Title Page

-

Document No.00118122

-

C420201 DHouse and T-Area Inspection

-

South32

-

Conducted on

-

Prepared by Gregory Kimber

-

Location OBC C420201

-

Personnel

Resources Needed:

-

Task Equipment: Two-way Radio, Pen, Head Lamp or Torch, vehicle.

PPE: WAPL standard issue, High Visibility Clothing Hearing Protection, and Dust Mask may be required in dusty conditions.

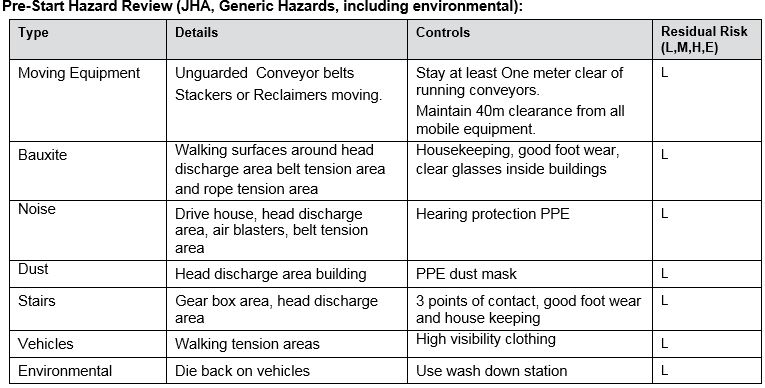

Pre-Start Hazard Review

Pre-Starts

-

All pre-starts completed on mobile equipment such as bobcat , LV’s etc?

-

Faults & defects recorded and reported?

-

Hazard board updated and Area Owner Cards in place?

Declaration

-

C2 return drum and tension area hosed?

-

All sample floors hosed?

-

Bauxite tunnel hosed & bobcat?

-

Bobcat windows clean?

-

Fines wall bobcat?

-

Stacker decks hosed?

-

All guarding secured in place & in good condition & and all gates & doors locked at time of inspection?

-

Stacker Feed Conveyors head end hosed including bend pulley area. Stacker Feed return idlers are free of fines, faulty trough rollers have been reported, notification raised.

-

Operators signature

Ablution Block and Crib Room – Facility 421, 320B

-

Condition of all equipment and fixtures. Walls clear of graffiti at time of check?

-

Ear plugs (part# 10168900) and dust masks (part# 10068858)?

VSD Secondary and Primary Cooling Water

-

Check cabinet, pumps & fittings for signs of leaks?

Drive House BL420002

-

Ear plug boxes full, order part # (10167817)?

-

Dust mask Box level, order part # (10068858)?

-

Drive house clean and tidy?

-

Are all oil spills cleaned / contained with absorbent pads?

-

Spill Kit on standby?

-

Number of OMALA 680 drums on standby?

-

Record & report any gearbox Bearing flows in “Alarm” or nearing the minimum threshold

-

Brake power pack – Any leaks?

-

Input / Output shaft seals ok (no oil leaks)?

-

Is there any unusual noise or vibration?

-

Inspect gearbox and oil hoses for leaks?

-

Snub pulleys & Koeppe wheels - Any unusual movement, noise & eccentricity?

-

Grease lines are in good condition and not leaking?

-

Is all guarding secured in place & in good condition & are all gates & doors locked?

-

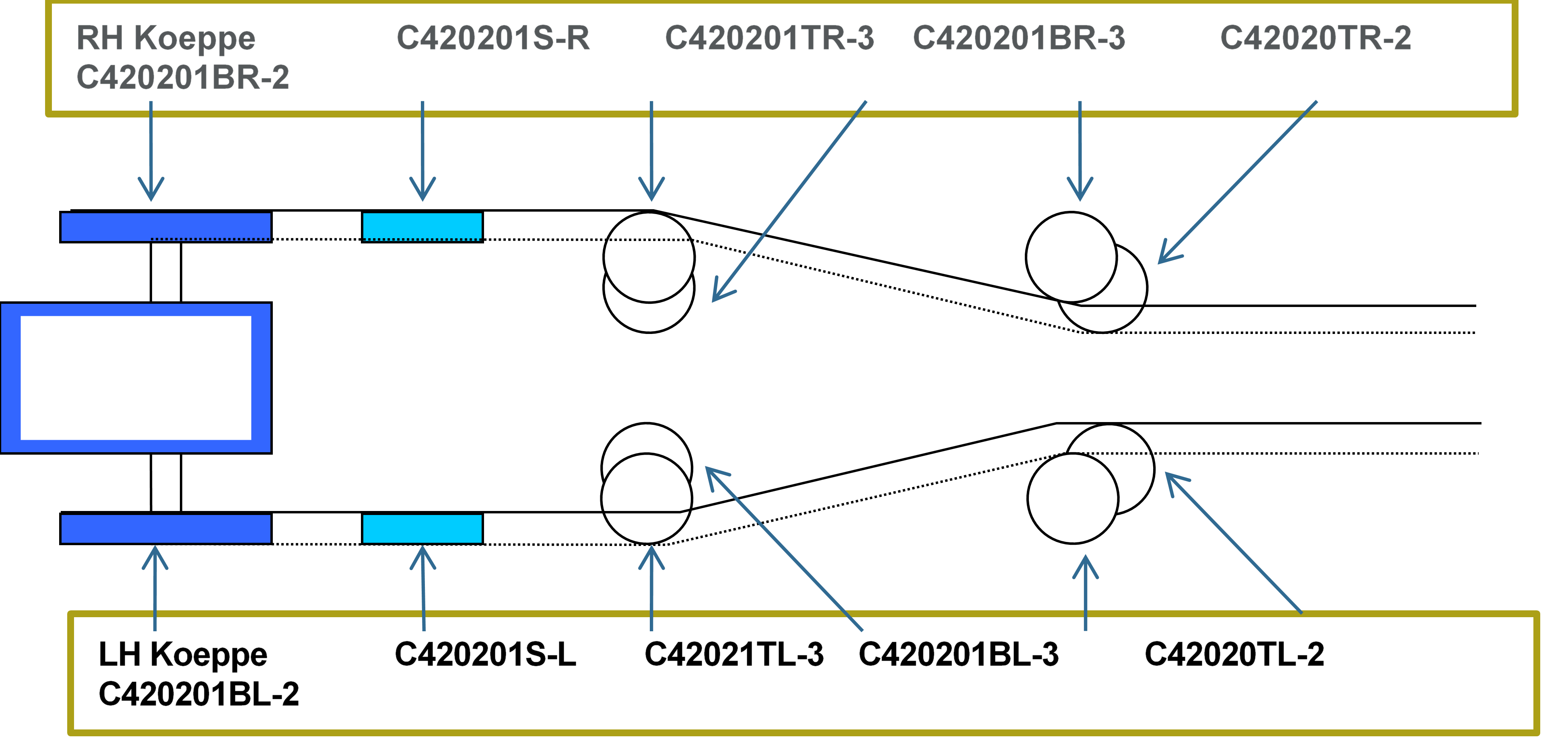

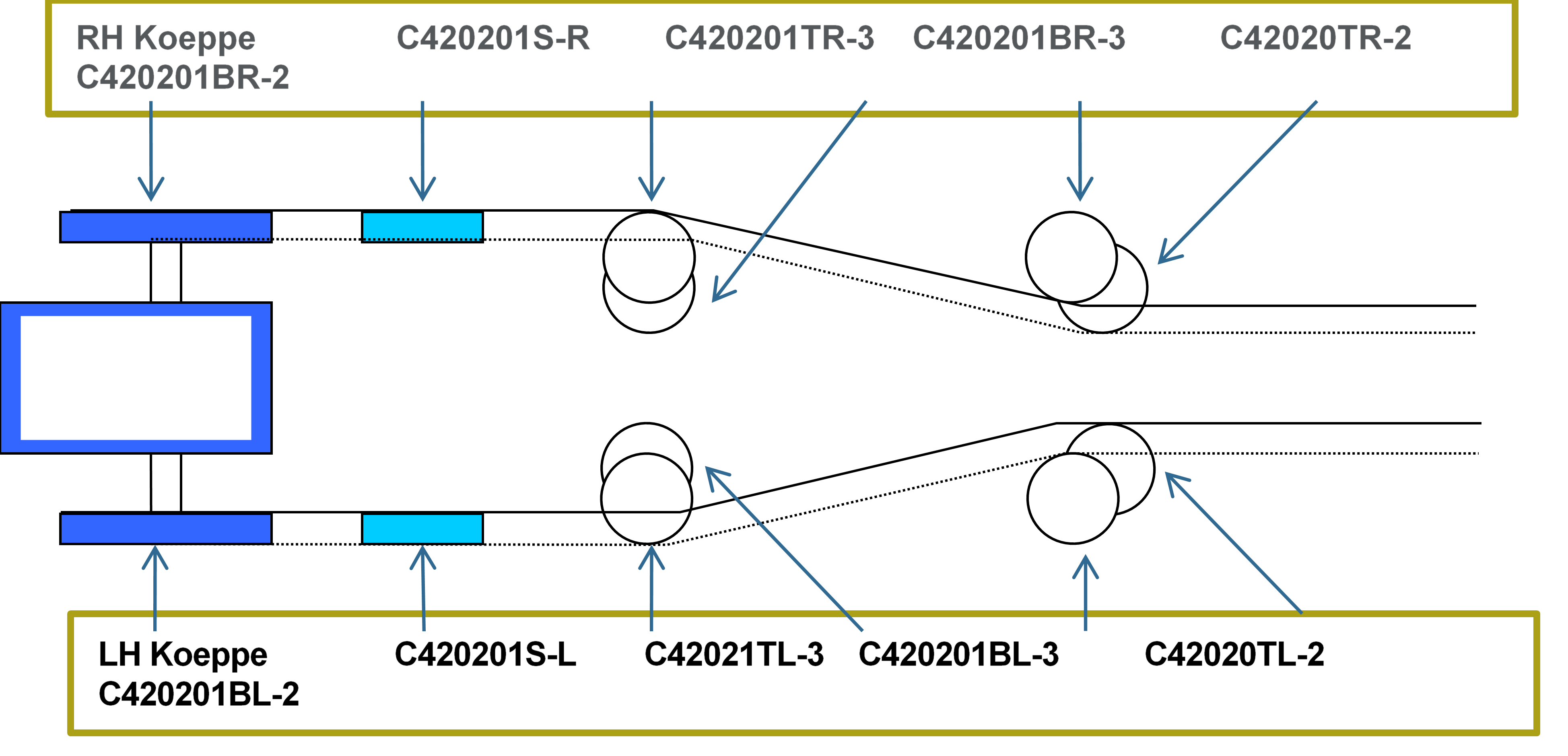

Snub pulleys & Koeppe wheels diagram

Head Discharge and Support Structure

-

Condition of Deflection Sheaves?

-

Condition of steel & poly pulleys & associated line gear?

-

Condition of steel & poly cantilever rollers?

-

Head Drum for unusual noise or movement?

-

Scrapers – Are they on the stops?

-

SFC#1 Air blasters firing correctly and in sequence? (2,3,4,5)

-

SFC#2 Air blasters firing correctly and in sequence? (2,3,6,7)

Bauxite Sample System

-

Primary sample cutter operation?

-

Belt Feeder # 1 (YO14013) operation?

-

Transfer belt (CO14011) operation?

-

Belt Feeder # 2 (YO14014) operation?

-

Condition of crusher drive belts (XO14011)?

-

Secondary cutter operation?

-

Acceptable sample reaching container. Approximately 1kg per 1000 tons conveyed?

Bauxite Tunnel

-

Stacker feed conveyor 1 skirt (CO15111) Condition?

-

Stacker feed conveyor 2 skirt (CO15211) Condition?

-

Tunnel lighting OK? (raise notification for any U/S lights) MN22

-

Tunnel housekeeping?

-

Sump pump is it operational? P420011

-

Is it in Auto or Manual?

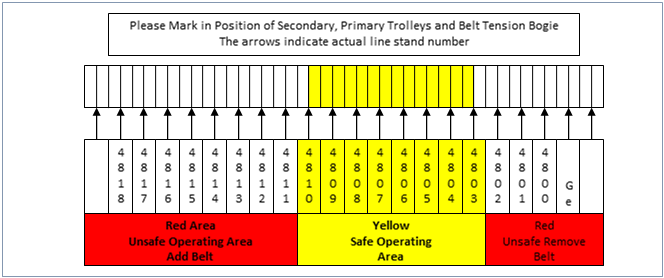

Belt Tension Area Bogie C420101BTB

-

-

Belt tension weight height? (bottom of top weight)

-

Condition of Cantilever rollers?

-

Condition of the steel pulleys & associated line gear?

-

Rails Clear of obstructions?

-

Check Return & Bogie drums for BUILD UP, noise & unusual movement? Does scraper require adjusting?

-

Condition of Return Sheaves & excessive build up?

Rope Tension Area

-

Left Hand Side

-

Right Hand Side

-

Skid plate located correctly & support stands evenly spaced?

-

Tension area pulley inspection carried out?

-

Rope tension weights above 3m?

-

Rope winch 1 & 2 coiled neatly on the drum?

-

Car wash operational including hose, spray unit & spray nozzles clear?

Stackers/Stockpiles

-

Which stacker is online?

-

What stockpile?

-

What is the reclaim bay number NW and SE of current stockpile?

-

Are BOTH Stacker Feed Conveyor tension tower weights in the Green?

-

Is the offline stacker isolated?

-

Has the offline stacker been cleaned (Including chute)?

Stacker Online Inspection

-

Boom skirt and roller condition?

-

Are the air blasters firing?

-

Lubrication and grease lines?

-

Lighting serviceable (raise notification MN22)?

-

All guarding closed, locked and in safe condition at time of inspection?

Safe Working Environment Shift Inspection

-

Ladders, Gates, Stairs

-

Ladders, Gates, Stairs- Condition

-

Ladders, Gates, Stairs- Clear of Obstructions

-

Ladders, Gates, Stairs- No product build up or spillage

-

Personal Access Walkways

-

Personal Access Walkways- Condition

-

Personal Access Walkways- Clear of obstructions

-

Personal Access Walkways- No product build up or spillage

-

Grid Mesh

-

Grid Mesh- Condition

-

Grid Mesh- Clear of obstruction

-

Grid Mesh- No product build up or spillage

-

Hand Rails

-

Hand Rails- Condition

-

Hand Rails- Clear of obstruction

-

Hand Rails- No product build up or spillage

-

Lighting

-

Lighting- Condition

-

No product build up or spillage

-

Wash Down Hoses

-

Wash Down Hoses- Condition

-

Wash Down Hoses- Secured correctly

-

Wash Down Hoses- Stored correctly

-

Objects With Potential to Fall From Height

-

Objects With Potential to Fall From Height- Stored correctly

-

Objects With Potential to Fall From Height- No product build up or spillage

-

Signage

-

Signage- Condition

-

Signage- Clear of obstructions

-

Signage- No product build up or spillage

-

Scaffolds

-

Scaffolds- Condition

-

Scaffolds- Tagged in date

-

Scaffolds- Clear of obstruction

-

Scaffolds- No product build up or spillage

-

Scaffolds- Secured correctly

-

Guarding

-

Guarding- Condition

-

Guarding- No product build up or spillage

-

Guarding- Secured correctly

-

Fire Protection Equipment

-

Fire Protection Equipment- Condition

-

Fire Protection Equipment- Tagged in date

-

Fire Protection Equipment- Clear of obstructions

-

Fire Protection Equipment- Secured correctly

-

Fire Protection Equipment- Stored correctly

-

Cords and Plugs

- Condition

- Tagged in date

- Clear of obstruction

- No product build up or spillage

- Secured correctly

- Stored correctly

-

Distribution Cabinets (Closed & Locked)

- Condition

- Tagged in date

- Clear of obstruction

- No product build up or spillage

- Secured correctly

- Stored correctly

-

Process Pads/Sumps

- Condition

- Tagged in date

- Clear of obstruction

- No product build up or spillage

- Secured correctly

- Stored correctly

-

Safety Shower Facility 015

- Condition

- Tagged in date

- Clear of obstruction

- No product build up or spillage

- Secured correctly

- Stored correctly

-

Skip Bins

- Condition

- Tagged in date

- Clear of obstruction

- No product build up or spillage

- Secured correctly

- Stored correctly

-

Roadways/Parking Bays (Chocks and Windrows)

- Condition

- Tagged in date

- Clear of obstruction

- No product build up or spillage

- Secured correctly

- Stored correctly

-

Barricades

- Condition

- Tagged in date

- Clear of obstruction

- No product build up or spillage

- Secured correctly

- Stored correctly

-

Bollards

- Condition

- Tagged in date

- Clear of obstruction

- No product build up or spillage

- Secured correctly

- Stored correctly

-

Crane – Nothing Attached

- Condition

- Tagged in date

- Clear of obstruction

- No product build up or spillage

- Secured correctly

- Stored correctly