Title Page

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

Safe Work Method Statement

-

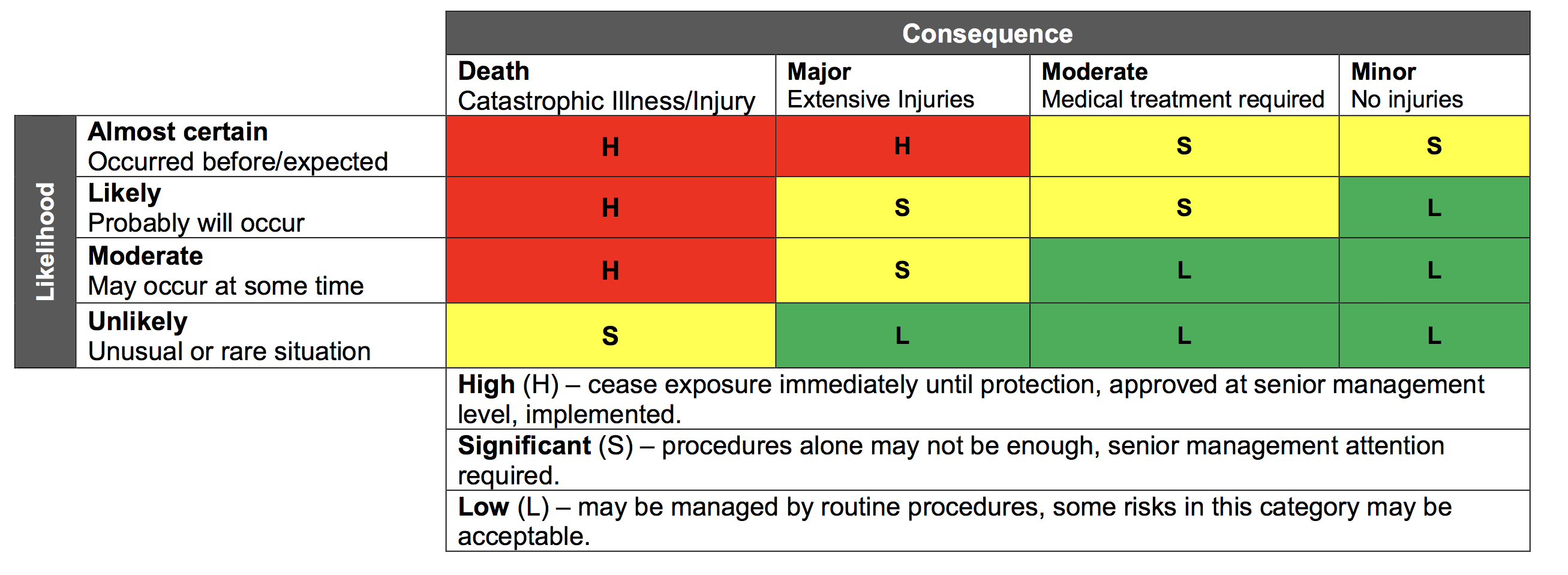

Instructions & Risk Rating Guide

-------------------------

1. Refer to this guide when answering the "Consequence or Impact of Hazards without controls" in the sections below

2. Select the relevant risk rating with and without controls. Try again if you select the wrong answer

3. Confirm you have reviewed this SWMS form and assessed the hazard by providing your digital signature

Step 1 - Assess the site for safety issues

Planning and preparation

-

Possible Hazard:

- Heat exhaustion, sunstroke, dehydration

- Slippery surface – causing slips, trips, falls, strains, sprains, fractures and injuries on the same level

- Radiation / ultra-violet burns Sunburn

- Burn (fire)

- Chemical burn

- Heat exhaustion, sunstroke, dehydration, cognitive impairment

- Burns, smoke inhalation causing serious injury or death

- Short / Long term exposure to hazardous chemical/s causing illness or death

- Muscular stress/ Musculoskeletal Disorder

- Entrapment - by vehicle

- Hit by flying or projected objects

- Deafness, hearing loss

- Person/s entering exclusion zone

o injured by mobile plant

o equipment

o chemicals etc on site

o distracting operators/ workers

- Entrapment - by machinery or equipment

- Exposure to mechanical vibration

- Fall off plant causing injury /death

- Being run over/ struck by mobile plant causing serious injury/ death

- Collision with objects / plant.

-----------------------------

Safety Controls:

- Consult with the person you are carrying out the work for on the potential hazards and risks associated with the task

- If represented by an elected Health and Safety Representative (HSR), they must be included in any consultation

- Any other persons on site who are affected by the same matter are consulted and co-operative arrangements are made

- Document consultation and action items.

Liaise with Principal Contractor to establish that the following on-site systems and procedures are in place:

- Health and Safety rules

- Induction for all workers – site specific

- Supervisory arrangements

- Communication

- Injury reporting

- Hazard reporting

- Personal Protective Equipment

- Exclusion Zones

- Risk Assessments

- SWMS and JSA’s.

Assess the exposure of workers & others to noise, including the frequency of exposure to noise levels that exceed the legislated Exposure Standard while undertaking bitumen/asphalt tasks and determine required controls such as Audiometric Testing and PPE. Refer to Noise Control SWMS for detailed information regarding the prevention of hearing loss and legislative requirements.

Task-specific bitumen safety induction training must be delivered by approved qualified persons for all new construction workers.

All operators/workers to be trained and competent: The training must:

- Be appropriate to the associated risks identified in the risk assessment

- Incorporate the safe use of equipment that are utilised in handling bituminous substances, including binders, agents, emulsifiers and oxidsiers

- Cover the correct use, care and storage of personal protective equipment (PPE) and also cover the subject of hygiene (in relation to working with hazardous substances)

- Include emergency and evacuation procedures.

Assess site. Ensure:

- Assessment of risks at site

- Fire protection equipment available

- Communication systems in place

- Emergency procedures- including fire / explosion response

- Safe access/egress

- Plant/equipment required is available

- Room for equipment

- Traffic management plan in place for materials delivery, suitable access areas

- Workers not exposed to hazards (close proximity to moving plant/vehicles etc)

- Plan for waste removal

- Signage to be used for warning of hot surfaces

- Placards on all vehicles / plant carrying dangerous goods

- Prohibit eating, drinking and smoking in works area.

NOTE: An emergency shower and eye wash station should be easily accessible.

Develop site specific SWMS and Risk Assessment. Include:

- Suitable weather conditions (hot/cold, wet/dry)

- Type of task (duration, temperatures of materials)

- Written instructions, site plans etc

- Roles and responsibilities of relevant workers

- Ensure suitable travel route chosen in advance.

Seek written permissions from relevant Authorities where required for lane closure, speed reductions etc

Develop and document suitable traffic management for site. Include:

- Clearance between moving traffic, plant and workers

- Mobile plant operating in close proximity

- Approaches to worksite, (lane closures/traffic diversions)

- Speed of traffic

- Traffic volume

- Traffic control for roadside delivery of materials (safe delivery points)

- Traffic control for access/egress for plant to roadway

- Pedestrians working in close proximity to plant in operation

- Control of public vehicles to site

- Use of safety barriers

- Traffic controllers

- Warning sign arrangement.

ENSURE the site-specific WHS plan details include:

- Regular emergency drills

- Procedures for dealing with the fire and explosion risks

- Instructions on raising the alarm in the event of an emergency

- How to summon emergency services

- How to declare an emergency occurrence.

Consultation with workers (including contractors) about potential emergency situations that may occur on site. If new or specific situations are identified as further potential workplace hazards, new measures must be added to ensure that these potential emergency situations are planned for.

Risk control for bituminous work must include emergency preparedness and response strategies for potentially serious hot surfaces, fire and explosions of bitumen materials and plant.

Emergency planning must:

- Address supervision and any special arrangements needed for dealing with bituminous work emergencies in remote or isolated areas

- Ensure all persons, including designated site emergency response teams, are trained in the first aid treatment of bitumen burns and relevant emergency response fire-fighting procedures

- Include management plans to not commence or cease work under specific bushfire ratings

- Ensure that persons involved in bituminous work are aware of Safety Data Sheets (SDS)

- Ensure that project documentation and site signage includes details of the site emergency contact nominee, including his or her 24-hour telephone contact details

- Include site-specific induction documentation - in particular, current contact details for local emergency and public medical facilities.

Working outdoors. Ensure:

- Suitable protective clothing

- Sun brim on hard hat

- Safety glasses - UV Rated

- Use 30+ sunscreen on exposed skin areas

- Adequate drinking water

- Access to shade during breaks

- Adequate breaks

- Check weather conditions – do not work in extreme weather.

Inspect vehicle. Ensure:

- Fluid levels ok (oil, coolant, brake, hydraulic, transmission etc). and no leaks

- Brake, indicator and emergency lighting functional

- No wear or damage of tyres and correct operational pressure

- Windscreen clear, undamaged

- Cabin and dashboard clear of debris/ stored items

- Brakes functional (including hand/park brake)

- Seatbelt present and fully functional

- Hoses/hose couplings are free of damage, good condition and in test date

- Valves fully functional, including emergency secondary valve

- Reverse beepers/cameras (if attached), flashing lights etc working

- Attachments are free of damage and able to be secured properly

- All guards are in place and safety decals legible

- Controls labeled correctly and functional

- Load measuring and overflow protection devices present and functional

- All emergency stop devices present, undamaged and functional

- Fire protection equipment onboard, secured and in test date (Dry chem. And CO2)

- First Aid kit supplied and adequate for task

- Conveyor and access areas clean

- Hopper and distributer truck exhaust systems cleaned free of debris

- Tanks are marked with capacity and SWL, within test date, undamaged and free of contamination

- Vehicle maintained per manufacturer requirements and registered for road use.

Ensure current Safety Data Sheet (SDS within 5 year issue date) available for asphalt and any solvent added (for cut-back straight flow materials).

Ensure a risk assessment is undertaken using the information obtained from the SDS – correct PPE, flammable ranges, Lower explosive levels – LEL etc.).

Ensure access to emergency shower/adequate eye wash facilities are provided.

Avoid inhalation. Use in well ventilated areas. Where an inhalation risk exists, mechanical extraction ventilation is recommended. Maintain fume levels below the recommended exposure standard.

---------------------------

Personal Protective Equipment:

- Lifting equipment/ aids as required

- Use of two person crews for non-standard fauna surveying- Boots with ankle support and steel toecaps -

Risk rating without controls

-

Wrong answer try again!

-

Risk rating with controls

-

Wrong answer try again!

Step 2 - Loading

-

Possible Hazard:

- Heat exhaustion, sunstroke, dehydration

- Slippery surface – causing slips, trips, falls, strains, sprains, fractures and injuries on the same level

- Chemical burn

- Burns from fire, smoke inhalation causing serious injury or death

- Short term exposure to hazardous chemical/s causing illness or death

- Muscular stress

- Entrapment - by vehicle

- Fall off plant causing injury /death

-----------------------------

Safety Controls:

Follow guidelines at loading site, including traffic management, speed signs and parking areas.

Ensure no ignition sources in loading area and all containers are earthed to prevent static electricity build-up.

Ensure transport documentation completed. Include:

- Labels,

- Weight/volume

- Risk controls

- SDS

- Signatures are obtained as required

- Load is as documentation describes.

Ensure all valves are closed and equipment secured for travel.

Note: Ignition sources include pilot lights, stoves, heaters, cigarettes, matches/lighters, grinding, welding, powerpoints, lighting, light switches, radio transmitters, mobile phones, battery powered forklifts etc.

-----------------------------

Personal Protective Equipment:

- High Visibility

- Helmets

- Hearing Protection

- Eye Protection -

Risk rating without controls

-

Wrong answer try again!

-

Risk rating with controls

-

Wrong answer try again!

Step 4 - Operation

Work

-

Possible Hazard:

- Heat exhaustion, sunstroke, dehydration

- Slippery surface – causing slips, trips, falls, strains, sprains, fractures and injuries on the same level

- Radiation / ultra-violet burns

- Burn / Sunburn

- Chemical burn

- Heat exhaustion, sunstroke, dehydration, cognitive impairment

- Burns, smoke inhalation causing serious injury or death

- Short / Long term exposure to hazardous chemical/s causing illness or death

- Muscular stress/ Musculoskeletal Disorder

- Entrapment - by vehicle

- Hit by flying or projected objects

- Deafness, hearing loss

- Person/s entering exclusion zone

o injured by mobile plant

o equipment

o chemicals etc on site

o distracting operators/ workers

-----------------------------

Safety Controls:

Hazardous Manual Handling. Avoid:

- Long periods of repetitive movements

- Awkward and sustained positions

- Prolonged sitting

- Use two or more people for lifting & moving heavy / awkward equipment

Follow access areas as described in site specific SMWS. Ensure:

- No ignition sources in area

- All persons cleared from the area

- Cold asphalt or water is not present on pour pipes, hoppers etc.

- Turn off burners before pour

- Circulate material for approximately 15 minutes after extinguishing burners

- Initiate pour, spread/compact as per manufacturer’s instructions

- No persons to enter pour area until pour has ceased

- Pour operator to communicate with spreaders when pour is complete

- Spreaders have sufficient PPE (including respiratory equipment if required)

- Operators use non-sparking tools

- Avoid awkward postures for 30 minutes at a time, or 2 hours over entire shift

- Adequate rest breaks taken and access to drinking water

- Follow traffic management and Safe Work Instructions for all work with asphalt/bitumen work and other mobile plant in close proximity to workers

- Truck operator has visual contact of entire crew before reversing

- Truck must be turned off and park brake applied before exiting

- Avoid heat, sparks, open flames and other ignition sources.

Remember: Ignition sources include pilot lights, stoves, heaters, cigarettes, matches/lighters, grinding, welding, powerpoints, lighting, light switches, radio transmitters, mobile phones, battery powered forklifts etc.

-----------------------------

Personal Protective Equipment:

- Ensure adequate drinking water and food is available onsite. - High Visibility

- Helmets

- Hearing Protection

- Eye Protection -

Risk rating without controls

-

Wrong answer try again!

-

Risk rating with controls

-

Wrong answer try again!

Step 5 - Maintenance

Maintenance

-

Possible Hazard:

- Slippery surface – causing slips, trips, falls, strains, sprains, fractures and injuries on the same level

- Chemical burn

- Short term exposure to hazardous chemical/s causing illness or death

- Muscular stress Disorder

- Entrapment - by machinery or equipment

- Fall off plant causing injury /death.

-----------------------------

Safety Controls:

Ensure all servicing, maintenance and repairs are performed by suitably qualified & competent persons as per manufacturer’s manual, including labels detailing safety and operational information, which are to be legible and complete including operating instructions with Safe Working Limit details.

Vehicles must be maintained with noise and vibration forces minimised, safeguards, warning devices and guarding in good working order to prevent persons being struck, entangled or otherwise impacted by the plant.

All vehicles and plant must be secured and left in a safe condition when unattended to prevent unauthorised operation,

. -

Risk rating without controls

-

Wrong answer try again!

-

Risk rating with controls

-

Wrong answer try again!

Emergency Procedures / Emergency Reponse

-

Emergency Response: Call 000 immediately.

Give immediate medical treatment to injured person/s if hot bitumen/asphalt on skin follow first aid instructions and do not remove.

First Aid:

Asphalt fumes:

- Move victim to fresh air

- Seek medical assistance immediately.

Hot asphalt:

- Apply cold water or ice pack to skin burns

- If burns cover more than 10% of body, apply lukewarm water to alleviate pain (heat in asphalt has to be removed)

- Do not remove from skin

- Do not bandage

- Seek immediate medical assistance.

Develop and implement an emergency response plan for the site. Include:

- Assembly points

- Communication

- Consultation methods

- Responsible persons

- Emergency contacts - names and phone numbers

- First aid equipment

- Fire Extinguishers – accessible & serviced.

Develop site-specific rescue procedures/SWMS

Ensure all workers on-site are trained and familiar with emergency and evacuation procedures.

Review

-

To ensure controls are implemented and monitored effectively:

• Toolbox /pre-work meetings will be undertaken

• Relevant persons will be consulted on hazards and contents of SWMS, work plans and other applicable information

• Control measures will be monitored throughout works:

o Spot checks

o Consultation

o Scheduled audits

• Corrective actions will be recorded and rectified in a timely manner SWMS will be reviewed and updated accordingly (in consultation with relevant persons)

Ensure all controls are reviewed as per the following:

• If controls fail to reduce risk adequately

• When changes to the workplace or work activity occur that create new / different risks where controls may no longer be effective

• New hazards identified

• After an incident involving work activities relevant to this SWMS

• During consultation with relevant persons indicate review is needed

• A Health and Safety Representative (HSR) requests a review in line with the requirements of the legislation.

Sign off - Safe Work Method Statement

-

Add person

Person

-

All people below who have provided signatures confirm that they have read and understand this Safe Work Method Statement

-

Name and role