Title Page

-

Job Address / Title

Safe Work Method Statement (SWMS) - Part 1

-

Activity: Electrical Wiring - Low Voltage

Review Number

-

Review Number: 1

-

Company Name: WRE Electrical PTY LTD

Address: 572 Cummins Lane, Broken Hill 2880

ABN: 74627943337

Company contact: Wiremu Roberts

Position: Director

Phone No: 0415598146

Relevant workers must be consulted in the development, approval and communication of this SWMS.

-

Wiremu Roberts ( Director )

SWMS APPROVED BY: (Employer/PCBU/Director/Owner)

-

Wiremu Roberts ( Director )

Project Details

-

Job Address:

-

Job Description:

-

Principal Contractor Company Name: Wiremu Roberts

WRE Electrical PTY LTD -

Date SWMS provided to Principal Contractor:

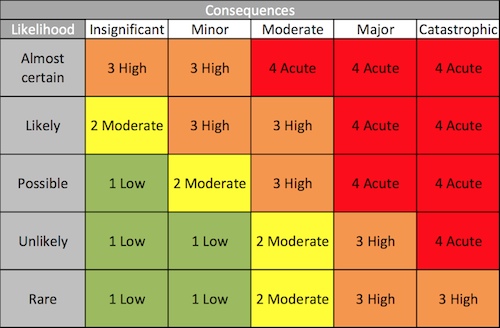

Risk Assessment Matrix

-

- 4A: Acute DO NOT PROCEED > requires immediate attention. Introduce further high-level controls to lower the risk level.<br><br>- 3H: High > Review before commencing work. Introduce new controls and/or maintain high-level controls to lower the risk level. Monitor frequently to ensure control measures are working. <br><br>- 2M: Moderate > Maintain control measures. Proceed with work. Monitor and review regularly, and if any equipment/people/materials/work processes or procedures change.<br><br>- 1L: Low > Record and monitor. Proceed with work. Review regularly, and if any equipment/people/materials/work processes or procedures change.

-

Hierarchy of Controls

-

• Elimination - Risk will be eliminated where possible<br> ↓<br>• Substitution Isolation Engineering - Where risk remains, one/combination of controls will be used<br> ↓<br>• Administrative - Where risk remains, administrative controls will be used<br> ↓<br>• Personal Protective Equipment (PPE) - Where risk still remains, it will be reduced as far as reasonably practicable with use of PPE.

Activity: Electrical Wiring - Low Voltage - Part 2

-

Overall Risk Rating after Controls

SWMS Scope

-

SWMS Scope: This SWMS relates to low voltage, non-live electrical connection, equipment and installation works.

This SWMS does not cover hazardous manual tasks, hazardous chemicals, traffic management, working in confined spaces or working with electrical equipment in sufficient detail. Dedicated SWMS should be developed for these tasks, and for any risks not covered in this SWMS.

Personal Protective Equipment (PPE) Ensure all PPE meets relevant Australian Standards. Inspect and replace PPE as needed.

-

Foot Protection

-

Hearing Protection

-

High Visibility

-

Head Protection

-

Eye Protection

-

Face Protection

-

Hand Protection

-

Protective Clothing

-

Sun Protection: Broad brimmed hat, UV rated clothing, SPF 30+ sunscreen, tinted safety glasses with adequate UV protection

-

Rings, watches, jewellery that may become entangled in machines must not be worn. Long and loose hair must be tied back.

-

Insulating gloves, insulating mats or sheeting, safety helmet, safety glasses, face protection and appropriate clothing (i.e. long sleeve cotton shirt and long pants) If glasses are worn ensure they are not metal as they may conduct electricity current.

High Risk Construction Work

-

This work activity may involve the following “High Risk Construction Work”:

• Moving Plant

• Pressurised gas distribution mains or piping chemical, fuel or refrigerant lines energised electrical installations or services

• Confined Spaces

• Asbestos

• Working at heights greater than 2 Metres, including work on telecommunications towers

• Structures or buildings involving structural alterations or repairs that require temporary support to prevent collapse.

Job Step: Planning

-

Consultation in relation to hazards and risks. Ensure:

- Consult with the person you are carrying out the work for on the potential hazards and risks associated with the task

- If represented by an elected Health and Safety Representative (HSR), they must be included in any consultation

- Any other persons on site who are affected by the same matter are consulted and co-operative arrangements are made

- Document consultation and action items. -

Liaise with Principal Contractor to establish that the following on-site systems and procedures are in place:

- Health and Safety rules

- Induction for all workers – site specific

- Supervisory arrangements

- Communication

- Injury reporting

- Hazard reporting

- Personal Protective Equipment

- Exclusion Zones

- Risk Assessments

- SWMS and JSA’s. -

Assess the exposure of worker/s to noise, including the frequency of exposure to noise levels that exceed the legislated Exposure Standard while operating the equipment associated with the low voltage electrical wiring and determine required controls such as Audiometric Testing and PPE. Refer to Noise Control SWMS for detailed information regarding the prevention of hearing loss and legislative requirements.

Audiometric Testing: If Audiometric testing is required it must:

- Be provided within three months of the worker commencing work

- Be started before people are exposed to hazardous noise (such as new workers or those changing jobs)

- Provide a baseline as a reference for future audiometric test results

- Have follow-up tests carried out at least every two years.

- Be carried out with consultation with your workers and their health and safety representatives

- Be carried out by competent persons in accordance with the procedures in the relevant Australian Standard

- Workers should be given the results of audiometric testing accompanied by a written explanation of the meaning and implications. -

Develop site-specific rescue procedures/SWMS.

Ensure all workers on-site are trained and familiar with emergency and evacuation procedures.

Ensure safety observers/spotters or others required to respond in the event of an emergency have undertaken training within the past 12 months in rescue and resuscitation procedures.

Electrical incidents should be reported to The Regulator.

All workers to be trained and competent to safely work with low voltage electrical wiring. Training should include:

- Site-specific inductions

- Training in this SWMS

- Nature of hazards / risks

- 1st aid

- Emergency procedures. -

Electric work (as defined by relevant Electrical Safety Acts) must only be conducted by competent person such as licensed electrician. Check your State for details.

Conduct an assessment of intended work site and develop a task specific SWMS. Include:

- Proximity to live electrical equipment

- Prospective fault levels

- Site conditions

- Asbestos identification (if applicable)

- Weather conditions

- Noise

- Lighting

- Spotters/safety observers

- Permits

- Proximity to vehicle/pedestrian traffic

- Working environment (such as areas with reduced mobility – behind switchboards, roof spaces etc.)

- Working at heights, confined spaces etc. (workers must have appropriate licences)

- Possibility of inadvertent operation of equipment that is being worked on (LOTO procedures)

- Disruption of services. -

Develop risk controls where applicable.

Note: LOTO (Lock out/tag out) procedures must be established. Include:

- Shut down

- Identify all energy sources

- Identify all isolation points

- Isolate all energy sources

- De-energize all stored energies

- Lock out all isolation points

- Complete and attach Danger Tag and lock(s) at each isolation point

- Test by “trying” to re-activate (without exposing the tester or others to risk). -

Person responsible to implement control measures: Wiremu Roberts

Job Step: Preparation

-

Working outdoors. Ensure:

- Suitable protective clothing

- Sun brim on hard hat

- Safety glasses - UV Rated

- Use 30+ sunscreen on exposed skin areas

- Adequate drinking water

- Access to shade during breaks

- Be aware of snakes if work area has long grass or dense vegetation

- Adequate breaks

- Check weather conditions – do not work in extreme weather. -

Ensure tools/equipment are appropriate for job, tested, functional and designed for purpose.

Testing Equipment:

- Good condition and working (particularly, leads, probes, clips)

- Clean, no cracked or broken insulation

- Suitable for all potential fault voltages

- Multimeters, RCD performance tester, earth loop impedence testers, voltage testers, insulation resistance tests etc, are tested for accuracy

- Suitable for hazardous/flammable areas if required

- Tested to work before use.

Tools:

- Properly designed and insulated hand tools

- Power tools Class II type (double insulated) as a minimum

- Tested and tagged, within date.

Note: The use of metallic measuring tapes, rulers and tools with exposed conductive parts should be avoided when working on or in the vicinity of live electrical equipment. -

If work involves Confined Spaces: Use Confined Spaces SWMS for information regarding specific hazards involved with working in Confined Spaces.

Examples of confined spaces involved with installing electrical wiring might include ceilings or wall cavities, when these examples meet the definition of a confined space.

Ensure a confined space entry permit is issued for each confined space entry.

Wear appropriate PPE for the specific tasks

Operate all tools and equipment as instructed by manufacturer. Use equipment SWMS as appropriate.

Ensure record keeping is maintained as per requirements for work in confined spaces.

When working in ceiling spaces:

- Avoid entering ceiling space – work from solid platform. If required, to enter, ensure joists/purlons are capable of holding weight of person and equipment and tested for Load capacity

- Don’t stand on fragile areas – such as plasterboard

- Walk along planks and crawl if required

- Ensure adequate ventilation

- Do not enter ceiling space if it is very hot

- Do not enter ceiling space if working alone. -

Ensure adequate communication with stand by person outside the ceiling space.

If using an Elevated Work Platform (EWP), follow EWP SWMS for work.

Ladders:

- Load rating of at least 120kg

- Correct size and length for job

- No damage, clean and dry

- Secured to work site (base and top)

- Metallic, wire- reinforced or conductive ladders should not be used around live electrical equipment

- Face ladder when ascending/descending

- Ensure 3 points of contact remain on ladder at all times

- Ensure only 1 person working from each ladder.

Do not:

- Attempt to move or extend ladder when on it

- Slide down stiles

- Step up or down two or more rungs at a time

- Use step-ladders to support planks

- Leave unattended when in position. -

WARNING: Note: Any dirty or damp ladders can become conductive.

Barriers and Insulating Mats:

- Should be marked to comply with relevant Australian Standard

- Inspected for any defects

- Suitable material to be effective.

Avoid jewellery, exposed metal zips, watches, and metal-framed glasses. If required to be worn, ensure properly insulated. Inform site supervisor / property owner of any disruption to electrical services. Ensure disruption will not impact on emergency or medical services, which may be reliant on supply of electricity. -

Person responsible to implement control measures: Wiremu Roberts

Job Step: Pre- start Inspection

Hazards include:

-

- Asbestos - exposure

- Electricity - Energised electrical equipment / installation

- Falls on the same level

- Objects on ground

- Uneven or slippery surface

- Work around moving mobile plant

- Work outdoors

- Hazardous Manual Tasks

o awkward, twisting, bending positions

o lifting, carrying, or putting down objects

o pushing, pulling objects.

Risks include:

-

- Inhalation of dust or fibres - asbestos etc.

- Dust inhalation

- Electrocution / Electric shock

- Explosion / Fire / smoke

- Exposure to toxic/hazardous atmosphere

- Trip, slip, fall on same level causing bruises, sprains, strains, fractures

- Muscular stress/ Musculoskeletal Disorder.

Control Measures to Reduce Risk

-

Risk Ratings Before Control: 3H

-

Hearing protection, ensure:

- It is worn by all persons throughout the period of exposure to noise

- It is suitable for the type of working environment and the work tasks

- It s comfortable and correctly fitting for the worker

- It is regularly inspected and maintained to ensure it remains in good, clean condition.

Follow LOTO procedures. Ensure:

- Circuit breakers, switches and combined fuse switch units are locked out

- Use locks or suitable temporary securing devices (that cannot be disrupted)

- Where isolation is done remotely, ensure all relevant conductors are bonded together and to general mass of earth at site. -

Note: Temporary bonding conductors must always be bonded together and attached to the general earth before attached to any de-energized component of the electrical installation.

Removal of the bonding conductors must be carried out in reverse order. Suitable PPE should be used when attaching or removing temporary bonding conductors.

Ensure:

- All equipment to be used meets Australian Standards 3000 Wiring Rules

- Site plan is available and on site

- Wire, Transformers, fittings and fixtures are ordered and ready to be installed.

Note: If asbestos is suspected or identified in the work zone during the inspection – do not progress with work - notify supervisor / property owner. Ensure correct safe work procedures in place before work commences. Refer to Asbestos SMWS for further information in regard to working near/with Asbestos. -

Person responsible to implement control measures: Wiremu Roberts

-

RIsk Ratings After Control: 2M

Job Step: Operation - wiring

Hazards include:

-

- Adverse weather - hot, cold, windy, wet

- Asbestos - exposure

- Confined Space

- Electricity - Energised electrical equipment / installation

- Falls from a height

- Falls on the same level

- Objects on ground

- Uneven or slippery surface

- Noise - single, sudden

- Work around moving mobile plant

- Work outdoors

- Insects, spiders (floor, wall & ceiling cavities)

- Hazardous Manual Tasks

o awkward, twisting, bending positions

o lifting, carrying, or putting down objects

o pushing, pulling, throwing, pressing objects

o repetitious movements

Risks include:

-

- Heat exhaustion, sunstroke, dehydration

- Being struck by lightning causing burns, electrocution

- Inhalation of dust or fibres - asbestos etc.

- Entrapment - confined space

- Dust inhalation

- Electrocution / Electric shock

- Explosion / Fire / smoke

- Exposure to toxic/hazardous atmosphere -

- Falling from height causing serious injury or death

- Trip, slip, fall on same level causing bruises, sprains, strains, fractures

- Hearing Loss

- Run over/struck by mobile plant causing serious injury or death

- Entrapment

- Crush injuries

- Burn – Sunburn

- Insect, spider bites or stings

- Muscular stress/ Musculoskeletal Disorder

Control Measures to Reduce Risk

-

RIsk Rating Before Control: 3H

-

Hazardous Manual Handling:

- Avoid long periods of repetitive movements

- Avoid awkward and sustained positions

- Avoid prolonged sitting

- Use mechanical lifting aids when possible

- Use two or more people for lifting & moving heavy / awkward equipment

- Regular breaks.

Follow task specific SWMS.

If there is likelihood that asbestos (in switchboards) will be disturbed (drilled, cut, and removed), develop specific SWMS for that task.

Transformer: The power behind every low-voltage system is the transformer. It plugs into a Ground Fault Circuit Interrupter (GFCI) protected outdoor electrical outlet and steps down the house current from 120 volts to 12 volts. -

NOTE: Transformers are rated according to the maximum wattage output.

Low-Voltage Electrical Cable:

- Low-voltage cable is available in 12-, 14-, and 16-gauge. The lower the number, the thicker the wire and the greater its capacity

- Which cable to use depends on the size of the transformer and the length of cable needed

- Check with the lighting manufacturer to determine the proper-size cable to use for your specific system.

Laying the Cable:

- Start by laying the light fixtures on the ground where you intend to install them

- Space the fixtures at 2 to 3 metres

- Unroll the spool of low-voltage electrical cable and lay the cable beside the fixtures

- If you come to an obstacle, such as a boulder, tree, or fence, string the cable under or around it

- Use a square blade shovel to cut a trench along the line where you want to place the light fixtures

- Do not need to remove any dirt from the trench

- Set the cable into the trench and push it all the way down to the bottom using a short, narrow piece of plywood

- Do not use the shovel or other tool, you may slice the cable. -

Installing the Transformer:

- Low-voltage cable consists of two insulated stranded-copper wires stuck together

- Peel them apart so you have about 10 centimetres free for each wire

- Then use wire strippers to remove about 15mm of insulation from each side

- Slide the wires through the retaining strap on the back of the transformer and then insert one wire under the A screw terminal, and the other wire under the B screw terminal

- Tighten the screws to secure the wires

Drive a pressure-treated 2 x 6 stake into the ground next to an outdoor electrical outlet

- Attach the transformer to the stake with galvanized or stainless-steel screws

- Secure the cable to the stake with insulated cable staples. -

Connect the Lights:

- Attach a plastic "while-in-use" cover to the outdoor electrical outlet. (This type of cover protects the outlet from rain but allows easy access)

- Plug the transformer's power cord into the outlet

- Connect each light fixture to the cable

- Sharp prongs inside the connectors pierce the cable and make contact with the wires

- Once you've connected the cable, stand up the light fixture and press its pointed stake deep into the ground

- Be careful not to hit the buried cable

- Check to make sure the fixture is straight, then move on to the next

- Once all the fixtures are installed, fill in the narrow cable trench with topsoil and top with grass seed.

On Completion:

- Test and commission the electrical installation as required

- Notify supervisor / property owner of restoration of electrical services. -

Person responsible to implement control measures: Wiremu Roberts

-

RIsk Rating After Control: 2M

Job Step: Maintenance

Hazards include:

-

- Electricity - Energised electrical equipment / installation

- Falls on the same level

- Objects on ground

- Uneven or slippery surface

- Hazardous Manual Tasks

o pushing, pulling objects.

Risks include:

-

- Electrocution / Electric shock

- Trip, slip, fall on same level causing bruises, sprains, strains, fractures

- Muscular stress.

Control Measures to Reduce Risk

-

RIsk Rating Before Control: 2M

-

Ensure all servicing; maintenance and repairs are performed by suitably qualified & competent persons.

Electrical equipment is to be checked after each use and maintained as per manufacturer’s requirements.

Testing equipment is to be maintained as per manufacturer’s manual within time frame required.

Ladders, EWP (Elevated Work Platform), Electrical equipment (drills etc.) hand tools (pliers, wire strippers etc) to be checked after each job, if the equipment has any faults they are to be tagged and locked out until repaired or replaced. -

Person responsible to implement control measures: Wiremu Roberts

-

RIsk Rating After Control: 1L

Emergency Procedures / Emergency Response

-

Emergency Response:

Call 000 immediately then administer first aid to injured person/s. Refer to emergency plan.

Develop and implement an emergency response plan for the site. Include:

- Assembly points

- Communication

- Consultation methods

- Responsible persons

- Emergency contacts - names and phone numbers

- First aid equipment

- Fire Extinguishers – accessible & serviced. -

If electric shock occurs:

- Free person from source of electricity if safe to do so (use dry, insulated materials such as a dry board, belt or clothing)

- Do not touch victim or power source until confirmation that electrical source removed

- When safe, approach victim and determine whether they are breathing.

- Undertake CPR if required.

Victim should seek medical attention, even for minor shock.

Severity of injury depends of strength of current. Example:

1-8mA = non-painful shock sensation

8-15mA = painful shock

15-20mA = painful shock, can’t let go/muscle contraction

50-200mA = ventricular fibrillation

200 + = burns, severe muscle contraction, heart can stop.

Ensure appropriate State Regulator is notified of any incident involving electricity. -

Person/s responsible to implement and follow emergency procedures and control measures: Wiremu Roberts

Review

-

To ensure controls are implemented and monitored effectively:

• Toolbox /pre-work meetings will be undertaken

• Relevant persons will be consulted on hazards and contents of SWMS, work plans and other applicable information

• Control measures will be monitored throughout works:

o Spot checks

o Consultation

o Scheduled audits

• Corrective actions will be recorded and rectified in a timely manner SWMS will be reviewed and updated accordingly (in consultation with relevant persons) -

Ensure all controls are reviewed as per the following:

• If controls fail to reduce risk adequately

• When changes to the workplace or work activity occur that create new / different risks where controls may no longer be effective

• New hazards identified

• After an incident involving work activities relevant to this SWMS

• During consultation with relevant persons indicate review is needed

• A Health and Safety Representative (HSR) requests a review in line with the requirements of the legislation. -

Person/s responsible to implement and follow monitoring and review procedures and control measures: Wiremu Roberts

Relevant Legislation, Codes of Practice:

-

Note: Retain only the legislation references applicable to your state of operation for this SWMS.

Codes of Practice

-

Commonwealth, NSW, QLD, ACT

-

o Work Health and Safety Act 2011

o Work Health and Safety Regulations 2011 -

Commonwealth, NSW, QLD, ACT, NT, SA, Tas.

-

Safe Work Australia (2011):

o Construction Work

o How to Manage and Control Asbestos in the Workplace

o First Aid in the Workplace

o Managing the Risk of Falls at Workplaces

o Managing the Risk of Plant in the Workplace

o Managing Noise and Preventing Hearing Loss in the Workplace

o How to Manage Work Health and Safety Risks

o Hazardous Manual Tasks

o Managing Electrical Risks in the Workplace

o Managing the Work Environment and Facilities

o WHS Consultation, Cooperation & Coordination

Australian Standards

-

o AS/NZS1269: 2005 Occupational noise management

o AS/NZS 4501:2008 (set) Occupational Protective Clothing

o AS4024.1: 1996 Safeguarding of machinery - General principles

o AS 4024.1:2006 Safety of machinery

o AS1473: 1991 Guarding & Safe Use of Woodworking Machinery

o AS.1892.5: 2000 Portable Ladders – selection, safe use and care

o AS 1319:1994 Safety Signs for Occupational Environment

o AS/NZS 3760:2010 In-service safety inspection and testing of electrical equipment

o AS/NZS 3000 Wiring Rules

o AS/NZS 3012:2010 Electrical installations - Construction and demolition site

Reference Documents

-

SafeWork Australia (2011): Managing Electrical Risks in the Workplace

EnergySafe Victoria (1997): Code of Practice: Safe Electrical Work – Low Voltage Installations

Electrical Safety Act 1998 (Victoria)

WorkSafe Western Australia: Electrical Safety Switchboards at Construction sites

Work Cover NSW: Code of Practice for Electrical Practices

Work Cover NSW: Code of Practice for Low Voltage Electrical Work

Work Health & Safety Queensland: Code of Practice: Electrical Works

World Health Organisation: “Dust - Definition and Concepts”

Sai Global: Australian Standard: AS/NZS 3760:2010 In-service safety inspection and testing of electrical equipment

Safe Work Method Statement (SWMS) - Part 3

-

Formal Training, Licences required for workers undertaking this task:

Qualified Electrician or working supervised by one

Appropriate and required tickets -

Plant/Tools/Equipment: (List plant and equipment to be used on the job).

Basic hand tools

battery operated tools

ladders

Worker Sign-off

-

This SWMS has been developed in consultation and cooperation with employee/workers and relevant Employer/Persons Conducting Business or Undertaking (PCBU). I have read the above SWMS and I understand its contents. I confirm that I have the skills and training, including relevant certification to conduct the task as described. I agree to comply with safety requirements within this SWMS including risk control measures, safe work instructions and Personal Protective Equipment described.

Employee

-

Employee/Worker Name and Signature:

-

Signature:

-

Job Role/Position

-

Employer/PCBU/Supervisor: Wiremu Roberts