Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

INGREDIENTS (SWEETENER) MONITORING

-

Sensory test for incoming materials conducted?

-

How good sensory implementation and consistency on the field?

-

Does raw sweeteners store in a good condition with consistent record keeping?

SYRUP (simple and finished) MAKING

-

Does syrup making process using the latest MMI?

-

Describe how they mix sugar and water

-

Describe if any malfunction design (leaking, corrosion, etc) on piping and tank storage.

-

When is the last time final syrup filter was changed?

-

Take a picture of data on actual syrup yield in last 3 days.

-

Describe how they keep and ensure storage times are met for final syrup/blended beverage/syrup

FILLING PROCESS

-

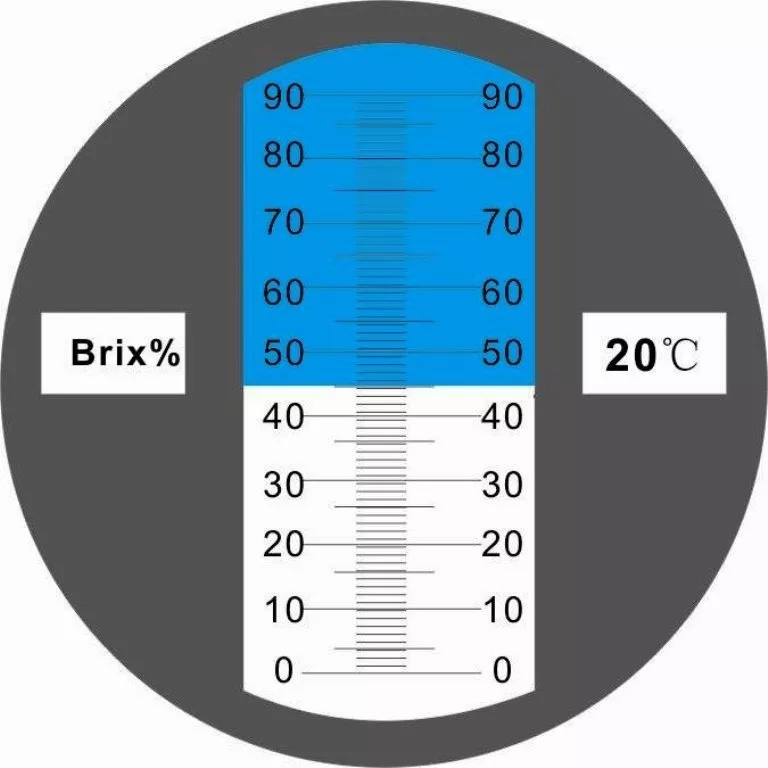

What is the actual brix target on the filling machine display

-

Historical CpK Inline monitoring

-

Take a picture of actual CpK inline monitoring data

CALIBRATION

-

Does DMA has been calibrated properly?

-

Please put detail of DMA years and series

-

Take picture of calibration label and DMA unit

-

Describe how they keep and ensure storage times are met for final syrup/blended beverage/syrup

-

Does sensor/probe on the final syrup tank has been calibrated properly?