Title Page

-

Conducted on

-

Prepared by

-

Location

Section 1. Imminent Health Hazards

-

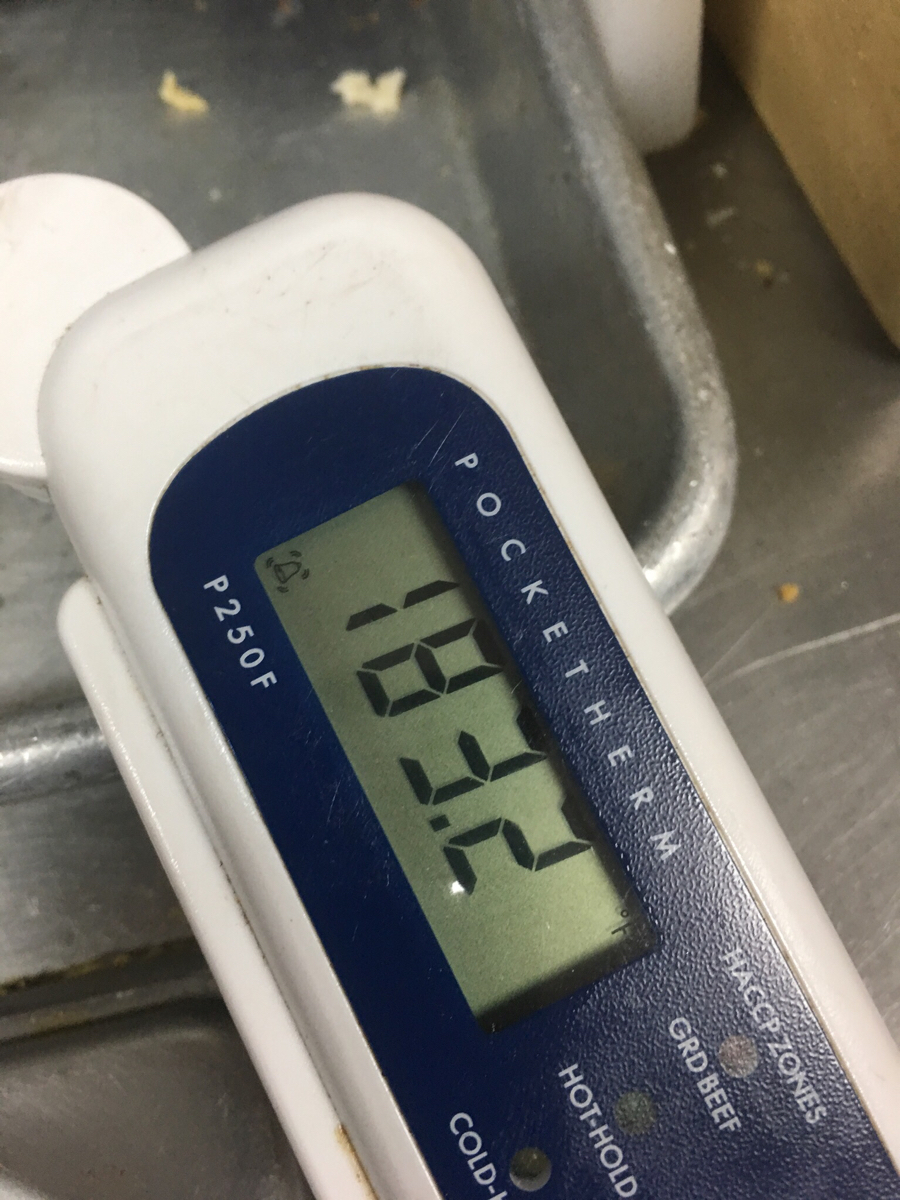

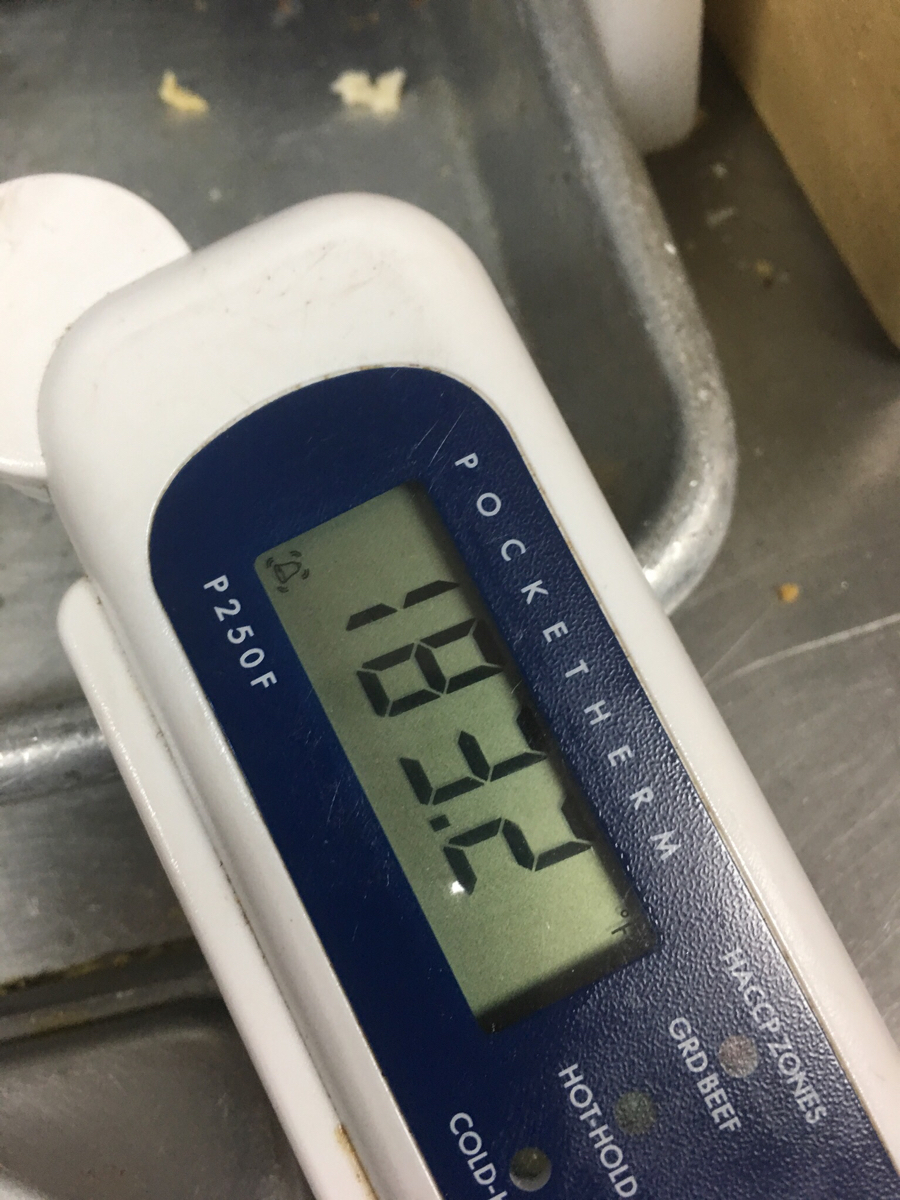

1.1) WIC product temperatures are maintained at 41F or below. WIF product temperatures are maintained @ 20F or below (Critical 5 pts)<br><br>(At least 5 product temperatures in each WIC & WIF measuring 2 products in the front, 2 products in the middle and 1 in the back)<br><br><br>(Temp Check a minimum of 5 products 2 in front , 2 in middle and 1 in back of each)

-

1.2) Personal present seem healthy. Persons displaying symptoms such as vomiting, diarrhea, jaundice, or sore throat with fever are excluded from the restaurant as an employee. Persons with exposed pustular lesions are restricted from working around exposed food or food-contact surfaces. Persons diagnosed with a reportable foodborne illness are excluded from the restaurant as an employee. ( Critical : 5 pts)<br>

-

1.3) Sewage disposal systems and water drains are operating properly (Critical 5 pts )<br><br>( Parking Lot, Restrooms, Back of House , Floor drains all free of sewage backing up)

-

1.4 ) No Pest infestation is present in facility (Critical 5 pts)<br><br>(Flies, Crickets BOH (20), Dining Room & Restroom (10), any number of roaches or mice.)

-

1.5) Plumbing provides adequate pressure and water is available at all BOH and restroom sinks. ( Critical 5 pts)<br><br>(Need to have available water with adequate water pressure in handwashing and warewashing sinks.)

Section 2. Time / Temperature Control

-

2.1) Cold-Holding of TCS food items at or below 41F in all cold-holding devices at MUT (Major 4 pts. )<br><br>(Honey Butter, Tarter Sauce, Tomatoes, Chopped Lettuce, Avocado, )<br><br>( If Items on MUT are under Time as a prevention method are they labeled correctly)

-

2.2) Cold-Holding of TCS food items at or below 41F in WIC/Super Cooler and at or below 10F in WIF (Major 4 pts.)<br><br>(<5 TCS foods above 41 in WIC, all items in Super cooler below 41, Ambient temperature of WIC and Super Cooler 41, WIF 10 )<br>

-

2.3) Cold -Holding of TCS food items at or below 41F in all other cold-holding devices (Grill/Drive reach-in coolers, reach-in freezers, under-counter coolers/freezers and shake machine). (Major 4 pts )<br>

-

2.4) Hot Holding of TCS food items at or above 135F in all hot-holding devices (stem wells, Prince Castles, warming drawers, etc. ( Major 4 pts)<br><br>(Strips, Bites, Chicken Grilled Chicken, Fish, Cup Gravy, Gravy Pot, Eggs, Sausage, Pie)

-

2.5) Cold holding units are equipped with accurate thermometers that are easily viewable. Placed in the warmest section. (Minor 3 pts.)<br><br>(Reach-In Coolers, Reach-In Freezers, Super Cooler, WIC, WIF all have Thermometers that are accurate and not broken and in warmest part close to the door.<br><br>(Reach-In Coolers , Reach-In Freezer, Super Cooler, WIC, and WIF

-

2.6) TCS food items are cooked to minimum internal temperatures. ( Major 4 pts. ) <br><br>(165 degrees , *155 shell eggs)

-

2.7) Foods that require time/temperature control for safety are properly handled, at proper temperature before being displayed and not left out of temperature-controlled environments for extended periods of time. Foods held by time alone are at proper temperature before being removed from temperature control. ( Major 4 pts.)<br><br>(TCS food left out over 10 minutes while prepping) (Food that requires thawing is thawed prior to putting into use)

-

2.8) Where time alone is used as a public health control, the food is time stamped with the time removed from temperature control at or below 41F, discard not to exceed 4 hours, and used or discarded within that time frame. ( Major 4Pts)<br><br>( Tomatoes, Lettuce, Leaf Lettuce , Avocado , Honey Butter, Tarter, Mayo ) <br>

-

2.9) Date Marking is applied at the time of preparation to foods which are prepared on site and are prepared on site and intended to be held cold more than 24 hrs. Foods are not held or sold past its expiration date. ( Major 4 pts. )<br><br>(Sliced Tomatoes, Chopped Lettuce, Diced Onions , Green Leaf Lettuce, Cheeses, Salads, Gravy, Coffee, Tea, Sauces, Avocados, Honey Butterin coolers, Tarter Sauce in coolers , Avocado in cooler, Apple Slices, PC Sauces, OJ, Milk, BIB syrup, Beef patties, any other food product held past use by date)

Section 3. Contamination Prevention

-

3.1) Foods are not contaminated. Foods and food contact surfaces are protected from potential microbiological, physical and chemical hazards. (Major 4pts.)<br><br>(Food Items Stored Correctly RTE foods above TCS foods in proper order top to bottom) (Utensils used for raw proteins not allowed to come in contact with RTE foods such as Proper spatula use.) (all food in sound condition with no mold , temperature abuse off colors, damaged or wet packaging) ( Sanitizers, Sani-Wipes, Wiping towels, stored under the MUT and Grills) (no chemicals stored next to or above food or food contact surface)

-

3.2 Foods are properly protected from contamination, (Minor 3 pts.) <br><br>(Foods in Coolers , Freezers and Super Coolers not properly covered) (Condensation or debris above food or food contact surfaces) (3.2) Food Packaging plates, Lids cups etc not stored inverted) (Tongs hanging where they can come in contact with clothing) (In use utensils are properly handled, ) (Scoop handles not touching Food)

-

3.3) Fruits and Vegetables are washed properly prior to processing and serving. (Minor 3pts.)<br><br>(Tomatoes washed in cool RUNNING water prior to preparation. , Iceberg Lettuce washed in cool Running water (ice may be used).

-

3.4) Foods are Properly identified with the common name of the product on the container. (Minor 3pts.)<br><br>(Bun oil bottle, Water bottle, shortening bottle, Vinegar bottle, sauce bottles.)

Section 4. Equipment and Utensil Cleaning and Sanitizing

-

4.1) Food Contact surfaces are properly cleaned and sanitized. (Major 4pts.)<br><br>(Utensils are washed, rinsed and sanitized prior to being re-used.), ( Proper wash, rinse , sanitize and air dry procedures being followed), (Sinks, washed, rinsed, sanitized prior to use). (Sanitizer Strips available and in use) (Ice Machine, Drink Machine, Tea urns, Coffee Urns, Lettuce, Tomato Onion Choppers Clean when stored.)

-

4.2) Food-contact surfaces are smooth, easily cleanable, and in good condition . (Major 4 pts.)<br><br>(Grill Spatulas, Egg Rings, Cutting Boards, Lettuce Chopper, Tomato Slicer , Onion Dicers clean and in good repair)

-

4.3) Nonfood-contact surfaces equipment and utensils are properly cleaned, such as sides of sinks, door handles and gaskets, sliding door tracks, shelves. Non-food surfaces of equipment and utensils are easily cleanable and in good condition. ( Minor 3 pts.)

-

4.4) Toxic Chemicals are used to the correct concentration. Chemicals are used correctly and only for their intended purpose. Containers previously used for Chemicals are not used for storing, dispensing, or transporting food. Food/packaging containers are not used to hold or dispense chemicals . (Major 4pts.) <br><br>Sanitizer Solution in sinks and or buckets between 220-400ppm. Chlorosan solution (for shake machine cleaning and sanitizing lower than 100ppm. No Chemical other than Quats used on food contact surfaces such as Peroxide, Contender . Bleach or any other unapproved is in the Unit

Section 5. Personal Hygiene and Food Handling.

-

5.1) Hands that have become contaminated are double -washed per policy (hands must be properly washed, and rinsed then washed and rinsed a second time, dried and followed by hand sanitizer). Hands are washed using hot water at least 100 degrees for 20 secondhand dried using disposable towels or a heated -air hand drying device. Hands are washed each time before donning gloves as required. (Major 4pts.)

-

5.2) No bare-hand contact occurs with RTE foods, except in locations authorized to use alternate operating procedures (AOP's) In AOP locations the Manager MUST provide verification they are exempt from wearing gloves. Disposable Gloves are worn over cut resistant gloves. ( Major 4 pts.)

-

5.3) Handwashing facilities are maintained accessible at all times. Hand-washing facilities in food-handling areas are used ONLY for that purpose, and only hand wash sinks are used for that purpose (Major 4 pts.)<br><br>(Nothing blocking free use of the sink like bread racks, trash cans etc. No dishes or utensils placed in the sink, nothing poured down the sink) (No stains or debris left over as evidence of sink being used as a place to dump or pour out things,) Sinks are clean)

-

5.4) Handwash sinks are supplied with readily available hot water, soap, disposable towels, or heated -air hand drying device trash can: and sign to remind Family Members to wash wands. (Restrooms and BOH) (Major 4 pts.)

-

5.5) No fake fingernails, no painted fingernails. Gloves are changed whenever damaged or torn. When handling exposed food. Gloves are worn over Bandages. (Minor 3pts)

-

5.6) Eating, Drinking and tobacco use are restricted to non food areas. Drinking is allowed from closed containers, such as a cup with a lid and straw, handled to prevent contamination of hands or food contact surfaces. Personal Items are properly stored in designated areas away from food, utensils, and equipment. (Minor 3 pts.)

-

5.7) Good Personal Hygiene practices are followed hair restraints are used around exposed food and food contact surfaces. Jewelry on the hands and wrists is limited to a plain ring with no set stones: fingernails are kept trimmed and clean. (Minor 3pts)

-

5.8) At Least One Manager possesses a valid CFM certificate. (Major 4 pts)

Section 6. Facilities and Controls.

-

6.1) Air Gaps/backflow prevention devices are in place where required. (Major 4 pts.)

-

6.2) Restaurant has hot water at a minimum of 110F in ware- washing areas and 100F in Restrooms. (Major 4pts)

-

6.3) Pest prevention program is effective. (Major 4 pts)<br><br>( No More than 5-10 flies, crickets, etc) No accumulation of dead insects (>10 dead crickets,,flies etc. ) (NoGnats observed in BOH near floor drains, bag in the box, electrical panels etc.

-

6.4) Floors , walls, ceilings and vents are free of excessive dust , debris and standing water. and are in good repair. ( Minor 3 pts)

-

6.5) Lighting is adequate for cleaning and food handling tasks: Lights are shielded or shatterproof above exposed food and food contact surfaces, and above packaged food if the package integrity could be affected by broken glass . (Minor 3 pts)

-

6.6) No pest entry points exist, such as gaps larger than 1/4 " beneath exterior doors. No pests harborage sites exist. such as dirty mop heads that are not hung to dry after use . Pest control devices are working properly and installed so that they will not contaminate food or food contact surfaces. Back door keep closed (Minor 3pts)<br><br>

-

6.7) Interior garbage containers are lined and emptied as needed ( Minor 3pts)

-

6.8) . Exterior garbage storage is covered and doors kept closed between uses. The surrounding area is maintained clean to avoid attracting pests . Grease Traps are working properly (Minor 3 pts.)

AUDIT COMPLETE

-

This Audit Completed By

-

Manager On Duty

-

Add signature