Information

-

Location (nearest town)

-

Foreman

-

Cooperative Name

-

Conducted on

-

Work being performed

-

Prepared by

-

Location

-

Audit Guidance: -All unsafe acts shall be stopped immediately. -Field Observations shall include photos for both safe and unsafe operations. Photos should be annotated with what the observer is focused on at the time of the audit. -Any item marked as a deficiency shall have a photo (if possible) and a detailed description. -All comments should identify those crew members performing the task correctly and/or incorrectly. -Equipment being inspected shall be listed and/or have a photo with the unit number displayed. -All audits shall be reviewed with the PIC prior to departure from the site. Corrective actions shall be assigned with due dates and noted on the audit. -Any audits being forwarded to the client shall be reviewed by more than one safety team member prior to being sent.

-

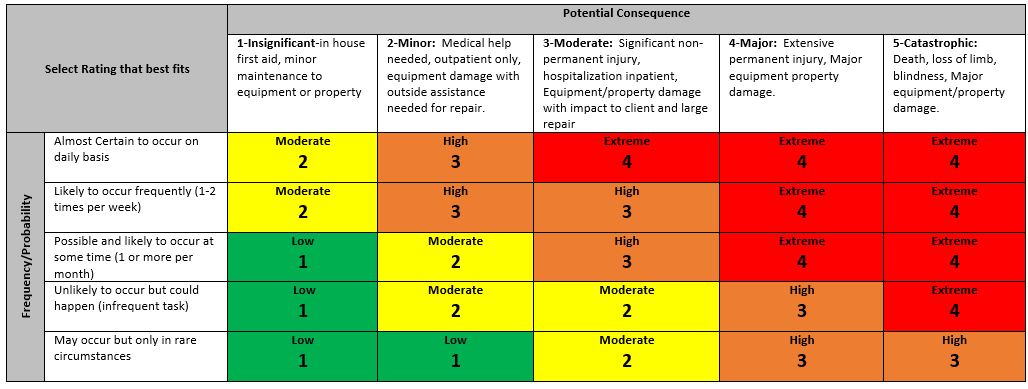

All audit findings shall have an assigned weight (1-4) assigned per the below matrix. Document the weighted number rating in the comment section associated with the applicable question.

Communication

-

When was the last time you were coached from a member of management on safety?

-

Prior to making a decision, do you think Likelihood or Consequences?

-

Human Performance tools observed and bieng utilized correctly?

-

Three part communication utilized?

-

Proper use of hand signals and flagging techniques? Spotters used appropriately?

-

Hand Held radios mounted, charged and being utilized properly?

Procedures and Documents

-

Tailboard/Job Hazard/Driving assessment completed?

-

Lessons Learned topic discussed?

-

Paperwork (Private Motor Carrier License, Haz-Mat Registration, Vehicle Registration(s), Insurance Certificate, IFTA License & Stickers, Annual Inspections(s).392.2-396.17?

-

Are SDS available for all hazardous chemicals on site ?

Displays and Labels

-

Is the work site properly marked and/or barricaded? 5' rule in compliance?

-

Early warning signs and/or flagging placed for overhead/underground hazards?

Environmental

-

Spill kits available and stocked? Spill response understood and practiced? Spills reported?

Schedule

-

Crew schedules identified and fatigue management addressed?

-

Proper PPE (Hard Hat, Glasses, Hearing Protection, leather or insulated gloves, FR, Safety Vest, Steel toe boots)?

-

Schedules communicated for multiple operations?

Work Practices

-

TOC/DOC notified ?

-

Taglines when moving suspended loads?

-

Are proper lifting/carrying techniques utilized?

-

Slip/trip and fall hazards identified and mitigated?

-

Chipper Safety?

-

Are employees using 3 points of contact when ascending, descending, and climbing?

-

Are cell phones being use appropriately?

-

Is employee mindful of line of fire and pinch points?

-

Are all compartments and fill caps locked when machines are unattended?

-

Proper rigging, lifting, hand signals, and good communication being utilized?

-

Is the housekeeping good?

Work Planning

-

Job Plan (does everyone know duties)?Have the job hazards been identified, prioritized, and documented?Work area clearly defined on JSA?Has an effective control/mitigation plan for identified hazards been developed?

-

Poison Ivy mitigation plan?

-

Has the emergency plan been documented and understood?

-

Is fall protection equipment in good condition and rescue plan in place?

-

If more than one crew present (contract or Entergy), lead(s) are identified and communication is occuring?

-

Animals, insects and plants mitigated?

-

One call locates completed?

Supervision

-

Emphasis of schedule exceeding safe work?

-

Designated person in charge and documented?

-

Supervision interfacing with workers?

-

Supervision verifying the job hazard analysis/job plan is being followed?

-

Crew lead demonstrated leadership ability?

Training/Qualification

-

Appropriate training complete and up to date?

-

Crew Members qualified for task being performed?

-

Crew knowledgeable of monthly safety topic?

Change Management

-

JSA updated periodically and whenever work task changes? Time stamped at lunch?

External Influence

-

Weather conditions discussed and documented?

-

Heat/cold mitigation plan in use and documented?

-

Public encrouchment on job site discussed and documented on JSA?

System/Equipment Operation

-

Are seat belts being used on applicable equipment while in operation?

-

Parking Brake (Apply) 393.41?

-

All PPE in good order and utilized? hard hat, eye protection, hearing protection, vest, footwear, gloves, glove clips, face shield, chaps etc.

-

Safe use of chainsaws?

-

Outriggers and outrigger pads?

-

Wheel chocks utilized?

-

Vehicle Grounds and barricades?

-

If applicable, Is FR clothing being worn?

-

If applicable, 100% fall protection being utilized?

-

Equipment Parked over bare dirt, end to end or side by side. N/A if not seen at time of audit

Personnel and Materials Management

-

Sufficient personnel assigned to task?

-

Adequate materials provided to complete task?

Equipment Selection and use

-

Is all equipment set up for safe use (outriggers set up properly as applicable)?

-

If applicable, Is PVD operational?

-

Are fire extinguishers on site, within date, and in good working order?

-

Are guards in place on grinders, portable saws, etc?

-

Chainsaw guards and safeties in place?

-

Fuel tanks full or left full? water drained from fuel system?

-

Non-frayed winch lines? oiled?

-

Are the proper tools for the job being utilized, and are tools in good condition with no modifications?

-

Eye wash station or solution in good working order and readily available?

Management

-

Short service employee's identified and assigned mentors? On JSA? Proper colored hard hat?

-

Timely response to known problems?

-

Policies, practices, procedures properly defined?

-

incidents/near misses reported in a timely manner?

Design Configuration

-

Are appropriate DOT signs and cones in place?

-

Equipment properly barricaded when work is performed near live voltage or when grounded?

Summary and signatures

-

Positive observations. List crew members and specific items they are doing correctly:

-

# of Personnel-Personnel Present (first and last Names)

-

Number of Trucks

-

Number of Trucks Audited

-

Inspectors signature

-

Crew lead signature