Title Page

-

Conducted on

-

Prepared by

-

Location

-

Site:

-

Site ID:

-

Survey date:

-

Email to send the report to:

-

Employer:

-

RPS:

-

RPS Training: within last 5 years and since IRR17 came into force:

-

Designation of controlled/supervised areas

-

Occupancy concerns?

-

Please note them here:

-

MPE:

- Shahed

- Alan

- Niall

-

Is the RPA Shahed Khan?

-

Name of RPA:

-

Perform Chargeable Risk Assessment for client:

Sources of Radiation

-

Select the source of radiation

- Veterinary X-Ray

- Chiropractic X-Ray

- Dental x-Ray

-

Number of units

-

Radon: Evidence of previous Radon monitoring / assessment

Equipment Details

-

Generator

-

Tube stand

-

Tube

-

Control panel

-

Bucky stand

-

LBD

-

Tank

-

Bucky trays

-

Processor

-

Battery pack

-

Last Svc:

-

CE Marked?

1.0 Radiation Protection

-

1.1 The X-Ray unit is used in a:

-

Measuring approximately m x m

-

1.2 The walls are

-

Approximate Pb equiv (mm)

-

-

Approximate thickness (cm)

-

1.3 The entrance door has a functioning locking mechanism

-

Indicating bolt advised?

-

Door / Glazing shielded?

-

Note the Pb Equ in mm

-

Access controlled by operator

-

1.4 Exposure switch has multiple controls

-

Location of exposure button (s)

-

Prevents Door Closure?

-

>3 long?

-

Operator is in a Protected area

-

1.5 Primary Method of Shielding:

-

How far (m)?

-

How thick (mm Pb)?

-

How thick (mm Pb)?

-

1.6 Lead rubber was provided?

-

-

1.7 Is personal monitoring performed?

-

-

Who?

-

Past Doses

-

1.8 Is leaded PPE provided?

-

Apron

-

Quantity

-

Thickness (mm Pb Equ)

-

Storage

-

Serviceable

-

Screening records

-

Gloves/mitts

-

Quantity

-

Thickness (mm Pb Equ)

-

Storage

-

Serviceable

-

Screening records

-

Thyroid shield

-

Quantity

-

Thickness (mm Pb Equ)

-

Storage

-

Serviceable

-

Screening records

-

Sleeves

-

Quantity

-

Thickness (mm Pb Equ)

-

Storage

-

Serviceable

-

Screening records

-

1.9 Local Rules Condition

-

Location

- In room

- Out of room

- Loose

- In log

-

Up to date

-

Officers details

- Employer

- RPA

- RPS

-

1.10 Warning Lights Present

-

Appropriate?

-

Controlled by separate switch?

-

Functional?

-

Notice present?

-

Appropriate?

-

Send a new sign?

-

Pregnancy warning?

-

Needs relocating?

-

1.11 Scatter Survey performed?

-

Exposure factors used?

2 Electro-Mechanical Condition

-

2.1 All major mechanical parts were found to be in a serviceable order:

-

2.2 Movement of the various parts were smooth:

-

2.3 Covers in good condition:

-

Securely attached:

-

2.4 Tube stand / mount / ceiling track secure / height adjustment functional / movements smooth

-

2.5 X-ray tube (stand) stationary following positioning and release

-

2.6 Counterweighting: X-ray tube

-

Verticle Bucky

-

2.7 Tube stand electro-mechanical brakes

-

2.8 Bucky stand electro-mechanical brakes

-

2.9 The x-ray tube apparently perpendicular to the table top.

-

2.10 The x-ray table:

- Rigid

- Level

- Stationary

- Floating table-top

-

2.11 Tube – grid/bucky alignment:

-

2.12 The cassette tray

-

2.13 Collimator

- Integral to the housing

- Securely attached

- Slightly loose

- Rotated freely

- Fixed orientation

- Smooth

- Sticky

- Do Not Stay Open

-

2.14 The visible suspension components were seen to be:

-

2.15 Grids:

-

Grid size

-

Ratio

-

Frequency

-

Interspace

-

Focal length

-

condition

-

2.16 Mains connection via:

-

2.17 Safe disconnect in emergency?

-

2.18 Phases

-

2.19 All controls and displays functioned correctly

-

Strain reliefs OK

-

2.20 All visible cables were sound

-

2.21 The earth wiring present?

-

Under tension?

-

2.22 The locking retaining rings for the HT cables are:

3. Image Processing

-

3.1 Ventilation adequate.

-

3.2 Image processing/capture was provided by the use of:

-

3.3 This was sitting on an appropriate:

-

3.4 Developer temperature °C

-

3.5 The films were adequately fixed

-

Washed

-

3.6 The rollers were in a reasonable condition

-

3.7 House keeping: send darkroom chart

-

Processor cleaning dates

-

Roller cleaning dates

-

Cassette cleaning dates

-

Chemicals changed dates

-

Sensitometry dates

-

Chemistry stored appropriately

-

3.8 The chemical waste is:

- Plumbed to drains via a silver recovery trap

- Waste bottles

-

3.9 A drip tray is advisable to protect film

-

Film type

-

Colour

-

Stored upright

-

Screen ISO

-

Screen Colour

-

Cleanliness OK

-

Cassette lightproof

-

Safelight

-

Appropriate

-

Housing leaking?

-

Light-proofing

-

3.10 Safe handling time

-

3.11 Optical density on the test film was reasonable

-

3.3 This was sitting on an appropriate:

-

3.12 Exposure index unit (DDI)

-

Details

-

3.13 Cassette storage

- N/A

- Along-dide

- Under reader

- In cupboard

- Requires improvement

-

3.14 Range of appropriate processing algorithms

-

3.15 Cassette artefacts

-

50 kV, 0.5 mAs @75cm (or aim for 20 µGy)

-

Small (18 x 24) sensitivity

-

Date started

-

DI @ centre

-

Medium (24 x 30) sensitivity

-

Date started

-

DI @ centre

-

Large (35 x 43) / ( 30/40/) sensitivity

-

Date started

-

DI @ centre

-

3.16 Any image artefacts due to objects in the beam path

-

Pleate damage?

-

Reader?

-

Dust/dirt?

-

Scratches/Pickoff

-

Scum?

-

Screens?

4. Radiographic Practice

-

4.1 Operators appropriately trained

-

4.2 Holding procedures performed?

-

Holders documented?

-

PPE from holding procedures seen on images?

-

4.3 Record keeping uses:

-

Give details

-

Time period audited: Has been kept up tp date

-

Full details of every radiograph

-

# Exposures in logbook

-

Patient measurement/weight

-

Exposure grading

-

# Exposure recorded on computer

-

4.4 The estimated average exposure (kV, mAs & cm)

-

4.5 Exposure chart:

- No

- Comprehensive

- Appropriate

- Displayed on wall

- Logbook

- Manual

-

4.6 L & R indicators available?

-

Demonstrated appropriately

-

4.7 Are the following available

- Cradles

- Wedges

- Sandbags

- Tie downs

- Callipers

- Filters

- Compression belts

- Gonad shields

-

4.8 Patient identity:

- Not done

- Digital

- Light marker

- Xrite tape

- Permanent marker

- Label

-

4.9 The reviewed images displayed consistently diagnostic densities

-

4.10 Optimal exposure determinations Y/N

-

Extremes of range displayed

-

Most in the range

-

4.11 Techniques were determined to be consistent

-

4.12 Artefacts demonstrated on the reviewed images

- No

- Regularly

- Occasionally

- Clothing

-

4.13 Split films

-

4.14 Collimation and positioning: Consistent?

-

Appropriate?

-

Positioning

-

Centring

-

Demonstrated 3 or 4 borders

-

Add comments

5. Equipment performance

-

-

Distance tape accurate to within 1cm?

-

Timer

-

Controls operating correctly

-

Early release Terminates?

-

Displays operating correctly

-

Continue or restart exposure

-

Focal spot position marked

-

Measured?

-

Early release: Alarm

-

HVL Recorded

-

Value?

-

Repeatability

-

measurements taken

-

AV indication of exposure

-

Set vs measured kV

-

operating as expected

-

mA Linearity

-

mAs Linearity

-

kV and DR waveforms obtained setting

-

Radiation - light film taken

-

Erasure Efficiency+ EI

-

Calliper check 5cm / 18cm

-

Limiting resolution (lp/mm)

-

Plate transport check

-

TO.20 exposure

-

Dental: Beam circular?

-

Dental: Beam central to cone?

-

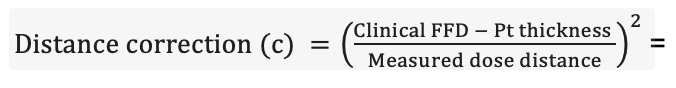

LAT lumbar spine: The current UK national Diagnostic Reference Level (DRL) is 10mGy (2.5Gy.cm2)

-

Measured dose (mGy)

-

Measured distance (cm)

-

Pt. Thickness (cm)

-

Clinical FFD (m)

-

-

Therefore entrance skin dose = (mGy)