Title Page

-

Site conducted

-

Date

-

Z0NE MAPPING

-

Zone

-

Sub-Zone/Area

-

Zone Leader

-

Sub-Zone Leader

-

Auditor

-

Directions

--------------------

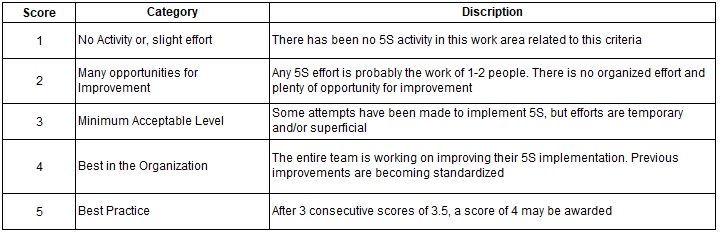

1. For each statement, choose the appropriate score.

2. Tap on 'Note' or 'Image' under each question to add a comment or evidence

4. For identified failed items, assign a corrective action by tapping on 'Action', provide a description, assign to a member, set priority and due date.

5. Complete all items in the checklist & review score per section to identify the overall rate score -

Take or attach a photo of workspace

1S - SORT

-

Q1. Only required tools, equipment, furniture, etc. are present at the workstation. Items not required to make the current product are removed from the workplace

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q2. Only required Inventory, Supplies, Parts and Material are present at the workstation

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q3. No items are stored or placed on walkway, Stairways, Corners, Fire exits, etc.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q4. Only required Item on the walls, notice boards, Gemba board, etc. Out-dated or otherwise unnecessary posters, memos, announcements, reports, etc. are removed from the workplace.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q5. No Safety Hazard (water oil, chemical, machines or any flammable material) exists.

- 5

- 4

- 3

- 2

- 1

- N/A

2S - SET-IN-ORDER

-

Q6. Locations for containers, boxes, bins, WIP, materials, etc. are clearly defined by painted lines/Tapes and properly labeled (part number, quantity, etc.).

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q7. Machines, Handling & other equipment's are properly labeled, locations are clearly defined and critical maintenance checks are established

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q8. Only current required documents and binders necessary to do the work are stored at workstations with proper label & identification.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q9. Tools, tackles, gauges & fixtures, etc. have a designated storage location that is within reach of the operator. The location is properly labeled. They are kept cleaned and free of any risk from damage.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q10. Fire hoses, fire extinguishers, Stop switches and breakers are highly visible and located for easy access in case of emergency. Exits are clearly labeled and un-obstructed.

- 5

- 4

- 3

- 2

- 1

- N/A

3S - SHINE

-

Q11. All floors are clean and free of debris, oil, and dirt. Cleaning of floors is done routinely and at appropriate predetermined intervals

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q12. Routine cleaning of machines is apparent, there is no oil, chips, scrap laying on work surfaces. Cleaning check sheet for machine is available.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q13. Work surfaces (tools, workbenches, dies, and other equipment including electrical boxes), Walls, partitions, railings, etc. are clean and painted.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q14. There is a schedule showing times, frequency and responsibilities to clean areas of the workplace such as windows, corners, walls, doors, top of cabinets, etc. Also the cleaning is performed as per this schedule and the same is updated

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q15. All cleaning equipment's are neatly stored and are readily available when needed

- 5

- 4

- 3

- 2

- 1

- N/A

4S - STANDARDIZE

-

Q16. 5S standard defined by the organization is followed. i.e. availability of 5S standard at each zone and uniform implementation as per the standard

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q17. 5S audits are performed in each work area at least monthly, results are shared with all workers and goals for new levels set with action items

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q18. The results of the previous audit are posted and clearly visible to the entire team. Areas for improvement identified during the previous audit have been completed.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q19. Display boards are present in each designated work area and accessible to all personnel in the area.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q20. Methods are reviewed on a regular basis, and as new methods are developed, they are quickly documented and adopted by others.

- 5

- 4

- 3

- 2

- 1

- N/A

5S - SUSTAIN

-

Q21. Disciplined controls to assure each of above items is maintained at highest level. There is a sense of responsibility by all employees to maintain systems.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q22. Time and resources are allocated to 5S activities (e.g. designated daily/weekly clean-up time, 5S team leader, etc.)

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q23. Root Cause Analysis & Corrective Actions on Previous Audit Observation.

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q24. Responsible manager/Zone Leader visits each work area on a regular basis and provides feedback on 5S efforts and results

- 5

- 4

- 3

- 2

- 1

- N/A

-

Q25. Recognition is given to teams who get involved in 5S activities.

- 5

- 4

- 3

- 2

- 1

- N/A

COMPLETION

-

Overall observation & recommendations

-

Name & Signature of AUDITOR/ or any Assigned Employee