Title Page

-

Site conducted

-

State Dept or full site

-

Conducted on

-

Prepared by

undefined

-

This audit is designed to reflect the annual site audit and best practice within Carlton Forest Group. As such, changes may be made at any point to reflect updates to the audit, best practice improvements or in light of risk reduction and lessons

learned.

When completing the audit, review the statements for each question. If there is more than one statement of compliance

for the question then any single failure will score the question as "No". All failed responses are as "No" unless otherwise

stated.

Lastly, when speaking with your colleagues please ensure that the conversation is positive and constructive.

Incident Management -- First Aid

-

Is it clearly defined who amongst the team are trained first aiders for this department?

-

This can be through signage stating who the first aiders posted in key locations such as the Safety Boards. Best

practice would also have first aiders wearing clearly defined clothing such as green hi viz. -

Are there enough first aid trained colleagues on shift now?

-

Minimum of 1 first aider to 50 employees. Find out who the first aiders are and make a judgement, if the requirement is

not obviously met then review the headcount with the shift leader. -

Are there sufficient available first aid supplies and are they in date?

-

Check 3 items in the first aid box, are they in date? Check the equipment for surgical gloves, adhesive bandages, sterile

pads, antiseptic spray, absorbent compress, ice pack as a minimum. -

Are Eye wash stations full and in date?

-

Check the date on each bottle of at least one rack in the area.

-

Are their sufficient eye wash stations in the area?

-

In areas where chemicals are used a station should be within 50 metres and there should be 15 minutes (1500ml) of eye

wash available or a mains fed maintained eye irrigation system. -

Does the site have access to a defibrillator which is within 400m?<br>

-

An AED or defibrillator should be within a 400 metre return walk of all locations to ensure a quick response to

emergencies -

Is the battery still charged and in date?

-

Are the electro pads in date?

-

Speak with a colleague

-

Can they tell you the name of a first aid trained employee on shift now?

-

Do they know where the closest AED is located?

-

Can you tell about the last accident in your area or on the site and what<br>actions have been taken?

-

If you witness or have an accident or Near miss when should you report it?

-

Correct answer is immediately!

-

Thank the colleague for their help

Health - Chemical Hazard Communication

-

Consider all substances and chemicals in use for the processes including for cleaning and non standard tasks. Look for

lubricants and similar products that are not on constant use. -

Are there chemicals or substances that are hazardous to health used / stored in the department?<br>

-

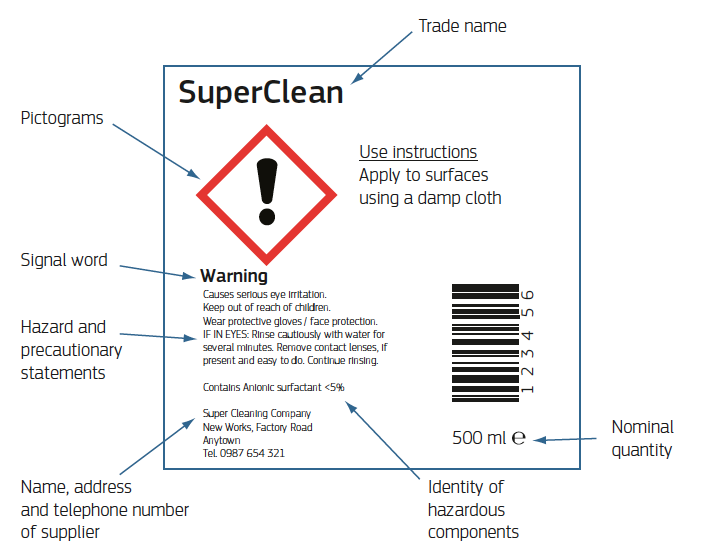

Labels should be on all original and all decanted containers to ensure contents are always clearly marked. The image

shows an example label including pictograms -

Are all chemicals containers including decanted chemicals clearly marked?

-

Flammable materials for use onsite should be stored in suitable flammable cabinets when not in use, the minimum quantity should be

outside of the cabinet for direct use. This includes aerosols. -

Are all flammable chemicals stored correctly?

-

Select Yes if the bunds are sufficient, no if not. NA if no liquid chemicals are used in the area or if there are no containers for chemicals i.e it is pumped from a location offsite. Also, if it can be evidenced that the

chemicals are sealed and not opened in the area and there is no risk of puncture, i.e. PIT movement. A bund should be capable of containing 110% of a potential spill from the materials stored. -

Are there suitable bunds for the chemicals used in the area?

-

Answer "No" to the next 2 questions if a bund should be in place but is not available.

-

Is there visible damage to the bund such as cracks or leaks?

-

Are there any contents in the bund that risk the 110% capacity of a potential<br>spill?

-

Are MSDS or chemical risk assessments available to the colleagues?

-

Speak with a colleague

-

Do the colleagues know where to find the CoSHH assessments?

-

Do the Colleagues know what an MSDS is?

-

Have they received training in the safe use of chemicals?

-

Thank the colleague for their help

Leadership and Engagement

-

Do Relevant dept's have a EHS information / communication Board?

-

-

Speak with a Colleague

-

Have you had a safety conversation with your manager in the last week?

-

This is an informal conversation or coaching on safe behaviour in the workplace.

-

Have you had a documented toolbox talk training in the last week?

-

f they say yes ask them to talk about the theme of the training and what they learned. Positive results if they can quote

the training topic from the last session within a week. -

Do you know what a Safety Improvement Opportunity (SIO) is?

-

A positive answer would state "Safety Improvement Opportunity" or describe that it is an observation of unsafe

conditions or behavior that is raised as an action -

Do you know how to raise an SIO and request action?

-

Positive result for raising it with their manager. Coach them in other methods of raising an SIO action. Advise them how to report that they have found SIO and any action they have taken to prevent an incident initially.

-

Thank the colleague for their help

Emergency Procedures - EAP

-

Speak to a colleague

-

Can you name 2 reasons why we may need to evacuate the site?

-

The accepted answers would be fire, explosion, flood, earthquake, snow and ice risk, chemical spill, threats of terrorism

or power outage. -

Have you had training for what to do in an emergency?

-

Give positive marks if they confirm training and understanding

-

Have you taken part in an evacuation drill in the last 12 months?

-

Give positive marks for a yes answer. If they have not been with the company 12 months then mark as N/A.

-

In the event of an evacuation, what are your actions?

-

Positive marks for, "Head to the nearest exit, proceed to my assembly point at (named location)" A stronger answer would also include, "Calmly, without collecting belongings, raising the alarm for others if necessary", coach the employee on points missed.<br>

-

Thank the colleague for their help.

Emergency Procedures - Fire Protection

-

Go to a fire point in the department, Check 3 - 5 for the whole site

-

Is access to the fire point clear, obstruction free?

-

You should be able to walk directly to the point, ideally the space in front is marked and clear for a minimum of 90cm

-

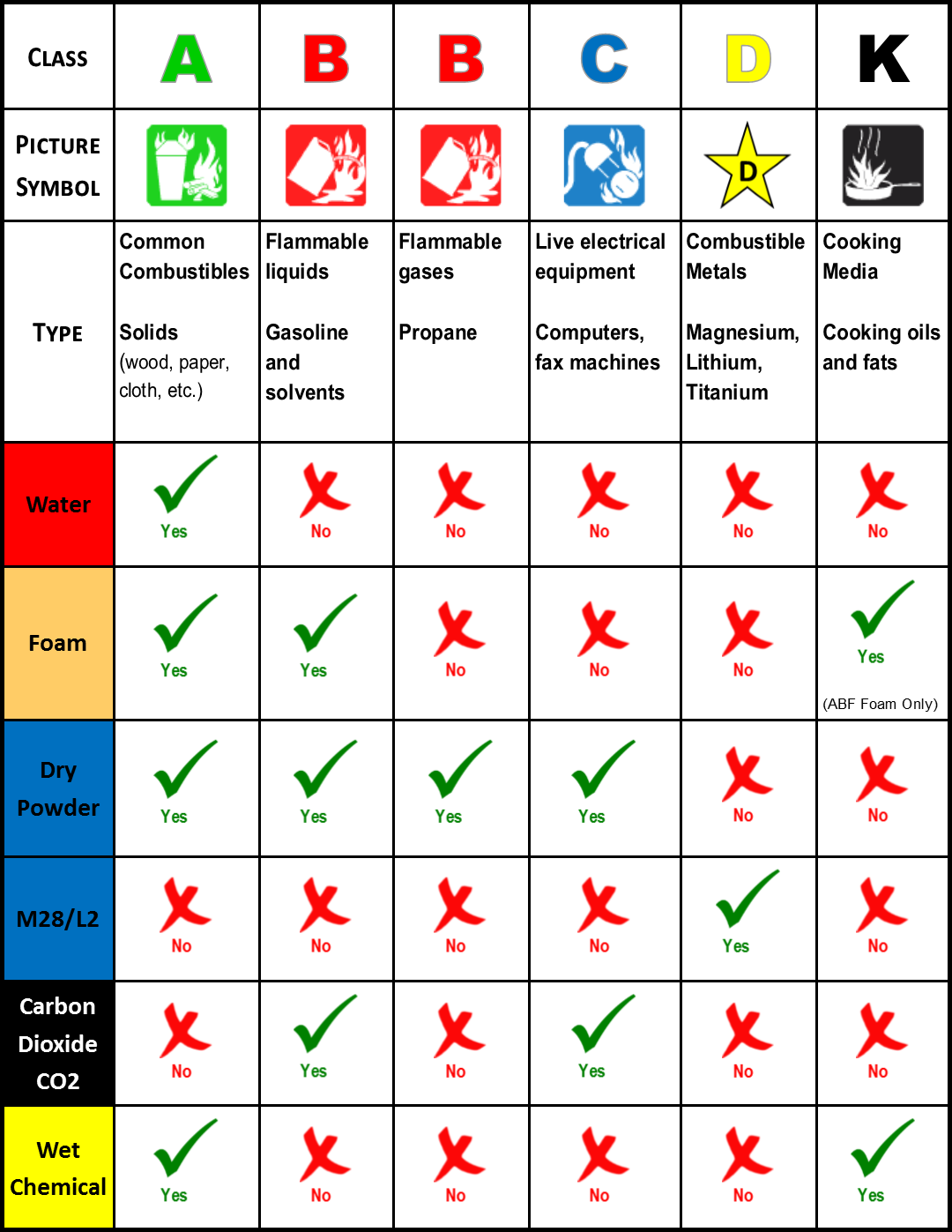

Are the fire extinguishers suitable for the risks in the area?

-

Ensure the extinguishers are suitable.

-

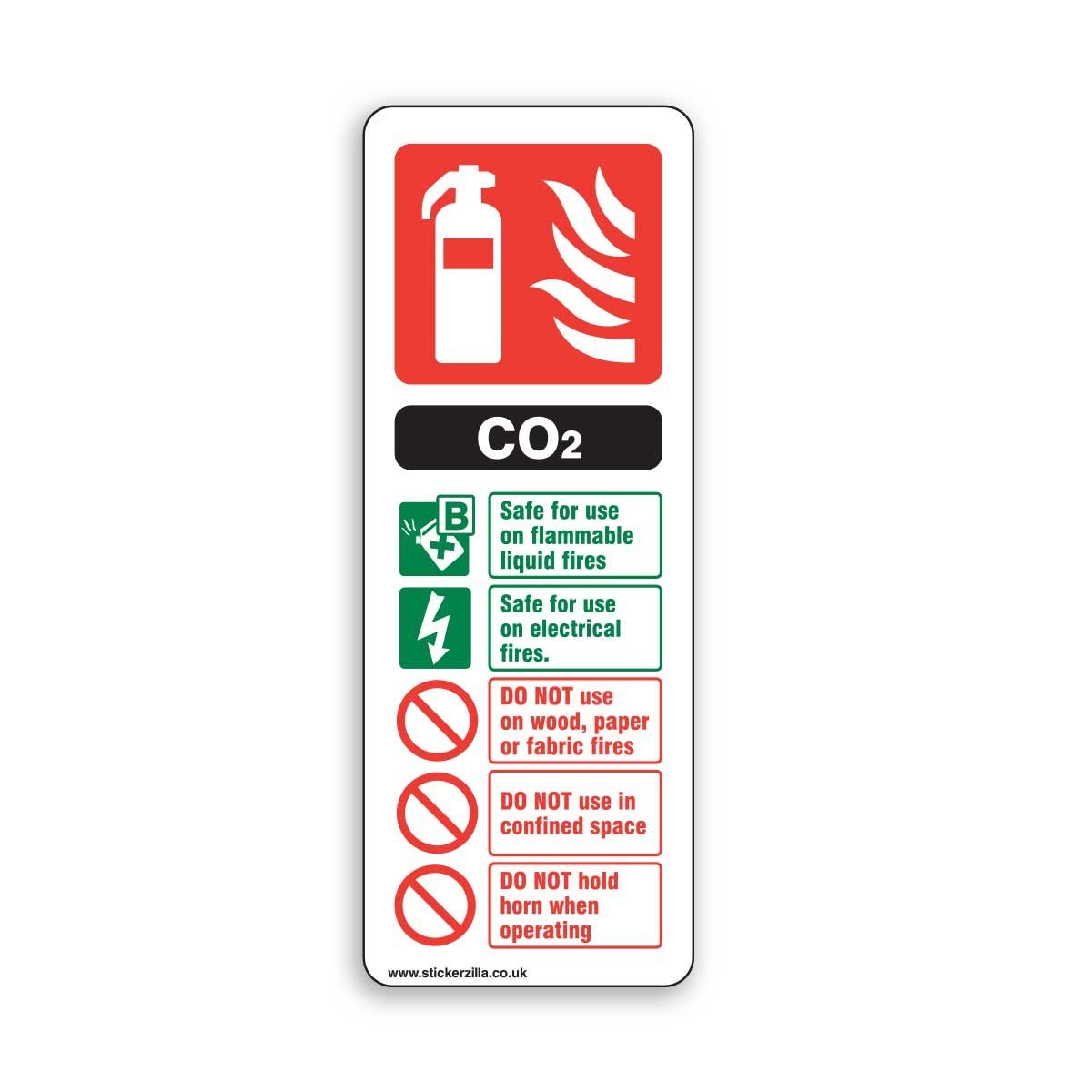

Has the fire point got clearly marked fire extinguisher labels behind each<br>item?

-

Example shown for Carbon Dioxide CO2

-

Are the fire extinguishers unused, with all the required elements intact?

-

The extinguisher should have the pin in preventing the trigger being depressed accidentally, an unbroken tag and the

pressure / fill gauge should be in the green zone. -

Has a visual check been carried out within the last calendar month of the<br>extinguishers?<br>

-

This check can be completed by a CFG employee who is trained to understand the expected standard. The check

should detail the labelling, pin and tag on the trigger and fill / pressure gauge. The check should be at the fire point or available in the fire log book or scanned copies on the shared drive. -

Have the extinguishers been checked by a trained person as fit for use?

-

This check is must be performed and signed for by a certified extinguisher maintenance provider annually?

Equipment - Mobile Plant & Material Storage

-

-

Are there fork lift trucks or similar operating in the department?

-

Are there fork lift trucks or similar operating in the department?

-

A Seat belt should be available and worn on all seated ride on powered industrial trucks

-

Is the driving standard acceptable?

-

PIT not overloaded. Driving in reverse if forward vision blocked by materials. Not at excessive speeds

-

Does the driver use the horn to warn of approach?

-

The driver should use their horn when passing through a doorway, rounding a corner or intersection. The horn sounding

should be at least two short bursts. -

Is there an audible reversing alarm?

-

Ensure that you check this, if necessary ask the driver to engage reverse. It should sound immediately and be loud

enough to hear over background noise. -

Are there suitable fixed barriers between all FLT traffic and all pedestrians?

-

Are both the driver and pedestrians observing the 3 metre rule?

-

If a pedestrian approaches a PIT, before the 3 metre zone is entered the driver must, 1. Apply the handbrake, 2. Turn off

the power or remove the fob to immobilise. -

Speak to a PIT driver

-

Have you received formal training for vehicle you are driving?

-

Can the driver show evidence of a pre-use check within their shift?

-

The driver should be able to present a signed document that suitably reviews the vehicle as safe to use. If it has not

been fully completed or cannot be located then failed. Digital systems that prevent use before the vehicle can be used

should be reviewed. -

Can the driver explain what they would do if they found a fault with the vehicle?

-

Mark "Yes" for stating that they would not use the equipment and inform their manager. Minor issues such as tyres worn

but not dangerous, visual marks to body or split seat should be remarked on the check but do not necessarily require the

vehicle to be put out of use. -

Review the FLT with the driver, does it have?

-

Keypad or fob start up for the equipment?

-

Blue spotlight front and rear pointing toward the ground?

-

Flashing orange beacon?

-

Fire extinguisher?

-

Check its been tested in the past 12 months

-

Thank the colleague for their help

-

-

Are goods vehicles loaded or unloaded in the area?

-

Is there a suitable safe zone for loading and unloading?

-

The zone should have 5 meter exclusion zone on all sides during operation. The zone must be level, hard surfaced, free from pedestrians and provide a safe space for the driver during operation. Signage should be in place and the loading zones marked out where possible.

-

Is the goods vehicle driver either in a safe location or sat in his cab during loading / unloading?

-

A goods vehicle driver may only enter the loading zone when the PIT is not in the area. There must

be a clear method of ensuring the goods vehicle drivers presence in the area prevents the PIT from

restarting operations. -

Are the goods vehicle keys taken from the driver and stored safely during loading and unloading?

-

This is to prevent the vehicle driving away during loading and unloading operations

-

Are container goods vehicles unloaded in the area?

-

-

Is there a suitable safe zone for unloading containers?

-

Is there an exclusion zone around the all sides of the ramp? Is the ramp on hard standing ground?

-

Are the wheels of the ramp and the wheels of the vehicle being unloaded chocked to prevent movement?

-

The ramp should be chocked so that it can't move away from the container, and the container from the ramp.

-

Is the ramp chained or suitably connected to the container?

-

Is the ramp chained or suitably connected to the container?

-

Are the keys taken from the goods vehicle and stored safely during loading and unloading?

-

This is to prevent the vehicle driving away during loading and unloading operations

-

-

Are raw materials and or finished goods stacked in the area?

-

Are materials stacked inside marked locations?

-

Are visible controls used to limit the height of stacking?

-

Maximum stack height signs should be placed around. Walls / Girders can also be painted to highlight the max height.

-

Is the stacking visibly safe and stable?

-

-

Is there material or finished goods racking in the area?

-

-

Is there protection for racking legs at ground level?

-

-

Are there barriers at the ends of each racking row to prevent vehicle contact?

-

-

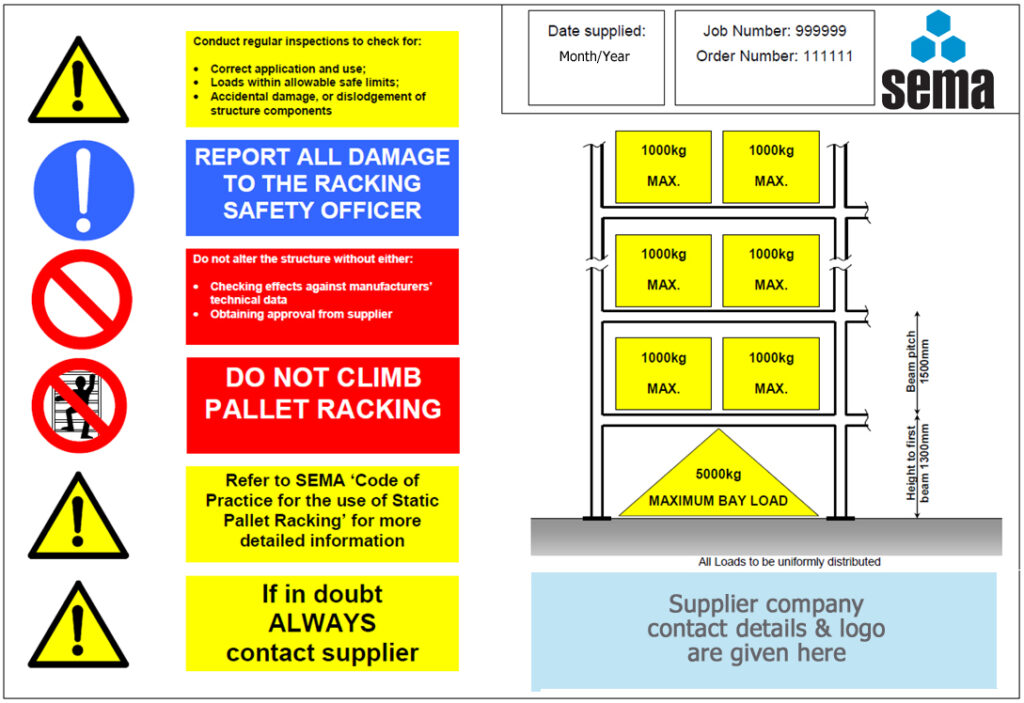

Does each rack row have a safety rating / load notice board?

-

Pins should be located in every joint between the beam and the leg to ensure it stays in place

-

Is there a pin securing each racking beam at both ends?

-

Look for any damage to the beams or legs. Impact such as what is shown would require all locations above and below the damage to be emptied immediately allowing trained inspection.

-

Is the Racking free from damage?

Equipment - Fixed Plant

-

Assess fixed machinery and equipment in within the audit boundary. If there is more than one machine in the audit boundary then vary the evidence review between the machines. This includes plant such as pallet wrappers, workshop machines and production plant.

-

Have pre-use checks been completed on the equipment and documented and signed?

-

Are all machine controls easily understood?

-

All controls must be clearly marked with their purpose, if the control has more than one position then these should be marked i.e. on/off, rotation speeds, lift /lower.

-

Is there a clearly defined red emergency stop button on a<br>yellow background?

-

There must be an emergency stop that click in and needs twisting, pulling or a key to release.

-

Consider the potential for access to hazardous moving parts, cutters, crushing points in equipment or between materials and process. You can document any number of risks here, click on the + to add another item.

-

Speak to a colleague

-

Have you had formal training in the operation of this process within the last year?

-

Positive result for confirming training in the last 12 months

-

Do you carry out pre use inspection of your process? What is the purpose?

-

The operator should be able to explain what they check against a schedule and why.

-

What would you do if a guard on the machine was damaged or missing?

-

The answer should include stop and "LOTO" the process and "inform my manager"

-

Thank the colleague for their help.

-

Risk Management - LOTOTO

-

Focus on one machine or FLT in the audit area

-

What is the Equipment / machine name within the audit area?

-

What sources of Energy are applicable?

-

Is there a clearly visible LOTO procedure posted or Isolation card available?

-

Are the isolators and or energy control valves easily accessible and in good condition?

-

There should be no damage to the device that could lead to failure of the system or the inability for the operator to safely LOTO

-

Are there enough suitable LOTO devices and LOTO locks to secure all the sources of hazardous energy?

-

There are many different types of LOTO device, consider the devices needed to isolate and LOTO all energies.

-

Are there devices available for multiple users to LOTO against all forms of energy?

-

If more than one person requires access during isolation then all persons must have their individual control of the LOTO device. Ensure that this is possible for this procedure. N/A can only be marked if the process is a single person operation.

-

Speak to a colleague

-

Can the employee explain the purpose of LOTO?

-

A positive answer would include phrases like "removing energy", "personal control", "preventing restart", "safe operation or maintenance".

-

Can the employee demonstrate how to LOTO? The employee must walk the auditor through each step confidently.

-

The employee must fully complete or walk the auditor through the process of LOTO that is relevant to their process. Failure to complete steps should result in a "no", returning to the procedure / Isolation card to check for accuracy before acting should not be penalised.

-

Thank the colleague for their help

-

Risk Management - PPE

-

PPE is vital as a last line of defense. Be vigilant in your assessment, any deviation should be recorded and the colleagues coached as to why it is important

-

Is the PPE standard for the process available / visible?

-

The review or risk assessment results should be available for the process in a standard that clearly shows what PPE is required for the task.

-

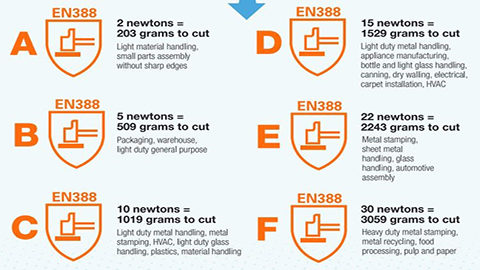

Are operators wearing the relevant gloves?

-

Does the operation include handling of glass or sheet metal?

-

Is the hand protection being used Cut resistant level E

-

Minimum cut level E for glass, metal or sharps. The 5th digit of the code is the cut resistance letter.

-

Is hearing protection required in the audit area?

-

Is hearing protection available to and worn by all staff in the relevant area?

-

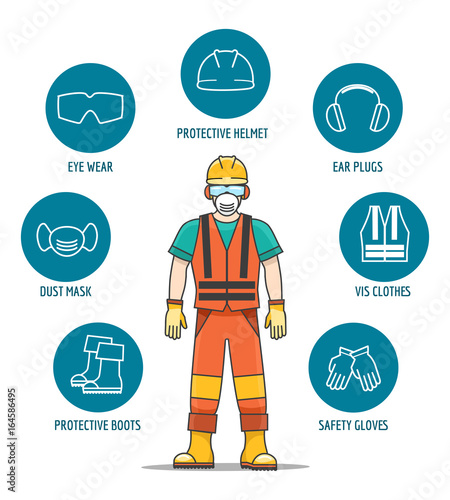

Is Hi Viz clothing being worn by all persons in the operational space?

-

High visibility (Hi Viz) must be worn by all persons to the torso when in any operational space. The image is an example of the standard.

-

Are safety boots being worn by all persons that tie up above the ankle?

-

Safety boots are designed to prevent injury to the feet and ankle. Toe protection, anti-slip soles and ankle support must be in place. If shoes are worn then marks as no (unless manager confirms that medical reasoning has been accepted by the business for wearing shoes), if boots are not laced up to protect the ankle then mark as no.

-

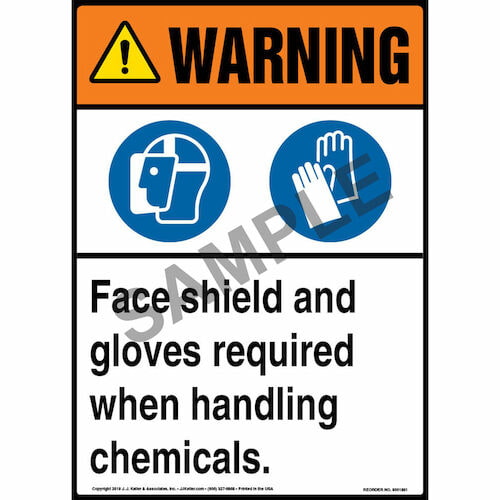

Are chemicals required to poured as part of the process?

-

Is a full face visor in use during the pouring or is the<br>equipment available and stated as mandatory need in the<br>location?

-

A full face visor should be worn to prevent splashes when pouring chemicals. A sign in the area must be erected to state the mandatory need to wear the visor when pouring chemicals. Mark as no is any of the criteria are not met.

-

Speak to a colleague

-

Can the colleague describe the required PPE for the process

-

Can the colleague describe how to obtain new PPE if theirs<br>needs to be replaced

-

A positive answer would be clear with the location and process of acquiring PPE. The reasons for changing could include if gloves are excessively worn or holed, masks are dirty and cannot be cleaned, boots are worn, leak in or cracked, high viz reflective strips come off etc

Thank the colleague for their help

Risk Management - Electrical Safety

-

Are there electrical panels, circuit boards located in the area?

-

Do all the electric panels, circuit boards and cabinets have a warning sign stating the electrocution risk?

-

A sign warning of the electrical risk should be visible on each cabinet, electric panel or circuit board panel. Best practice would also state the voltage and access restrictions.

-

Are all the visible panels, circuit boards and cabinets closed and locked?

-

Access to live parts should not be possible without strict controls. All cabinets should be closed and locked so that untrained persons cannot gain access

-

Taking a closer look at the cabinets, are all cabinets sealed<br>without openings due to missing buttons, poorly fitting doors or general damage that would allow dust to enter the<br>cabinet?<br>

-

Dust build up inside electrical cabinets vastly increased fire risk. All cabinets should seal sufficiently to prevent this from happening.

-

-

-

Are there any handheld power tools in the area of the<br>process?

-

Does the activity create trailing cables?

-

The use of battery tools would prevent trailing cables or through measures to keep the cables off the ground with tool balancers as an example. Engineering tasks should not be discounted from this.

-

Are power tools in visibly good condition?

-

Are Power tools and extension leads Pat Tested and in date?

-

Look for cracks in the tool housing, discoloration due to overheating or damage to the cable or plug.

Risk Management - Elevated Work

-

Working at height activities in the process do not include working off of fixed platforms with suitable access and egress such as fixed stairs with fixed handrails. They should include use of mobile steps or other means of accessing at height that are variable or require additional controls.

-

Are their any working at height activities that are part of the<br>process or is equipment available in the area?

-

Are mobile powered personnel lifts (MEWP, Platform or Cherry Picker) part of the process or available in the area?

-

Are the keys locked up and away from the working at height<br>equipment?

-

Keys for this equipment should be stored safely due to the specialist training for their use and the permit to work process.

-

Is the MEWP basket floor free from any and all debris?

-

Waste and debris can lead to trips. When working at height all risks are amplified, baskets should only contain the occupant and the requirements of the specific task.

-

-

Is the MEWP equipment in use at present?

-

Is the work being completed under a working at height permit?

-

All work completed on MEWP or leaning ladders must be controlled through the permit to work system. A copy should be available at the location of the activity.

-

Are the MEWP operators wearing a full harness and short<br>lanyard?

-

All persons working in a MEWP basket must wear a full harness with short or adjusted short lanyard. This is to act as fall prevention rather than fall arrest. A belt harness is not acceptable.

-

Are the MEWP operators wearing hard hats with chin straps?

-

Hardhat head protection should be worn at all times inside a MEWP basket. This is due to the risk of lifting into fixed objects and head injury in the event of fall arrest from the harness. It is vital to have the chin strap in the event of fall arrest, helmets such as the one pictured may be more

comfortable for this activity as they must be worn at all times. -

Is access to the area of operation secure or barriered to<br>prevent others walking too close or under the activity?

-

Barriers should be considered where there is risk that others may walk under or close to the activity. As working at height has the risk of materials and tools dropping protection must be given to those below.

Risk Management - Combustibles

-

Is there any evidence of combustible dust build up around the area?

-

Are dust creating activities fitted with extraction systems?

-

Is there any evidence of leaks from the extraction system(s)?

-

Are Gas tanks and cylinders stored correctly and secure, in a safe area and in good condition?

-

Risk Management - Hand Tools

-

Vibrating tools are hand held equipment such as, drills, grinders, and screw drivers. Any tool that is hand held and delivers some feedback to the user.

-

Are vibrating tools used in the area?

-

Are the tools marked to clearly show the vibration level, last test date and time of use allowed.

-

Example shown of tags that should be attached to equipment so that the user knows the vibration

levels of the specific tool. -

Speak to a colleague

-

Can the employee explain the risk to health from using<br>vibrating tools and why use should be controlled and limited?

-

Give positive marks for understanding the limitations for the tools in use and the knowledge of vibration white finger. (causing poor circulation, loss of feeling in the fingers also would be a correct answer)

-

Are knives or any tools for cutting material or packaging used in the area?

-

Does the blade auto retract or is it a concealed blade knife?

-

Are the knife users wearing safety gloves?

Environmental Management - Spills and Waste Management

-

Are their waste bins available in the department or process<br>area?

-

Is the waste material inside the bin and not over spilling?

-

Waste bins should not be over spilling, where lids are in used they should be closed fully, where not the waste should not exceed the height of the top of the bin. Material can fall out in transit leading to contamination.

-

Are the bins clearly marked (for instance colour coded) stating what waste can go in each bin?

-

Best practice would be colour coded and a statement of what can go in each bin

-

Are spill kits available in the area?

-

Spill kits should be in easy reach, unobstructed and clearly marked to score yes.

-

Are the spill kits appropriate for the possible fluids and location?

-

Spill kits should be specific to the risk on the area by type and volume of material. If there are

drains in the area then there must be a means of blocking the drain to prevent chemicals entering the water systems. (A drain cover or other means of closing the drain immediately available) -

Are the spill kits full and complete?

-

Good practice here is to have a clear list of contents for the spill kit so this is easy to understand. If you are not able to state whether the kit is full and complete then mark as no.

-

Is there evidence of the spill kits being checked?

-

A clear check system is best practice to ensure that kits are available during an event and that all uses are monitored and reported. Only state as yes if you can see a current status check within the last calendar month.

-

General Conditions - Housekeeping Inspection

-

Are safe walkways clearly defined?

-

-

Are pedestrian routes free from obstructions?

-

Are material locations clearly marked?

-

Material locations should be marked to clearly separate from operational and walking spaces

-

Are materials only stored in marked locations?

-

-

Is the area free from trip hazards from fixed wires, trailing<br>cables or air lines?

-

10 When the entire team cannot find 1 single housekeeping improvement opportunity in the area. 9 Area is not perfect but has only 1-2 minor (i.e. – broom was not properly stored) 8 Area that is very good with 3-4 minor opportunities for improvement. 7 Area is good in general but has several (example 5) minor issues 6 Area is average – several minor opportunities for improvement at least 1 of which is major (issue repeated more than once, lack of orderliness very noticeable, poses a serious safety risk) 5 Area is on the low end of average and several issues (8-10) with at least 1 being systemic 4 Area has housekeeping opportunities everywhere you look It is obvious a system is not in place or being utilized for housekeeping. 3 Housekeeping issues everywhere, obvious disregard for housekeeping as a value, some issues serious, navigation through the area is difficult. 2 Serious safety issues are present due to housekeeping, many issues minor and major, navigation through the area due to the housekeeping is a challenge. 1 Clutter creates serious safety issues. Clutter prevents you from getting to the other side of the area without physically moving something out of the way