Title Page

-

TANK NO:

-

Site conducted

-

Location

-

Conducted on

Tank Description

General

-

Nameplate:

-

Where is it located

-

Design Std.:

-

Manufacturer:

-

Cathodic Protection:

-

Product:

-

Specific Gravity:

-

Normal Oper. Temp.:

-

Nom. Tank Pressure:

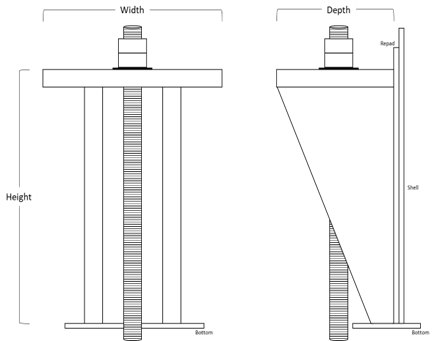

Dimension

-

Diameter:

-

Nom. Capacity:

-

Height:

-

Working Height:

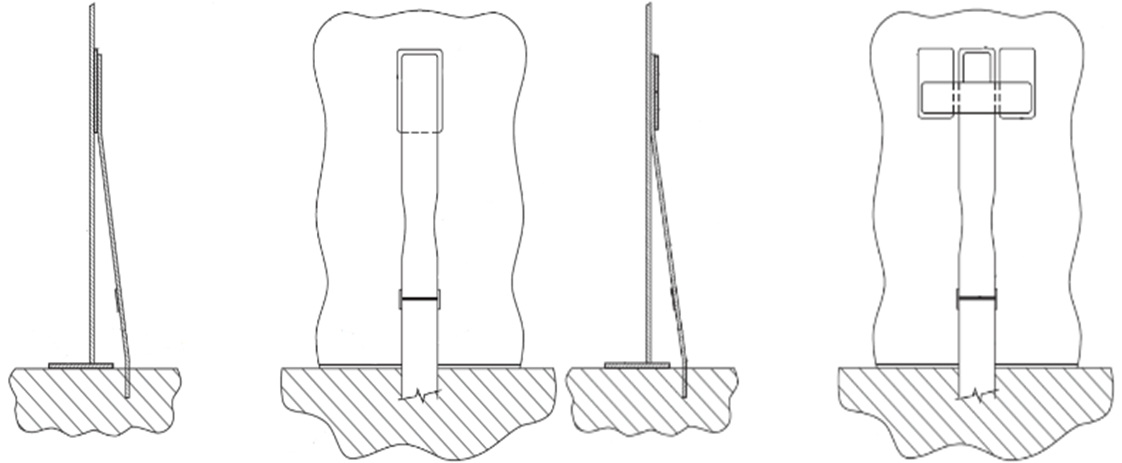

Geometry

-

Foundation:

-

Bottom:

-

Shell:

-

Explain

-

Fixed Roof:

-

Explain

-

Floating Roof:

-

Primary Seal:

-

Secondary Seal:

Dates

-

Year Built:

-

Last Inspection Internal:

-

Last Inspection External:

-

Last Coated:

Access

-

Shell/Fixed Roof Access:

-

Floating Roof Access:

Coatings

-

Bottom: Internal:

-

Bottom: External:

-

Shell: Internal:

-

Shell:External:

-

Fixed Roof: Internal:

-

Fixed Roof: External:

-

Floating Roof: Internal

-

Floating Roof: External:

Tank Material Data Table

-

Shell Course 1 Material

-

Shell Course 2 Material

-

Shell Course 3 Material

-

Shell Course 4 Material

-

Shell Course 5 Material

-

Shell Course 6 Material

-

Shell Course 7 Material

-

Shell Course 8 Material

-

Bottom Plate Material

-

Annular Plates Material

-

Fixed Roof Plates Material

-

Floating Roof Plates Material

undefined

SUMMARY AND REPAIR RECOMMENDATIONS

-

The following is a summary of the significant findings of the inspection. (Item numbers correspond with item numbers on the API 653 Checklist). Note: Recommendations noted in this section are preliminary and may be subject to change pending Engineering calculations, as well as an Engineering review of the inspector's report.

-

INSPECTION SUMMARY

-

FOUNDATION:

-

BOTTOM:

-

SHELL:

-

NOZZLES AND APPURTENANCES:

-

FIXED ROOF:

-

FLOATING ROOF:

-

Other

1. Containment, Foundation and Fire Suppression

1.1.1 FOUNDATION SETTLEMENT EVALUATION

-

Perform MT or PT on welds at areas where settlement failed or where edge settlement is present. Acceptable / Ref. Summary / N/A

-

Perform Settlement survey of the tank. Acceptable / Ref. Summary / N/A

1.1.2 General

-

Check for signs of bottom leakage. Acceptable / Ref. Summary / N/A

-

Tank Bottom Release Prevention Systems. Acceptable / Ref. Summary / N/A

-

Inspect for excessive vegetation against bottom of tank. Acceptable / Ref. Summary / N/A

-

Inspect for cavities under foundation. Acceptable / Ref. Summary / N/A

1.1.3 Site Drainage

-

Check for presence of containment drains.

-

Verify if containment drains are clear and free of debris.

-

Check for evidence of standing water against tank.

-

Verify if surrounding grade allow water to drain away from the tank.

1.1.4 Tank Foundation

-

Inspect for broken concrete, spalling and cracks. (particular attention under back-up bars used in butt welded annular ring under the shell)

-

Note station location of deterioration

-

Check for presence of leak detection. Verify condition and no bottom leakage

-

Check whether the concrete ringwall allows rainwater to properly drain away

-

Verify condition of the foundation drip ring Acceptable / Ref. Summary / N/A (if applicable)

Asphalt Apron

-

Check for settling of tank into asphalt Acceptable / Ref. Summary

-

Inspect for broken, deteriorated or cracks in asphalt.

Earth

-

Check for settling of tank into ground / earth.

Grillage member

-

Grillage member details and orientation Spacing (center to center): Qty.: Inspect Grillage members for corrosion or distortion.

Anchorage

-

Verify if the tank anchors are API standard N/A Acceptable / Ref. Summary type. If not, detail type.

-

Inspect anchor bolt(s) or anchor strap(s) for distortion, indicating serious foundation settlement or tank overpressure uplift. Acceptable / Ref. Summary

-

Inspect nut(s) for a tightened snug fit, degradation of the anchor chair assembly Acceptable / Ref. Summary / N/A

-

Inspect anchor straps for degradation and concrete deterioration. Acceptable / Ref. Summary / N/A

-

Anchor Chair Dimension

-

Anchor Chair Detail & Dimensions

-

Qty:

-

Spacing (ft.)

Anchorage

-

Repad? Yes No

-

Tell-Tale? Yes No

-

Repad Size: Width X Height X Depth

-

Bolt Size: Single Nut Double Nut

-

Single nut or Double nut

-

Anchor Strap Detail and Dimensions

-

Type: A or B

-

Qty:

-

Spacing (ft.)

-

Repad? Yes No

-

Tell-Tale? Yes No

-

Repad Size: Width Height

1.1.5 Fire Suppression System

-

Verify the condition of the fire suppressant system.

-

Check the overall condition of the foam

-

Open-top / EFR: Check the condition of the fire suppressant shell extensions for corrosion or defects

-

Inspect overall condition of deluge system and components (corrosion, missing or damaged parts, etc.)

FOUNDATION RECOMMENDATION PHOTOS

-

PHOTOS

-

DESCRIPTION

1.2 BOTTOM

1.2.1 Overview

-

Verify if tank is clean, gas free and safe for entry. The tank shall be isolated (product, steam, electrical, etc.) to prepare for entry.

-

Check for evidence of falling objects (roof rafters, large patches of scale, corroded through plates, etc.).

-

Complete a Floating Roof Checklist to determine that the floating roof is secured for confined space entry.

1.2.2 Bottom

-

Perform a visual inspection of the bottom plates. Document all findings and limitations (client must be notified of limitations while on site).

-

Visual inspect for bottom depressions, bulges, and edge settlement.

-

Perform Magnetic Flux Leakage (MFL) scan of tank bottom.

-

Document pit depth with pit type (sharp edged, lake type, general, scattered, etc.).

-

Collect and review bottom plate and critical zone UT (if applicable) per proposal.

-

Check for reinforcing plates under brackets, supports, gauge poles, etc. and perform a visual inspection.

-

Visually inspect floating roof leg striker plates for weld corrosion, pitting, cutting, or excessive dimpling.

-

Visually inspect for the presence and condition of previous repairs (patch plates, puddle welds, etc.).

-

Overall condition of the coating system (notate coating failure such as cracks, blistering, chalking, discoloration, rust blooms, adhesion failure, etc.).

-

Are recordable indications and defects identified on the bottom layout and logged in the bottom reduction form?

Bottom Welds

-

Perform a visual inspection of all lap/butt welds and internal shell-to-bottom weld. Document all findings and limitations (client must be notified of limitations while on site).

-

Vacuum Box Inspection of lap/butt welds

-

Magnetic Particle (MT) or Liquid Penetrant Inspection of lap/butt welds and/or internal shell-to-bottom weld.

Bottom Sump(s)

-

Perform a visual inspection of the sump(s). Document all findings and limitations (client must be informed of limitations while on site).

-

Document pit depth with pit type (sharp edged, lake type, general, scattered, etc.).

-

Collect and review bottom sump UT for significantly low reading(s).

-

Magnetic Particle (MT) or Liquid Penetrant (PT) Inspection of sump-to-bottom weld.

-

Magnetic Particle (MT) or Liquid Penetrant (PT) Inspection of sump welds.

-

Coating condition of the sump(s).

RECOMMENDATION PHOTOS

-

PHOTOS

-

DESCRIPTION

1.2.3 Bottom Edge Projection

-

Inspect bottom edge projection for corrosion. If corrosion is present, consideration must be given to the extent of which it extends under the shell and internal bottom.

-

Verify if soil or gravel are covering the bottom edge projection and/or the lower shell. If applicable, remove soil or gravel in areas for inspection. Detail findings and average depth of soil or gravel in summary.

-

Average depth of soil or gravel:

-

Check for inadequate plate projection away from the shell that is less than 3/8" in length and less than 0.100 thickness.

-

Overall condition of coating system (notate coating failure such as cracks, blistering, chalking, discoloration, rust blooms, adhesion failure, etc.).

-

Verify type and condition of bottom-to-foundation seal (moisture barrier), if applicable.

-

Does the tank have a single bottom or double bottom?

-

Distance between bottoms?

-

Verify the underside of the new bottom is welded, caulked, or neither.

-

Verify condition of dead shell material.

-

Check if drain ports are present between double bottom

-

Are valves in the closed position?

RECOMMENDATION PHOTOS

-

PHOTO

-

DESCRIPTION

1.3 Shell

1.3.1 Shell Plate

-

Are conditions present that would limit the inspection of the external shell? (Client Acceptable / Ref. Summary / N/A must be informed of limitations while on site)

-

Overall condition of coating system (notate coating failure such as cracks, blistering, chalking, discoloration, rust blooms, adhesion failure, etc.)

-

Collect and review external shell UT per proposal or Client spec. Perform shell thickness calculations.

-

Verify condition of exterior shell-to-bottom weld (corrosion, leaks, defects, etc.)

-

Verify presence and condition of tank nameplate(s).

-

Inspect the external shell for pitting, corrosion, discoloration, or other types of damage mechanisms. Perform the appropriate corrosion analysis for the extent of pitting/ corrosion present.

-

Inspect for significant shell deformations (i.e., flat spots, bulging, peaking, banding, excessive hammer marks or gouges).

-

Inspect external vertical and horizontal weld seams for weld defects and signs of weeping or leaks as viewed from grade, stairway, and manlifts or scaffolding (if applicable).

-

Evaluate existing shell inserts and/or lapped patch plates. Verify the purpose of these details and determine whether the sizes, weld spacing, and thicknesses comply with the code .

-

Inspect shell attachment support welds for presence of corrosion or defects. Note if supports were installed with reinforcing pads welded to the shell.

-

If applicable and access allows, inspect the shell above the wind girder(s) and/or stiffening ring(s) for pitting/corrosion due to standing water.

-

Inspect shell insulation for visible damage and sealant failure around insulation protrusions which allows for water ingress. Check for saturated or sagging insulation.

-

Note if insulation was removed to allow for visual inspection of the shell exterior. Document and evaluate the extent of CUI damage if present.

External Riveted Shell

-

If no records exist, document, or photograph the rivet pattern, rivet size and note whether the joint is butt riveted or lap riveted.

-

Check for and estimate the amount of metal loss on the heads of rivets and bolts.

-

Check for signs of weeping or leaks around the rivets or bolts and seams.

-

Inspect vertical seams to see if they have been full fillet-lap welded.

-

Inspect rivets, threaded connections, and riveted coupling-to-shell seams to see if they have been full fillet-lap welded.

SHELL RECOMMENDATIONS PHOTOS

-

PHOTO

-

DESCRIPTION

1.3.2 Nozzles and Appurtenances

-

Document shell penetrations on the Nozzle & Appurtenance Table.

-

Evaluate each nozzle and manway in accordance with current API 650 and API 653 guidelines for acceptability (weld spacing, centerline, nozzle neck thickness, reinforcement size and thickness).

-

Perform MT or ACFM examination on shell penetrations that do not meet the minimum required weld spacing per API 650, Figure 5.6, to determine acceptability for continued service.

-

Inspect manways, nozzles, and bolting for external coating failure and presence of corrosion (thinning, pitting, scale, etc.).

-

Inspect all external welds of nozzles, manways, reinforcing plates, and couplings for signs of leakage, defects, or corrosion.

-

Inspect for flange and/or valve leaks around manways, nozzles, and appurtenances with specific attention to bolting, gaskets, and seals.

-

Inspect for shell plate dimpling around nozzles, caused by excessive pipe deflection.

-

Inspect mixer(s) for inadequate flange and cover thickness, evidence of leakage, defects, and condition of supports.

-

Inspect davit arms and welds on shell mounted davit clips above large valves or equipment.

-

Check for reinforcement on all shell penetrations over 2” NPS.

-

Verify tell-tales on reinforcing plates are not plugged (caulk or grease is acceptable to prevent corrosion).

-

Split segment reinforcing plates: Verify that each segment has telltales present.

-

Check the condition of temperature indicators / probes (corrosion, mechanical damage, etc.).

-

Check for presence and condition of grounding cables and grounding attachments to the shell.

-

Inspect condition of insulation and sealant around manways and nozzles.

NOZZLE RECOMMENDATION PHOTOS

-

PHOTO

-

DESCRIPTION

1.3.3 Shell Vents / Overflows

-

Detail shell vents. Shell vent rows. No. of vents row 1 (bottom): Vent Size: No. of vents row 2 (top): Vent Size:

-

How many Shell vent rows?

-

How many vents on each row?

-

Inspect for corrosion on the shell vent hoods and screens. Note how many screens are missing or damaged.

-

Detail overflow slot(s) on the Nozzle & Appurtenance Table with weld spacing from the horizontal weld and size. (note if estimated due to accessibility)

-

Check overflows for corrosion and adequate screening

-

Verify overflow(s) are not located above any tank valves or equipment, stairways, or nozzles.

SHELL VENTS / OVERFLOW RECOMMENDATIONS

-

PHOTO

-

DESCRIPTION

1.3.4 Wind Girder / Stiffening Ring

-

Detail how many wind girder(s).

-

Detail how many stiffening ring(s).

-

Inspect the wind girder(s) / stiffening ring(s) for corrosion especially at the shell welded junction.

-

Check support welds to shell for pitting especially at the shell plate junction.

-

Note whether supports have reinforcing pads welded to shell.

-

Check if the wind girder(s) and/or stiffening ring(s) are seal welded or stitch welded. If more than one, specify which in Ref. Summary.

-

Check for drain holes and the condition of drain holes.

Wind Girder / Stiffening Ring RECCOMENDATION

-

PHOTO

-

DESCRIPTION

1.3.5 Tank Access Structure

-

Identify type of handrails.

-

Identify and report size of handrails.

-

Inspect treads for corrosion or defects.

-

Inspect attachment welds for corrosion or defects.

-

Identify cold joints and sharp edges, with attention to handrails and midrails.

-

Inspect stairway stringers for corrosion, coating failure, and weld failure. Inspect attachment of stairway treads to stringer.

-

Inspect stairway supports to shell welds and reinforcement pads.

Vertical Ladder

-

Inspect ladder rungs and frame for degradation.

-

Inspect ladder cage for degradation.

Top Landing / Platform

-

Identify and report type and size of handrails.

-

Confirm handrail toe boards are a min. 3.5” in height with no excessive gaps.

-

Inspect condition and proper function of safety drop bars, safety gates or safety chains.

-

Inspect frame for corrosion and coating failure.

-

Inspect attachment welds for corrosion or defects.

-

Identify cold joints and sharp edges, with attention to handrails and midrails.

-

Inspect the attachment of frame to supports and/or supports to tank for corrosion and weld failure.

-

Check reinforcement pads where supports are attached to the shell or roof for corrosion or defects.

-

Inspect the surface that deck plate or grating rests on, for thinning and holes.

-

Inspect deck plate for corrosion caused thinning or holes (not drain holes) and coating failure.

-

Inspect grating for corrosion-caused thinning of bars and failure of welds.

-

Check for grating tie down clips and inspect for defects.

ACCESS RECOMMENDATIONS

-

PHOTO

-

DESCRIPTION

1.4 Tank Roof

1.4.1 Fixed Roof -External

-

Inspect for low areas, excessive waviness, or bulging on the roof deck.

-

Inspect for active corrosion, pitting or holes.

-

Perform visual inspection of the lap welds and/or butt welds for corrosion or defects.

-

Overall condition of coating system (notate coating failure such as cracks, blistering, chalking, discoloration, rust blooms, adhesion failure, etc.).

-

Collect and review plate UT for significantly low reading(s). Client must be notified while on site.

-

Perform visual inspection of roof-to-shell joint if visible.

-

Check for and evaluate CUI damage if insulation was removed for inspection.

-

Document and identify all recordable indications and defects on the fixed roof layout.

Nozzles and Appurtenances

-

Inspect condition of roof manways, nozzles and appurtenances (corrosion, coating failure, damage, missing bolts, etc.).

-

Take photos of all instrumentation connected to nozzles and photos of any data-plates and nametags attached.

-

Check for openings or exposed electrical connections or wiring.

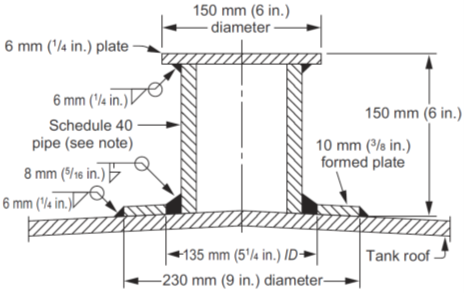

Scaffold Support

undefined

-

-

Inspect scaffold support for corrosion.

-

Is the scaffold support an API standard type attachment?

-

Is there a reinforcing plate present?

-

Pipe diameter (in.)

-

Thickness of pipe

-

Diameter of reinforcing plate (in.)

Insulation

-

Inspect for damage, tears, deteriorated sealant, bulging, wet insulation, etc.

-

Does the insulation limit or prevent inspection of the roof to shell joint?

Standard Venting (rim vent hoods)

-

Verify vents allow free air flow and screens are free from debris.

-

Check and detail vents that have missing screens and/or vent hoods.

-

Verify vent hoods are secured with a pin and in the down position. Check for missing bolting hardware.

Emergency Venting (Mechanical, PRV, PSV, etc.)

-

Check for setting of mechanical vents from the nametag and notate on the fixed roof nozzle table.

-

Check and detail vents that have missing screens and/or vent hoods.

-

Take photos of each vent and tag if present. (even if tag isn’t legible)

Geo-Dome

-

Geo-Dome: Check for evidence of leaking panels (areas of water on the internal floating roof) and damaged panels (tears, holes, etc.)

-

Geo-Dome: Check for pinholes and tears in the roof panels and any visible missing components.

-

Geo-Dome: Check for damaged or deteriorated skylights.

FIXED ROOF RECOMMENDATIONS

-

PHOTO

-

DESCRIPTION

1.4.2 Internal Floating Roof (IFR)

-

Steel: Overall levelness and condition of the floating roof.

Floating Roof Drain(s)

-

Floating Roof Drain Type and Qty.

Primary Seal

-

Inspect seal fabric for deterioration, hole, tears, and cracks.

Secondary Seal

-

Inspect seal fabric for deterioration, hole, tears, and cracks.

Appurtenance Seal(s)

-

Check condition of seal around columns, guide pole(s) and gauge pole(s).

Roof Supports (Floating Roof Legs and Cable Suspension)

-

Inspect legs and sleeves for signs of thinning and corrosion.

Bonding/Grounding

-

Bonding/Grounding: Verify if floating roof is equipped with a minimum of four (4) bonding shunts or a minimum of two (2) flexible multi-strand cables from the fixed roof to the internal roof.

-

Number of Shunts:

-

Number of Cables:

Anti-Rotation

-

Steel: Type of Anti-rotation. Verify condition and if misalignment is present.

Rolling Ladder & Runway

-

Inspect rolling ladder for corrosion.

FLOATING ROOF RECOMMENDATIONS

-

PHOTO

-

DESCRIPTION

1.4.3 External Floating Roof

-

Inspect for pitting, holes, weld corrosion and evidence of product on deck

-

Overall condition of coating system (notate coating failure such as cracks, blistering, chalking, discoloration, rust blooms, adhesion failure, etc.).

-

Verify deck lap seams have been stitch welded within 12 inches of each penetration.

-

Collect and review deck plate UT for significantly low reading(s).

-

Document and identify all recordable indications and defects on the floating roof layout.

-

Check condition of foam dam.

Pontoons

-

Check all pontoons for signs of water, product, residue, and vapors (numbering should begin counterclockwise from the gauge pole).

Nozzle and Appurtenances

-

Inspect condition covers, seals, and gaskets for all floating roof penetrations (e.g., sample hatch, vacuum breakers, manways, etc.).

-

Inspect nozzles for signs of defects, corrosion, and coating failure.

Floating Roof Leg

-

Inspect legs and sleeves for signs of thinning and corrosion.

-

Inspect the High/Low leg pins and holes for corrosion and tears.

-

Inspect legs for distortion and surrounding deck plate for tears or cracking. Verify reinforcing plates are present around legs.

Grounding

-

Has the floating roof been equipped with a grounding system?

Primary Seal

-

Inspect seal fabric for deterioration, hole, tears, and cracks.

Secondary Seal

-

Inspect seal fabric for deterioration, hole, tears, and cracks.

Rolling Ladder & Runway

-

Inspect rolling ladder for corrosion.

-

Inspect for wear and corrosion where rolling ladder attaches to gauging platform.

FLOATING ROOF RECOMMENDATION

-

PHOTO

-

DESCRIPTION

1.4.4 Tank Gauging

External Gauge

-

Inspect automatic gauge housing for damage.

-

Detail Make, Model No., Serial No. and Mfr. Date. of tank gauge

Internal Gauge

undefined

-

-

Gauge Pole Details: Size: Slotted? ☐ Yes, Slot Size:

-

Check for gauge well corrosion and/or distortion.

-

Check if the gauge pole supports are welded to the shell or repad and not the bottom. Check support welds for corrosion or defects.

-

Check condition of gauge well seal system (i.e., ‘sock’). Typically present on tanks with floating roofs.

TANK GAUGING RECOMMENDATION

-

PHOTO

-

DESCRIPTION

Inspector

-

API Inspector:

-

API Cert #:

-

REFERENCE PHOTOGRAPHS

- OVERVIEW

-

OVERVIEW

-

DESCRIPTION

FOUNDATION

-

FOUNDATION

-

DESCRIPTION

EDGE PROJECTION

-

EDGE PROJECTION

-

DESCRIPTION

SHELL

-

SHELL

-

DESCRIPTION

SHELL NOZZLES AND APPURTENANCES:

-

SHELL NOZZLES AND APPURTENANCES:

-

DESCRIPTION

FIXED ROOF:

-

FIXED ROOF:

-

DESCRIPTION

FIXED ROOF NOZZLES

-

FIXED ROOF NOZZLE

-

DESCRIPTION

FLOATING ROOF:

-

FLOATING ROOF:

-

undefined