Information

-

Central Office NSM Audit

-

Document No.

-

CO

-

Conducted on

-

Prepared by

-

Location

GROUNDS

-

Grounds free from rubbish and leaves

-

Vegetation sprayed/removed

-

Fences, gates in a good condition and secure

-

Drive, concrete areas undamaged

-

Container secure (Riccarton)

-

Pits secure, bolt rubber protectors on

-

No signs of vandalism or forced entry

-

Drains free from blockage

-

Comments

BUILDING(OUTDOOR)

-

Building is free of graffiti

-

Building is free of damage/cracks.

-

Guttering is secure and unblocked

-

Entrance door is free of damage and signs of forced entry

-

Security System control pad is free of damage and operational

-

Outdoor lighting is off (during daylight hours)

-

Gas discharge indicator is free from damage

-

Comments

PROCESS COOLER OUTDOOR UNITS

-

Unit housing is free from damage/graffiti

-

Control Enclosures free from damage and locked

-

Pipe lagging is fitted and secure

-

Fan grilles free from damage

-

Fan blades are free from damage

-

Piping free from leaks

-

Coils free from mould and debris

-

Comments

ELECTRIAL PLANT ROOM

General

-

Obtain a photograph of the Hazard Board

-

All entries on the HID board relevant, non relevant entries removed

-

Area free of rubbish and tools

-

Whiteboard marker and eraser on site

-

Floor is dust free

-

Lighting operates correctly, no damaged bulbs

-

Emergency lighting is on

-

Concrete slab and walls free from cracking

-

Cable trays free from damage, no loose cables

-

Cable tray bolts tight

-

Room free from moisture and leaks

-

Area free from vermin

-

Fire extinguisher on site and testing current (every 6 months)

-

Doors open freely and self close

-

Exit button undamaged and operates correctly

-

Comments

Main switchboard

-

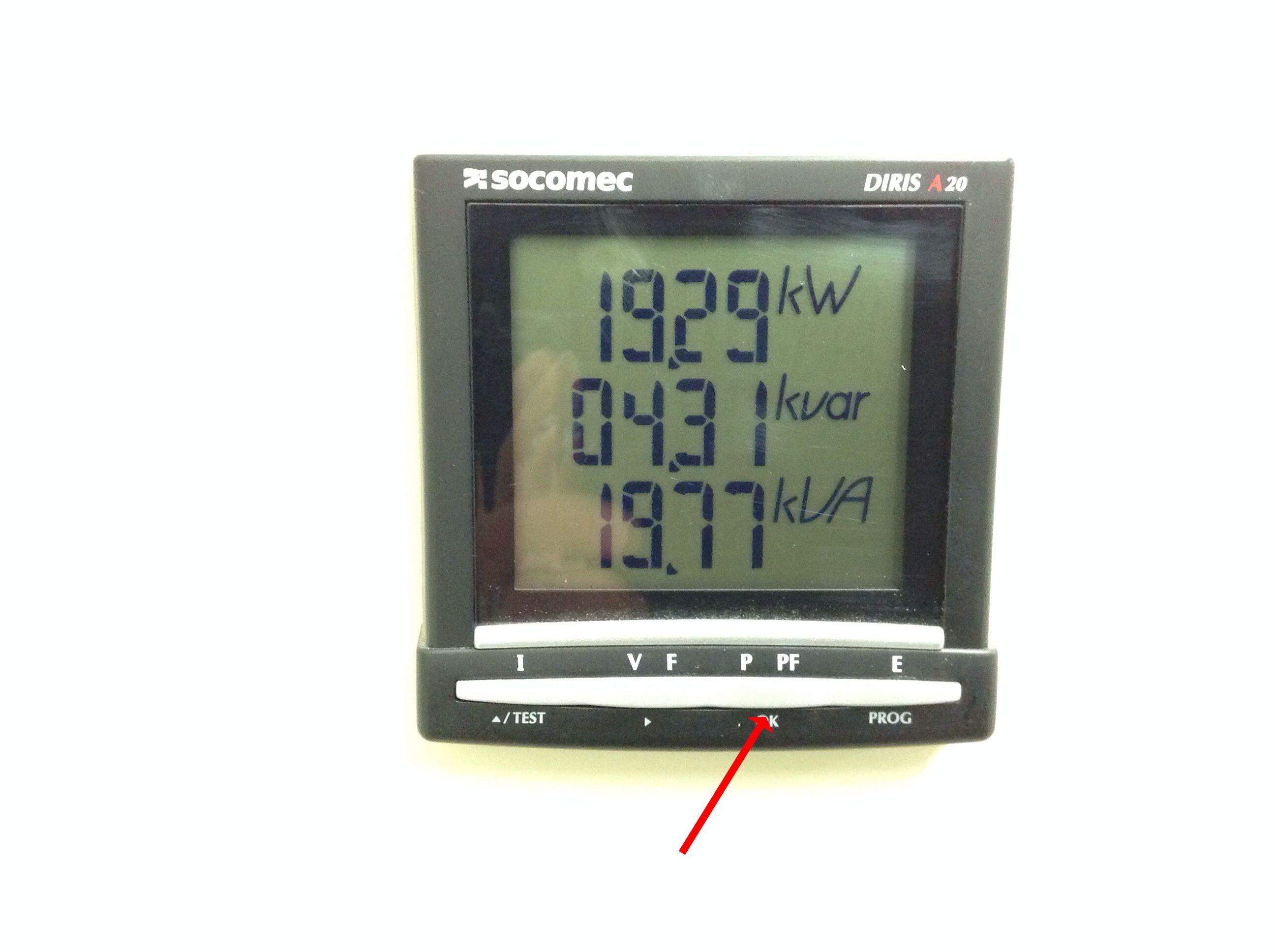

Obtain photo of the Socomec DirisA20 Power meter front screen (the meter should display power read outs in kW. This can be achieved by pressing the P/PF button)

-

Socomec DirisA20

-

kW displayed on meter

-

Mains healthy "green", mains/gen changeover switch healthy "green"

-

Switchboard free from rubbish and dust

-

Drawings on site

-

Switchboard access keys in the meter cabinet

-

Comments

DC Systems

-

Battery system identification no clearly identify System A and System B

-

All batteries in good condition and not bulging

-

All battery terminals and links free from corrosion

-

All cabling secure and free from damage

-

Battery stands and covers free from damage

-

Green status light on each cabinet lit

-

System A Voltage

-

System A Current

-

System B Voltage

-

System B Current

-

Rectifier modules no alarms present(green light)

-

Comments

Fire Systems

-

Cabinet free from damage

-

Associated cabling and conduit free from damage

-

Comms light lit

-

No alarms present

-

In auto mode

-

Comments

Security Systems

-

Cabinet free from damage and locked

-

Marshalling box free from damage and locked

-

Walk test the Room PIR and ensure it's operation

-

Associated cabling and conduit free from damage

-

Comments

GENERATOR ROOM

General

-

Area free of rubbish and tools

-

Floor is dust free

-

Area free from vermin

-

Lighting operates correctly, no damaged bulbs

-

Emergency lighting is on

-

Concrete slab and walls free from cracking

-

Cable trays free from damage, no loose cables

-

Cable tray bolts tight

-

Room free from moisture and leaks

-

Fire extinguisher on site and testing current (every 6 months)

-

Doors open freely and self close

-

Bunding installed and sealed

-

Air intake baffle is free from damage

-

Comments

Generator Control Panel

-

Control panel free from damage

-

Associated cabling and conduit free from damage and secure

-

Check Genset in Auto (Escalate if in Manual)

-

Check Genset heaters on

-

Check no alarms present

-

Record alarms if any

-

Generator Battery voltage

-

Comments

Generator general

-

Generator free from damage

-

Generator free from water leaks

-

Generator free from fuel leaks

-

Generator free from oil leaks

-

Battery isolator closed

-

Emergency button de-pressed

-

Check air filter indicator

-

Check water jacket heater operational

-

Over temperature mechanism undamaged

-

Comments

Fire Gas Discharge System

-

Gas bottles free from damage

-

Delivery Solenoid and bottle free from damage (small grey bottle)

-

Yellow tag present on delivery solenoid and solenoid cap on

-

Check main bottle pressure in "green range"

-

Check delivery bottle (small grey) pressure in "green range"

-

Gas bottles fixings secure and free from damage

-

Comments

MECHANICAL PLANT ROOM

General

-

Area free of rubbish and tools

-

Floor is dust free

-

Area free from vermin

-

Lighting operates correctly, no damaged bulbs

-

Emergency lighting is on

-

Concrete slab and walls free from cracking

-

Cable trays free from damage, no loose cables

-

Cable tray bolts tight

-

Room free from moisture and leaks

-

Fire extinguisher on site and testing current (every 6 months)

-

Doors open freely and self close

-

Comments

Process Cooler General

-

Process cooler free from damage

-

Operating without excess noise

-

Free from water leaks

-

Check standby unit air filter clean

-

Small unit air filters located behind the access door

-

Comments

Process Cooler Control Panel

-

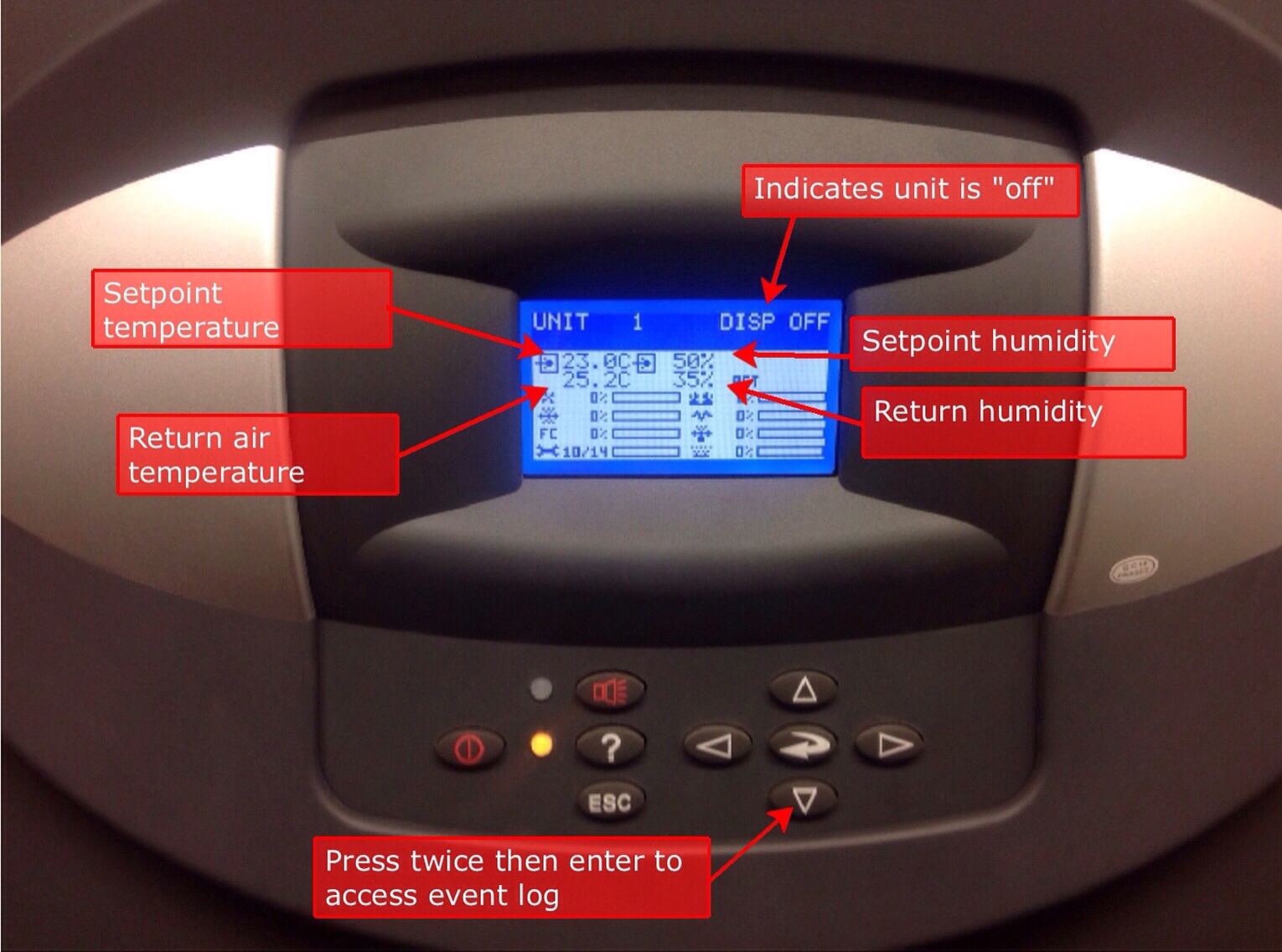

Duty Unit #

-

No alarms present

-

Records alarms here

-

Duty unit air temperature set point

-

Duty unit return air temperature

-

Duty unit humidity setpoint

-

Duty unit return humidity

-

Controller

-

Comments

Humidifier Water Pump

-

Humidifier control panel closed and free from damage

-

Isolator selected to "on" position

-

Associated cabling and conduit free from damage

-

Tank and associated plumbing free from leaks

-

Comments

Process Cooler Switch Board

-

Free from damage and closed

-

Fresh air fan selector switch in "on" position

-

No alarms present

-

Process Cooler access door Allen key inside the switchboard

-

Switchboard is free from dust and cable clippings

-

Drawings on site

-

Comments

EQUIPMENT ROOM

General

-

Area free of rubbish and tools

-

Dust sticky mat installed and spare available(kept under battery stand)

-

Floor is dust free

-

Area free from vermin

-

Fibre duct lids installed

-

Lighting operates correctly, no damaged bulbs

-

Emergency lighting is on

-

Concrete slab and walls free from cracking

-

Cable trays free from damage, no loose cables

-

Duct and 144F cable numbers installed

-

Cable tray bolts tight

-

Room free from moisture and leaks

-

Fire extinguisher on site and testing current (every 6 months)

-

Doors open freely and self close

-

Yellow patch lead cable management tray installed on cable rack, lids closed

-

No fibre shards left on site

-

Comments

OFDF

-

Phil McClintock to complete this section

Cabinets

-

All cabinets labelled

-

All cabinets attached to the seismic restraint structure

-

Free from ingress of vermin

-

Cabinet filters free from dust

-

All patch leads managed correctly

-

No loose fibre dust caps

-

No temporary installed equipment

-

Comments

DC distribution boards

-

Free from damage and closed

-

DC System A & B clearly identified

-

Free from dust and cable clippings

-

Cables labelled

-

No signs of overheating

-

Circuit Breaker Identification Card up to date

-

Obtain a photograph of the Circuit Breaker Identification Card

-

Comments

SUMMARY

-

FINAL COMMENTS/CONCLUSION

-

NOTES FOR NEXT AUDIT

-

INSPECTOR

-

REGIONAL MANAGER

FOR OFFICE USE ONLY

-

POSITIVE RESPONSES

-

NEGATIVE RESPONSES

-

TOTAL RESPONSES

-

SHOP RATING

-