Title Page

Assessment Details

-

Document No.

-

Audit Title:

-

Add the scope of the Assessment

-

Date of Assessment:

-

Name of Assessor

-

Name and employee number of employee being assessed

-

Signature of employee

-

Add a photograph of the employee.

Model Type

-

Record the model type and serial number of unit being assembled during assessment.

ESD Controls

-

Is the operator practicing correct ESD Controls as per PTB006<br><br>Is the operator wearing an ESD wrist strap.<br><br>Is the operator wearing the correct PPE.

-

Verify operator has completed daily ESD check sheet QA1350<br><br>

Documentation

-

Does the operator have access to the quality control plan.<br><br>

-

Does the operator understand the quality control plan.<br><br>Ask the operator to explain some of the key parts of the control plan that relates to their current operation.

Equipement

-

Is the correct wiring jig being used.<br><br>How does the operator verify that the correct jig is being used.<br><br>Does the operator verify the jig model type against the BOM.

-

Does the jig ID number match the number on TKN file

TKN Files / Work instructions

-

Does the operator have a good working knowledge of TKN files.<br><br>Is the operator able to read and understand TKN files.<br><br>Ask the operator to explain the part of the process from the TKN files that relates to Capacitor Wiring assembly.

Capacitor Wiring Assembly

-

Verify the operator refers to the TKN files before fitting the capacitor wires.

-

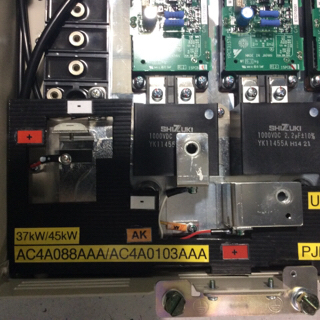

Verify that the operator used the correct PJIG when checking correct capacitor wire assembly.<br><br>Did the operator verify the PJIG against the TKN files before use.<br><br>Record the details.<br><br>Take a photograph of final assembly of the capacitor assembly with jig to verify correct capacitor wiring assembly.

-

Verify that the operator refers to the TKN files after fitting for correct assembly of capacitor wires.

-

Verify correct inspection marks has been applied.<br><br>Record the details.<br><br>Take a photograph of the final capacitor wiring assembly with inspection marks.

Risks

-

Ask the operator to explain the risks if the quality controls that have been put in place for Capacitor Wiring are not followed.

Health and Safety

-

Record any instances of health and safety issues.

Summary of Competence

-

Make a statement about the final competence achieved.