Title Page

-

Conducted on

-

Prepared by

-

Location (Cell Number)

-

Machine (CL) Number

Part 1 - Equipment being worked upon at the time of the inspection

-

Is a maintenance technician or contractor working on the machine at this time?

-

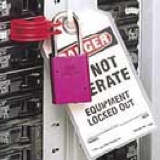

Is the equipment clearly locked out, with the correct RED LOTO padlocks, hasps and identification tags on each source of hazardous energy?

-

Is the work area clearly and securely protected by barriers, tapes and signs to prevent unauthorised entry?

-

Please take photos of the work area, whether barriered off or not

Part 2 - Equipment-Specific Lockout Procedure

-

Can the technician / contractor identify the equipment-specific lockout procedure?

-

Why not?

-

Do the hazardous energy sources match those identified in the equipment-specific lockout procedure? (get the technician / contractor to demonstrate for you)

Part 3 - Demonstration of Lockout in Action

-

Is the person performing maintenance tasks a contractor?

-

Was Lockout applied by an MB Aerospace authorised employee with the contractor present?

-

The LOTO procedure requires that Lockout is applied by an MB Aerospace authorised person and carried out with the contractor present; the verification steps should then be taken and BOTH apply their locks and tags

-

Why was an MB Aerospace technician not present while Lockout was applied?

-

Was the equipment locked out in accordance with the procedure?

-

Can the MB Aerospace technician / contractor demonstrate / explain the verification steps?

-

Ask the technician / contractor to show you the Lockout key(s) - they should have one key per Lockout padlock, on their person at all times - especially if leaving the equipment unattended for any length of time

-

Has the technician / contractor got the key(s) available for examination?

-

If the answer is NO - where are the key(s)?

Part 4 - Lock

-

Is the lock(s) used an MB Aerospace-issued red lock, applied with a hasp and correct ID Tag?

-

If not, why not?

Part 5 - Equipment Return To Service

-

IF the equipment is ready to be returned to operational service, are machine guards & safety devices replaced?

-

Have they been positively checked for correct function, before handing back?

-

Are all other employees in a safe zone, well away from the machine at first start-up?

Part 6 - Comments & Findings

-

Are there any comments you wish to make from your findings?

-

Are there any corrective actions required, to ensure safety of employees & contractors?

Signatures

-

Name of person(s) performing maintenance operation:

-

Name of person completing this inspection:

-

Maintenance supervisor / manager