Information

IAEC CREW INSPECTION

-

REC Name

-

REC contact person

-

Conducted on

-

Prepared by

-

Location of inspection (individual report per location)

Person In Charge

CREW MEMBERS

DESCRIPTION OF WORK BEING PERFORMED

JOB PLANNING

-

Employee in charge on site

-

Documented Tailgate - hazards, special precautions, energy source controls, PPE required and employee fitness

-

Any alternative energy sources to be aware of (wind, solar, etc.)

-

Adequate number of crew for the job

-

Weather conditions

-

Terrain conditions in work area

PERSONAL PROTECTIVE EQUIPMENT

-

Is eye protection being worn at all times?

-

Are hard hats used according to procedure manual requirements?

-

Is hand protection being used?

-

Gloves and sleeves (if applicable) worn cradle to cradle, lock to lock, ground to ground and in good condition?

-

Proper rated FR clothing worn?

-

Is hearing protection used when needed?

-

Proper fall protection worn?

-

Add media

VEHICLES, TRAILERS AND EQUIPMENT

-

Boom clean

-

Pre-flight of controls

-

Controls marked

-

Wheels chocked

-

Outrigger pads used

-

Vehicles and equipment grounded per safety manual?

-

Co workers rubber gloves located outside of truck for possible bucket rescue

-

Current DOT inspection

-

Add media

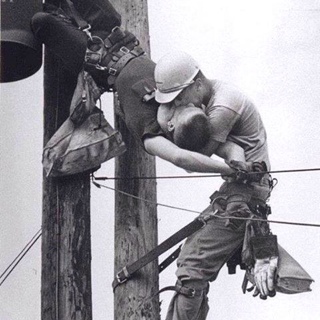

CLIMBING

-

Employee certified as climber

-

Inspected tools before climbing

-

Long sleeve shirt worn while climbing

-

Hand line used

-

Is Fall Restraint being used when climbing wood structures?

-

Add media

OVERHEAD CONSTRUCTION OR MAINTENANCE

-

Is all equipment inspected prior to use?

-

Is the equipment being used correctly?

-

Are the lines properly de-energized, tested and grounded per safety manual?

-

Are all grounds in good working condition?

-

Are handlines being used?

-

Crew maneuvered loads in a safe manner?

-

Is there good housekeeping?

-

Add media

ENERGIZED WORK

-

Are gloves and sleeves correct rating and date?

-

Are gloves air tested and visually inspected prior to use?

-

Is adequate cover-up material being utilized?

-

Are minimum approach distances being maintained?

-

Is there someone observing employees performing "hot work"?

-

Is company policy followed i.e. rubber glove use? (lock to lock, ground to ground)

-

Are handlines being used?

-

Add media

GENERAL

-

Are slings, handtools, hoist, grips, handlines and all other tools in good working condition?

-

Are chainsaws and proper PPE availible? (chaps, cut resistant boots, eye protection, hearing protection and head protection)

-

Is the work area cleaned when the job is finished?

-

Add media

TRAFFIC CONTROL

-

High visiblility vests worn?

-

Signs used in accordance to traffic control rules and regulations?

-

Cones used in accordance with traffic control rules and regulations?

-

Flagger used when needed?

-

Law enforcement utilized when needed?

-

Flagging done properly?

-

Four way flashers used?

-

Strobe/Rotating light in use?

-

Crew size adequete for proper traffic control?

-

Add media

URD WORK

-

Competent person on job site?

-

Are all excavations evaluated and safe?

-

Adequate trench protection?

-

Means of egress in trench?

-

Spoils 2ft from trench?

-

Used approved device and method when lifting URD equipment (transformers, switchgear, peds etc.)

-

Add media

HOT STICKS

-

Clean and free of moisture?

-

Stored properly

-

Live line tool test date.

-

Add media

Dairyland Power Cooperative

Patrick Bethke

-

Add signature

Steve Knudsen

-

Add signature

Lance Burke

-

Add signature