Title Page

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Electrical Safety Minimum Requirements

-

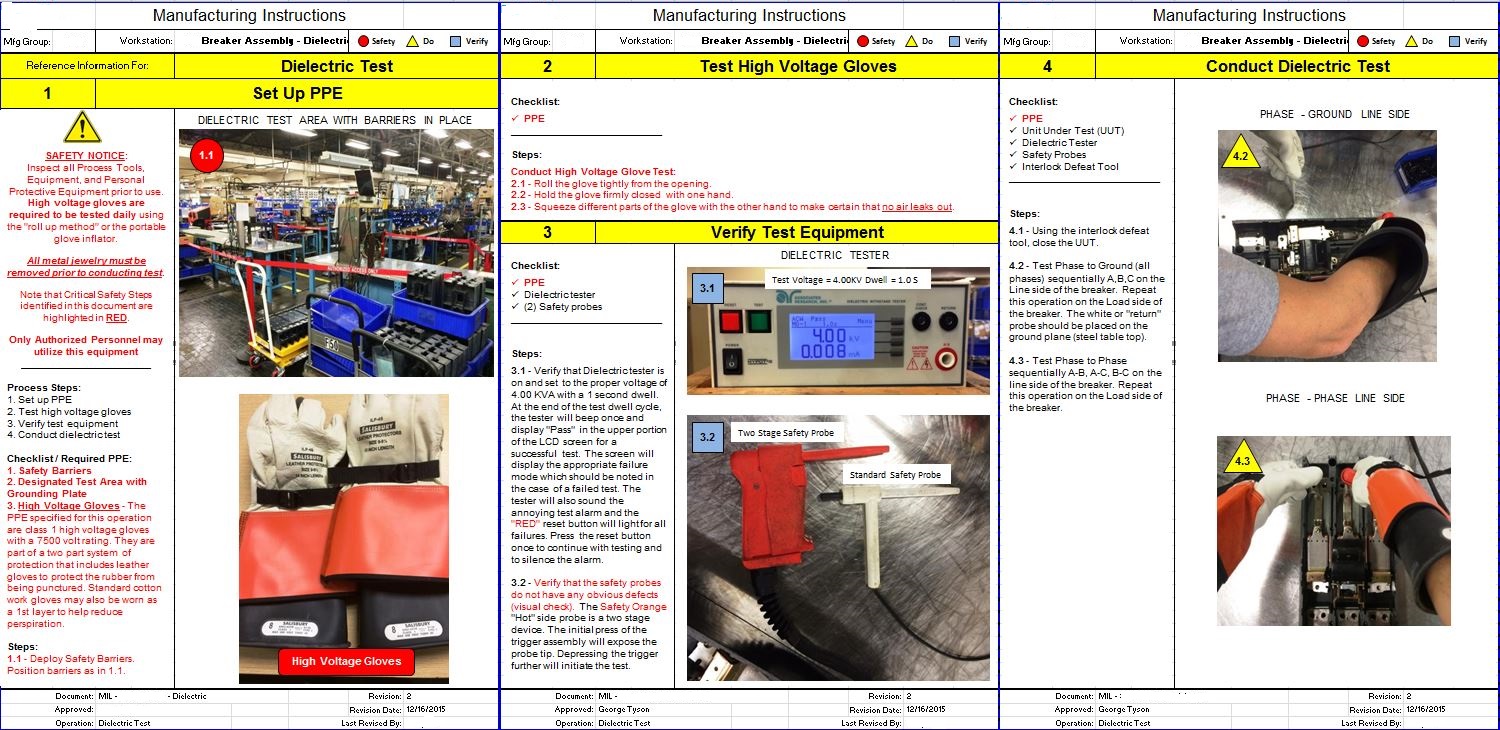

Do written Standard Work test procedures exist for each testing/troubleshooting task and are they posted in the work area. Are all tasks performed in accordance with the Standard Work?

-

Standard work example

-

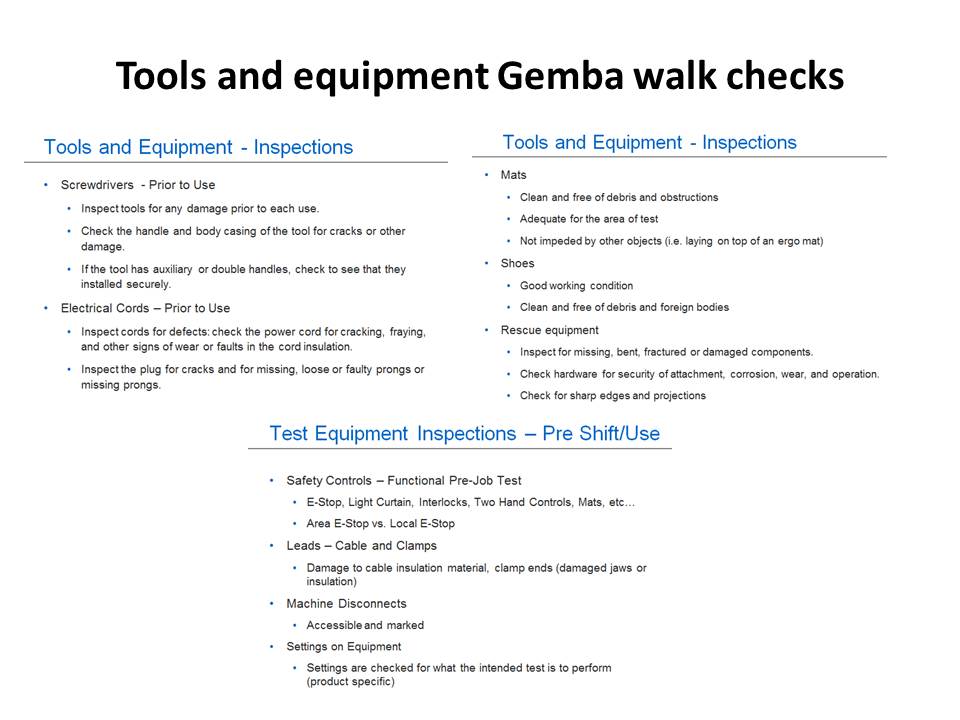

Are all tools and test equipment used within the original design specifications and are they in good working condition?

-

Test equipment and tool info

-

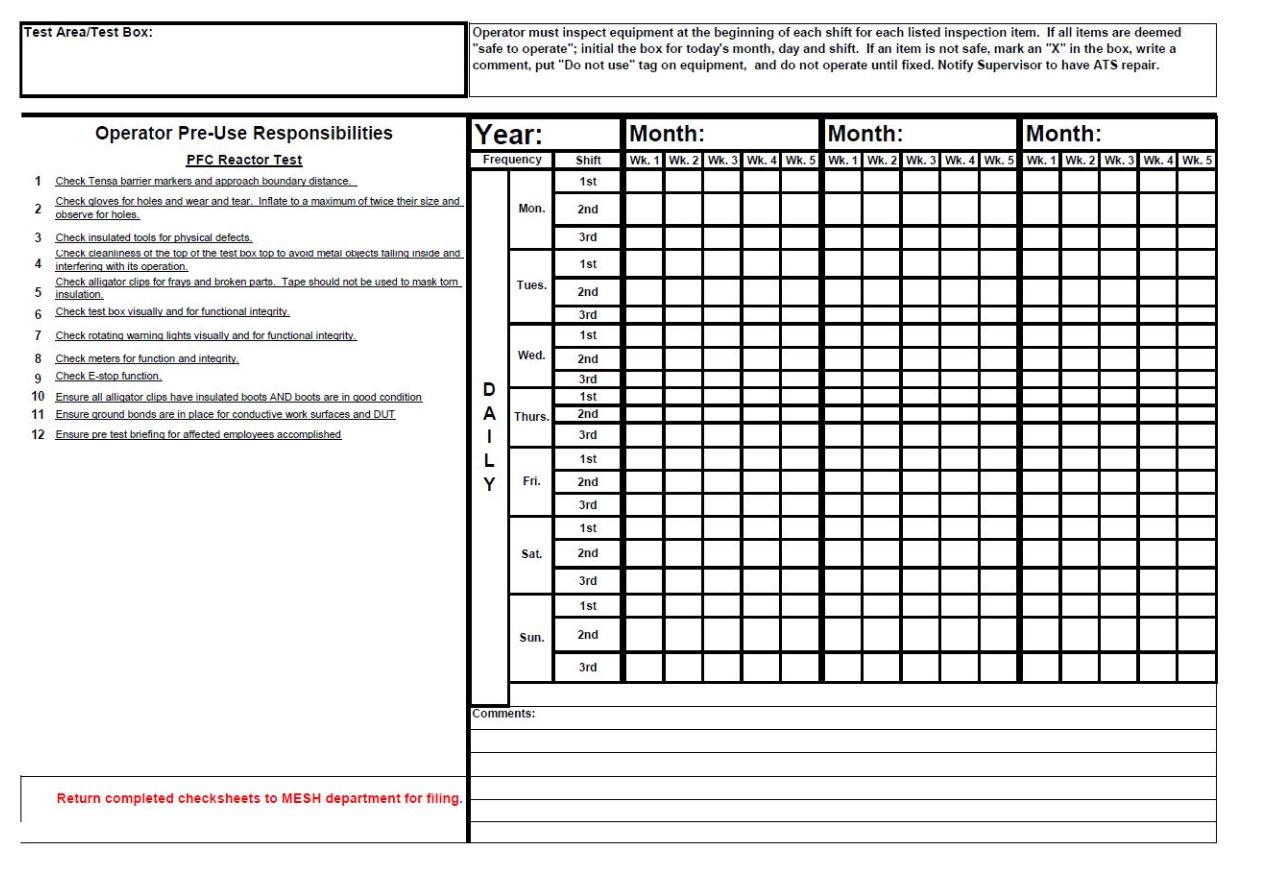

Are written pre-use checklists in place at the workstation and include all tools, equipment, PPE and safety equipment checks?

-

Example of pre-use

-

Is adequate medical equipment to address the potential injuries associated with the test equipment in place and are operators trained in their use?

-

Example of medical equipment

-

All electrical testing and troubleshooting is performed in an authorized, access controlled and/or designated area.

-

Example of authorized test area

-

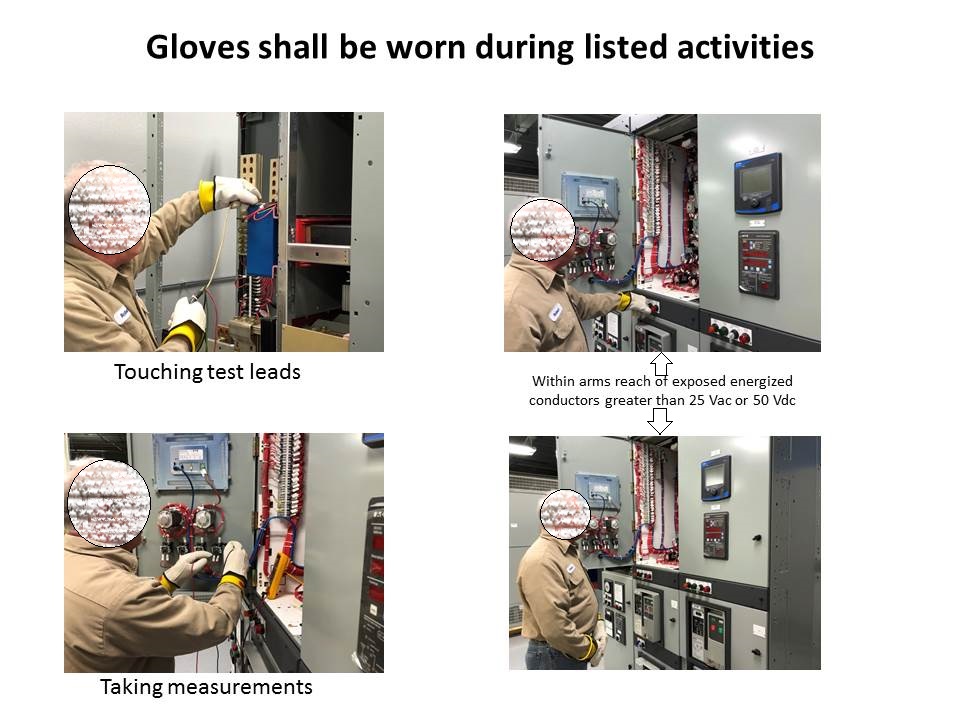

PPE for shock hazard for exposure to voltages > 25 Vac or > 50 Vdc is used and is rated for the exposure level (unless equipment is labeled as having been certified as remediated).

-

Glove usage example

-

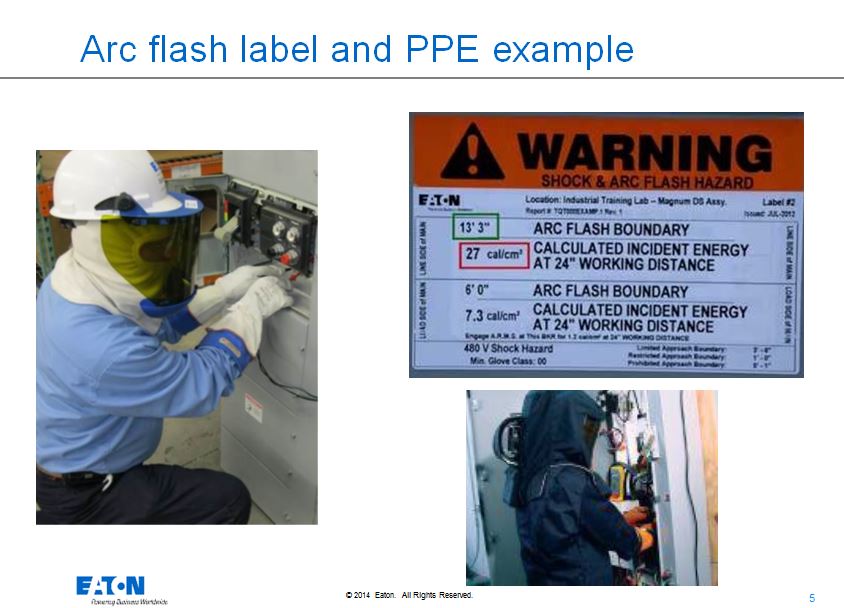

PPE for arc flash hazard is used and rated for the maximum incident energy level. Sources are labeled with the maximum incident energy which they are capable of producing.

-

Arc flash info

Risk Assessment & Engineering Controls

-

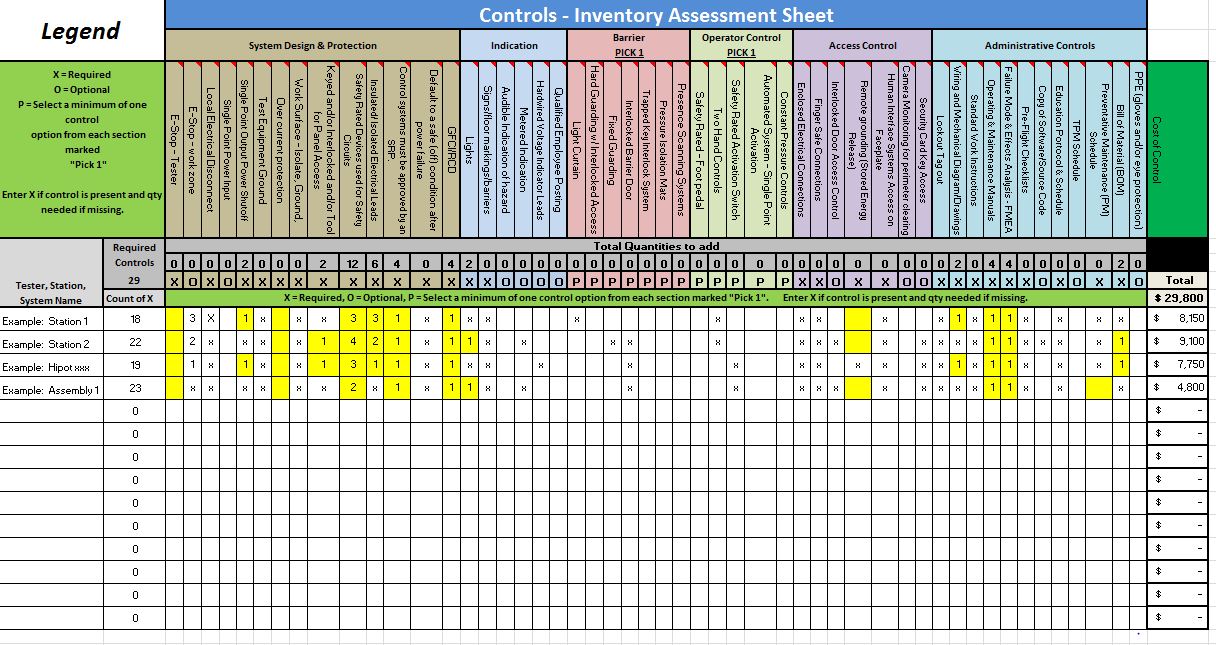

Has the test equipment been evaluated for shock hazard using the site's "Equipment Design Electrical Safety Controls Assessment" Tool.<br>Are action Plans in place that documents the tasks to be taken, target dates, estimated costs and the lead person responsible for addressing each of the missing safety controls from the assessment tool?

-

Example of controls assessment

-

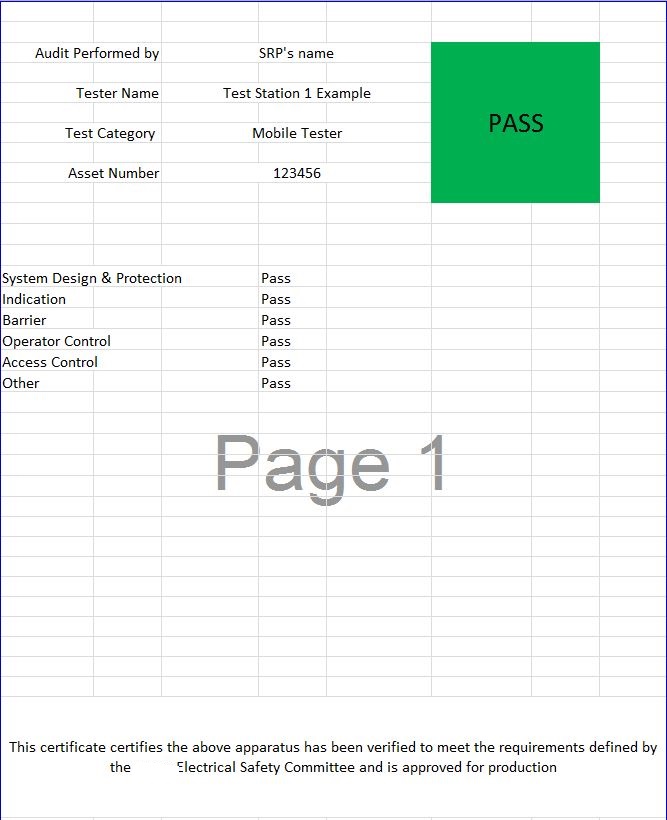

Has the "Controls Verification Checklist" been completed with passing results, and has the Certificate been posted on the test equipment?.

-

Example of Verification tool

Administrative Controls-Personal Protective Equipment

-

Does each electrical test operator possess their own set of PPE - exception being for infrequently used PPE?

-

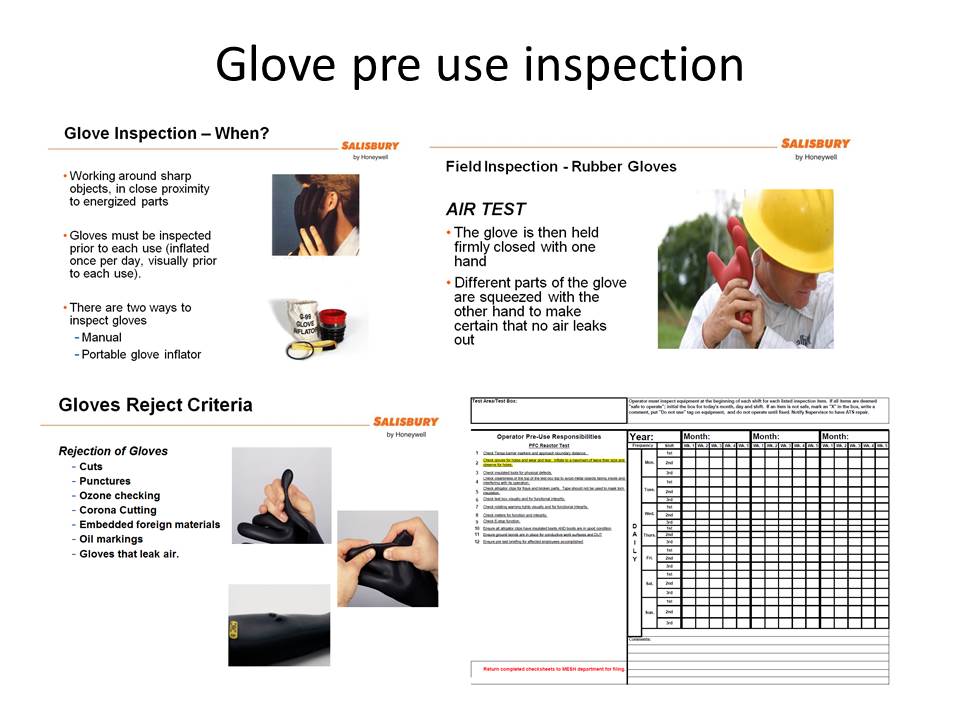

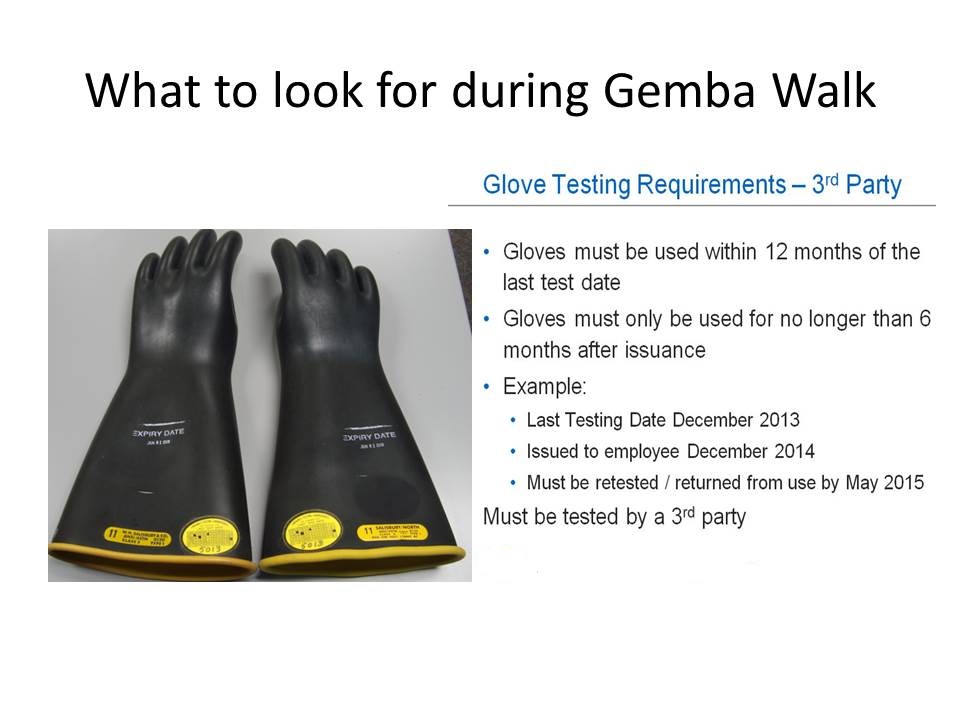

Are electrically insulating gloves air pressure tested before each day’s use and after any incident that could be suspected of having caused damage?

-

Glove inspection info

-

Have rubber insulating gloves been electrically tested within the past 6 months?

-

Glove inspection info

-

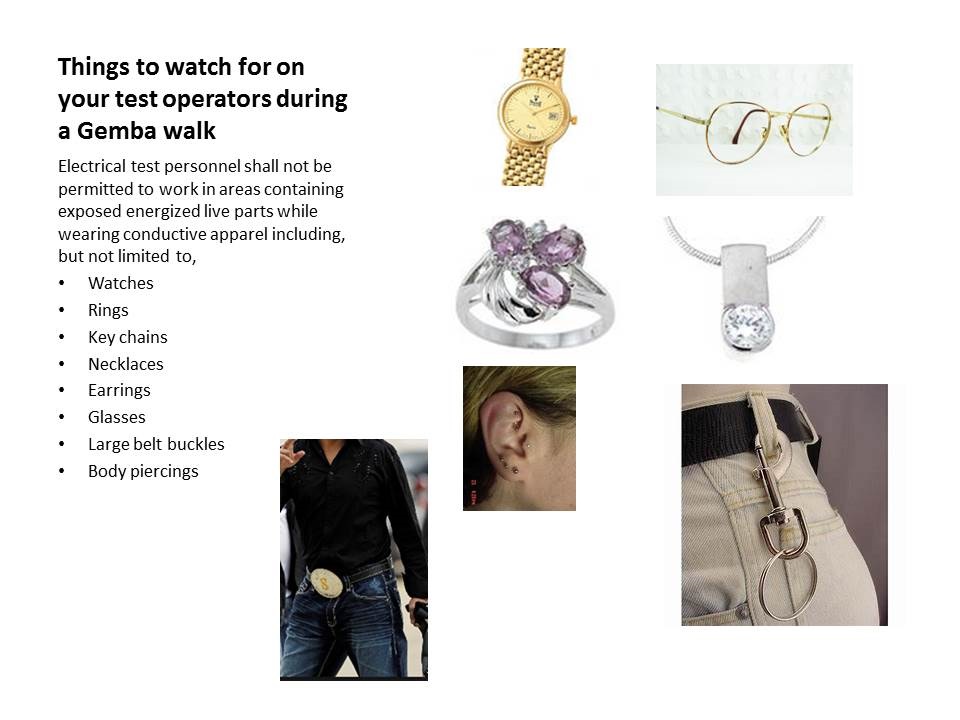

Are conductive articles (jewelry, necklaces, watches, large belt-buckles, etc.) removed while conducting electrical testing?

-

Conductive article info

Administrative Controls-Lockout/Tagout

-

Are all necessary referenced documentation (LOTO procedures, Mfg Instruction Leaflets (IL), Equipment manuals, etc.) available as required.

-

Example LOTO area

-

If qualified to perform LOTO, the employee can demonstrate & explain the verification steps.

Administrative Controls-Employee Training

-

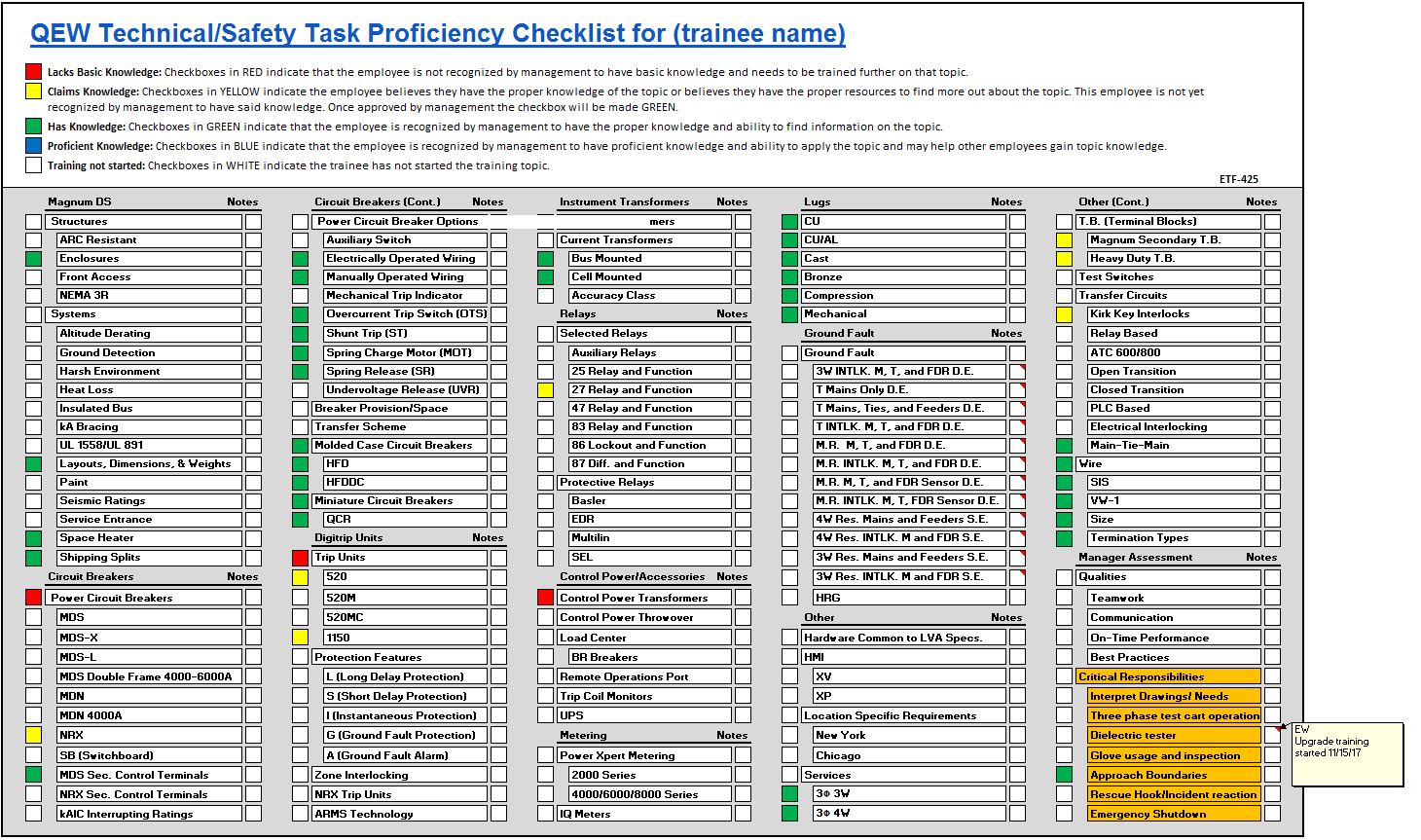

Is there documentation that outlines the required training for operators to be qualified to work at the electrical test station?

-

Skills inventory and training example

-

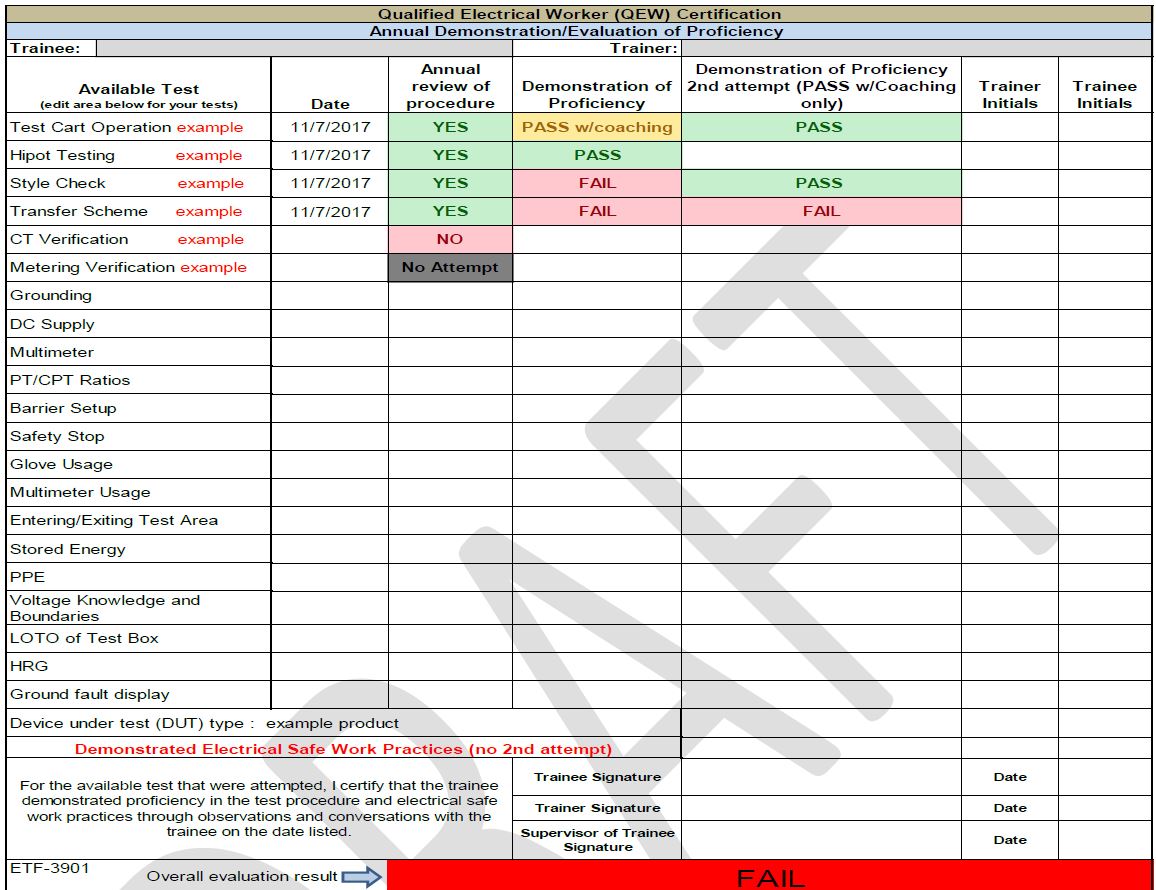

Has the operator completed all the required training (including demonstration/evaluation) to be qualified to work at the electrical test station?

-

Demonstration/evaluation example

-

Where electrical energy storage is possible (capacitors, batteries etc.), is the employee qualified to perform Zero Energy Verification (ZVV) processes. For qualification, the employee has a) access to required the test procedure documents and equipment, and b) records of having completed training for conducting ZVV?

-

Also ask if Megger testing is sometimes accomplished in this area. (Megger testing has stored energy potential)

Ask for training records ETPE-ZV1 -

Where dielectric testing is conducted, is the employee qualified via a) access to the required test procedure documents b) records of completing the required training, and C) Evaluation/demonstration of task proficiency being competed?

-

Ask to see record of Eaton University training module ETPE-DT1

Administrative Controls-Other Requirements

-

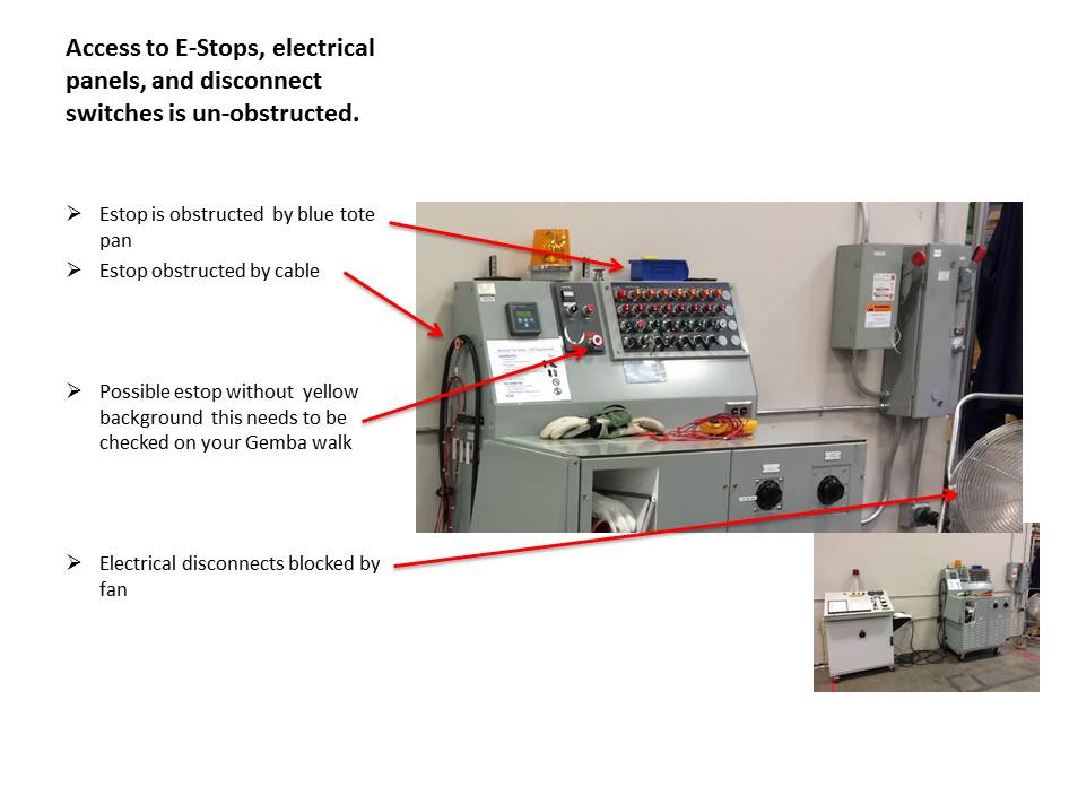

Is access to E-Stops, electrical panels, and disconnect switches un-obstructed?

-

Example of test area E-stops, panels, and disconnect issues

-

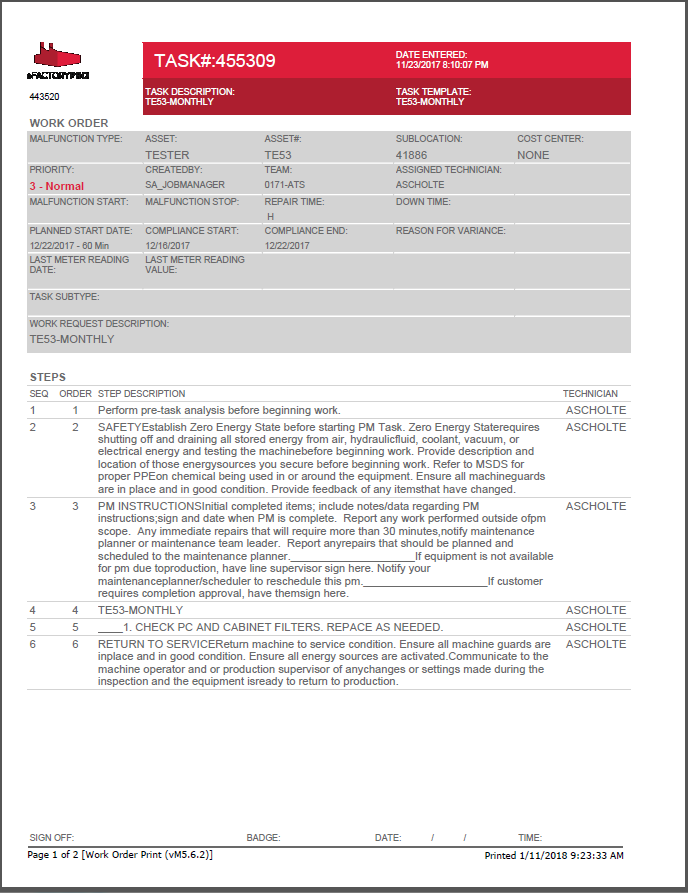

Is a Preventative Maintenance schedule is in place and conducted on a regular basis, as evidenced by a tracking sheet posted on the equipment?

-

Example of maintenance program

-

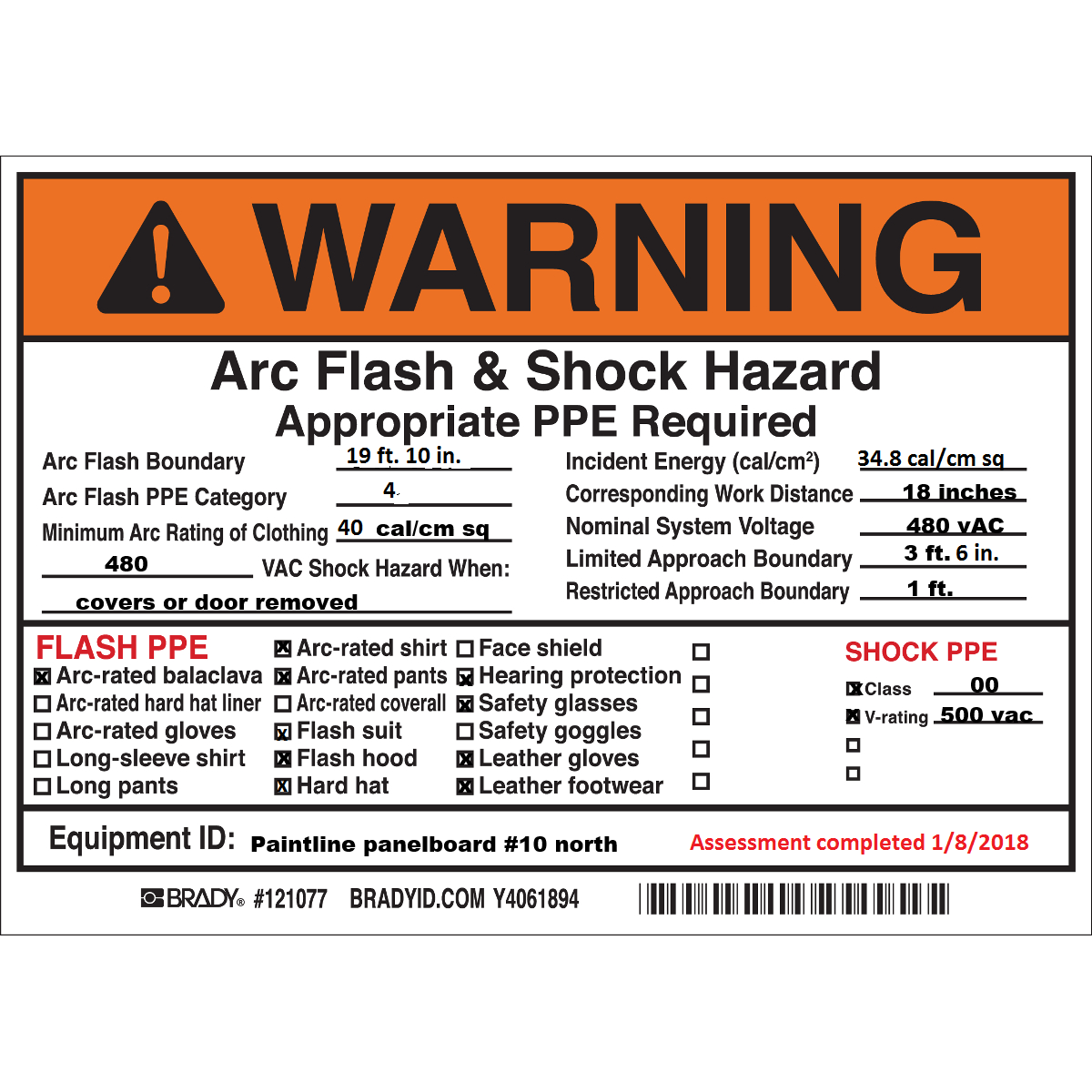

An Arc Flash assessment 1) has been conducted within the last 5 years for Service Entrance equipment down through equipment rated 240 V nominal, and 2) the results have been implemented including the posting of the required label showing approach boundaries, arc flash energy, and the personal protective equipment (PPE) necessary.

-

Example of arc flash label generated from arc study

-

Does equipment appear to be visually free from damage or signs of having been tampered with?