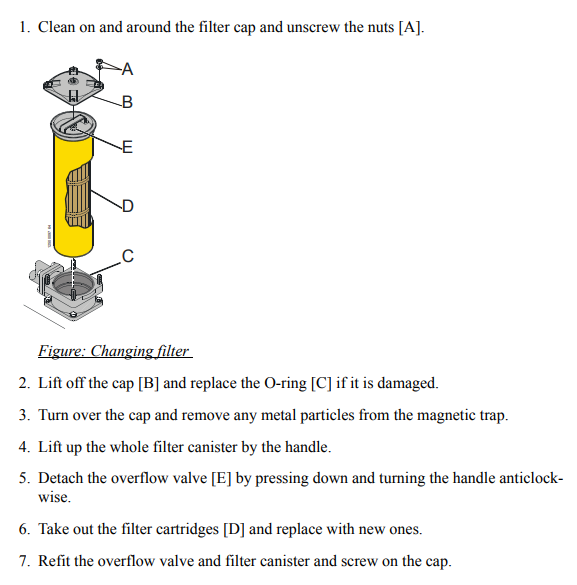

Replace lube filter and lube oil

-

Technician Comments / Actions Taken

-

Inspection of all magnetic traps

-

Technician Comments / Actions Taken

-

Check of wear, function semi-wrench parts

-

Technician Comments / Actions Taken

-

Check of wear, function of worktable parts

-

Technician Comments / Actions Taken

-

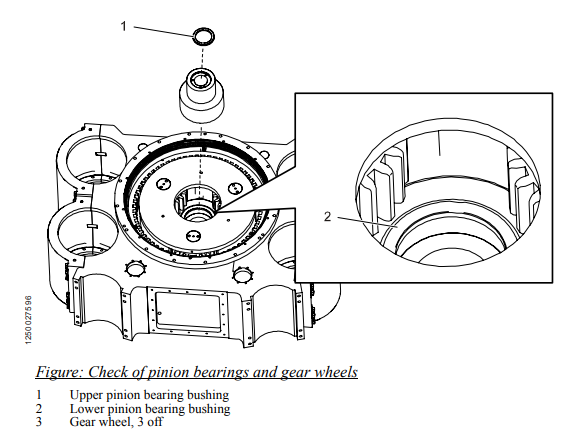

Replacement of pinion bearing and seals

-

Replacement of pinion bearing and seals

-

Technician Comments / Actions Taken

-

Check of pressure relief valves for critical functions

-

Technician Comments / Actions Taken

-

Drive Pack - Replacing Heat Exchanger

-

Technician Comments / Actions Taken

-

Thrust Pack - Replacing Heat Exchanger

-

Technician Comments / Actions Taken

-

Lube system

-

Lube System - Replacing Heat Exchanger

-

Technician Comments / Actions Taken

-

Hydraulic tank filter element

-

Drive Pack - Replacement of hydraulic tank filter

-

Technician Comments / Actions Taken

-

Drive Pack - Replacement of air filter

-

Technician Comments / Actions Taken

-

Thrust Pack - Replacement of hydraulic tank filter

-

Technician Comments / Actions Taken

-

Thrust Pack - Replacement of air filter

-

Technician Comments / Actions Taken

-

Replacement of wearing parts (semi wrench)

-

Technician Comments / Actions Taken

-

Check of pressure relief and flow valves

-

Technician Comments / Actions Taken

-

Inspection of hydraulic hoses and couplings

-

Technician Comments / Actions Taken

-

Check of accumulator pressure

-

Technician Comments / Actions Taken

-

Rotation pack - Inspection of spider coupling

-

Technician Comments / Actions Taken

-

Thrust Pack - Inspection of spider coupling

-

Technician Comments / Actions Taken

-

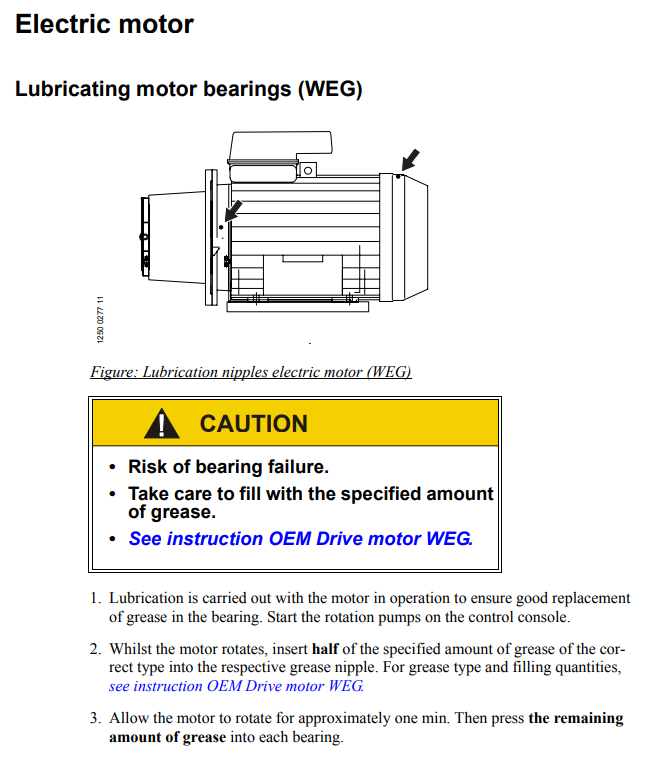

Lubrication of pump motor bearing (drive pack)

-

Lubrication of pump motor bearing (drive pack)

-

Technician Comments / Actions Taken

-

Lubrication of pump motor bearing (thrust pack)

-

Technician Comments / Actions Taken

10. RECORD CONCESSION NUMBERS FOR THE WEEK

- Any concession numbers active?

-

Do you have any active concession numbers for the week?

-

Concession Name

-

Concession Number

-

Concession Approver

Additional Work Completed

- Additional Work/Action

-

Was there there any additional work/action completed during maintenance?

-

Maintenance Task

-

Parts Used

-

Used Part Serial Number

-

Quantity in store

-

Quantity to order

-

Oil Used

-

Oil Type

-

Used litres during maintenance

-

Left litres on site

-

Litres Volume To Order

Sign Off and Submit Page

-

Additional Comments

-

Raisebore Fitter

-

Supervisor