Title Page

-

Conducted on

-

Select date

-

Prepared by

-

Location

PAGE 1

PROJECT INFO:

-

Project Number & Name

-

Foremen

-

Superintendent

-

Inspector

-

Date

GENERAL REQUIREMENTS:

-

Job Site Trailer or Towable trailer have proper signage (labor law , applicable safety signs, coronavirus info)

-

First Aid kits inspected and documented.

-

Weekly Tool Box Talks being conducted and documented.

-

Emergency Contact Numbers posted and visible for crew / or Emergency Action Plan posted and reviewed.

-

HAZCOM program reviewed an explained to crew memebers

-

First Aid, CPR, AED trained people on site.

-

Miss Utility Dig Ticket on site / or Foreman shows how to use LETS system.

-

Vehicle Inspection up to date

-

Vehicle have registration and current insurance cards

-

Towable trailers inspection stickers & registrations & insurance cards.

Job Site Sanitation & Housekeeping:

-

Work area clean & free from tripping hazards.

-

Night time work well lighted for work to be performed.

-

Waste containers at laydown yard being used properly & laydown yard organized

-

Are Porta Johns cleaned and properly supplied to meet VOSH requirements.

-

Eye Wash stations mounted in towable trailers or in site trailer.

-

Drinking water in sanitizes cooler and adequate supply.

Fire Prevention & Flammables:

-

Are their Adequate fire extinguisher and types required on site

-

all flammable liquids in appropriately designated containers with proper labeling.

-

Gas cylinders separated and secured properly if applicable.

-

Any secondary containers used have proper HAZCOM labels to identify contents.

-

No Smoking signs displayed in areas that need them (fueling stations, gas cylinders).

-

Refueling stations barricaded properly

-

Refueling stations fire extinguisher mounted 26' + from station with proper sinage

PPE & Equipment:

-

All required PPE being utilized by all (hard hat, safety glasses, gloves, class III vest in roadway).

-

Silica Dust are controls being utilized and adequate for application.

-

Hearing protection utilized if over 85 dba.

Electrical:

-

GFCI plugs being utilized and tested.

-

Electrical cords free from damage and have the ground pin intact.

-

Electrical hand tool outfitted with double insulation.

-

Electrical dangers posted if needed when working around overhead lines.

-

Equipment that requires a secondary ground being utilized peoperly.

Ladders:

-

Ladders being used have proper labeling and legiable.

-

Ladders being inspected (have crew demonstrate inspection)

-

Ladders properly secured.

-

Walk Throughs provided and used properly.

-

Ladder training instruction provided and documented.

PAGE 2

RIGGING:

-

15 Ton Swivel hook have latch, and no excessive wear.

-

Shackles USA made, no excessive wear.

-

Lifting chains all Tags legible and free from damage

-

Webb slings no tear or damage if so remove from service.

-

Tag lines being used while lift being performed.

-

OTHER

EXCAVATIONS:

-

Ladder in ditch 4' or deeper

-

Excavations 5' or more utilizing either slope/ speed shore/ trench box.

-

Competent person on site and have proper documentation.

-

All spoils minimum 2' away from ditch and free from tripping hazards.

-

Hand digging best practices being utilized (NO MECHANIZED EQUIPMENT within 2').

-

Trench boxes have all pins with keepers in place, NO DUCT TAPE.

-

Spreader bars in good condition no bends that could cause failure.

-

Trench over 4' should be monitored for air contaminant's.

-

OTHER

CONFINED SPACE:

-

Competent Person on site and determines what is a Confined Space or Permit Confined Space.

-

Permit Confined space proper documentation on site and being turned in to Safety Department for annual review.

-

Competent person explained the Attendant and Entrant responsibilities.

-

Gas Monitor been bump tested within 24 hours.

-

Calibration being done annually or within parameter's of monitor being used.

-

Emergency Action Plan been reviewed before entering hole.

-

Is Confined Space Properly set up, to keep people not utilized outside work area.

-

OTHER

HEAVY EQUIPMENT:

-

Fire Extinguisher mounted, inspected & documented.

-

Equipment Inspections being completed daily.

-

Seat Belt being used.

-

All back up alarms operational and demonstrated, equipped with horn.

-

Proper Labeling inside cab for overhead power lines with 50kva or less.

-

All Glass intact and free from damage.

-

all mirrors intact and free from damage.

-

OTHER

TRAFFIC CONTROL:

-

Traffic Control set up according to MUTCD or Virginia Lane closure requirements.

-

If Flaggers being used, do they have proper training and cards on their person.

-

is Equipment in roadway with out Controls being utilized.

-

If road detours in use are they maintained properly.

-

Controls in place for the public to understand, and keep out of harms way from equipment.

-

OTHER

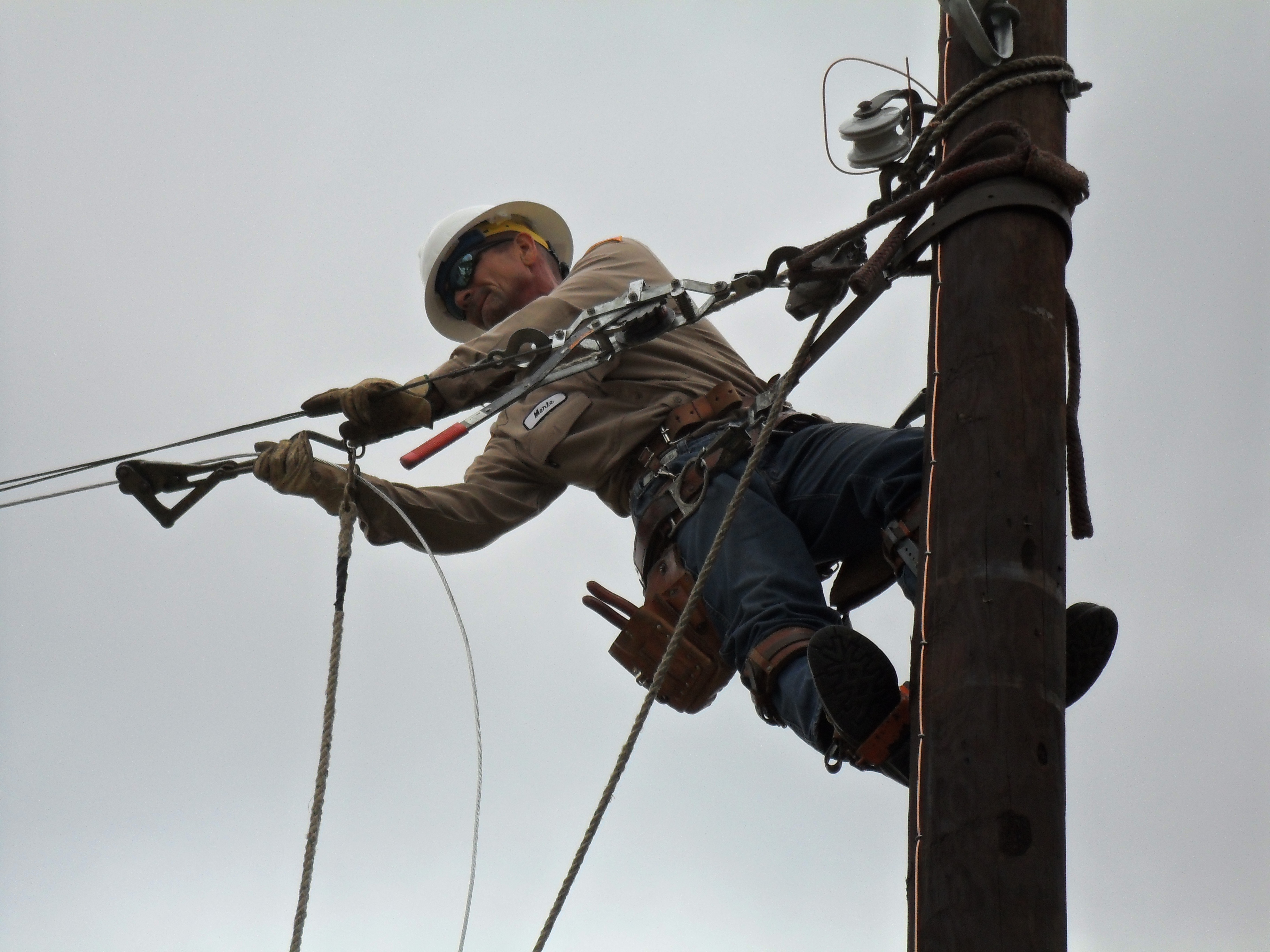

FALL PROTECTION:

-

Is Competent Person on site while being utilized.

-

Is adequate protection in place for job being performed.

-

Is work area set up to keep public out of harms way.

-

Fall equipment Inspected and documented before each use.

-

Anchor points being used able to withstand 5,000 lb.

-

OTHER