Title Page

-

Job/Task

-

Date

-

Shift

-

How many techs are required for the task?

-

Login

-

Login 1

-

Login 2

-

Login 1

-

Login 2

-

Login 3

-

Please create a suitable number of OMRAs, with a maximum of 3 techs on each.

-

Location

Before Task

-

Do you have the relevant skills and training for the task?

-

You are only allowed to work a task which you are qualified for. Stop the task if you do not have the relevant training/skills, or if you are unsure.

-

Do you have the correct PPE for the task?

-

STOP WORK: ensure correct PPE is worn before continuing. Please review the task specific Risk Assessment and VSOP for guidance on the correct PPE for the task.

-

What tools and equipment does your task require?

- Handtools

- Mains Powered Tools

- Access Equipment

- N/A

-

Are the Handtools fit for purpose?

-

Do not carry out the task until you have handtools that are fit for purpose. View the RAMS related to the task for more information on the necessary handtools to use.

-

Are mains powered tools fit for purpose?

-

Ensure you are using the correct tools for the task. Refer to the VSOP and Risk Assessment for guidance before continuing.

-

Are Mains Powered Tools PAT tested?

-

Without an in-date PAT test label on the power tool you are not allowed to carry out the task. Quarantine the tool.

-

Carry out a Pre-Use Inspection before continuing.

-

Pre-Use check complete?

-

Do not continue until Pre-Use Inspection is complete.

-

Does this task require LOTO?

Work Location

-

Is there a Risk to Others? (e.g. Associates, Contractors, Visitors, other Technicians)

-

Have you Cordoned Off the Area?

-

CAUTION: please ensure others are protected from harm.

-

Have you warned AA's in the Area?

-

BEFORE continuing, warn ALL NEARBY associates of the works.

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Is there a risk from Slips, Trips and Falls?

-

Have you ensured the work area is as clean as possible?

-

Clean area of spills, debris and other slip hazards to prevent accidents during work.

-

Have all trip hazards been removed that can are able to be removed?

-

Remove any trip hazards before commencing work to avoid accidents.

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Are Vehicles driving by/inside the task's work area?

-

Are you using a vehicle for the Task?

-

Have you performed the mandatory Pre-Use Inspection?

-

STOP WORK: It is MANDATORY to complete a Pre-Use Inspection of the vehicle BEFORE use. Complete this, then continue.

-

Have you planned the route?

-

WARNING: It is safe practice to plan your route before using the vehicle. Also, notify nearby associates and those affected along the route.

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Have you Cordoned Off the work area?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Does the work area have Inadequate Lighting?

-

Did you set up an additional Light Source

-

STOP WORK: Please ensure lighting is at an adequate level before starting work.

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

Working at Height

-

Is there a risk of Falls from Height?

-

Are you using Access Equipment? (MEWP)

-

Do you have the appropriate training for Working at Height? (IPAF 3A/3B, Harness)

-

STOP: Do not conduct work at height if you have not had the correct training

-

Are all technicians in access equipment wearing hard hats, harnesses and lanyards?

-

When using access equipment, you must wear a hard hat, harness and restraint lanyard.

-

Are you using portable ladders?

-

Do you have the appropriate training for Working at Height? (Ladder User)

-

STOP: Do not conduct work at height if you have not had the correct training

-

Stiles not damaged, bent or corroded?

-

Do not use a ladder that has not passed the pre-use check!

-

Feet present and undamaged?

-

Do not use a ladder that has not passed the pre-use check!

-

Rungs not damaged, bent or corroded?

-

Do not use a ladder that has not passed the pre-use check!

-

Locking Mechanism not damaged, bent or corroded?

-

Do not use a ladder that has not passed the pre-use check!

-

Platform not damaged, bent or corroded?

-

Do not use a ladder that has not passed the pre-use check!

-

Treads not slippery or overly worn?

-

Do not use a ladder that has not passed the pre-use check!

-

Is the ladder tag in place and in-date?

-

Do not use a ladder that has not had a recent thorough inspection!

-

Are there open edges (not. including stairs)?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Is there a risk from Falling Objects?

-

Have you Cordoned Off the Area?

-

Are you wearing a Hard Hat/Bump Cap?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

Mechanical Hazards

-

Is there a chance of Objects being Projected?

-

Are you wearing Eye/Face Protection?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Is there risk of injury from Sharp Objects?

-

Are you wearing gloves?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Is there a risk of Entanglement/Entrapment?

-

Do you need to apply LOTO?

-

Have you blocked off the hazard?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Is there a risk of injury from Stored Energy/Unsecured Loads?

-

Have you released the Stored Energy/secured any Loads?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

Health Hazards

-

Does the task involve Manual Handling of Heavy Objects?

-

Do you have support for team lifting Heavy Objects?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Does the task involve Hazardous Substances?

-

Do you have the appropriate PPE to handle the Hazardous Substance?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Is there a risk of Asphyxia or Drowning associated with this task?

-

Have you ensured you are not Lone Working?

-

Do you have Respiratory Protection in place?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Is there a risk of Dust Inhalation?

-

Do you have appropriate Respiratory Protection?

-

Do you have a Hoover for the dust created?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Will the task involve Noise Exposure?

-

Do you have appropriate Hearing Protection?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

-

Will the task expose you to Vibration?

-

Have you set a time limit for Vibration exposure?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

Heat, Fire and Explosion

-

Is there a risk from Heat, Fire or Explosion?

-

Do you have a Permit to Work?

-

If you do not have a permit to work for a task that includes risk of Fire or Explosion, you are only allowed to carry out the task in the Hot Works area of the Work Shop.

-

Do you have Respiratory Protection in place?

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

Electric Shock

-

Is there a chance of Electric Shock?

-

Have you applied LOTO the power source?

-

Please take a picture of your LOTO Locks

-

Have you cordoned ff the area? (1.5m radius)

-

Do you have a Permit to Work in Place?

-

Stop work, you must have permit to work for live electrical working without a cordon.

-

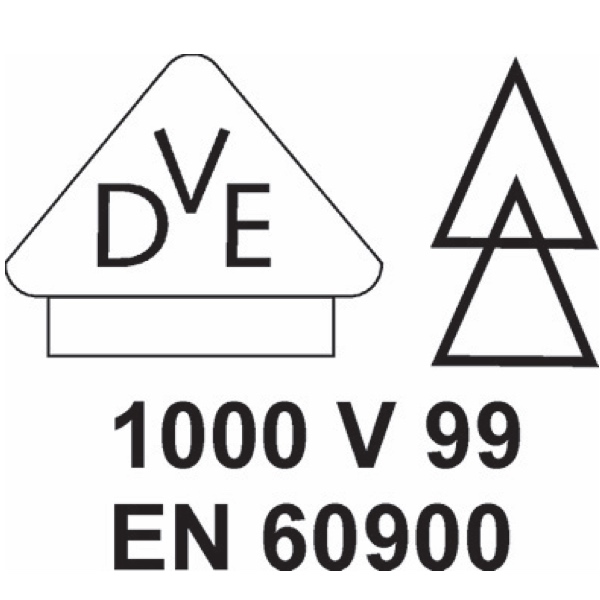

Do you have 1000V VDE Rated Handtools for the task? (EN60900 Double Triangle)

-

Do you have a Permit to Work in place?

-

Stop work, for live electrical working you must use rated insulated tools for the work.

-

Is the Technician completing the work electrically trained?

-

Stop work, live eletrical work must only be carried out by those trained in safe electrical maintenance

-

Are there any Additional Safety Measures in place?

-

What additional safety measures?

Other Risks

-

Did you identify any other Risks?

-

What other Risks were identified?

-

What Safety Measures were taken to reduce these Risks?

Task Sign Off

-

Is there an in-date Risk Assessment and VSOP for this task? (Check the Task & Tools Sheet if unsure)

-

Does this task involve a High Risk Operation?

- Lone Working

- Work at Height

- Scaffolding

- Confined Spaces

- Excavations

- Drilling, Cutting Floors/Walls

- Live Testing

- LOTO

- Jam Busting

- Lifting, hoisting, rigging

- Use of Pups/Reach

- Hazardous Substances

- Hot Works

- Temp. Generators

- Prototypes

- Inhibiting Safety Devices

-

Do you have a Permit to Work in Place?

-

You must have a Permit to Work in place for jobs with High Risk Operations that do not have approved VSOPs and RAs.

-

Is the task a PPM?

-

For Non-High Risk Operation Task a WHS team member is required to countersign the Pre-Task Stop n Go. If no WHS on site, your RME Shift Lead is permitted to sign.

-

WHS (Safety Team) Sign Off

-

Technician Sign Off

-

Thanks for completing the Pre-Task Stop n Go, work efficiently but safely.