Information

-

Workshop Safety Audit

-

Document No.

-

Conducted on

-

Prepared by

-

Location

- D1

- D2

- D3

Management Systems

-

Training records – Staff (e.g. Induction; courses; profiles etc.)

-

Training records – Students (machine inductions; knowledge test etc.)

-

Risk assessments – Plant/equipment; hazardous substances etc.)

-

Plant/equipment – Servicing; Maintenance/inspection; SOP’s; Operator manuals; Lock-out/Tag-out etc.

-

Evacuation Procedure: Room diagrams; audible alarm signal and practices conducted.

-

Incident Reporting process in place: injury notification and investigations

-

First Aid: trained staff; first aid kits; first aid room

-

Communication: facility meetings; notices; signage; notice-board; ordering process; etc.

1. Layout

-

Area is clean, tidy and free of hazards.

-

Adequate storage areas provided.

-

Floor is free of obstructions and slip resistant.

-

There is adequate ventilation.

2. Environment

-

Temperature is comfortable.

-

Lighting is adequate.

-

Area is free from odors.

-

Machine extraction system is in working order.

-

Spray booth extraction system is in working order.

-

Air Purifier and monitor is turned on.

3. Emergency Procedures

-

Written evacuation procedures and exits displayed.

-

Portable fire extinguishers have been provided and maintained.

-

Escape routes and emergency doors are clear.

-

Emergency Stop buttons on.

-

Procedures are in place for isolated workers.

-

Emergency and hazard signage is clearly visable.

4. First Aid Facilities

-

Appropriate first aid and emergency facilities in the near vicinity and staff and students are aware of them.

-

Kits are clearly signed, stocked and contents are in-date.

-

Names and contacts of first aiders displayed and up to date.

5. General Facilities

-

Washing facilities are clean and functional.

-

Passageways and store rooms well lit.

-

Warning and Safety signage in good condition.

-

Isolation valves are readily accessible and clearly labelled.

-

Walls, windows, doors and furniture in good condition.

6. Manual Handling

-

Manual handling Standard Operating Procedures (SOP) are available.

-

Personnel in inspection area are inducted and trained in manual handling.

-

Trolleys or mechanical hoists are available and are being considered for heavy items or loads.

-

Step ladders or safe steps available to access light items stored on high shelves.

-

All manual task-related incidents have been adequately investigated and control measures implemented and reviewed.

-

Staff have been asked for safer ways to do the job.

7. Storage

-

Materials stored in racks and bins wherever possible are not above shoulder height.

-

Storage designed to minimize lifting problems I.e. heavy objects not stored on upper racks.

-

Racking securely fixed to the floor or wall.

-

Safe lifting sign displayed.

-

Are storage areas labelled appropriately and organized.

8. Slips and Trips

-

Personnel in inspection area are inducted and trained in slips and trips

-

Warning signs are available and erected near spills

-

There are special provisions for slip resistance in wet areas.

-

All slip and trip incidents have been adequately investigated and control measures implemented and reviewed.

-

Significant hazards have been identified and assessed all the factors that will affect the risk has controls implemented.

-

Walkways are free of hazards.

9. Electrical Safety

-

Personnel in inspection area are inducted and trained in Electrical Safety and are following applicable SOPs. (Safe Operating Procedures).

-

All portable equipment has current test tags.

-

Residual current devices (RCD) are installed at switchboards or fixed into sockets. (It should be clearly marked on socket).

-

Portable RCD device is available and has been tested.

-

Flexible cord, plugs and extension leads are in good condition and have either moulded or transparent type plugs.

-

Power points are suitable for the location and are positioned safely.

-

Power boards are used and dust removed daily. (not double adapters).

-

Faulty equipment is tagged out. (Tags are available).

10. Chemical Aspects

-

Personnel in inspection area are inducted and trained in Chemical Handling and are following applicable SOPs (Safe Operating Procedures).

-

Eye wash and shower area clear and in working condition.

-

MSDS (not older older than 5 years) are available for workers reference and included in the hazardous substances register.

-

Up to date easy to find and read list/register summary of all chemicals used.

-

A risk assessment has been completed for all chemicals and harmful substances stored and used at the workplace.

-

Actions have been take to control risks. For example , an investigation has been done to find out whether an alternative safer chemical is available.

-

Decanted containers are labeled with name, risk and safety instructions.

-

Original containers have the manufacturer's label.

-

Chemicals stored according to compatibility and bundled i.e. in flammable or corrosive cabinets.

-

Are minimal amounts of corrosives stored, and/or used?

-

Only flammables stored in flammable liquid cabinet?

-

Are the warning signs on the cabinet legible? (e.g. DG Class 3 diamond, no smoking, no ignition sources).

-

Spill control systems are in place i.e. bunding containers, absorbing materials etc

-

Banned substances or timbers are not used e.g. CCA; western red cedar

-

Disposal process for unwanted/out-of-date chemicals

11. Personal Protective Equipment

-

Instruction and information of PPE are available.

-

Signage of PPE requirements displayed on equipment.

-

Required PPE available

-

Appropriate signs displayed to standard requirements visible, correctly located and in good condition, (Inside and outside).

12. Noise

-

A risk assessment on noise has been conducted where it is likely that workers Re exposed to noise levels.

-

Control measures have been put in place to reduce the risk of injury as a result of noise, including the provision of personal hearing protection.

-

Staff and Students have received information and training in relation to noise at the workplace.

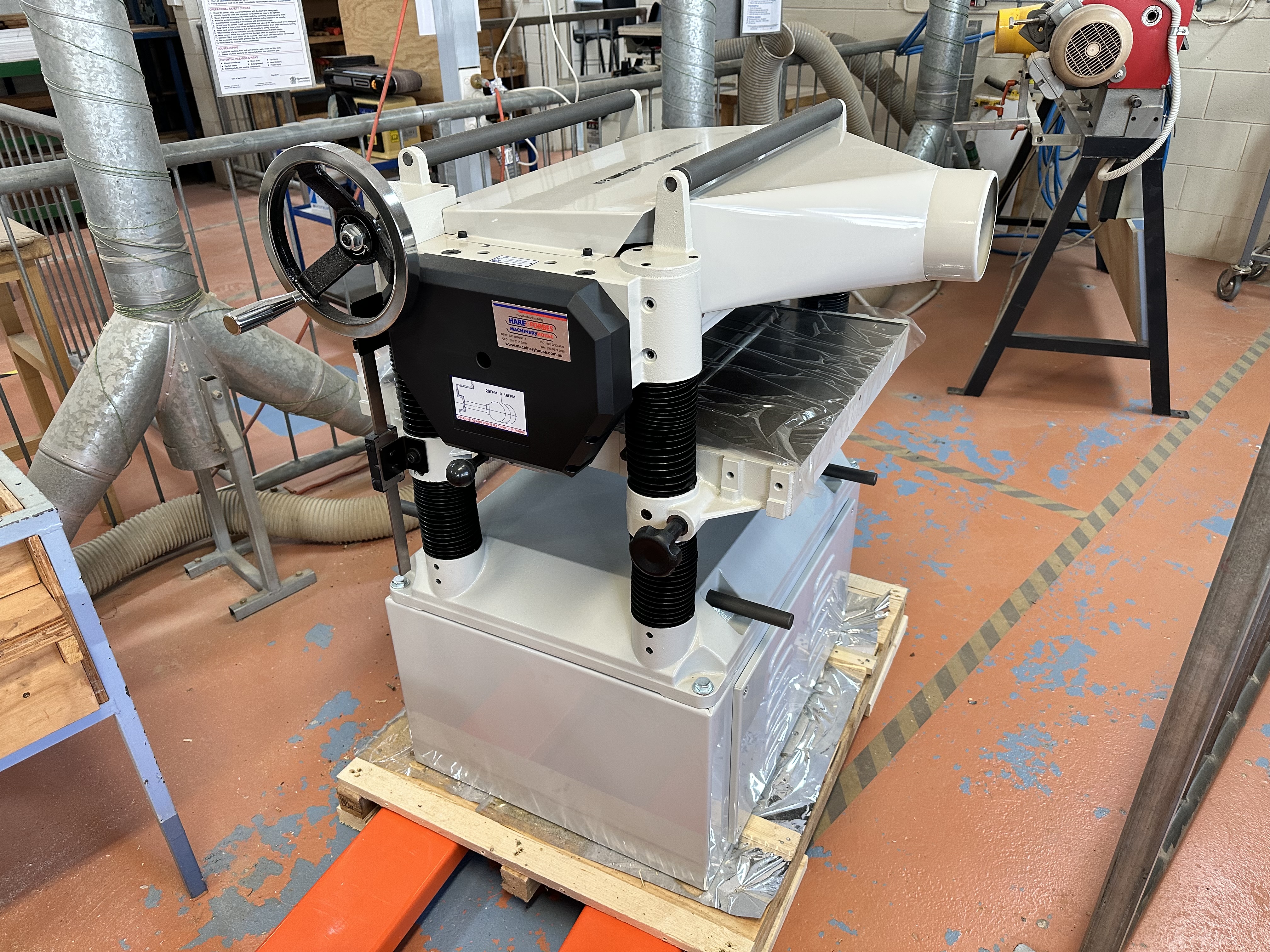

13. Machinery and Plant

-

Records are kept of maintenance, alterations and inspections.

-

Are SOP signs clearly visible?

-

Manufacturer's manuals and operator instructions are readily available.

-

Inspection records are made and kept in relation to plant.

-

Work area is organized for the safety of the mobile plant operator and pedestrians. (Safe walkways on floor?)

-

Pre-start safety check of mobile plant is carried out in accordance to Manufactures instructions

-

Are records of training held for appropriately trained people? e.g OnGuard.

-

Emergency stops tested and are working.

-

Welding screens available, maintained and in good condition.

14. Guarding

-

Operators and maintenance personnel properly trained, familiar with the operation and set up of machinery and able to demonstrate safety features.

-

Where fixed guards are provided, they prevent operation of the machinery when open, the guards are prevented from opening while the machinery is in operation unless otherwise designed to do so.

-

Where a presence sensing system is used, it operates as intended and stops the machinery when the light beams or sensors are interrupted.

-

Guards protect against hazards to the rear and sides of machinery.

-

Pre-operational checks are conducted to ensure safety features are in working order.

-

Warning signs and decals clearly visible.

-

Where it is not practical to provide guarding and people are required to operate or pass close to dangerous moving parts, a safe system of work in place to reduce risk.

-

Manufacturer's manuals are available for operators.

15. Welding Safety

-

Staff appropriately trained and inducted in the dangers of performing welding tasks.

-

Students appropriately supervised by a competent person when welding.

-

Welding operators provided with the appropriate PPE. Appropriate (AS/NZS) gloves, welding glasses/shields and aprons are available for welding processes. CHECK Gloves etc do not have holes and 2 sets are available in each bay.

-

Effective ventilation and fume extraction available for welding/cutting processes

-

Appropriate warning signs in welding areas.

-

All arc-welding bays are adequately screened from welding flash.

-

Ventilation systems working adequately.

-

Manifolds are located and guarded to protect from damage; system regularly maintained.

-

Oxy and plasma cutting benches/supports in good condition.

-

Separate storage area for full and empty gas cylinders.

-

Gas hoses and hand pieces in good condition – tips and equipment stored appropriately.

-

Areas have good design and layout – space; suitably painted.

-

All electric welding benches are insulated from the floor and/or the operator is insulated from the floor by rubber matting or duck boards.

-

Electrical cables and electrodes in good condition – electrode and earth cables and connections.

-

Gas cylinders are stored in an upright position and chained to a wall or stand.

16. Compressed Gas

-

Cylinders contents are identified and appropriately secured.

-

Cylinders are stored according to dangerous goods class and empty cylinders are separated from full ones.

-

Gas lines are free of leaks, kinks, wear & tear.

17. Spray Painting Booth/ Area

-

Spray painting booths are located away from a possible source of ignition

-

Lights and switches are spark proof

-

Filters and extraction system regularly checked – services recorded

-

Paints and solvents are stored away from painting area/s

-

Hazardous substances not used e.g. Isocyanates; trichloroethylene; benzene etc.

18. Plant Rooms - Dust Extraction

-

Located in secure (locked) and weather proof area

-

Designed to reduce/control noise from plant

-

Good access to collection bins for cleaning

-

System regularly serviced – records kept

19. Plant Rooms - Compressor Plant Installation

-

Located in secure (locked) and weather proof area

-

Designed to reduce/control noise from plant

-

Compressor fixed to prevent vibration

-

Good access to service compressor

-

System regularly serviced – records kept

Other Hazards

-

Other hazards

Please sign and email the report to the HOD & WHSO.

-

Date & Time of Inspection

-

Signature