Title Page

-

Project:

-

Prepared By:

-

Inspection Date:

-

Location:

Customer

-

Company Name:

-

Customer Name and Surname:

-

Customer Job Title :

Overview

-

High-Level Overview:

-

Image Obtained Using Google Earth

Version

-

Version 24 (Updated 10 March 2024)

External Building Inspection

- Project Specific Recommendation

-

Substrate Type

- Concrete

- Plastered

- Brick

-

Condition of Concrete Substrate

-

The concrete substrate exhibits significant signs of wear and damage. There are visible cracks, spalling, and areas of delamination. The surface is uneven with potential signs of water damage or efflorescence. There may be exposed rebar or aggregate, indicating a deeper structural issue. Immediate intervention and repair are recommended.

-

The concrete substrate appears to be in sound condition with minimal to no visible defects. The surface is even, and there are no signs of cracks, spalling, or delamination. The substrate seems well-maintained and should continue to perform well with regular upkeep.

-

The concrete substrate shows moderate signs of wear. There might be minor cracks and surface imperfections, but no major structural issues are evident. Some areas may require patching or resurfacing to prevent further deterioration. Regular monitoring and maintenance are advised.

-

Condition of Plastered Substrate

-

The plastered surface is heavily damaged with large cracks, holes, and areas of missing plaster. There's evidence of moisture damage, mold growth, or efflorescence. The substrate is flaking in several places, and the integrity of the plaster is compromised. Immediate repair and possibly re-plastering are required in areas.

-

The plastered substrate is smooth and free from significant defects. There might be minor cosmetic imperfections, but the overall integrity of the plaster is intact. With regular maintenance, the substrate should remain in good condition for the foreseeable future.

-

The plastered surface has some minor cracks and imperfections. There might be small areas where the plaster is starting to detach or show signs of wear. While the substrate is generally intact, some areas may benefit from patching or a thin re-plastering repairs.

-

Condition of Bricked Substrate

-

The brick substrate shows severe signs of deterioration. Many bricks are cracked, chipped, or loose. The mortar joints are eroding, and there's evidence of efflorescence or moss growth. There may be signs of water penetration or frost damage. Immediate repointing and brick replacement are necessary

-

The brick substrate is in good condition. Bricks are solid, with no visible cracks or chips. Mortar joints are full and intact. The substrate has been well-maintained and, with regular upkeep, should continue to serve its purpose effectively.

-

The brick substrate has some wear but is generally intact. There might be occasional cracked or chipped bricks, and some mortar joints might be thinning. Periodic monitoring and spot repairs, including repointing of some areas, are recommended.

-

Substrate coated

-

Coating condition

-

The paint system is in a state of significant deterioration. There are extensive areas of peeling, flaking, and/or blistering throughout. The color has faded unevenly, and there may be signs of underlying damage such as moisture intrusion or mold growth. The paint no longer provides adequate protection to the substrate, and its aesthetic appeal is greatly compromised. Repainting is required immediately to prevent further damage to the substrate and to restore the appearance of the surface.

-

Product Recommendations

- Tammsprime 689

- Pro-struct 684/4

- TammsCoat

-

TAMMSCOAT is a high build, water-based acrylic coating used to protect and decorate sound masonry and concrete walls. TAMMSCOAT is available in a multitude of colours.

-

A tough, durable, exterior high build coating designed to protect concrete, plaster, masonry, wood and primed metal surfaces from wear and extreme weather conditions. It is particularly recommended for surfaces in areas exposed to wet, high humidity, salt air and industrial fallout conditions, e.g. bridges, office blocks, flats, schools, hospitals, factories and hotels. Suitable as maintenance coatings and demarcation lines for asphalt and concrete surfaces exposed to light traffic conditions as found on pathways, driveways, recreational sports facilities and parking lots.

-

TAMMSPRIME 689 is a high quality, solvent-based acrylic copolymer wall coating designed to have excellent penetrative properties which binds and consolidates friable porous surfaces ideal for substrates such as new and old plaster, fibreboard

and concrete surfaces. The choice of mineral fillers enhances the product’s waterproofing, yet breathable characteristics. Ideal as a primer for subsequent coats of high quality adhesion promoted acrylic paints such as Pro-Struct 684/4 Muralflex, Pro-struct 684/6 and TAMMSCOAT. The product is designed for the protection of concrete and masonry structures, specially in harsh environments. -

The paint system is in good condition, showing minimal signs of wear. The paint coverage is uniform with no visible peeling, flaking, or blistering. The color remains vibrant and consistent across the surface. The finish provides a protective coating to the substrate and maintains its aesthetic appeal. Regular cleaning and minor touch-ups may be all that is required to keep the paint in good condition. Continued monitoring and adherence to regular maintenance cycles will help in preserving the quality and longevity of the paint system.

-

Product Recommendations

- Tammsprime 689

- Pro-struct 684/4

- TammsCoat

-

TAMMSCOAT is a high build, water-based acrylic coating used to protect and decorate sound masonry and concrete walls. TAMMSCOAT is available in a multitude of colours.

-

A tough, durable, exterior high build coating designed to protect concrete, plaster, masonry, wood and primed metal surfaces from wear and extreme weather conditions. It is particularly recommended for surfaces in areas exposed to wet, high humidity, salt air and industrial fallout conditions, e.g. bridges, office blocks, flats, schools, hospitals, factories and hotels. Suitable as maintenance coatings and demarcation lines for asphalt and concrete surfaces exposed to light traffic conditions as found on pathways, driveways, recreational sports facilities and parking lots.

-

TAMMSPRIME 689 is a high quality, solvent-based acrylic copolymer wall coating designed to have excellent penetrative properties which binds and consolidates friable porous surfaces ideal for substrates such as new and old plaster, fibreboard

and concrete surfaces. The choice of mineral fillers enhances the product’s waterproofing, yet breathable characteristics. Ideal as a primer for subsequent coats of high quality adhesion promoted acrylic paints such as Pro-Struct 684/4 Muralflex, Pro-struct 684/6 and TAMMSCOAT. The product is designed for the protection of concrete and masonry structures, specially in harsh environments. -

The paint system shows moderate signs of wear and aging. While the majority of the paint surface is intact, there are localized areas where the paint is beginning to peel or blister. Fading of color is noticeable, and the finish may have lost its original luster. The paint still offers some degree of protection, but re-painting might be advisable to keep in line with maintenance cycles. Addressing these issues now can prevent them from developing into more serious problems, ensuring the longevity of the substrate and maintaining the aesthetic quality of the surface.

-

Product Recommendations

- Tammsprime 689

- Pro-struct 684/4

- TammsCoat

-

TAMMSCOAT is a high build, water-based acrylic coating used to protect and decorate sound masonry and concrete walls. TAMMSCOAT is available in a multitude of colours.

-

A tough, durable, exterior high build coating designed to protect concrete, plaster, masonry, wood and primed metal surfaces from wear and extreme weather conditions. It is particularly recommended for surfaces in areas exposed to wet, high humidity, salt air and industrial fallout conditions, e.g. bridges, office blocks, flats, schools, hospitals, factories and hotels. Suitable as maintenance coatings and demarcation lines for asphalt and concrete surfaces exposed to light traffic conditions as found on pathways, driveways, recreational sports facilities and parking lots.

-

TAMMSPRIME 689 is a high quality, solvent-based acrylic copolymer wall coating designed to have excellent penetrative properties which binds and consolidates friable porous surfaces ideal for substrates such as new and old plaster, fibreboard

and concrete surfaces. The choice of mineral fillers enhances the product’s waterproofing, yet breathable characteristics. Ideal as a primer for subsequent coats of high quality adhesion promoted acrylic paints such as Pro-Struct 684/4 Muralflex, Pro-struct 684/6 and TAMMSCOAT. The product is designed for the protection of concrete and masonry structures, specially in harsh environments. -

Horizontal Tops

-

Coating of up-stand walls and horizontal tops with a fibre-reinforced elastomeric waterproof barrier is crucial for preventing water infiltration, which can cause structural damage and mold growth. The fibre reinforcement adds durability and strength, while the elastomeric nature ensures flexibility, allowing the coating to move with temperature changes without cracking. This protective layer shields the building from various elements, reduces maintenance costs, enhances energy efficiency, and prevents efflorescence, ultimately preserving the building's structural integrity and appearance over time.

-

Product Recommendations

-

The Pro-struct 680FR Fibre Reinforced Elastomeric Waterproof Barrier serves as an effective waterproofer for external concrete and plastered surfaces, establishing a robust, water-resistant layer before the application of Pro-struct 684/4 or Tammscoat protective coatings. This product features a flexible crack-bridging membrane that is both resilient and impact-resistant, ensuring excellent adhesion to concrete, masonry, and roofing materials.

-

Cracks

-

Building cracks are structural flaws or fissures in the walls, foundations, or surfaces of a building. They can vary in size and depth and are caused by various factors such as settling, thermal expansion and contraction, moisture changes, or structural weakness. Cracks can be superficial or indicative of serious structural issues, requiring professional assessment to determine their severity and necessary repairs.

-

Product Recommendations

-

TAMMS THIN PATCH is a polymer modified, cement-based mortar formulated for repairing defects in concrete and masonry surfaces for featheredge up to 12.5mm.

-

Plaster Delamintion

-

Building plaster delamination refers to the process where the plaster layers start to separate from each other or from their underlying surface. This can be due to a variety of reasons such as moisture intrusion, poor adhesion, or structural movement. The result is that the plaster no longer adheres properly, leading to bulging, cracking, or even falling off in sheets. It's a significant concern because it not only affects the aesthetic appearance of a building but can also indicate underlying structural issues.

-

Product Recommendations

-

Pro-Struct Mortarproof 610/601 is an extremely versatile material and as such lends itself to a number of applications. As an additive to cement bagging, rendering, plaster, patching mortars, tile mortar, industrial floor screeds, etc., where waterproofing of cement mixes is required. It improves the bond of subsequent paint coats and can be used as an adhesive to bond plaster or screeds.

-

Spalling

-

Spalling is the breaking off of material fragments from a larger structure, often seen in concrete or brick substrates. This deterioration is characterized by chunks or flakes that have detached, often due to corrosion of reinforcing elements, or other environmental factors. Spalling can expose the inner materials to further damage and degradation.

-

Product Recommendations

-

TAMMS STRUCTURAL MORTAR is a single-component repair mortar applied by low pressure spray or by hand for structural concrete repairs. TAMMS STRUCTURAL MORTAR is a proprietary formulation of Portland Cement, graded aggregates, migrating corrosion inhibitors (MCITM), unique fibres and polymers to increase adhesion, strength and sprayability.

-

Expansion Joints

-

Building expansion joints are structural separations designed to accommodate movement in buildings due to thermal expansion, contraction, and other factors. These joints prevent cracks by allowing parts of the building to move independently without causing stress or damage to the overall structure. They are essential in larger buildings and in areas with significant temperature variations or seismic activity.

-

Sealant condition

-

The sealants on the expansion joints exhibit significant signs of deterioration. There's evident cracking, hardening, or loss of adhesion, leading to gaps or voids in the sealant. This compromises the joint's ability to accommodate movement and can allow water or debris ingress, risking damage to the underlying structure.

-

Product Recommendations

-

Dymonic® 100 is a high-performance, high-movement, single-component, medium-modulus, low-VOC, UV-stable, non-sag polyurethane sealant.

-

The sealants on the expansion joints are in excellent condition. They adhere well to the joint edges, remain flexible, and show no signs of cracking or detachment. The sealant effectively accommodates the movement of the joint and provides a watertight seal, ensuring protection against environmental factors.

-

Product Recommendations

-

Dymonic® 100 is a high-performance, high-movement, single-component, medium-modulus, low-VOC, UV-stable, non-sag polyurethane sealant.

-

The sealants on the expansion joints show moderate wear. While they still provide a level of sealing, there are areas of minor cracking or slight detachment from the joint edges. Periodic monitoring is advised, and some localized resealing might be necessary to ensure continued performance.

-

Product Recommendations

-

Dymonic® 100 is a high-performance, high-movement, single-component, medium-modulus, low-VOC, UV-stable, non-sag polyurethane sealant.

-

Wall to Frame Seals

-

Building wall-to-frame sealants are materials used to fill and seal gaps between a building's wall and its frame. Their primary functions include preventing air and water leakage, enhancing insulation, and protecting against environmental elements. These sealants are typically made from silicone, polyurethane, or acrylic compounds, offering flexibility, durability, and resistance to temperature changes and moisture. They are crucial for maintaining the structural integrity and energy efficiency of buildings,

-

Sealant condition

-

The sealants between the wall and window frames show significant deterioration. There are visible gaps, shrinkage, or areas where the sealant has completely detached. This compromises the window's ability to prevent water and air infiltration, potentially leading to moisture damage and reduced energy efficiency.

-

Product Recommendations

-

TREMflex 50 is a low modulus joint sealant, especially formulated to ensure bubble free cure even at very high temperatures and humidity climatic conditions. It cures by reaction with atmospheric humidity to produce a joint sealant with a 50% joint movement accommodation factor. The sealant guns and tools consistently well at even the most extreme temperatures.

-

The sealants between the wall and window frames are in excellent condition. They adhere firmly to both the wall and frame, providing a continuous, flexible seal. There are no visible defects, ensuring optimal protection against external elements and maintaining the window's insulating properties.

-

Product Recommendations

-

TREMflex 50 is a low modulus joint sealant, especially formulated to ensure bubble free cure even at very high temperatures and humidity climatic conditions. It cures by reaction with atmospheric humidity to produce a joint sealant with a 50% joint movement accommodation factor. The sealant guns and tools consistently well at even the most extreme temperatures.

-

The sealants between the wall and window frames display moderate signs of wear. There might be minor cracking or slight detachment at certain points, but the majority of the seal remains intact. Some areas may require touch-ups or resealing to ensure a complete and effective seal.

-

Product Recommendations

-

TREMflex 50 is a low modulus joint sealant, especially formulated to ensure bubble free cure even at very high temperatures and humidity climatic conditions. It cures by reaction with atmospheric humidity to produce a joint sealant with a 50% joint movement accommodation factor. The sealant guns and tools consistently well at even the most extreme temperatures.

-

Metal Railings

-

Coating condition

-

The metal hand railings exhibit significant signs of deterioration. The coating is extensively damaged, with large areas of peeling, flaking, or complete loss of the protective layer. There is visible rust and corrosion, particularly at joints and weld points. The structural integrity of the railings may be compromised, posing safety risks. Immediate repair and recoating are necessary.

-

Product Recommendations

- Carboguard 880

- Carbomastic 15

- Carbothane 137hs

-

Carboguard 880 is a high solids, low VOC, fast cure and corrosion resistant epoxy coating. It can be used as a primer or an intermediate coat over recommended primers. It may be topcoatedwith itself, or a broad variety of high performance finish coats. This product has excellent wetting properties giving it the capability of going over marginally prepared substrates. It is ideal for maintenance and shop fabrication applications.

-

Aluminium-pigmented, low-stress, high solids mastic with a proven field history. Carbomastic15 was the pioneer mastic coating in a number of industrial markets and today still provides unmatched levels of barrier protection and corrosion resistance over existing finishes and rusted or ISO 8501 St2 or St3 cleaned steel.

-

Carbothane 137 HS is a fast-drying, high build, two component polyurethane coating which exhibits excellent dry times and handling characteristics required by Original Equipment Manufacturers. Has excellent UV resistance and good corrosion resistance in direct to metal applications for C1 to C3 environments, over primers for C4 to C5 environments.

-

The metal hand railings are in excellent condition. The coating is intact and provides a uniform finish, effectively protecting the metal from weathering and corrosion. There are no visible signs of rust, and the structural integrity of the railings appears uncompromised. Regular maintenance should be sufficient to keep the railings in good condition.

-

Product Recommendations

- Carboguard 880

- Carbomastic 15

- Carbothane 137hs

-

Carboguard 880 is a high solids, low VOC, fast cure and corrosion resistant epoxy coating. It can be used as a primer or an intermediate coat over recommended primers. It may be topcoatedwith itself, or a broad variety of high performance finish coats. This product has excellent wetting properties giving it the capability of going over marginally prepared substrates. It is ideal for maintenance and shop fabrication applications.

-

Aluminium-pigmented, low-stress, high solids mastic with a proven field history. Carbomastic15 was the pioneer mastic coating in a number of industrial markets and today still provides unmatched levels of barrier protection and corrosion resistance over existing finishes and rusted or ISO 8501 St2 or St3 cleaned steel.

-

Carbothane 137 HS is a fast-drying, high build, two component polyurethane coating which exhibits excellent dry times and handling characteristics required by Original Equipment Manufacturers. Has excellent UV resistance and good corrosion resistance in direct to metal applications for C1 to C3 environments, over primers for C4 to C5 environments.

-

The metal hand railings show moderate signs of wear. The coating has some areas of chipping or fading, and minor rust spots are visible, especially in areas with high usage or exposure to the elements. While the overall structure of the railings remains sound, targeted maintenance, such as sanding and touch-up painting, is recommended to prevent further deterioration.

-

Product Recommendations

- Carboguard 880

- Carbomastic 15

- Carbothane 137hs

-

Carboguard 880 is a high solids, low VOC, fast cure and corrosion resistant epoxy coating. It can be used as a primer or an intermediate coat over recommended primers. It may be topcoatedwith itself, or a broad variety of high performance finish coats. This product has excellent wetting properties giving it the capability of going over marginally prepared substrates. It is ideal for maintenance and shop fabrication applications.

-

Aluminium-pigmented, low-stress, high solids mastic with a proven field history. Carbomastic15 was the pioneer mastic coating in a number of industrial markets and today still provides unmatched levels of barrier protection and corrosion resistance over existing finishes and rusted or ISO 8501 St2 or St3 cleaned steel.

-

Carbothane 137 HS is a fast-drying, high build, two component polyurethane coating which exhibits excellent dry times and handling characteristics required by Original Equipment Manufacturers. Has excellent UV resistance and good corrosion resistance in direct to metal applications for C1 to C3 environments, over primers for C4 to C5 environments.

Waterproofing Inspection

- Project Specific Recommendation

-

Waterproofing of Balconies and Walkways

-

Waterproofing issues on balconies and walkways include cracking, poor drainage, faulty membrane installation, deterioration of sealants, and degradation of waterproofing materials due to weather exposure. These problems can lead to water infiltration and damage, making regular inspection and maintenance crucial for their longevity and safety.

-

Product Recommendations

-

Vandex Cemelast is a two-component polymer modified, cementitious surface treatment, elasticized waterproofing slurry. It consists of Vandex BB75 (dry component) and Vandex Cemelast Liquid (polymer component).

Owing to its composition of cement, quartz with well graded aggregate and selected additives, as well as the admixture of the polymer component, a waterproof and elastic coating is achieved. The initial and final bonding ability of Vandex Cemelast is excellent, making it suitable to be applied on horizontal as well as vertical surfaces. It is durable, resistant to frost and heat after setting and at the same time vapour permeable. It is an active barrier to carbon dioxide (CO2) and resistant to water aggressive for concrete. Vandex Cemelast is tested for use in contact with drinking water -

Stonchem 441 is a 100% solids polyurea-polyurethane hybrid lining system applied at a nominal thickness of 1 to 3mm, depending on conditions of use. This immersion grade lining provides a durable, flexible, waterproof membrane that can

withstand significant impact and abrasion. This system can be applied over a broad range of substrates and in varied environmental conditions. Stonchem 441 has very good resistance to wastewater, caustics and moderate concentrations of acids. -

Waterproofing of Flat Roofs

-

Condition of Waterproofing

-

The waterproofing system on the flat roof is in a state of significant disrepair. There are visible signs of extensive damage such as large cracks, blisters, or areas where the waterproofing membrane has torn or lifted. Pooled water, leakage marks, and water stains are evident, indicating that the system is failing to prevent water ingress. The insulation and underlying structure may be compromised, and immediate remedial action is required to prevent further damage.

-

Product Recommendations

-

Tremgard MTX is a high strength, two component, fast curing hybrid urethane waterproofing coating. Tremgard MTX is a low highly penetrative coating which, upon curing, forms a flexible membrane, making it highly suitable for all types of waterproofing applications on all types of substrates. Tremgard MTX has excellent adhesion on all substrates and can also be applied on wet and damp surfaces.

-

The waterproofing system on the flat roof is in good condition. The membrane is intact with no visible damage such as cracks, blisters, or tears. There are no signs of water leakage or pooling, indicating effective water shedding and sealing. The system appears to be well-maintained and should continue to provide reliable waterproofing with regular inspections and routine maintenance.

-

Product Recommendations

-

Tremgard MTX is a high strength, two component, fast curing hybrid urethane waterproofing coating. Tremgard MTX is a low highly penetrative coating which, upon curing, forms a flexible membrane, making it highly suitable for all types of waterproofing applications on all types of substrates. Tremgard MTX has excellent adhesion on all substrates and can also be applied on wet and damp surfaces.

-

The waterproofing system on the flat roof shows signs of moderate wear and tear. There are small cracks or minor blistering in the membrane, and some areas may show early signs of water penetration or deterioration. While the system still provides a degree of waterproofing, it requires close monitoring and maintenance. Localized repairs or partial replacement of the waterproofing layer may be necessary to extend its lifespan and ensure adequate protection.

-

Product Recommendations

-

Tremgard MTX is a high strength, two component, fast curing hybrid urethane waterproofing coating. Tremgard MTX is a low highly penetrative coating which, upon curing, forms a flexible membrane, making it highly suitable for all types of waterproofing applications on all types of substrates. Tremgard MTX has excellent adhesion on all substrates and can also be applied on wet and damp surfaces.

-

The surface of the flat roof is bare, with the primary roofing material directly exposed to the elements. There are no signs of a waterproof layer, such as a membrane, liquid coating, or bituminous sealing. The absence of waterproofing leaves the roof vulnerable to water damage, especially in areas prone to ponding or where drainage is inadequate.

Without proper waterproofing, the roof is susceptible to a range of issues. Prolonged exposure to water can lead to deterioration of the roof material, resulting in leaks, mold growth, and structural weakening. The lack of waterproofing can significantly shorten the lifespan of the roof and increase the likelihood of costly repairs or replacement.

The current state of the flat roof area without waterproofing presents a significant concern for the building's longevity and safety. Immediate steps should be taken to implement an effective waterproofing strategy to protect the building from potential water damage and to ensure the roof's performance over time. -

Product Recommendations

-

Tremgard MTX is a high strength, two component, fast curing hybrid urethane waterproofing coating. Tremgard MTX is a low highly penetrative coating which, upon curing, forms a flexible membrane, making it highly suitable for all types of waterproofing applications on all types of substrates. Tremgard MTX has excellent adhesion on all substrates and can also be applied on wet and damp surfaces.

-

Waterproofing of Box Gutters

-

Condition of Waterproofing

-

The metal box gutters are in poor condition, exhibiting significant signs of wear and damage. There are visible rust patches, holes, and extensive areas of corrosion compromising the structural integrity and functionality of the gutters. Water leakage is likely occurring, which may lead to further damage to the building structure and foundation. The gutters are not effectively channeling water away from the building, posing a risk of water damage to the property.

Recommendation:

Given the severe deterioration, temporary repairs are not advisable as they are unlikely to be cost-effective or long-lasting. Replacement of the metal box gutters is strongly recommended to ensure proper drainage and to prevent potential water damage to the building. The new installation should be inspected regularly and maintained to prevent a recurrence of these issues. -

The metal box gutters are in good condition, showing minimal to no signs of wear. There is no visible rust, corrosion, or structural damage. The gutters are effectively managing water flow, protecting the building's structure and foundation from water damage.

Recommendation:

To maintain the gutters in their current condition and to protect against future deterioration, it is recommended to coat them with Tremgard MTX, a water-based polyurethane. This preventative measure will help to ensure the longevity of the gutters, reducing the likelihood of rust and corrosion. Regular maintenance and inspections should be scheduled to detect and address any issues promptly. -

Product Recommendations

- Tremgard MTX

- Carboguard 545

-

Tremgard MTX is a high strength, two component, fast curing hybrid urethane waterproofing coating. Tremgard MTX is a low highly penetrative coating which, upon curing, forms a flexible membrane, making it highly suitable for all types of waterproofing applications on all types of substrates. Tremgard MTX has excellent adhesion on all substrates and can also be applied on wet and damp surfaces.

-

The metal box gutters are in fair condition. They show signs of wear such as minor rust spots and slight deformations but remain structurally sound and functional. There are no significant holes or areas of deep corrosion, and the gutters are generally performing their intended function of directing water away from the building.

Recommendation:

To extend the life of the gutters and improve their appearance, it is recommended to prime them with Carboguard 545 and top-coat with Tremgard MTX, a water-based polyurethane. This coating will provide a protective layer against further rust and corrosion, sealing minor imperfections and preventing water infiltration. Regular inspection and maintenance should continue to monitor the condition of the gutters and ensure the coating remains effective. -

Product Recommendations

- Tremgard MTX

- Carboguard 545

-

Tremgard MTX is a high strength, two component, fast curing hybrid urethane waterproofing coating. Tremgard MTX is a low highly penetrative coating which, upon curing, forms a flexible membrane, making it highly suitable for all types of waterproofing applications on all types of substrates. Tremgard MTX has excellent adhesion on all substrates and can also be applied on wet and damp surfaces.

-

Carboguard 545 is a two component cross-linked epoxy polyamide Micaceous Iron Oxide coating, which can be used as fast drying primer or a finish coat with excellent water resistance. Carboguard 545 serves as a blast holding primer for systems submerged in water, a lining for hot water cylinders operating between 75°C to 90°C in continuous or partial immersion, a primer on concrete substrates, and as a single coat direct-to-metal MIO finish.

-

The surface of the flat roof is bare, with the primary roofing material directly exposed to the elements. There are no signs of a waterproof layer, such as a membrane, liquid coating, or bituminous sealing. The absence of waterproofing leaves the roof vulnerable to water damage, especially in areas prone to ponding or where drainage is inadequate.

Without proper waterproofing, the roof is susceptible to a range of issues. Prolonged exposure to water can lead to deterioration of the roof material, resulting in leaks, mold growth, and structural weakening. The lack of waterproofing can significantly shorten the lifespan of the roof and increase the likelihood of costly repairs or replacement.

The current state of the flat roof area without waterproofing presents a significant concern for the building's longevity and safety. Immediate steps should be taken to implement an effective waterproofing strategy to protect the building from potential water damage and to ensure the roof's performance over time. -

Product Recommendations

- Tremgard MTX

- Carboguard 545

-

Tremgard MTX is a high strength, two component, fast curing hybrid urethane waterproofing coating. Tremgard MTX is a low highly penetrative coating which, upon curing, forms a flexible membrane, making it highly suitable for all types of waterproofing applications on all types of substrates. Tremgard MTX has excellent adhesion on all substrates and can also be applied on wet and damp surfaces.

Roof Inspection

- Project Specific Recommendation

-

Existing Substrate

-

Applying Over:

- Acrylic

- Bituminous Coating

- Chroma-Deck

- Galvanise - New

- Galvanise - Weathered

- Heat Fused Membranes

- Zinc / Alum Sheeting

- Other

- Fibre Cement

-

Coating condition

-

The roofing structures, including the previously coated metal roof sheeting, show extensive signs of wear and deterioration. There is significant corrosion, with large areas of the coating peeling or completely gone. Metal flashing and cappings exhibit rust and may be lifting or separating from their intended positions. Roof screws are corroded, with some possibly loose or missing, compromising the structural integrity of the roof. Immediate application of anti-corrosion roof coatings and waterproofing systems is necessary to prevent further damage and to extend the life expectancy of the roofing structure.

-

The roofing structures are in good condition. The previously coated metal roof sheeting maintains most of its protective coating, with minimal signs of wear or corrosion. Metal flashing and cappings are secure and free from significant rust or damage. Roof screws are intact and show no signs of corrosion. While the current condition is good, periodic application of anti-corrosion roof coatings systems can be beneficial to maintain this state and further extend the roof's longevity.

-

The roofing structures are in a moderate condition. The previously coated metal roof sheeting displays areas of minor rust and coating breakdown, but the majority remains intact. Metal flashing and cappings show some signs of wear, such as minor rusting or slight lifting. Roof screws are generally in good condition, though some may show early signs of corrosion. Application of anti-corrosion roof coatings systems is recommended to address these issues and to prolong the lifespan of the roof.

-

Coating condition

-

The roofing structures show significant signs of deterioration. The factory-coated metal roof sheeting has extensive areas of corrosion, peeling, and fading of the coating. Metal flashing and cappings are visibly damaged or have become detached, compromising the roof's integrity. Roof screws may be rusted or loose, indicating potential leaks or structural weaknesses. The overall condition suggests that immediate intervention is necessary. Application of anti-corrosion roof coatings and/or waterproofing systems is highly recommended to halt further damage and extend the life expectancy of the roofing structure.

-

The roofing structures are in good condition. Factory-coated metal roof sheeting retains its integrity and aesthetic appearance with minimal signs of wear. Metal flashing, cappings, and roof screws are secure and free from corrosion or damage. The roof appears well-maintained and is expected to perform well over the coming years. Regular inspections and preventative maintenance, such as applying anti-corrosion coatings system, can further enhance the durability and longevity of the roofing structure.

-

The roofing structures exhibit moderate wear. The factory-coated metal sheeting may have minor areas of corrosion or coating degradation, but remains largely intact. Flashing and cappings show some wear but are generally performing their intended function. Some roof screws might show signs of rust or wear but have not yet compromised the roof's integrity. While not critical, maintenance, including the application of anti-corrosion coatings systems, would be beneficial to address the early signs of wear and extend the roof's lifespan.

-

Coating condition

-

The roofing structure is in a state of significant disrepair. Metal roof sheeting shows extensive corrosion, with areas of rust and pitting compromising the material's integrity. Metal flashing and cappings are similarly deteriorated, with visible rust, detachment, or deformation. Roof screws may be corroded or loose, leading to potential leaks or structural weakness. The overall condition suggests an urgent need for repair or replacement. Application of our anti-corrosion roof coatings and/or waterproofing systems is highly recommended to halt further deterioration and extend the life expectancy of the roofing structure, although some areas may require replacement before treatment.

-

The roofing structure is in good condition with minimal signs of wear. There is little to no visible corrosion on the metal roof sheeting, and the material maintains its structural integrity. Metal flashing and cappings are intact and securely in place, showing no significant signs of rust or damage. Roof screws are tight and free from corrosion. To maintain this condition and further extend the life expectancy of the roofing structure, periodic application of our anti-corrosion roof coatings and/or waterproofing systems is recommended as a preventative measure.

-

The roofing structure shows moderate signs of wear and corrosion. Metal roof sheeting has areas of rust and minor pitting, but remains largely intact. Flashing and cappings may show signs of rusting or slight detachment but are generally performing their intended function. Some roof screws might be showing signs of corrosion. Early intervention with our anti-corrosion roof coatings and/or waterproofing systems could significantly extend the roof's lifespan and improve its overall performance.

Warrenty Expectations

-

Type of Warrenty:

-

Corrosion Enviroment

-

Guarantee Required

-

Applying Over:

- Acrylic

- Bituminous Coating

- Chroma-Deck

- Galvanise - New

- Galvanise - Weathered

- Heat Fused Membranes

- Zinc / Alum Sheeting

- Other

- Fibre Cement

-

Proposed Corrosion Protection system for the coating of Existing Substrate roof, exposed to a C3 corrosion environment, as defined in ISO-12499.

-

System

- Alumanation 301

- Solarseal / Solarmastic

- Solarseal

- Solargard 6083 / Solarmastic

- Solargard 6083 / Solarprime AC

- Solarthane

- Solarseal / Solarprime AC

- Solarthane / Solarmastic

- Solarmastic

-

Standard Recommendation Reference Number

- TS-11-C3-12Y

- TS-11-C4-8Y

- TS-11-C4-12Y

- TS-11-C5-5Y

- TS-11-C5-8Y

- TS-11-C5-12Y

-

Standard Recommendation Reference Number

- TS-3-C3-5Y

- TS-3-C3-8Y

- TS-3-C3-12Y

- TS-3-C4-3Y

- TS-3-C4-5Y

- TS-3-C4-8Y

- TS-3-C4-12Y

- TS-3-C5-3Y

- TS-3-C5-5Y

- TS-3-C5-8Y

-

Standard Recommendation Reference Number

- TS-5-C3-5Y

- TS-5-C3-8Y

- TS-5-C3-12Y

- TS-5-C4-3Y

- TS-5-C4-5Y

- TS-5-C4-8Y

- TS-5-C5-3Y

- TS-5-C5-3Y

-

Standard Recommendation Reference Number

-

Standard Recommendation Reference Number

-

Standard Recommendation Reference Number

- TS-2-C3-8Y

- TS-2-C3-12Y

- TS-2-C4-5Y

- TS-2-C4-8Y

- TS-2-C5-3Y

- TS-2-C5-5Y

-

Standard Recommendation Reference Number

- TS-4-C3-5Y

- TS-4-C3-8Y

- TS-4-C3-12Y

- TS-4-C4-3Y

- TS-4-C4-5Y

- TS-4-C4-8Y

- TS-4-C5-Not Recommended

-

Standard Recommendation Reference Number

- TS-1-C3-5Y

- TS-1-C3-8Y

- TS-1-C3-12Y

- TS-1-C4-3Y

- TS-1-C4-5Y

- TS-1-C4-8Y

- TS-1-C4-12Y

- TS-1-C5-3Y

- TS-1-C5-5Y

- TS-1-C5-8Y

- TS-1-C5-12Y

-

Standard Recommendation Reference Number

- T-12-C3-5Y

- T-12-C3-8Y

- T-12-C3-12Y

- T-12-C4-3Y

- T-12-C4-5Y

- T-12-C4-8Y

- T-12-C4-12Y

- T-12-C5-3Y

- T-12-C5-5Y

- T-12-C5-8Y

- T-12-C5-12Y

-

Guarantee Required

-

Applying Over:

- Acrylic

- Bituminous Coating

- Chroma-Deck

- Galvanise - New

- Galvanise - Weathered

- Heat Fused Membranes

- Zinc / Alum Sheeting

- Other

- Fibre Cement

-

Proposed Corrosion Protection system for the coating of Existing Substrate roof, exposed to a C4 corrosion environment, as defined in ISO-12499.

-

System

- Alumanation 301

- Solarseal / Solarmastic

- Solarseal

- Solargard 6083 / Solarmastic

- Solargard 6083 / Solarprime AC

- Solarthane

- Solarseal / Solarprime AC

- Solarthane / Solarmastic

- Solarmastic

-

Standard Recommendation Reference Number

- TS-11-C3-12Y

- TS-11-C4-8Y

- TS-11-C4-12Y

- TS-11-C5-5Y

- TS-11-C5-8Y

- TS-11-C5-12Y

-

Standard Recommendation Reference Number

- TS-3-C3-5Y

- TS-3-C3-8Y

- TS-3-C3-12Y

- TS-3-C4-3Y

- TS-3-C4-5Y

- TS-3-C4-8Y

- TS-3-C4-12Y

- TS-3-C5-3Y

- TS-3-C5-5Y

- TS-3-C5-8Y

-

Standard Recommendation Reference Number

- TS-5-C3-5Y

- TS-5-C3-8Y

- TS-5-C3-12Y

- TS-5-C4-3Y

- TS-5-C4-5Y

- TS-5-C4-8Y

- TS-5-C5-3Y

- TS-5-C5-3Y

-

Standard Recommendation Reference Number

-

Standard Recommendation Reference Number

-

Standard Recommendation Reference Number

- TS-2-C3-8Y

- TS-2-C3-12Y

- TS-2-C4-5Y

- TS-2-C4-8Y

- TS-2-C5-3Y

- TS-2-C5-5Y

-

Standard Recommendation Reference Number

- TS-4-C3-5Y

- TS-4-C3-8Y

- TS-4-C3-12Y

- TS-4-C4-3Y

- TS-4-C4-5Y

- TS-4-C4-8Y

- TS-4-C5-Not Recommended

-

Standard Recommendation Reference Number

- TS-1-C3-5Y

- TS-1-C3-8Y

- TS-1-C3-12Y

- TS-1-C4-3Y

- TS-1-C4-5Y

- TS-1-C4-8Y

- TS-1-C4-12Y

- TS-1-C5-3Y

- TS-1-C5-5Y

- TS-1-C5-8Y

- TS-1-C5-12Y

-

Standard Recommendation Reference Number

- T-12-C3-5Y

- T-12-C3-8Y

- T-12-C3-12Y

- T-12-C4-3Y

- T-12-C4-5Y

- T-12-C4-8Y

- T-12-C4-12Y

- T-12-C5-3Y

- T-12-C5-5Y

- T-12-C5-8Y

- T-12-C5-12Y

-

Guarantee Required

-

Applying Over:

- Acrylic

- Bituminous Coating

- Chroma-Deck

- Galvanise - New

- Galvanise - Weathered

- Heat Fused Membranes

- Zinc / Alum Sheeting

- Other

- Fibre Cement

-

Proposed Corrosion Protection system for the coating of Existing Substrate roof, exposed to a C4 corrosion environment, as defined in ISO-12499.

-

System

- Alumanation 301

- Solarseal / Solarmastic

- Solarseal

- Solargard 6083 / Solarmastic

- Solargard 6083 / Solarprime AC

- Solarthane

- Solarseal / Solarprime AC

- Solarthane / Solarmastic

- Solarmastic

-

Standard Recommendation Reference Number

- TS-11-C3-12Y

- TS-11-C4-8Y

- TS-11-C4-12Y

- TS-11-C5-5Y

- TS-11-C5-8Y

- TS-11-C5-12Y

-

Standard Recommendation Reference Number

- TS-3-C3-5Y

- TS-3-C3-8Y

- TS-3-C3-12Y

- TS-3-C4-3Y

- TS-3-C4-5Y

- TS-3-C4-8Y

- TS-3-C4-12Y

- TS-3-C5-3Y

- TS-3-C5-5Y

- TS-3-C5-8Y

-

Standard Recommendation Reference Number

- TS-5-C3-5Y

- TS-5-C3-8Y

- TS-5-C3-12Y

- TS-5-C4-3Y

- TS-5-C4-5Y

- TS-5-C4-8Y

- TS-5-C5-3Y

- TS-5-C5-3Y

-

Standard Recommendation Reference Number

-

Standard Recommendation Reference Number

-

Standard Recommendation Reference Number

- TS-2-C3-8Y

- TS-2-C3-12Y

- TS-2-C4-5Y

- TS-2-C4-8Y

- TS-2-C5-3Y

- TS-2-C5-5Y

-

Standard Recommendation Reference Number

- TS-4-C3-5Y

- TS-4-C3-8Y

- TS-4-C3-12Y

- TS-4-C4-3Y

- TS-4-C4-5Y

- TS-4-C4-8Y

- TS-4-C5-Not Recommended

-

Standard Recommendation Reference Number

- TS-1-C3-5Y

- TS-1-C3-8Y

- TS-1-C3-12Y

- TS-1-C4-3Y

- TS-1-C4-5Y

- TS-1-C4-8Y

- TS-1-C4-12Y

- TS-1-C5-3Y

- TS-1-C5-5Y

- TS-1-C5-8Y

- TS-1-C5-12Y

-

Standard Recommendation Reference Number

- T-12-C3-5Y

- T-12-C3-8Y

- T-12-C3-12Y

- T-12-C4-3Y

- T-12-C4-5Y

- T-12-C4-8Y

- T-12-C4-12Y

- T-12-C5-3Y

- T-12-C5-5Y

- T-12-C5-8Y

- T-12-C5-12Y

Attachments and Supporting Documents

- Project Specific Recommendation

Value Added Information and Considerations

-

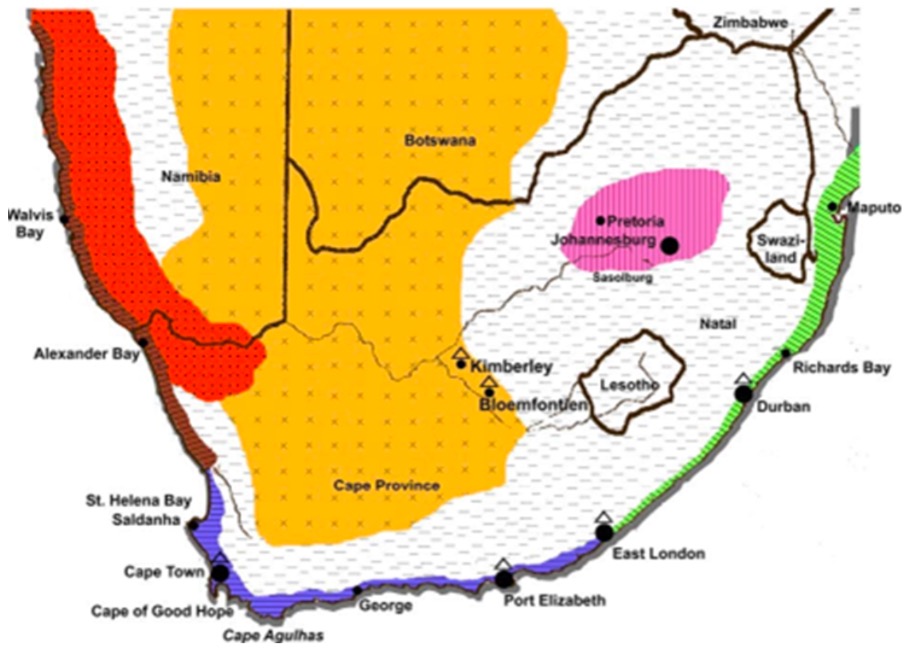

Corrosion Zones Defined

-

ISO 12944-5:2019 is a part of the ISO 12944 series that deals with the classification of environments, design considerations, quality of materials, preparatory works, and application methods associated with the protective painting of steel structures. Specifically, ISO12944-5:2019 provides detailed guidelines on the types and uses of different protective paint systems. This standard aims to provide effective means of protecting metal structures, ensuring longevity, and mitigating risks from corrosion.

Classification Of Environment

ISO 12944-5 provides categories for different corrosivity environments (from low to very high) for varying degrees of corrosion risk. For instance, roofs in coastal areas will be exposed to a different set of conditions than roofs in inland environments. By identifying the environmental conditions that a metal roofing structure will be subjected to, appropriate protective measures can be taken. -

Corrosion Zone

- C-1

- C-2

- C-3

- C-4

- C-5

- C-X

-

C1 - Heated buildings with clean atmospheres, e.g. offices, shops, schools, hotels - no interior corrosion, external conditions only.

-

C2 - Atmospheres with low levels of pollution. Mostly rural areas. Unheated buildings where condensation may occur, e.g., depots, and sports halls.

-

C3 - Rural, light to heavy industrial, and urban areas with pollution from nearby designated industries or small industries causing significant pollution. Also covers mild marine areas at least 1000m away from the marine environment, with a noticeable salt smell.

-

C4 - Covers heavy industries with high emissions, noticeable chemical odours (sulphur, acids), factories, and buildings with moderate humidity, prone to moderate corrosion due to technical and chemical conditions. Also extends to the marine environment within 100-300m inland from the shore.

-

C5 - Encompasses heavy industries/chemical sectors with strong emissions/odours (sulphur, acids). Addresses high to extremely high corrosion, including coastal buildings within 100m from the shore.

-

Case Histories

- Alumanation 301

- Solargard 6083 / Solarmastic

- Solargard 6083 / Solarprime AC

- Solarthane

- Solarseal / Solarprime AC

- Solarthane / Solarmastic

- Solarmastic

-

It’s only a matter of time for every metal roof to eventually have water ingress and for rust to take it’s toll. If you want to give owners the best protection at the best value, while saving time and money, you need to make one choice: the Alumanation 301 system. By selecting the Alumanation 301 system, you can offer the building owners a significantly less costly means of restoring their roofs compared to the enormous expense of roof replacement.