Title Page

-

AS SALAAM AIR (Z) Co. Ltd. EMB 120 DAILY CHECK SHEET

-

Conducted on

-

Document No.

-

AIRCRAFT

-

A/F HOURS

-

A/F CYCLES

-

APU HOBBS

-

Location

-

WORK PACK No.

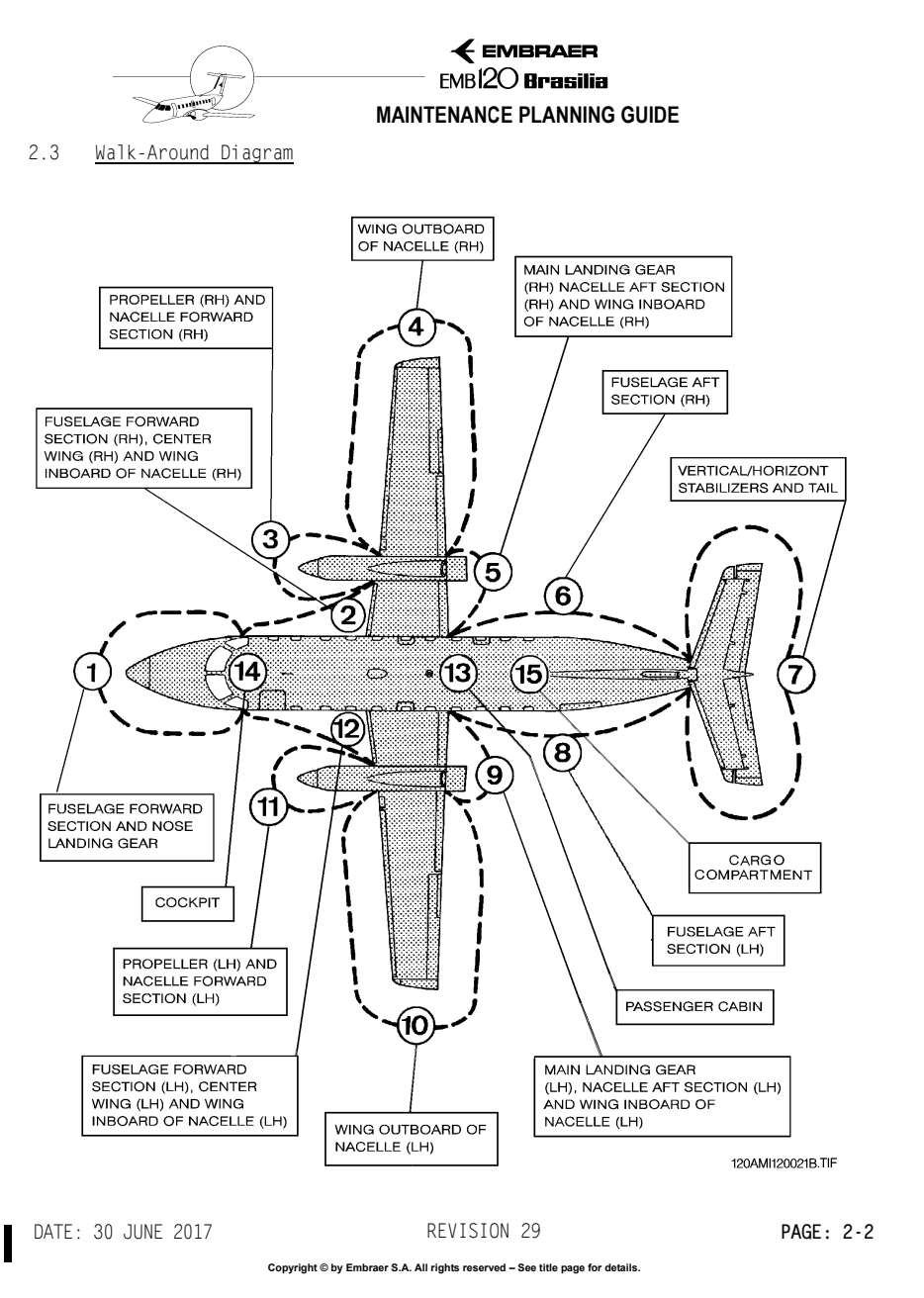

EXTERNAL WALK AROUND CHECKS

ALL AREAS

-

Check for no evidence of damage or fluid leakage.

-

Ensure that all access panels and doors are closed and secured.

AREA 1

FUSELAGE FORWARD SECTION AND NOSE LANDING GEAR

-

Visually check tires for wear or damage.

-

Check LH Nose tire pressure.

-

Check RH Nose tire pressure.

AREA 3 AND 11

PROPELLER AND NACELLE FORWARD SECTION

-

Visually check propeller, including spinner, for evidence of damage and signs of oil leakage.<br>(MSI 61-10)

-

Visually check engine cowling doors and latches for condition (*).<br>(MSI 71-11-01)

-

Visually check engine cooling air inlet/outlets for condition and absence of foreign matter.<br>(MSI 71-11-01).

-

Visually check engine oil cooler air inlet/outlet for absence of foreign matter.

-

Visually check nacelle engine air intake and deicing boots for condition and absence of foreign matter. (MSI-71-61-02)

AREA 4 AND 10

WING OUTBOARD OF NACELLE

-

Check fuel quantity indicating system and carry out refueling precheck if pressure refueling is to be performed.

-

Visually check NACA air inlet for absence of foreign matter.

AREAS 5 AND 9

MAIN LANDING GEAR, NACELLE AFT SECTION, AND WING INBOARD OF NACELLE

-

Visually check tires for wear or damage.

-

Check RH OUTBOARD tire pressure.

-

Check RH INBOARD tire pressure.

-

Check LH OUTBOARD tire pressure.

-

Check LH INBOARD tire pressure.

-

Visually check main wheel P/N 3-1544 for condition.<br>NOTE: According to BF Goodrich CMM 32-40-01.

-

Perform hydraulic reservoir depressurization by actuating the manual relief valve.<br>NOTE: After the last flight of the day.

AREA 7

VERTICAL/HORIZONTAL STABILIZER AND TAIL CONE

-

Check GARRETT APU oil level. (MSI 49-21)

-

Check GARRETT APU compressor air intake and turbine exhaust ducts for foreign material or obstructions.

-

Verify GARRETT APU exhaust gas temperature by observing peak EGT during starting and stabilization at NO-LOAD and FULL-LOAD operation.

-

Verify GARRETT APU controller by observing operation during start acceleration governed speed and shutdown.

-

Visually check APU inlet screens and starter generator air inlet/outlet in the tail cone.

INTERNAL VISUAL CHECKS

AREA 13 - PASSENGER CABIN

-

Check emergency equipment for condition.<br>(MSI 25-62-01/MSI 25-62-02)

-

Check escape hatches for correct closure.

-

Check portable fire extinguisher safety pin and nozzle for condition.

-

Check lavatory waste container fire extinguishing system temperature indicator.

AREA 14

COCKPIT

-

Check emergency equipment for condition.<br>(MSI 25-62-01/MSI 25-62-02)

-

Check portable fire extinguisher and portable oxygen cylinders for condition.<br>(MSI 25-62-01/MSI 25-62-02)

-

Check crew oxygen masks for condition.

-

Check portable fire extinguisher safety pin and nozzle for condition.

AREA 15<br>

CARGO COMPARTMENT (ALL CARGO CONFIGURATIONS)

-

Inspect smoke barrier access door and blow out panels for damages that may affect sealing integrity.

SYSTEM AND COMPONENT CHECKS - AREA 14 COCKPIT

-

Check autopilot disengagement using AP PUSHER DIS switch on control wheel.

-

Check electrical trim by actuating TRIM switch on control wheel and observing that TRIM annunciator light, on flight control panel, comes on (*).

-

Check inverter transfer function (*).<br>(MSI 24-22-01/MSI 24-22-02)

-

Verify battery temperature monitor circuit operation (*).<br>(MSI 24-35-01/MSI 24-35-04)

-

Check back up/emergency battery and standby horizon by positioning back up battery switch to test (*).

-

Check engine/APU fire detection/extinguishing system using “PRESS-TO-TEST” button on Engine Fire Control Panel (*).

-

Check rudder operation with both systems OFF, then with one system ON at a time and,finally, with both systems ON (Normal Mode).<br>(MSI 27-21-02) (*).

-

Verify stall warning system operation including stick shaker and stick pusher, aural warning, and fast/slow indicator.<br>(MSI 27-32-01/MSI 27-32-04/MSI 27-32-06) (*).

-

Check flap control unit by performing “bit” test on the annunciator panel (*).

-

Check low fuel pressure warning lights operation.

-

Check fuel system crossfeed and booster pump autotransfer function (*).

-

Verify windshield overheat circuit operation (*).

-

Verify airfoil/air intake deicing monitor system operation.<br>(MSI 30-11-03/MSI 30-11-21) (*).

-

Verify angle-of-attack (AOA) and sideslip sensor heating operation.<br>(MSI 30-32-04) (*).

-

Verify total air temperature (TAT) and pitot-static heating system operation.<br>(MSI 30-33-00)

-

Test take-off warning on the aural warning unit (*). (MSI 31-52-00)

-

Check EFIS transfer control panel operation (If installed) (*).

-

Verify ADI comparator warning computer operation by positioning ATT MON switch (if installed), on glareshield panel, to TEST and check that attitude display amber light comes on, on multiple alarm panel (*).

-

Check propeller feathering through propeller electrical feathering circuit.<br>(MSI 61-10-01) (*).

-

Verify propeller auxiliary pump operation.<br>(MSI 61-20-04) (*).

-

Verify autofeather operation (Auto - feathering system operational test with engines running) (*).

-

Check brakes by operating both inboard and outboard test switches while depressing pedals to confirm all four green lights indications (*).

-

Check propeller deicing system (If operation under icing conditions is scheduled) (*).