Audit Overview

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

01- Housekeeping / Injury Prevention / PPE

Housekeeping

-

Wooden pallets must lie flat, and don't lean on edge.

-

Furniture, ladders, and step-stools are in sound condition.

-

Clear access to eyewash station(s) are maintained.

-

Equipment and tools are put away when not in use, and have a designated home. Carts and pallet jacks are stored safely.

-

Floors surfaces are even, clean, and dry, with no slippery areas.

-

Are walkways adequately clear and free of congestion. All aisles maintained at 30" widths

-

Work spaces are well maintained, have adequate lighting, and are cleaned at end of shift.

-

Outside areas are regularly swept and organized.

-

Stairs and risers are kept clear.

-

No food or open beverage containers present in production areas. Food is consumed in designated eating areas.

-

Production equipment is not used for food preparation.

Injury Prevention

-

Containers are stored safely so as not to cause a tripping or fall hazard. Ensure that materials are removed evenly to prevent collapse or toppling.

-

Hoses and cords must not present a trip hazard or obstruct walkways.

-

Are hand railings and horizontal safety chains are in good condition?

-

All shelving and racking (5' or higher), must either be secured to each other, or if available, to the wall.

-

Breakable or sharp items are firmly secured, when stored overhead.

-

General storage shelves equipment with lips or earthquake barring (if 54" or higher).

-

Large equipment is anchored or restrained.

-

Special hazards have posted signs, such as Corrosive, Rotating Equipment, and Hot Surfaces.

PPE

-

Masks (Covid-19 or N-95) are consistently used by all associates on production floor.

-

Personal Protection Equipment is stored in a clean location.

-

Production staff is wearing proper type safety shoes.

-

Protective gloves are used where required, and are the correct type for the job.

-

Loose clothing or long hair is confined above shoulder length when required (especially around rotating equipment).

-

Respirators (if required), are clean, properly maintained, and correct type. Fit test is attached and current (dated 1 year or sooner).

-

Face Shields, goggles, or glasses, are used when required and kept clean

-

Hearing protection (if required), is correctly worn.

-

Work aprons, shop coats, and disposable coveralls are worn when required.

-

Audio headphones are not worn on production floor.

-

First Aid Kit(s) is checked weekly to maintain adequate inventory levels.

-

Bloodborne pathogens kit (un-used) is located by First Aid Kit.

02 - Emergency Preparedness / Fire Prevention

Emergency Preparedness

-

Evacuation drill is conducted at least once every six months.

-

Evacuation plan is displayed and understood by associates.

-

Emergency phone numbers are kept current, and posted in common area.

-

Emergency exit doors are visibly marked with lit signage.

-

Exit and exit pathways are clearly marked for emergency evacuation purposes.

-

Exit pathways and doors must be kept clear (30") of tripping hazards and obstructions.

-

Exit doors can be opened easily from the inside.

Fire Prevention

-

Fire alarm system functions normally and can be heard from all locations within the building.

-

Flammable materials are not stored next to exit doors.

-

All materials are kept 18" or more from sprinkler heads.

-

Fire extinguishers are hung off the floor and remain readily accessible with 30" clearance.

-

Fire extinguishers are inspected monthly with inspection date noted. Serviced annually by qualified vendor.

-

Propane tanks are in good condition (eg. valves, fittings, gauges, not cracked, etc).

-

Propane powered industrial equipment trucks have been verified to have good hose and fitting connections.

-

Propane tank storage container has protective front, back, and sides.

-

Propane tank storage is clearly marked with proper safe handling procedures.

-

Flammable liquid cabinets are properly labeled.

-

Flammable liquid cabinets are equipped with self-closing doors, or have UL rating.

-

Flammable liquid cabinets are properly vented.

-

Static bonding and grounding used when transferring flammable liquids.

-

Non-sparking electrical equipment used where flammable liquids present.

03 - Electrical Safety

-

All 110 volt plugs require a grounding plug.

-

Extension cords are not used as replacement for permanent wiring.

-

Electrical panels require at least 36" of frontal clearance, and 30" width. All panels must be labeled.

-

Electrical cords do not have any exposed insulation, splices, cuts or frayed wires. No wire nuts or tape used outside of conduit.

-

Plugs, sockets, switches, and cover plates are free from damage.

-

Tension relief is required on flexible electrical cords to eliminate strain on connections.

-

Disconnect switches must be legibly and durably marked to indicate the purpose.

-

Materials are not stored on top of electrical boxes, transformers, or service panels.

-

Electrical equipment is shielded from overhead liquid sources.

-

Breaker box doors remain closed when not in use.

-

On and Off electrical control switches are provided for all equipment.

-

Emergency safety switches have been tested every 6 months.

-

Electrical control switches are labeled, and indicate what they control.

-

Floor heaters are plugged directly into wall socket, and have rollover kill switch.

-

Light bulbs at or below 7 feet have protective shields.

04 - Chemical Safety

-

All containers containing wastes, universal wastes, or process materials are in good condition, with no visible signs of leakage, and are clearly labeled.

-

Drip pans are used to prevent spillage.

-

Container labels identify the contents by name or chemical composition.

-

Container labels must be complete, clearly legible, and must include hazard warnings.

-

If a container can't be labeled, a sign, placard, batch ticket or process sheet must be utilized to identify container contents and hazards.

-

Lids and caps replaced on all chemical containers (including wastes) when not in use.

-

Locally kept SDS documents are maintained, current, and easily available to staff.

05 - Machine Safety

-

Existing guards in good condition.

-

Starting and stopping devices within easy reach of operator.

-

Noise level is managed.

-

Materials are not stored permanently on top of Equipment, so as not to create fall hazard.

-

Mixers, presses, and other production equipment are staged safely when not in use. Mixers should be stored in down position when not in use.

-

Bending or stooping is not required.

-

Pneumatic and hydraulic hoses are protected and free of damage.

-

Propane tanks are secured from falling over or being damaged.

-

Cranes/Hoists/Dollies are available, and are in good working condition.

-

Detectors and alarms maintained in proper working condition, tested periodically, and documented.

-

Equipment and tools are in working order. Broken equipment is locked out, and broken tools are removed from the production floor.

06 - Guarding and LO/TO

-

Required guards are in place at all times when operating equipment and powered hand tools.

-

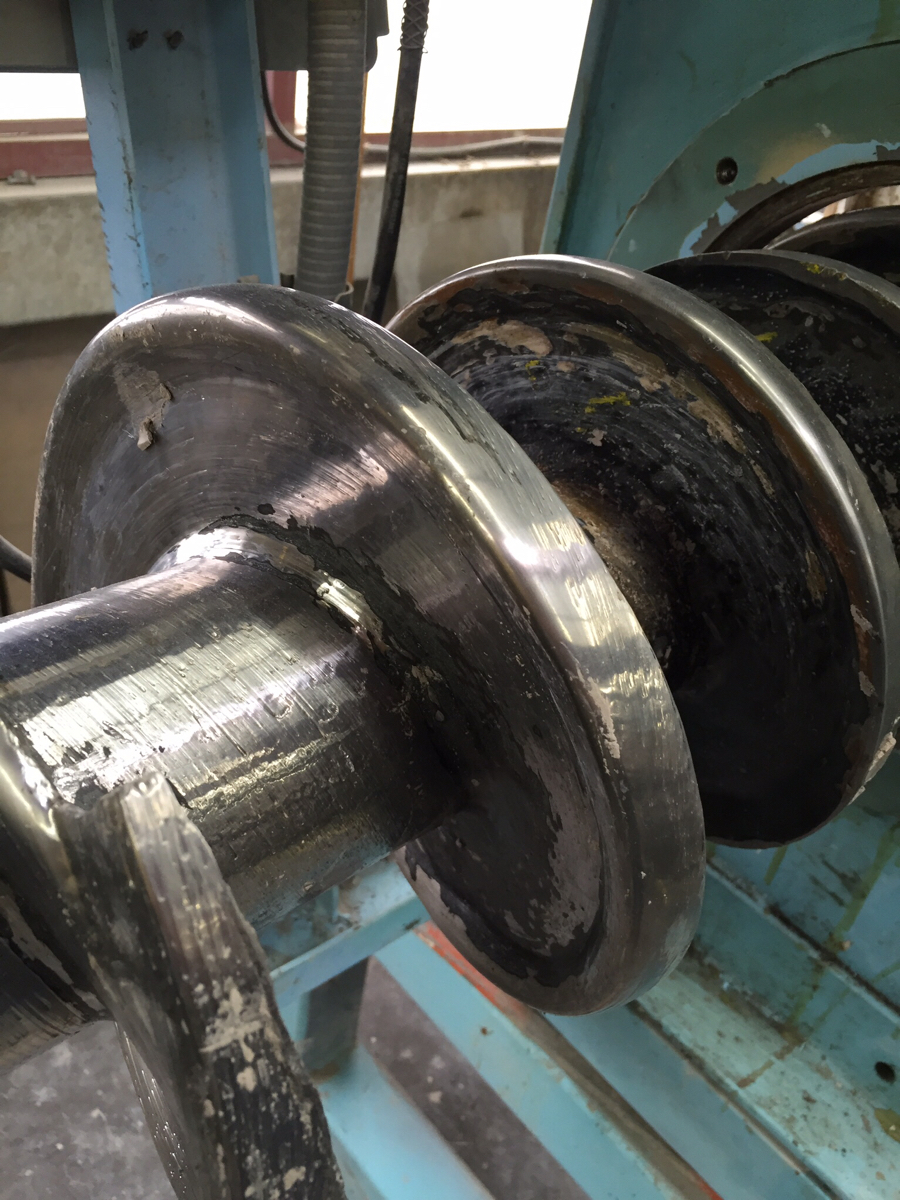

Pinch and shear points, rotating parts, flying chips, sparks, etc, must be effectively guarded by physical barriers, presence or pressure sensing devices, electrical interlocks, or other means.

-

Guards that require both hands to operate properly must not be by-passed.

-

Adequate visibility is maintained through guards, as necessary.

-

Lockout procedures are implemented and followed.

-

Broken equipment is fully tagged and locked out, per LO/TO procedures. Smaller broken items are removed from production floor.

-

Compressed air blow off nozzles must have back pressure relief holes in the end of each nozzle.

-

Sharp edges at or below 7 feet are identified by striping or padding.

-

Safety shielding is used for any operation having explosion or implosion potential.

-

Lock-out tags are available. Maintenance repair tags are available?

07 - Environmental

-

All waste streams are managed correctly.

-

Exhaust hose/flexible ducting used to contain processes in good condition, with no holes or disconnected sections.

-

Liquid and dry spills are cleaned up quickly.

-

Spill response kits are adequately stocked and in good condition.

-

Designated oily rag containers are available and utilized.

-

Designated oily rag containers are clearly marked and recognizable.

-

Oily trash and rag containers are kept closed.

-

Chemical-contained trash and rags are collected separately from oily trash and oily rags.

-

Waste Disposal Procedures are available in work areas where this waste is generated.

-

Solvent sink is in good working order (maintenance shop only).

-

Solvent since area is labeled with operating instructions (maintenance shop only).

-

Used solvent is stored and/or discarded with cover (maintenance shop only).

-

PPE is used when operating Solvent Sink (maintenance shop only).

08 - Pressurized Systems / Compressed Gas Cylinders

-

Compressed gas cylinders contents labeled.

-

Cylinders are upright and properly secured.

-

Lines are labeled as to contents and flow direction where they enter or emerge from building, at cylinders, manifolds, valves, drains, vents, meter connections, tees, and where they change direction.

-

Flow restrictor is in place on all toxic or flammable supply lines. Some plants have individual restrictors.

-

Supply lines are supported at least every five feet.

-

Access to equipment, valves, regulators, etc. adequate for use.

-

Regulator and gauge plates not cracked or missing.

-

Line gauge pressure in use falls in middle third of gauge's total range.

-

Hot water heater relief device is tagged and indicates current inspection (1 year or less).

-

Regulators and manifolds secured with brackets.

-

Solid front/back-release or shielded pressure gauges used on all regulator and pressure systems.

-

Oxidizer and flammable cylinders in storage, separated 20 feet or more, or an approved 1/2 hr firewall.

-

Cylinder valves turned off when not in use.

-

Protective caps installed on regulator fittings and supply lines when disconnected from the cylinder or other supply.

-

Cylinders stored with valve protection caps in place when disconnected.

-

Pressurized equipment provided with relief devices.

-

No valves installed between pressurized systems and relief devices unless there is a written procedure that requires valves to be locked open during normal operation.

-

Pressure relief devices pointed away from potential occupied areas, in a safe direction.

09 - Fume Hoods / Local Exhaust Ventilation

-

Hoods clean and orderly.

-

Annual inspection by Maintenance personnel conducted and valid for 1 year or less and is posted.

-

Maximum hood sash opening marked and adhered to.

-

Hood vent flaps operate properly.

-

Hood walls/back free of holes with access panel covers in place.

-

Chemicals and equipment set back at least 6 inches from sash and set back properly marked.

Summary

-

Overall comments supporting safety observations.

-

Provide any examples of best practices demonstrated or noticed during safety audit walkthrough.

-

Name of primary auditor conducting walkthrough.