Title Page

-

-

DAILY PRODUCTION RECORD

-

Conducted on

-

The following checks are to be conducted daily. Where a task or check was not conducted as the area/item was not used, then leave the area blank.

-

Template developed by RMA Management Consultants

-

Pre-start Checks

Daily Pre-Start, General Hygiene and Maintenance Checks

-

These pre-start, hygiene and maintenance checks shall be conducted in all areas on each production day.

-

Are personal equipment & Hand washing, coats, aprons, chain mesh gloves. hand washing facilities working & clean Soap, towelling, basin accessible<br>Knife pouch, knives & kits clean<br>

-

Are Cold room/s & Freezer walls, floor, ceiling, lighting, doors, door seals, door handles, shelving, rails, racks, condenser units etc. clean and in good order<br>

-

In the process/packaging areas, are benches, cutting boards, vacuum packer, wrapper, product containers, trays & tubs wash up trough, <br>Walls, doors, floors, ceiling, lighting, Rails, racks & shelving, in good working order.

-

Are there any Pest Control issues.

-

Are storage areas, Clean and tidy, Items up off floor, containers clean, including shelving, racks, plant & machinery room.<br>External areas<br>

-

Are staff wearing clean protective clothing and shoes, is hair is covered when required, There are no exposed cuts and sores, Staff apear to in good health, Hands are being washed when required, There is no smoking, eating or drinking while processing or within value added areas, There is no risk of contamination by foreign objects like hair, jewellery,

-

Are the staff toilets clean and tidy

-

Are the loading and unloading areas clean and tidy

-

Are containers (rubbish) are emptied regularly, Industrial bins, wheelie bins clean & surrounds clean, All other waste disposed of in appropriate manner

-

Are chemicals stored separately, Storage areas are kept clean and tidy, Stock is rotated: F.I.F.O, Ingredients containers are labelled and lidded, Product containers, cartons are stored off the floor,

-

There is NO cross-contamination risks between meat/chicken/seafood/cooked/raw and other products are separated as required?

-

Are the various pieces of equipment clean and working OK? (including: sausage filler, mincer, crumbing line, slicers etc)

-

Record any further pre-start comments as well as any maintenance issues here.

-

You can add photos here of any areas of concern.

-

Person conducting checks to write Name here..

Green Shed Across Road Chiller/Freezer

Chiller 1

-

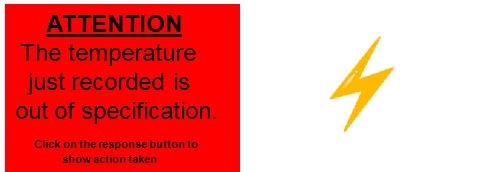

Select action to be taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

Chiller 2

-

Select action to be taken..

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

Freezer 1 (Stand alone)

-

Select action to be Taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Person doing checks must sign ..

Cold Room and Freezer Temperature Checks

-

Chilled and frozen temperatures should be taken twice each production day. Chillers should be at< 5oC or less and freezers <- 15oC

Morning Storage Temperature Checks

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

When required, record details of any issues from above items here. As required photos can be added below to highlight the issue.

-

Nominated person to initial here to signify that the above information is correct

Afternoon Storage Temperature Checks

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

Please Note

-

Select the action taken

- Food transferred to another unit

- Temperature retaken after 30 minutes and back within spec.

- Issue reported for maintenance

- All food discarded

- Temperature Fine

-

When required, record details of any issues from above items here. As required photos can be added below to highlight the issue.

-

Person doing these above checks is to write there name here..

Random Process and Product Checks

-

This section is to be used to record random process and product checks front and back room process/packaging activites to ensure the relevant controls are being maintained.

Random Process and Product Checks 1

-

Enter time checked

-

Describe process/product being checked

-

Was the area clean and tidy and relevant hygiene controls maintained

-

Where applic. Is the correct label being used with correct information noted including dates etc.

-

Does the process meet relevant specification. (size and weigh etc.)

-

Add any further repack/process information or comments

Random Process and Product Checks 2

-

Enter time checked

-

Describe process/product being checked

-

Was the area clean and tidy and relevant hygiene controls maintained

-

Where applic. Is the correct label being used with correct information noted including dates etc.

-

Does the process meet relevant specification. (size and weigh etc.)

-

Add any further repack/process information or comments

-

Person conducting the above checks is to write name here.

Distribution

-

On a random basis. check the temperatures of out going product as well as the vehicle condition

Random Inside Orders Check 1

-

Enter time checked

-

Record customer and product being checked..

-

Packaging correctly closed, labelled and in clean cartons

-

Select vehicle being used

- XQ77VS

- 761AG5

- 995TRL

- 486SCG

- 225SSL

- 069TEH

- XB28EY

- 136GG2

- XQ78ZO

- 028FU4

-

Delivery vehicle clean and tidy (including box walls, floors and ceiling etc.)

- Yes

- No

- N/A

-

Was the vehicles chiller operating at time of loading

Random Inside Orders Check 2

-

Enter time checked

-

Record customer and product being checked..

-

Packaging correctly closed, labelled and in clean cartons

-

Select vehicle being used

- XQ77VS

- 761AG5

- 995TRL

- 486SCG

- 225SSL

- 069TEH

- XB28EY

- 136GG2

- XQ78ZO

- 028FU4

-

Delivery vehicle clean and tidy (including box walls, floors and ceiling etc.)

- Yes

- No

- N/A

-

Was the vehicles chiller operating at time of loading

- Yes

- No

- N/A

Random Outside Orders Check 1

-

Enter time checked

-

Record customer and product being checked..

-

Packaging correctly closed, labelled and in clean cartons

-

Select vehicle being used

- XQ77VS

- 761AG5

- 995TRL

- 486SCG

- 225SSL

- 069TEH

- XB28EY

- 136GG2

- XQ78ZO

- 028FU4

-

Delivery vehicle clean and tidy (including box walls, floors and ceiling etc.)

-

Was the vehicles chiller operating at time of loading

Random Outside Orders Check 2

-

Enter time checked

-

Record customer and product being checked..

-

Packaging correctly closed, labelled and in clean cartons

-

Select vehicle being used

- XQ77VS

- 761AG5

- 995TRL

- 486SCG

- 225SSL

- 069TEH

- XB28EY

- 136GG2

- XQ78ZO

- 028FU4

-

Delivery vehicle clean and tidy (including box walls, floors and ceiling etc.)

- Yes

- No

- N/A

-

Was the vehicles chiller operating at time of loading

- Yes

- No

- N/A

-

person conducting the above checks to write there name here..

Operational Hygiene

-

On a random basis , check all operational hygiene and cleanliness around the plant eg( condensation,hand washing,vermin control,rooms)

Random Operational Hygiene Checks 1

-

Enter time checked

-

Record Area being Checked..

-

All workers washing hands/boots and keeping generally clean..

-

Area clear of condensation..

-

Area clear of any rubbish on floors etc...

-

Area clear of any Vermin/Pest..

Random Operational Hygiene Checks 2

-

Enter time checked

-

Record Area being Checked..

-

All workers washing hands/boots and keeping generally clean..

-

Area clear of condensation..

-

Area clear of any rubbish on floors etc...

-

Area clear of any Vermin/Pest..

-

person conducting the above checks to write there name here..

In-house protein swabing

-

This section is to be completed when protien swabbing is conducted.

Tap here to enter results of a protien swab

-

Enter date and time swab conducted

-

Add here the details where the swab was taken

-

Was test 1 a pass

- Yes

- No

- N/A

-

When applic was test 2 a pass

- Yes

- No

- N/A

-

When applic was test 3 a pass

- Yes

- No

- N/A

-

Where required add additional comments here

-

Person who conducted the tests to write there name here..