Information

-

Audit Title

-

Client

-

Conducted on

-

Prepared By

-

Location

-

Are Corrective Actions Needed?

1. Employee Welfare

-

1.1 Potable water readily available for all employees

-

1.2 Adequate toilets, washing facilities and maintenance

-

1.3 First aid and blood borne pathogens kit with spray bottle (1:5 ratio bleach to water)

2. Procedures

-

2.2 Startup kit information posted

-

2.3 3SP's with SDS's are up to date and available in trailer/office

-

2.4 Have all Foreman reviewed their company's 3SP's during orientation?

-

2.5 Site safety orientation conducted and logged for all employees (Provide Picture). Orientation stickers issued for hard hats.

-

2.6 Orientation quizzes documented and CISAP drug cards captured for all employees

-

2.7 Is the subcontractors Safety Documentation Checklist log updated (Provide Picture) with weekly safety inspections, weekly toolbox trainings, and daily huddle paperwork?

-

2.8 Emergency Evacuation Procedure Rehearsal for the month (to be conducted every 6 months when walls are up).

-

2.9 No smoking signs posted and enforced

3. Access

-

3.1 Adequate no trespassing & construction signs, public access is restrictedd

-

3.2 Proper illumination is in all areas is maintained and adequate (5 foot candles for general access)

-

3.3 Emergency exits identified and labeled when walls are up

-

3.4 Public is protected from open excavations, falling objects, equipment and other hazards

-

3.5 ABC fire extinguishers available within 100' of travel distance, clearly visible, and inspected on a monthly basis

-

3.6 Walking/Working surfaces are free of trip/slip/fall hazards. (Including water, cords, and debris near doorways/stairways)

-

3.7 Is Housekeeping in safe and sanitary condition?

-

3.8 All impalement hazards are protected, including but not limited to rebar, steel form pins, and other stub ups

4. Chemical, Fuel and HazCom

-

Are Fuels/Chemicals (Diesel, Gasoline, Propane, Oxy/Acet, other bulk chemicals stored onsite?

-

4.1 Bulk fuel stored in approved, secured areas with spill containment, spill kit and a fire extinguisher in place

-

4.2 Bonding used during the transfer of flammable fuel from the bulk fuel container

-

4.3 Bulk fuel containers grounded properly, have proper barricades, and stored 20' from building

-

4.4 Fire extinguisher located no less than 25' but no more than 75' from the bulk fuel container

-

4.5 Compressed gas cylinders stored upright and secured with valve caps in place

-

4.6 Oxygen/fuel cylinders are separated when not in use or installed with a manufactured/rated fire wall

-

4.7 All chemicals have proper GHS labeling and associated Safety Data Sheets in the 3SP

5. Elevated Work

-

Remember: There is NO safe distance from a leading edge!

-

Is there any work above ground level on the project?

-

5.2 Fall protection systems have 5,000 # anchorage, proper connectors, body harness worn correctly (D-ring between shoulder blades), and an adequate lanyard

-

5.3 Guard rail system in place (42" +- 3" with 200# capacity) for the top rail and mid rail (150# capacity) and toe board in place. If using wire rope as a guard rail, it must be flagged at 6' intervals.

-

5.4 Holes and openings covered, secured, and labeled "hole" or "cover"

-

5.5 All warning flagging is of proper material (50 lbs tensile strength), height (34"- 39"), and proper distance from the leading edge (6' for roofers, 15' for others)

-

5.6 Are all fall protection systems engineered and being used properly? I.E. horizontal lifelines

-

5.7 Is there a rescue plan in place for all current fall protection situations

-

5.8 Step ladders are used properly, have adequate footing, and are a safe distance from a leading edge (distance to the edge should be equal to or greater than the length of the ladder

-

5.9 Extension ladders are at a 4:1 ratio; 36" above the landing or have grab rail and tied off

-

5.10 Are ladders in good condition and properly labeled I.E. load stickers and do not step warnings

-

Is there any scaffolding onsite?

-

5.12 Scaffolding inspected and documented prior to every shift

-

5.13 Competent person on site for scaffolding erection, dismantling, and inspection

-

5.14 Proper guardrail is in place on all sides of each accessible level, including the scaffold ends and material loading stations

-

5.15 Scaffolding set up properly with ALL cross-braces, base plates, mud sills (if necessary), and locked casters

-

5.16 All scaffold components are in good condition (no cracks in planks longer than the width of the plank, correct pins being used, etc.)

-

5.17 Planks extend 6" over supports (or have been cleated) but do not extend past 12"

-

5.18 Is there proper scaffold access?

6. Electrical

-

6.1 Extension cords are rated for outdoor use and have hard or extra hard markings (S, ST, STJ)

-

6.2 Extension cords are not running through doorways, wall openings, or other spaces which they could be damaged

-

6.3 All extension cords and gas lines are elevated with Quick Hooks or other non-conductive material to prevent trip hazards or damage to the sheathing.

-

6.4 Extension cords, welding leads, and tool cords have no damages to insulation or electrical tape repairs

-

6.5 Extension cords are not daisy-chained

-

6.6 GFCI must be used at the source of all electrical construction equipment and rated for construction use

-

6.7 Live electrical junction boxes and temp power connections properly guarded against incidental contact and water

-

6.8 All electrical cabinets and panels are restricted from access by locked panel/door or by locking and tagging out each breaker

-

6.9 Is all power shut down and locked out for demo operations

7. Tools

-

7.0 Proper guarding being used on all tools and equipment

-

7.1 Powder actuated cartridges are spent and emerged in a container filled with water

-

7.2 Are negative air filter machines running and cleaned regularly?

8. PPE

-

8.1 100% hard hats usage, free of damages

-

8.2 100% safety glasses, including prescription eye wear that meets ANSI standards with side shields

-

8.3 Task-specific PPE is properly utilized (face shields, gloves, respiratory, hearing protection, chaps, etc.)

-

8.4 High visibility clothing is worn when working around vehicles

-

8.5 All PPE stored and maintained per manufactures instructions I.E. fall protection and respiratory protection

9. Trenching/Excavating

-

Remember: At 5' deep, cave-in protection is required on all sides but may be needed in shallower trenches.

-

Are there any Excavations/Trenching onsite?

-

9.1 Has a pre-work meeting been conducted with the safety team and appropriate parties?

-

9.2 Competent person(s) identified:

-

9.3 Has the competent person completed the Excavation Permit?

-

9.4 Has the competent person completed the Trench Inspection form daily, prior to anyone entering the trench?

-

9.5 What type of soil has the soil been classified?

-

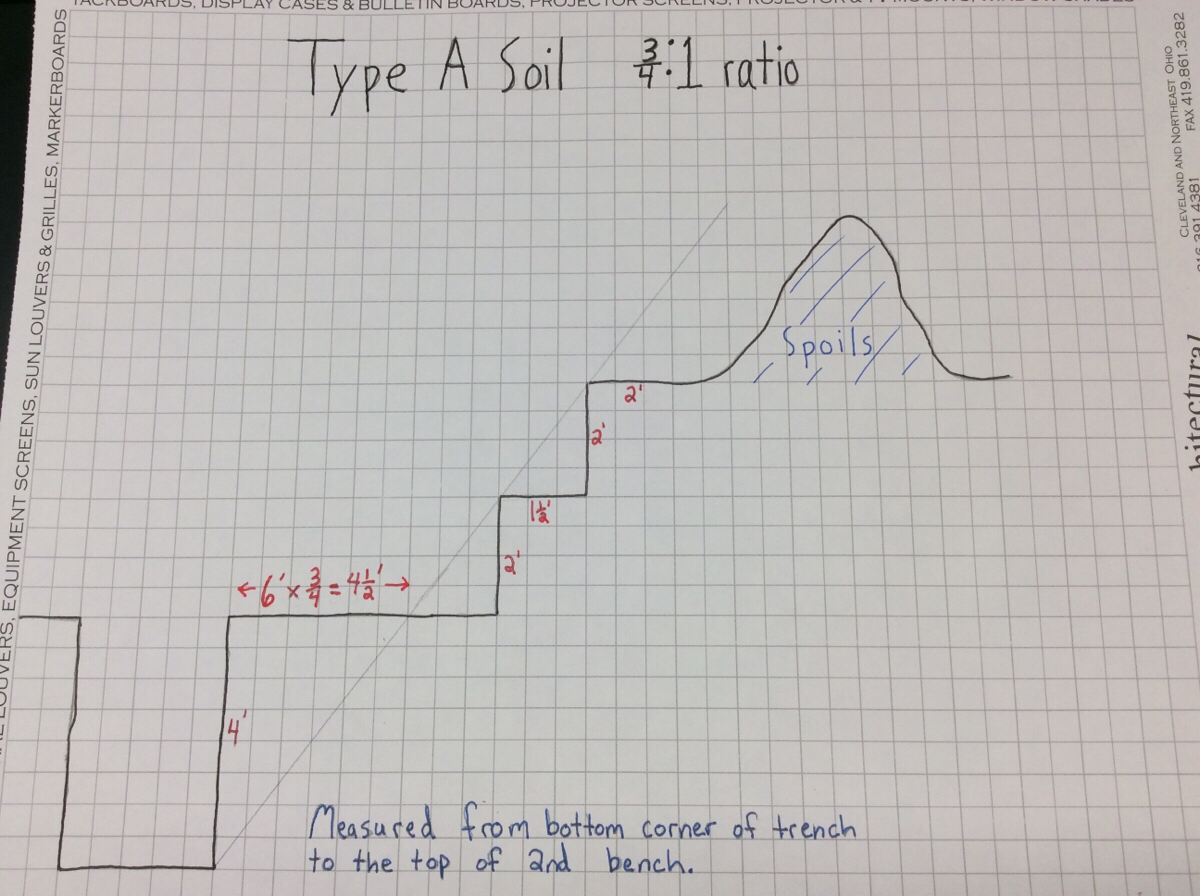

Must use trench box or shoring when 5' or deeper. Sloping and benching can be at 3/4:1 ratio

-

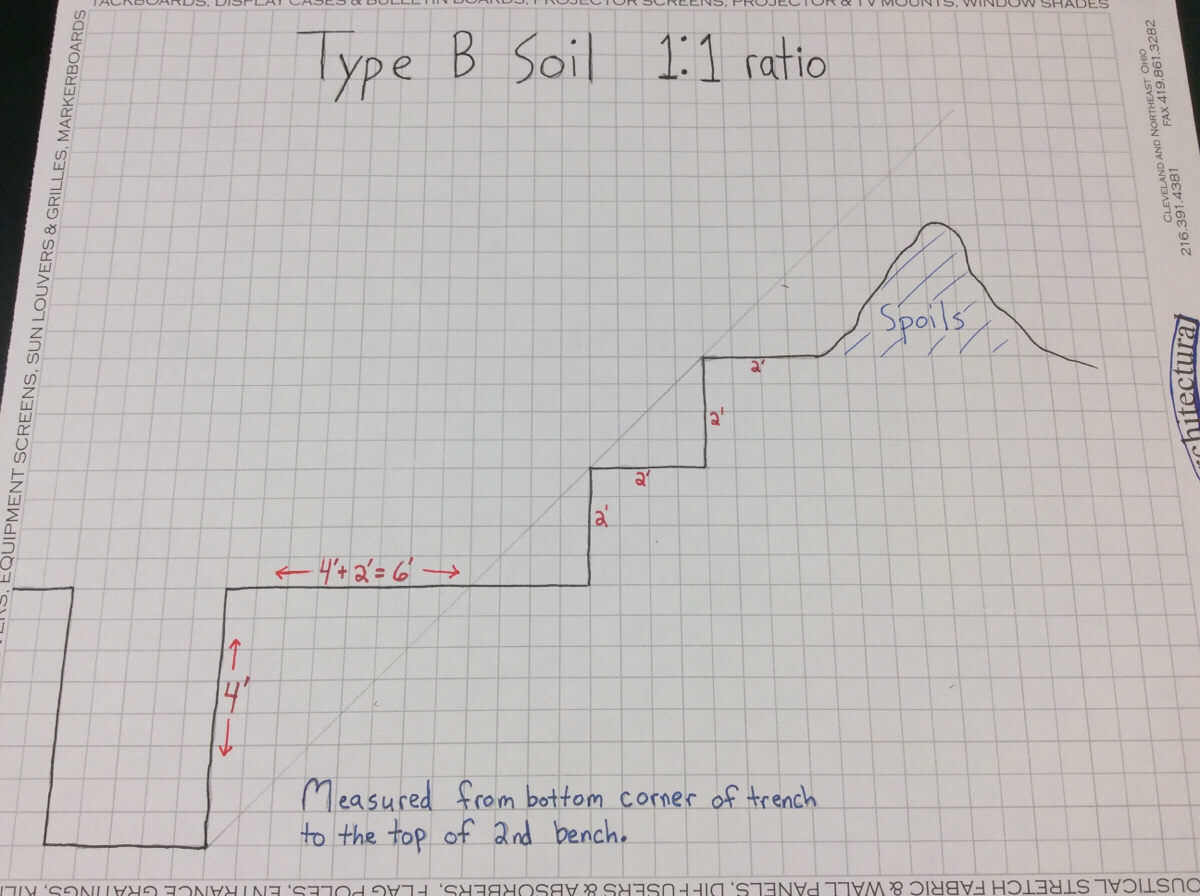

Must use trench box or shoring when 5' or deeper. Sloping and benching can be at a 1:1 ratio

-

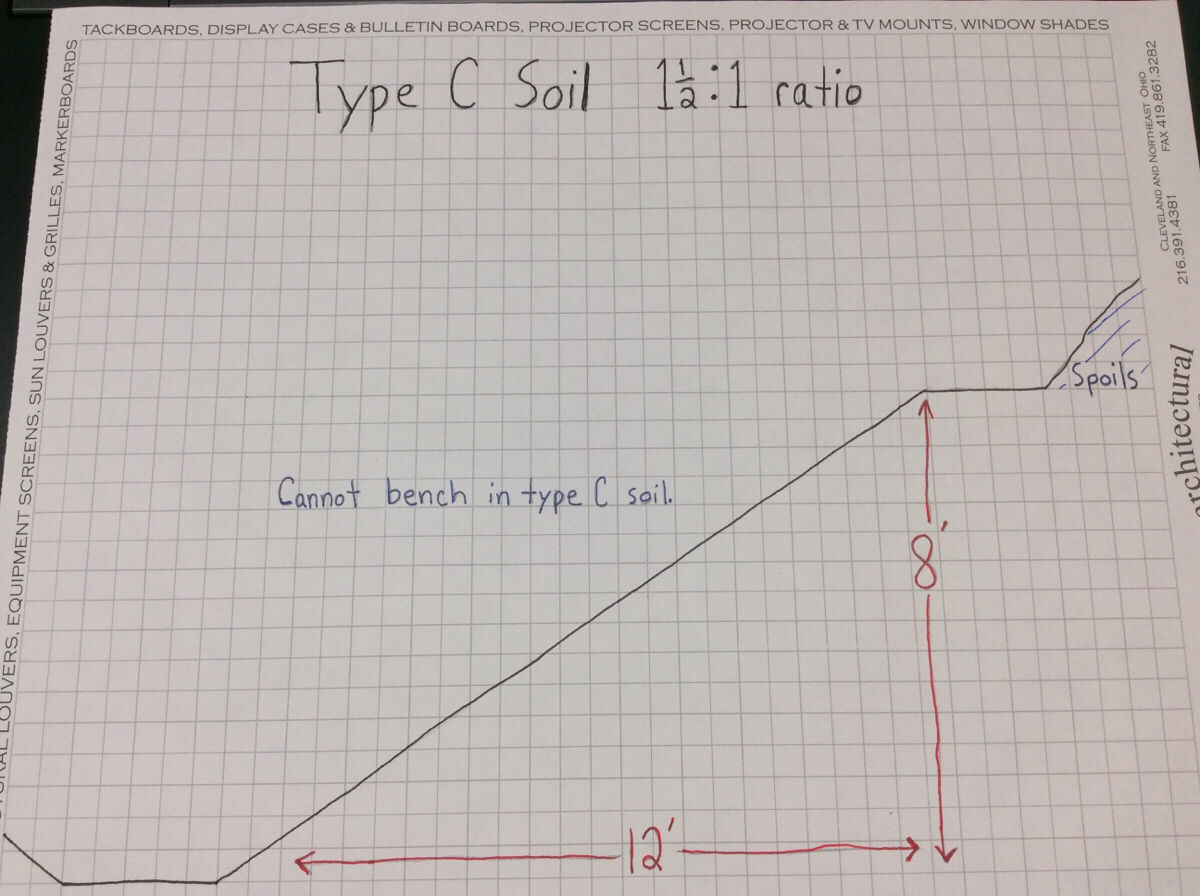

Must use trench box or shoring. Slope can be a 1 1/2:1 ratio. No benching in type C soil.

-

Assume soil is Class C.

-

9.6 Excavations are properly sloped, benched or shielding is in place

-

9.7 Trenches 4' or deeper have a ladder, ramp or steps no further than 25' from furthest worker

-

9.8 Is there protection for the general public and/or other trades from falling into the excavation?

-

9.9 All underground utilities' exact location and depth found by a non-conductive device, hydro vacuuming, or ground penetrating radar.

-

9.10 No digging with machinery within 3' of the buried utility unless electronic sensor/monitor is used, then distance decreased to 18

10. Cranes

-

Is there a crane in use onsite?

-

10.1 Pre-lift meeting conducted with the safety team and all appropriate parties

-

10.2 Cranes have documented daily inspections and annual certifications

-

10.3 Crane swing radius is barricaded

-

10.4 Qualified signal and rigging person identified

-

10.5 All wire rope, synthetic slings, hooks, and sheaves in good condition with legible identifiers and documented daily inspection

-

10.6 Tag lines are used on all loads that could become dangerous due to wind?

-

10.7 Are all the outriggers fully extended, cribbed and on sturdy ground?

-

10.8 Are there any overhead obstructions near the boom radius?

-

10.9 All workers clear of the overhead flight path

11. Mechanical Equipment (Aerial Lifts, Fork Lifts, Excavators, Skid Steer, etc.)

-

Any mechanical equipment on site?

-

11.1 All mechanical equipment has been inspected on a daily basis with documentation

-

11.2 All components of equipment in good working order and being used properly (seat belts, gates, etc.)

-

11.3 Equipment operated by qualified, trained operators

-

11.4 Aerial lifts inspected on an annual and frequent basis

-

11.5 Aerial lift operator(s) are properly tied off with retractable lanyards

-

11.6 Are any gas powered equipment or propane heaters being used internally (ceiling and walls are up)?

-

Are carbon monoxide testers being used?

12. Hot Work

-

Any hot work onsite?

-

12.1 Hot work permits completed prior to all hot work

-

12.2 Welding curtains installed for welding and cutting

-

12.3 Fire extinguishers in place

-

12.4 All hot work is contained from endangering others

-

12.5 Is fire watch in place during and for 30 minutes after hot work has stopped?

-

12.6 If cutting with an abrasive saw, a spark shield is in place preventing hot particles from endangering other work areas/personnel.

13. Confined Space

-

Any work being performed in Confined Spaces?

-

13.1 Has a pre-work meeting been conducted for all confined space activities with the safety team and each contractor involved?

-

13.2 Have all work activities been coordinated to ensure each contractor does not expose other contractors to their hazards?

-

13.3 Has the confined space checklists been documented prior to starting work?

-

13.4 What has the space been deemed?

-

Do you have continuous air monitoring to ensure potential atmospheric hazard is not an issue?

-

Are all physical hazards eliminated or isolated?

-

Is the competent person filling out the Permit-Required Confined Space Form daily and posting it at the entry location?

-

Are air samples being continuously monitored and updated on the form?

-

Are authorized entrant, attendant, and supervisor on site?

-

Are warning signs posted at the entry location(s) of the space?

14. Silica Dust

-

Are their any silica dust generating tasks on site?

-

14.1 Are all tasks covered by:

- Table 1

- Exposure Assessment

- Neither

-

TABLE 1: Is the correct APF respirator being worn as per Table 1 based on the longevity of the task?

-

TABLE 1: Are ALL engineering and work practice controls being utilized as per Table 1 based on indoor/outdoor requirements?

-

EXPOSURE ASSESSMENT: Is the air sampling data reflective of the current workplace conditions including the same process and production rate, type of material, control methods, work practices, and environmental controls? The air sample must accurately characterize the task being performed.

-

Must conduct Exposure Assessment or follow all engineering, work practice, and respiratory protection controls under Table 1. Must do one or the other.

-

Conduct Exposure Assessment or follow ALL engineering, work practice, and respiratory protection under Table 1. Must perform one or the other unless the task is less than 15 minutes, cumulative, for the entire day.

-

Are silica practices meeting the silica standard?

-

14.2 Are other trades and non-construction people protected from silica exposure?

-

14.3 No dry sweeping for silica-based housekeeping

-

14.4 Silica tasks are being discussed and coordinated in weekly Foremen meetings?

-

14.5 Has the exposure control plans of contractors been updated regularly?

-

14.6 Each contractor working with silica materials has an Exposure Control Plan on site (even if the 3SP is not approved)

-

14.7 All workers wearing respiratory protection have an annual medical evaluation and fit test documentation

Other Issues/Notes

-

Other Issues

Jobsite

-

Jobsite Photos

Signature

-

Signature