Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

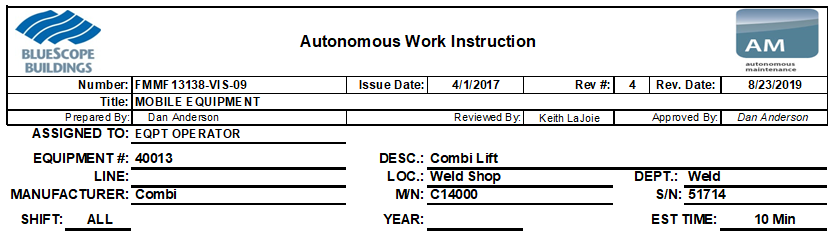

Equipment # 40013

Task Description

AUTONOMOUS WORK INSTRUCTION

TASK DESCRIPTION

-

APPLY ALL SAFETY PROCEDURES BEFORE STARTING; TAKE TWO FOR SAFETY!!!

-

Notify Maintenance if any deficiencies are found during inspection. SUMBIT A WORK ORDER REQUEST!

VISUAL CHECKS

-

1 - Check exterior panels, structure, safety cage for damage (walk around).

-

2 - Check fenders, antiskid, grip tape, and grab handles are in good condition.

-

3 - Check paint, exterior, and doors are free from damage and clean.

-

4 - Check all headlights, reflector tape, and beacon lights are in good condition.

-

5 - Check all capacity and safety labels are present and legible.

-

6 - Check tires for excessive cracks, gouges, and punctures.

-

7 - Hand check all lug nuts on wheels for tightness; If loose, contact maintenance.

-

8 - Check forks for cracks, bends, twists, and ensure locked into position.

-

9 - Check mast, back rest, hinges and lift chains for excessive wear, damage, missing or broken parts, excessive slack in chains, cracks, or mis-alignments.

-

10 - Check all components that handle or carry load to include spreader bar when installed; Ensure proper fit and check for any damage.

-

11 - Check hydraulic hoses and connections to ensure good condition and correct routing.

-

12 - Check for evidence of leaking fuel, hydraulic oil, engine oil, coolant, and transmission fluid.

-

13 - Check LPG system to ensure it is in good condition; Ensure locking pin is engaged in collar slot, pressure relief value is at the 12 o'clock position; filler valve has cap; and verify the inspection date.

-

14 - Check fluid level of gas -- add as needed; Verify O-rings in filler valve and the service valve are present and in good condition.

-

Amount added.

-

15 - Check Engine Oil Level (Refill with 15W-40 as needed)

-

Amount added.

-

16 - Check Hydraulic Fluid (Refill with AW-46 as needed)

-

Amount added.

-

17 - Check Transmission Fluid (Refill with Dextron as needed).

-

Amount added.

-

18 - Check Coolant Level (Refill with Green 50/50 Mix, put usage in comment).

-

Amount added.

-

19 - Check Battery Water Level & battery connections are tight and free of corrosion.

-

20 - Ensure all loose material in cab is removed or stowed securely.

-

21 - Check fire extinguisher is properly charged and secure; Eye wash bottle is present.

-

22 - Check seat belt condition, no cuts or nicks; Properly functions and adjusts.

FUCNTIONAL CHECK (Check With Engine Running)

-

23 - Check all lights (4 beacons, 4 working lights: 2 forward, 2 reverse), mirror position and other safety devices are in good working condition.

-

24 - Start engine; Ensure all controls operate freely & handles/levers return to neutral position.

-

25 - Check warning alarms (horn & backup siren) & windshield wiper for good working condition.

-

26 - Check all gauges and indicator lights are functioning.

-

27 - Check breaks, inching pedal and parking brake function properly.

-

28 - Check directional controls and steering system operates normally.

-

29 - Check hydraulic controls (lift, tilt, & side shift) for condition and function).

-

30 - Listen for any unusual sounds; Report any findings to maintenance; Blow out radiator with air hose.

END OF SHIFT VISUAL INSPECTION

-

31 - Walk around exterior to check for damage.

NOTES

-

Note: Please note any findings for clarification & complete a Work Order for any items requiring repair; include additional comments.

-

Note: If horn, lights, parking brake, or windshield wiper does not work properly, the truck is considered unsafe, immediately lock out equipment, attach an out of service tag, & notify your Team Leader & Maintenance. (Maintenance shall make repairs ASAP)

COMMENTS

-

Add any additional comments here.