Title Page

-

Site conducted

-

Conducted on

-

Conducted by

-

D/N Shift

-

Crew

Shift Audit

Health and Safety General

-

Have any hazards in the OCE Report been rectified?

-

Is a JSA in place and signed off by operators and OCE? (Enter location/ task in notes.)

-

Has Seatbelt compliance and functionality checked in at least two vehicles? (Enter vehicle details in notes.)

Drill Prep Activities / Dozer working near High Wall Crests (High Risk Activity)

-

Is there drill prep being performed in you work area?

-

Minimum of three supervisor inspections required per shift. Note specific work being completed

-

Verify Minestar plan uploaded with primary standoff line in place

-

Verify CMW has not been reversing up to the primary standoff

-

Verify bund heights are at the standard for Drill Prep as defined by SRM SWI Work Area & Bench Setup

-

Verify that Geo Technical hazards have been demarcated.

-

Verify Drill prep access signage is in place. E.g., 1. Drill prep sign with channel number. 2. before reducing bunding -'Reduced bunding past this point' sign

Work area general

-

Loading Unit:

- EX33

- EX32

- EX27

- EX75

- EX77

- EX921

- EX938

- SHE37

- SHE38

- EX78

- EX95

- EX91

- EX92

- EX93

- EX95

- OTHER

- LDW271

- LDW273

- LDW290

- LDW292

- EX35

- EX27

- EX79

- EXD310

- C201

- REJECT

- EX76

- EX94

- EX96

-

Have you started in a new work area?

-

Has area been inspected by OCE before starting?

-

Does the area require a JSA to manage any hazards?

-

Is the material competent?

-

Has all Bunding, dig plan and OCE report been checked for any hazards or non compliance

-

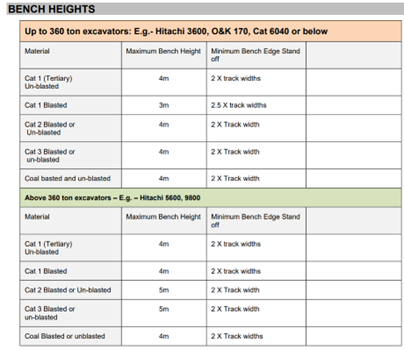

Height compliance as per SRM SWI Excavator Operations

-

What is the bench height? Is it to standard?

-

Bench Height -

-

Are you following correct plan for dig unit to manage safe productive dig (HW, Crest, Toe, Limits and any Geo tech hazards in area)

-

What is the competency of the material in dig

-

Has an area inspection been conducted above and below the work area? E.g., Adequate catch bunding above or below? (Minimum three checks and verify with operators)

-

Have you got equipment working above or below any work area?

-

Have OCE and Supervisor have accessed the area for an inspection?

-

Is catch bund adequate to stop the expected material that may fall?

-

Is signage in place or required, restricting access to the area?

-

Is relocation of any other equipment above and below work area required?

-

Have ongoing inspections of catch bund is required to ensure it remains sufficient to catch material that is expected to fall been carried out?

-

Are there any other hazards that need to be controlled?

-

The relevant operators been made aware of controls being implemented to manage the hazard in their area?

-

Is the primary Dump on plan? (Limits, Floor & RL and are bund heights to standard?

-

Is co dumping rejects available as per 24hr plan?

-

Bund base width – inspect the tip head bunding to determine if undercutting has occurred and the base widths are adequate.

-

Bund construction material - determine the category of bund material used at the tip head – (identify if it is CAT1,2 or 3)

-

Is the secondary dump available? Has it been checked (Limits, Floor, RL, Bund heights & toe bunds)

-

Has Dig to design/Minestar/Argus checks been completed to ensure accuracy and compliance?

-

Road at correct width and in good order? Minimum 793 =31.5m 797 36m and maximum road width total 40m

-

Road width -

-

Are road at correct Grade and crossfall - compliant with standard as per cross grade report (>4% will require remediation or a risk based approach)

-

Does the work area have adequate lighting having regard for shadow, contrast, and glare?

-

Hazardous Tyre Bay in place and signed correctly?

-

Area setup to standard? (circuit entry signs correctly positioned & AMA signs correct)

-

Are shovel cables removed from any water pooling areas and free from any rock fall potential?

-

Have you checked cable length left? How much is left and is there a reroute risk?

-

Is delineation visible and to standard?

-

Bunding is to required standard on dumps/roads? (Nothing at toe of bunds and not too steep or Insitu)

-

Have crib huts areas been checked for compliance to standard? (pedestrian separation, park areas, lighting, trip hazards and delineation)

-

Are all hot seating and refuelling bays compliant?

-

General Comments:

Wet weather & Preparation

-

Is wet weather predicted in <5 days

-

Has the daily wet weather enabling plan been actioned in your area of work?

-

Have drains been checked and are they to the correct standard to ensure water pooling risk is managed?

-

Is there a potential for an in-rush of water or pooling water in the work area?

-

Is the Shovel cable above any low lying areas free from immersion risk?

-

Have any sumps in the work area been bunded or demarcated?

-

Has a after wet weather checklist been completed following any rain events?

-

Compliance

-

Has an intersection checklist been completed for all new intersections?

-

Has a water cart checklist been completed and attached?

-

Has grader scarified any ramps or shiny surfaces this shift?

-

What corners and ramps been rejected this shift (Minimum 100m)

Rom Area

-

Rom Area

-

Do we have 2 lane access to the Bin?

-

Are the Ramps up on to coal stockpiles Compliant? (E.g. Correct width, Grade is 10% or less, the ramp exit is square to any through traffic.)

-

Does the ROM work areas have adequate lighting having regard for shadow, contrast and glare?

-

Is stockpile access at 90deg to ROM access

-

ROM area set up, is to standard? (E.g., running tracks graded, dust controlled effectively, appropriate signage in place.)

-

Has there been any ROM/Bin Downtime

Additional Information

-

Comments:

Sign-Off

-

Add signature