Title Page

-

Cone I.D.

-

Date

-

Undertaken By

-

Location

Friction Sleeve Outer Diameter Measurements

-

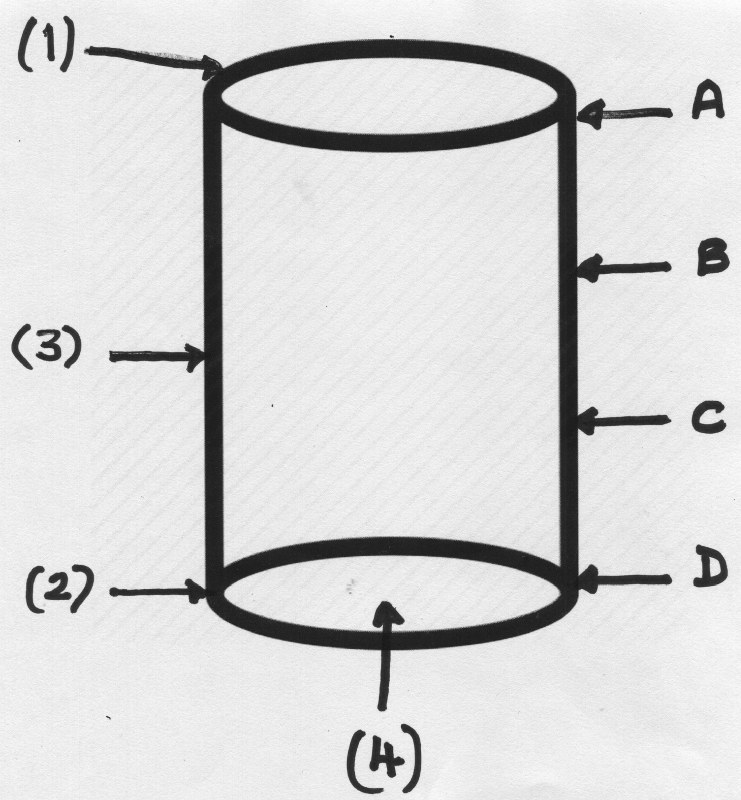

Diagram 1

-

Dimension A in mm

-

Dimension B in mm

-

Dimension C in mm

-

Dimension D in mm

-

Difference between greatest and smallest in mm

-

Rules: The difference must not exceed the 0.100 mm allowable tolerance

-

Sleeve Condition

-

(1) End Condition

-

(2) End Condition

-

(3) Surface Condition

-

(4) Internal Condition, Seals

-

Conclusion

-

Comments

-

Friction Sleeve Rules

-

Cone sleeve diameter must be greater than cone diameter but no more than 0.350mm

-

Sleeve wear must not exceed 0.100 mm for the length of the sleeve

-

Surface area should equal 150cm2

Cone Tip or Point Observations

-

-

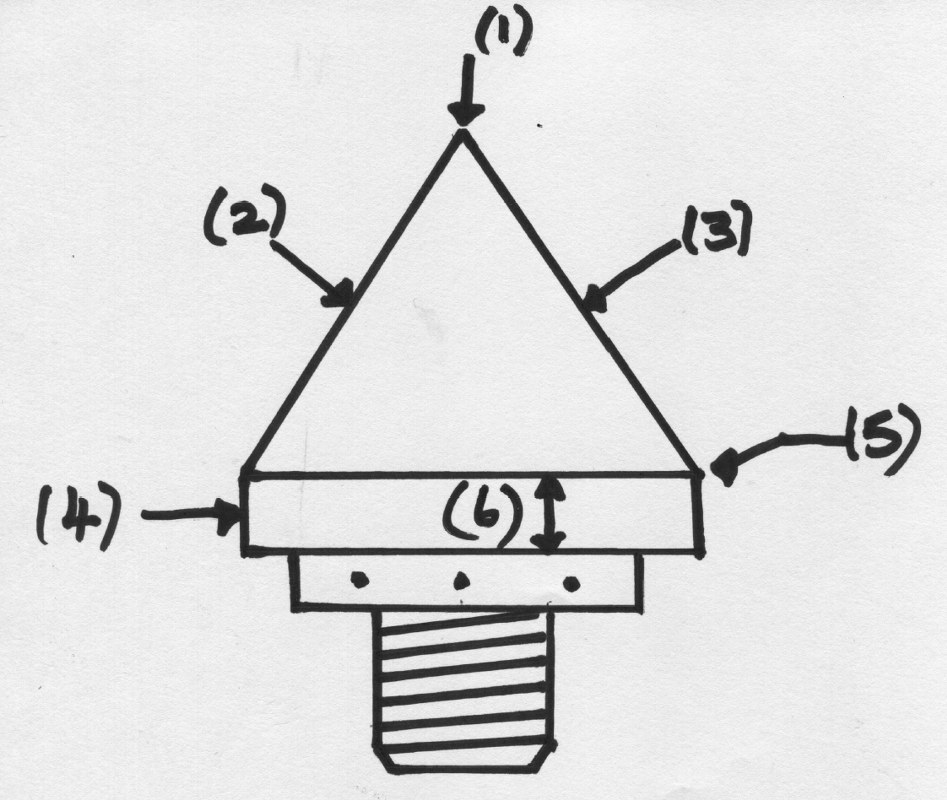

(1) Tip Angle 60 Deg +/- 5 Deg

-

(2) Surface Condition

-

(3) Wear Shape

-

(4) Dia Check 35.3mm to 36mm

-

(5) Edge Check

-

(6) Collar Thickness 5mm +/- 2mm

-

Cone Tip Conclusion

-

Comments