Title Page

-

At Maxima Training Group (Aust) Ltd, our job is to make sure the workplaces where we place our workers are safe prior to placement and they remain safe during the assignment. To achieve this, in consultation with you, the host employer, we are required to evaluate your systematic approach to managing workplace Health and Safety, which in turn allows us to make the safest decision about the supply of workers. This form is designed to give us an overview of your safety systems and the amenities available to our workers. Only by proactively working together, can we effectively manage hazards and reduce the likelihood and severity of illness and injury.

-

Host Trading Name:

-

Host Business Name / Previous Name / Other Names (if applicable):

-

Host ABN:

-

Host Representative:

-

Risk Assessment Address and any Workplace location/s:

-

List the Area / Suburb/s and State this assessment is applicable to (i.e. "Forbes NSW" or "Hindmarsh / Prospect SA" or "Port Augusta Council Area SA"):

-

Date Completed:

-

Job Title of Placement/s:

-

Maxima Risk Assessor:

-

Risk Assessment Number (i.e. "01"):

-

Due date for next assessment:

Privacy & Information Collection Notice

-

Maxima are committed to preserving the confidentiality of information supplied to it by customers, potential customers, enterprises or individuals involved in joint or collaborative projects, trainees, on-hire employees, staff, jobseekers, participants and other agencies both government and non-government.

Maxima will treat all such documents and information which comes to their knowledge, or to which they are exposed, as being strictly confidential. All documents, pictures, evidence gathered to complete this form are kept in a secure location and are only accessible by select employees of Maxima. Your information will not be given to any other person or agency unless you have given us permission or we are required to by law.

1. Host Work Health and Safety Systems

1.1 Safety Profile

-

Is there a current Safety Profile for this position and/or location with this host? (Maximum of 5 years expiry or less if there are any changes or at Maxima's discretion)

-

Have there been any changes to the WHS Management System, Supervisor or Safety Role Contacts since the completion of the Safety Profile? (Select all those that have changed)

-

No, the Safety Profile is up to date and requires no changes.

-

Yes, items within the Safety Management System require updating (i.e. Safe operating procedures, incident notification, etc).

-

Confirm that the current safety management system has the following elements by providing evidence of its implementation

-

Written Health and Safety Policy available to workers:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Process in place, however not in the form of a documented procedure

- No evidence available as item has not been implemented yet

- Not Applicable

-

Please raise an action to develop a written health and safety policy that is readily available to all staff and satisfies the requirements as stated in WHS / OHS legislation.

-

Please describe why this is not applicable:

-

Documented consultation, cooperation and communication procedure with an issue resolution process:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Process in place, however not in the form of a documented procedure

- No evidence available as item has not been implemented yet

- Not Applicable

-

Please raise an action to develop and implement a written communication and consultation process with issue resolution that complies with the relevant: WHS / OHS legislation, workplace health and safety regulator requirements and the Code of Practice: Work health and safety consultation, co-operation and co-ordination

-

Please describe why this is not applicable:

-

How will Maxima workers be consulted and communicated with?

- Daily Prestart Meetings

- Health and Safety Representative

- Induction and training

- Issue resolution process in place

- Permits for high risk work

- Regular WHS Meetings

- Representatives from all PCBU's (businesses) who work in the same location meet to discuss upcoming / relevant work that may impact each other.

- Safety Alerts (via noticeboard, text, email, etc)

- Toolbox Talks

- The Principle Contractor provides a documented procedure

- WHS Committee

- WHS Management Plan for Construction Project details the arrangements in place for consultation, cooperation and coordination between the PCBUs / other businesses at the site.

- WHS Noticeboard

- Worker participates during the development of Risk Assessments / JSA's / Standard Operating Procedures / SWMS

- Workers are provided with robust JSAs/SWMSs/Risk Assessments/SOPs and are encouraged to voice concerns whilst reviewing it.

- Other

- No consultation method in place

-

Please describe the other methods for consulting with workers:

-

Documented incident management and investigation procedure:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Process in place, however not in the form of a documented procedure

- No evidence available as item has not been implemented yet

- Not Applicable

-

Please raise an action to develop and implement an incident notification and investigation process that complies with the relevant: WHS / OHS legislation and workplace health and safety regulator requirements.

-

How are incidents currently managed:

- Informal / non-documented process for the notification and management of incidents is communicated to workers (i.e. verbally during induction, signage).

- Incidents are reported, recorded and investigated with any identified corrective actions monitored through to completion to reduce the chance of a similar incident reoccurring.

- Incident and injury statistics are reported on to management and relevant areas in the organisation (i.e. Injury Frequency Rates / TRIFR)

- Notifiable incidents (the death of a person, a serious injury or illness, or a dangerous incident) are reported to the relevant WHS Regulator and Maxima when it involves a Maxima worker

- Host is aware that notifiable serious injuries include: if a person has immediate treatment as an inpatient in a hospital or immediate treatment from a doctor, registered nurse or paramedic (even if he or she isn’t directly admitted to hospital) for any of the eight types of serious injuries listed in the WHS Act. (i.e. head knocks causing loss of consciousness; burns requiring intensive care or critical care which may need a compression garment or a skin graft; and laceration injuries such as tears or wounds that may include stitching to prevent loss of blood or other treatment to prevent loss of bodily function or infection) [Further info: https://www.safeworkaustralia.gov.au/system/files/documents/1702/incident-notification-fact-sheet-2015.pdf]

- Rehabilitation and return to work process in place with assigned RRTW Coordinator/s

- Incidents and injuries are reported, however more work is required in other areas of the process (i.e. investigation process absent or inadequate)

- No investigation process in place

- Corrective actions identified during investigation are not monitored or implemented.

- Incidents or investigation findings are not shared with the rest of the business or relevant parties.

- Other

-

How will our workers notify your organisation of hazards and incidents:

- In Writing - hard copy / paper forms

- In Writing - Via email or text

- Online reporting system

- Reported to Safety Officer

- Reported to Supervisor

- Verbally - raised during toolbox / meetings

- Verbally - to supervisor / safety officer / other

- Other

-

Please describe:

-

Please describe why this is not applicable:

-

Documented hazard identification and risk assessment and management procedure/s:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Process in place, however not in the form of a documented procedure

- No evidence available as item has not been implemented yet

- Not Applicable

-

Please describe why this is not applicable:

-

Please raise an action to develop and implement a risk management system that complies with the relevant: WHS / OHS legislation, workplace health and safety regulator requirements and the Code of Practice: How to manage work health and safety risks

-

What is the current hazard and risk management process:

- Hazard / risks are reported by workers

- Reported hazards / risks are actioned

- Informal / non-documented risk management system with hazard identification and risk assessment process communicated to work (i.e. verbally during induction)

- Job Dictionary / Manual Tasks Job Profile

- Job Safety Analysis

- Position Description

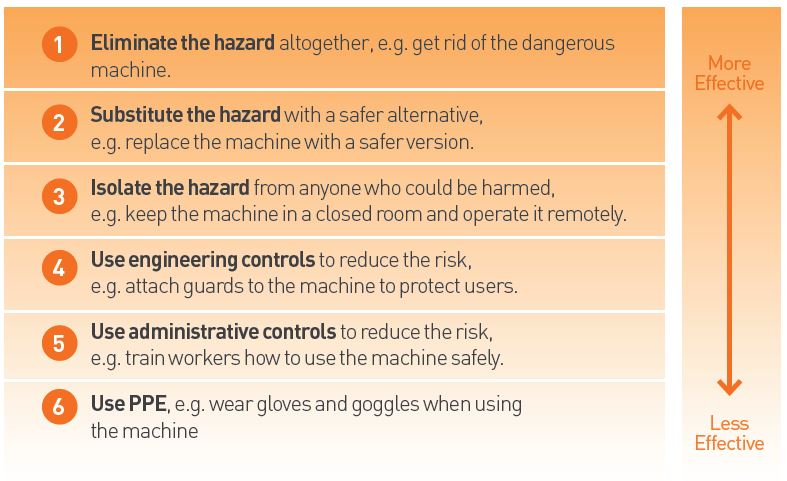

- Risk controls are consistent with the ‘hierarchy’ of control (elimination, isolation, substitution, engineering, administrative, personal protective equipment).

- Risks are verbally communicated / discussed with workers prior to conducting task

- Risk Register - identifying major workplace hazards

- Risk Assessments

- Safe Operating Procedures

- Other

- No evidence of reported hazards / risks being actioned by supervisors

- No risk management process in place due to low risk work

-

Please describe:

-

The provision of the necessary information, training or instruction for the worker/s by the host: (Select all that apply and provide evidence)

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Accredited Certification / License (e.g. First Aid Cert, High Risk Work Licence, White Card, etc)

- Documented procedure / instruction on how to complete work tasks safely (i.e. Safe Work Procedures / JSA / SOP / SWMS / Risk Assessment / Work Instructions) [EVIDENCE REQUIRED]

- External formalised qualification (Apprenticeship / Traineeship)

- E-learning Modules

- Host Workplace Induction - detailing the workplace, emergency response procedures and equipment, work tasks their hazards and controls. [EVIDENCE REQUIRED]

- Host will record the completion of training provided to workers

- Initial task supervision

- Ongoing supervision

- On-the-job training (i.e. job shadowing, show do show, etc) system)

- Process in place, however not in the form of a documented procedure

- Site-specific Induction (i.e. when working across multiple sites or on longer term job sites that are not privately owned residential homes (i.e. construction site, plant or depot), etc)

- Task/equipment-specific training for new/additional tasks / equipment

- Training Matrix managed by host has identified competencies required for the role

- Validation of competency (VOC) for operating plant / equipment / carrying out new tasks

- Other

- No evidence available as item has not been implemented yet

- Not Applicable

-

Provide evidence of all applicable safe work procedures:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- No evidence available as item has not been implemented yet

-

Provide evidence of the site induction content / it's completion by worker:

- Photographic evidence attached

- A copy of the document/s detailing the process will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence and deemed it adequate at the time of the risk assessment.

- No evidence available as item has not been implemented

- Not applicable

-

Raise an action for host to develop and implement a host workplace induction prior to worker placement.

-

Please describe why this is not applicable:

-

Raise an action for host to develop and implement a host workplace induction and relevant training prior to worker placement.

-

Yes, the Supervisor details have changed.

-

Who will directly oversee the safety of our workers day-to-day? (Please list the name and contact details of all Supervisors)

-

Level of supervision to be provided:

- Continuous

- Frequent (hourly)

- Occasional (every few hours)

- Minimal (once daily)

- Supervised Remotely

- None

- Other

-

Yes, the Safety Roles / RRTW Coordinator details have changed.

-

Please list the Name/s, Position/s and Contact Details (phone and or email) of the following:

-

Rehabilitation and Return to Work Coordinator (Name/s, Position/s, Contact/s):

-

Safety Officer (Name/s, Position/s, Contact/s):

1.2 Safety Management System Evidence

-

Confirm that the safety management system has the following elements by providing evidence of its implementation

-

1.2.1 Written Health and Safety Policy available to workers:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Process in place, however not in the form of a documented procedure

- No evidence available as item has not been implemented yet

- Not Applicable

-

Please raise an action to develop a written health and safety policy that is readily available to all staff and satisfies the requirements as stated in WHS / OHS legislation.

-

Please describe why this is not applicable:

-

1.2.2 Documented consultation, cooperation and communication procedure with an issue resolution process:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Process in place, however not in the form of a documented procedure

- No evidence available as item has not been implemented yet

- Not Applicable

-

Please raise an action to develop and implement a written communication and consultation process with issue resolution that complies with the relevant: WHS / OHS legislation, workplace health and safety regulator requirements and the Code of Practice: Work health and safety consultation, co-operation and co-ordination

-

Please describe why this is not applicable:

-

How will Maxima workers be consulted and communicated with?

- Daily Prestart Meetings

- Health and Safety Representative

- Induction and training

- Issue resolution process in place

- Permits for high risk work

- Regular WHS Meetings

- Representatives from all PCBU's (businesses) who work in the same location meet to discuss upcoming / relevant work that may impact each other.

- Safety Alerts (via noticeboard, text, email, etc)

- Toolbox Talks

- The Principle Contractor provides a documented procedure

- WHS Committee

- WHS Management Plan for Construction Project details the arrangements in place for consultation, cooperation and coordination between the PCBUs / other businesses at the site.

- WHS Noticeboard

- Worker participates during the development of Risk Assessments / JSA's / Standard Operating Procedures / SWMS

- Workers are provided with robust JSAs/SWMSs/Risk Assessments/SOPs and are encouraged to voice concerns whilst reviewing it.

- Other

- No consultation method in place

-

Please describe the other methods for consulting with workers:

-

1.2.3 Documented incident management and investigation procedure:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Process in place, however not in the form of a documented procedure

- No evidence available as item has not been implemented yet

- Not Applicable

-

Please raise an action to develop and implement an incident notification and investigation process that complies with the relevant WHS / OHS legislation and workplace health and safety regulator requirements.

-

How are incidents currently managed:

- Informal / non-documented process for the notification and management of incidents is communicated to workers (i.e. verbally during induction, signage).

- Incidents are reported, recorded and investigated with any identified corrective actions monitored through to completion to reduce the chance of a similar incident reoccurring.

- Incident and injury statistics are reported on to management and relevant areas in the organisation (i.e. Injury Frequency Rates / TRIFR)

- Notifiable incidents (the death of a person, a serious injury or illness, or a dangerous incident) are reported to the relevant WHS Regulator and Maxima when it involves a Maxima worker

- Host is aware that notifiable serious injuries include: if a person has immediate treatment as an inpatient in a hospital or immediate treatment from a doctor, registered nurse or paramedic (even if he or she isn’t directly admitted to hospital) for any of the eight types of serious injuries listed in the WHS Act. (i.e. head knocks causing loss of consciousness; burns requiring intensive care or critical care which may need a compression garment or a skin graft; and laceration injuries such as tears or wounds that may include stitching to prevent loss of blood or other treatment to prevent loss of bodily function or infection) [Further info: https://www.safeworkaustralia.gov.au/system/files/documents/1702/incident-notification-fact-sheet-2015.pdf]

- Rehabilitation and return to work process in place with assigned RRTW Coordinator/s

- Incidents and injuries are reported, however more work is required in other areas of the process (i.e. investigation process absent or inadequate)

- No investigation process in place

- Corrective actions identified during investigation are not monitored or implemented.

- Incidents or investigation findings are not shared with the rest of the business or relevant parties.

- Other

-

How will our workers notify your organisation of hazards and incidents:

- In Writing - hard copy / paper forms

- In Writing - Via email or text

- Online reporting system

- Reported to Safety Officer

- Reported to Supervisor

- Verbally - raised during toolbox / meetings

- Verbally - to supervisor / safety officer / other

- Other

-

Please describe:

-

Please describe why this is not applicable:

-

1.2.4 Documented hazard identification and risk assessment and management procedure/s:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Process in place, however not in the form of a documented procedure

- No evidence available as item has not been implemented yet

- Not Applicable

-

Please describe why this is not applicable:

-

Please raise an action to develop and implement a risk management system that complies with the relevant: WHS / OHS legislation, workplace health and safety regulator requirements and the Code of Practice: How to manage work health and safety risks

-

What is the current hazard and risk management process:

- Hazard / risks are reported by workers

- Reported hazards / risks are actioned

- Informal / non-documented risk management system with hazard identification and risk assessment process communicated to work (i.e. verbally during induction)

- Job Dictionary / Manual Tasks Job Profile

- Job Safety Analysis

- Position Description

- Risk controls are consistent with the ‘hierarchy’ of control (elimination, isolation, substitution, engineering, administrative, personal protective equipment).

- Risks are verbally communicated / discussed with workers prior to conducting task

- Risk Register - identifying major workplace hazards

- Risk Assessments

- Safe Operating Procedures

- Other

- No evidence of reported hazards / risks being actioned by supervisors

- No risk management process in place due to low risk work

-

Please describe:

-

1.2.5 The provision of the necessary information, training or instruction for the worker/s by the host: (Select all that apply and provide evidence)

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- Accredited Certification / License (e.g. First Aid Cert, High Risk Work Licence, White Card, etc)

- Documented procedure / instruction on how to complete work tasks safely (i.e. Safe Work Procedures / JSA / SOP / SWMS / Risk Assessment / Work Instructions) [EVIDENCE REQUIRED]

- External formalised qualification (Apprenticeship / Traineeship)

- E-learning Modules

- Host Workplace Induction - detailing the workplace, emergency response procedures and equipment, work tasks their hazards and controls. [EVIDENCE REQUIRED]

- Host will record the completion of training provided to workers

- Initial task supervision

- Ongoing supervision

- On-the-job training (i.e. job shadowing, show do show, etc) system)

- Process in place, however not in the form of a documented procedure

- Site-specific Induction (i.e. when working across multiple sites or on longer term job sites that are not privately owned residential homes (i.e. construction site, plant or depot), etc)

- Task/equipment-specific training for new/additional tasks / equipment

- Training Matrix managed by host has identified competencies required for the role

- Validation of competency (VOC) for operating plant / equipment / carrying out new tasks

- Other

- No evidence available as item has not been implemented yet

- Not Applicable

-

Provide evidence of all applicable safe work procedures:

- Photographic evidence attached

- A copy of the document/s will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence at the time of the assessment and deemed it adequate

- No evidence available as item has not been implemented yet

-

Provide evidence of the site induction content / it's completion by worker:

- Photographic evidence attached

- A copy of the document/s detailing the process will be emailed with this assessment to WHSAction@maxima.com.au

- Risk Assessor visually inspected evidence and deemed it adequate at the time of the risk assessment.

- No evidence available as item has not been implemented

- Not applicable

-

Raise an action for host to develop and implement a host workplace induction prior to worker placement.

-

Please describe why this is not applicable:

-

Raise an action for host to develop and implement a host workplace induction and relevant training prior to worker placement.

1.3 Supervision

-

Who will directly oversee the safety of our workers day-to-day? (Please list the name and contact details of all Supervisors)

-

How will our workers be supported and supervised while on the job?

- Buddy / Designated Peer

- Multiple / Shift Supervisor - May differ depending on shifts

- Supervisor - Same every shift

- Work Group / Team

- Other

-

Workers will also be supervised by:

-

Please list the name, title and contact details of their Supervisor/s:

-

Level of supervision to be provided:

- Continuous

- Frequent (hourly)

- Occasional (every few hours)

- Minimal (once daily)

- Supervised Remotely

- None

- Other

1.4 Safety Roles / RRTW Coordinator

-

Please list the Name/s, Position/s and Contact Details (phone and or email) of the following:

-

Rehabilitation and Return to Work Coordinator (Name/s, Position/s, Contact/s):

-

Safety Officer (Name/s, Position/s, Contact/s):

1.5 Skills, Experience and Checks

-

What experience or qualifications are required to perform this work?

- 2+ Years in similar role or industry

- ASIC

- Driver's Licence

- First Aid

- Police Check

- Trade qualification in field

- White Card

- Other

- Not Applicable

-

Please describe:

1.6 Personal Protective Equipment (PPE) & Workwear

-

Select what PPE is required and who will provide it. Check against Supply Order (when available)

-

The Host will provide the following required PPE / Workwear:

- Host Branded Uniform

- No PPE required

- Full brim hat

- Hard Hat

- Sun visor for hard hat

- High Visibility long sleeved shirt

- High Visibility long sleeved shirt and pants

- Hearing Protection

- Gloves

- Steel capped / safety boots

- Enclosed shoes

- Safety Glasses

- Face shield

- Welders mask

- Fitted Respirator (Half / Full Face) P2 or higher

- Disposable respirator P2 or higher

- Oxygen fed respirator and suit

- Disposable coveralls / chemical suit

- Long sleeved shirt, long pants (not high vis)

- Chaps

- Other

-

List what class / type (i.e. Class 5, Double hearing protection, Earmuffs:

-

Additional items the Host is required to provide:

-

The Worker will provide the following required PPE / Equipment:

- N/A - Worker not required to provide any PPE or equipment

- Body Protection - High Visibility long sleeved shirt

- Body Protection - High Visibility long sleeved shirt and pants

- Body Protection - Disposable coveralls / chemical suit

- Body Protection - Chaps

- Clothing - Business Attire

- Clothing - Smart Casual

- Clothing - Long sleeved shirt, long pants (not high vis)

- Eye Protection - Safety Glasses

- Eye Protection - Face shield

- Eye Protection - Welders mask

- Footwear - Steel capped / safety boots

- Footwear - Enclosed shoes

- Hand Protection - Gloves

- Headwear - Full brim hat

- Headwear - Hard Hat

- Headwear - Sun visor for hard hat

- Hearing Protection - Ear Plugs

- Hearing Protection - Ear Muffs

- Respiratory Protection - Disposable respirator P2 or higher

- Respiratory Protection - Fitted Respirator (Half / Full Face) P2 or higher

- Respiratory Protection - Medical mask

- Respiratory Protection - Oxygen fed respirator and suit

- Trade tools and equipment

- Other

-

List what class / type (i.e. Class 5, Double hearing protection, Earmuffs:

-

Additional items the worker is required to provide:

-

Maxima will provide the following required PPE / Workwear:

- Host Branded Uniform

- No PPE required

- Full brim hat

- Hard Hat

- Sun visor for hard hat

- High Visibility long sleeved shirt

- High Visibility long sleeved shirt and pants

- Hearing Protection

- Gloves

- Steel capped / safety boots

- Enclosed shoes

- Safety Glasses

- Face shield

- Welders mask

- Fitted Respirator (Half / Full Face) P2 or higher

- Disposable respirator P2 or higher

- Oxygen fed respirator and suit

- Disposable coveralls / chemical suit

- Long sleeved shirt, long pants (not high vis)

- Chaps

- Other

-

List what class / type (i.e. Class 5, Double hearing protection, Earmuffs:

-

Additional items Maxima is required to provide:

1.7 Medicals and Health Monitoring

-

Is pre-employment screening, functional capacity or ongoing health monitoring required? (i.e. pre–employment medical, hearing tests, drug & alcohol testing)

-

HOST provided pre-employment screening or ongoing health monitoring (i.e. pre–employment medical, hearing tests, drug & alcohol testing).

- N/A: Will not be providing screening or monitoring for worker/s

- Asbestos Health Surveillance

- Drug & Alcohol - Pre-screening

- Drug & Alcohol - Random Tests

- Lung Functionality

- Manual Tasks / Physical Fitness / Capability

- Pre-employment Medical

- Regular Hearing Tests

- Other

-

Please describe:

-

MAXIMA provided pre-employment screening, functional capacity or ongoing health monitoring (i.e. pre–employment medical, hearing tests, drug & alcohol testing)

- N/A: Will not be providing screening or monitoring for worker/s

- Asbestos Health Surveillance

- Drug & Alcohol - Pre-screening

- Drug & Alcohol - Random Tests

- Lung Functionality

- Manual Tasks / Physical Fitness / Capability

- Pre-employment Medical

- Regular Hearing Tests

- Other

-

Please describe:

-

Do you require Maxima to arrange any pre-employment screening / medical prior to commencement? (Please list any special requirements (i.e. sleep test, full physical capabilities test, etc) in the "Note" section below.

- N/A: Will not be providing screening or monitoring for worker/s

- Asbestos Health Surveillance

- Drug & Alcohol - Pre-screening

- Drug & Alcohol - Random Tests

- Lung Functionality

- Manual Tasks / Physical Fitness / Capability

- Pre-employment Medical

- Regular Hearing Tests

- Other

Additional Comments & Photographic Evidence

-

Add additional comments here:

-

Additional Photos / Photographic Evidence

2. The Workplace

-

Have the Amenities (including First Aid and Emergency Response facilities) been checked within the last 12 months by Maxima?

2.1 Amenities

-

Provide photo evidence of the following amenities to show they are readily available to Maxima's worker/s and are provided in a safe, accessible and clean manner.

-

2.1.1 Hand washing facilities

- Photograph attached

- Risk Assessor visually inspected and deems it adequate at the time of the inspection.

- Item/s in poor condition, inadequate or requiring repairs

- Not currently available to worker

- Not Applicable

-

Please describe why this is not available or applicable:

-

Raise an action to rectify and describe or use a photo to explain the issue.

-

2.1.2 Toilets with adequate facilities, privacy and security

- Photograph attached

- Risk Assessor visually inspected and deems it adequate at the time of the inspection.

- Item/s in poor condition, inadequate or requiring repairs

- Not currently available to worker

- Not Applicable

-

Please describe why this is not available or applicable:

-

Raise an action to rectify and describe or use a photo to explain the issue.

-

2.1.3 Filtered and / or cool drinking water

- Photograph attached

- Risk Assessor visually inspected and deems it adequate at the time of the inspection.

- Item/s in poor condition, inadequate or requiring repairs

- Not currently available to worker

- Not Applicable

-

Please describe why this is not available or applicable:

-

Raise an action to rectify and describe or use a photo to explain the issue.

-

2.1.4 Eating facilities and appropriate areas to consume food (i.e. out of the sun)

- Photograph attached

- Risk Assessor visually inspected and deems it adequate at the time of the inspection.

- Item/s in poor condition, inadequate or requiring repairs

- Not currently available to worker

- Not Applicable

-

Please describe why this is not available or applicable:

-

Raise an action to rectify and describe or use a photo to explain the issue.

-

2.1.5 Storage for personal belongings

- Photograph attached

- Risk Assessor visually inspected and deems it adequate at the time of the inspection.

- Item/s in poor condition, inadequate or requiring repairs

- Not currently available to worker

- Not Applicable

-

Please describe why this is not available or applicable:

-

Raise an action to rectify and describe or use a photo to explain the issue.

-

2.1.6 The workplace (building, depot or vehicle) is kept: (select all that apply)

- In a hygienic manner

- Free from unpleasant odours

- Reasonably clean and tidy

- Free of trip hazards (i.e. cords across walkways)

- Free of unevenly / hazardously stacked items (i.e. boxes)

-

Provide photo evidence of workplace / workstation:

2.2 Emergency Response

-

2.2.1 First Aid Facility Evidence:

- Photograph attached

- Risk Assessor visually inspected and deems it adequate at the time of the inspection.

- Item/s in poor condition, inadequate or requiring repairs

- Not currently available to worker

- Not Applicable

-

The first aid facilities available:

- Burns Kit

- Chemical Shower

- Defibrillator

- Eye wash

- First aid kit readily available, regularly checked, with in date items and stocked with all necessary items relevant to the risks (i.e. snake bite, burns, etc)

- First aid kit signage applied correctly

- First Aid Officer / Trained Staff

- First Aid Officer Photo Board Displayed

- First Aid Procedures / Signage Displayed

- First Aider Sign above First Aider

- Snake Bite Kit

- Other

- First aid equipment has expired, requires testing/maintenance or not functioning as required

- No first aid equipment / facilities available

-

Additional first aid facilities available:

-

Briefly describe what is in a poor condition / out of date or not available and raise action as required:

-

Appendix C of the First Aid in the Workplace Code of Practice outlines recommended first aid requirements, with the minimum for low risk workplaces being: 1 First Aider for every 50 workers, a basic first aid kit and a first aid room where there are 200 workers or more. Please note that a vehicle is considered a workplace when being driven for work purposes. https://www.safeworkaustralia.gov.au/system/files/documents/1908/code_of_practice_-_first_aid_in_the_workplace_0_0.pdf

-

Please describe why this is not applicable:

-

Appendix C of the First Aid in the Workplace Code of Practice outlines recommended first aid requirements, with the minimum for low risk workplaces being: 1 First Aider for every 50 workers, a basic first aid kit and a first aid room where there are 200 workers or more. Please note that a vehicle is considered a workplace when being driven for work purposes. https://www.safeworkaustralia.gov.au/system/files/documents/1908/code_of_practice_-_first_aid_in_the_workplace_0_0.pdf

-

2.2.2 Fire Fighting Equipment Evidence:

- Photograph attached

- Risk Assessor visually inspected and deems it adequate at the time of the inspection.

- Item/s in poor condition, inadequate or requiring repairs

- Not currently available to worker

- Not Applicable

-

The fire fighting equipment available:

- Axe

- Deluge Suppression / Fire System

- Emergency Response Team Sign - Identifies Fire Wardens

- Fire blanket in test date

- Fire command centre

- Fire extinguisher/s in date and appropriate to the type of fires possible

- Fire reel / hose

- On site fire fighting team

- PPE - specialised for fighting fires (jackets, hard hats)

- Respiratory Protective Equipment

- Signage correctly placed above fire suppression equipment

- Smoke detectors

- Sprinkler system

- Other

- Fire fighting equipment is out of date (i.e. extinguishers should be tested every 6 months)

- No fire fighting equipment available

-

Briefly describe what is in a poor condition / out of date or not available and raise action as required:

-

Briefly describe what additional equipment is available

-

Please describe what this is not applicable:

-

Please describe why this is not currently available or applicable:

-

2.2.3 Emergency Response Evidence

- Photograph attached

- Risk Assessor visually inspected and deems it adequate at the time of the inspection.

- Item/s in poor condition, inadequate or requiring repairs

- Not currently available to worker

- Not Applicable

-

The emergency response facilities available:

- Alarm / Warning System (i.e. AV system that plays beeping and/or verbal instructions; airhorn).

- Emergency Alarm Activation Points

- Emergency Exit Signs

- Emergency Lighting (i.e. flashes during emergency or lights up pathways in power outage)

- Emergency procedures that reflect the types of emergencies that could be encountered

- Emergency procedures consider all nearby external PCBUs / Businesses / Individuals, their potential emergencies and communication with them during an emergency.

- Emergency Response PPE - Coloured Hard Hats, vests, etc

- Emergency response procedures captured in JSA / SWMS / SOPs (i.e. Vehicle as a workplace)

- Emergency Response Team Sign

- Evacuation Route Plans / Signage

- External Emergency Response Team (i.e. managed by the facility the host is based in)

- Personal Emergency Alarm (i.e. Duress alarm, mobile phone, IVMS)

- Regular Evacuation Drills

- Other

- Emergency response item out of date or not functioning as required

- No emergency response facilities in place

-

Additional emergency response equipment available:

-

Emergency plans and procedures relevant to the workplace must be implemented and tested at regular intervals for every workplace. Please note that a vehicle is considered a workplace when driven for work purposes.

-

Briefly describe what is in a poor condition / out of date or not available and raise action as required:

-

Emergency plans and procedures relevant to the workplace must be implemented and tested at regular intervals for every workplace. Please note that a vehicle is considered a workplace when driven for work purposes.

-

Please describe why this is not available or applicable:

-

2.2.4 Are emergency exits / routes free of obstructions?

-

Immediately rectify or raise action if cannot be completed during the assessment.

2.3 Incidents and Injuries

-

2.3.1 What is the most common cause/s of injuries and/or incidents in the workplace:

2.1 Incidents and Injuries

-

2.1.1 What is the most common cause/s of injuries and/or incidents in the workplace:

Additional Comments & Photographic Evidence

-

Add additional comments here:

-

Additional Photos / Photographic Evidence

3. The Work

- 3.1 The Work

When completing this profile for more than 1 position, a separate "3.1 The Work" section must be completed for each job title.

-

3.2 Job Title (only 1 can be listed in each section):

-

3.3 Summary of job tasks:

-

3.4 Work Arrangements:

- Standard full-time - 5 day week, 38-40 hours, work between 6am-6pm/consistent start/end times

- Full-time - 9 day fortnight, 76-80 hours per fortnight, work between 6am-6pm/consistent start/end times

- 1 day per week (School-based Trainee/Apprentice) with optional additional hours during holidays

- Shift work - 38-40 hours per week, irregular or rotating start/end times

- Afternoon/Night shift - 76-80 hours per fortnight, consistently work on afternoon/night shift

- Casual - up to 38 hours per week, irregular start/end times

- Part-time - up to 4 days per week, regular start/end times between 6am-6pm

- Overtime required occasionally (once a month or less)

- Overtime required regularly (at least once a fortnight)

- Additional hours required during peak times / projects / certain times of the year (i.e. plant shutdowns, seasonal requirements - insect spraying)

- On-call

- Fly-in Fly-out (FIFO)

- Other, please describe in notes.

-

3.5 Shift Start Time/s - Finish Time/s: Break Time/s or break duration:

-

3.6 Select the Work Activity:

- Accommodation / Hotel Management - Category 2

- Airport Operations (Baggage, Freight, Ground Crew) - Cate 3

- Allied Health / Physio - Category 2

- Animal Services - Category 3

- Arboriculture, Horticulture, Landscaping and Gardening - Cate 3

- Cleaner - Domestic / Commercial Building or Workplace - Category 2

- Conservation and Land Management - Cate 3

- Construction - (Civil, Road, Plant), Plant Operator, Builder, Labourer, Bricklayer, Carpenter - Cate 3

- Construction - Foreman/Site Supervisor, Engineer, Maintenance Planner - Cate 3

- Customer Service - Airline / Airport - Category 2

- Customer Service - Financial / Banking - Category 2

- Customer Service - Post Office - Category 2

- Customer Service - Public Administration / Government - Category 2

- Customer Service - Retail - Category 2

- Education and Training - Category 2

- Electrical, Data, Telecommunications or Solar Trade - Cate 3

- Engineering / Mechanical technician / Servicing Work - Automotive, Heavy Vehicle, Mobile Plant - Cate 3

- Event Management / Arts and Recreation - Category 2

- Event, stage or live production assistant - Cate 3

- Financial or insurance services (via phone only) - Category 1

- Food and Beverage Service - Category 2

- Food Service - Commercial or Industrial Cooking - Category 2

- Forestry, Agriculture and Farming - Cate 3

- Healthcare and Social Assistance - Category 2

- Information Technology - support, repair & maintenance of computers / communication equipment - Cate 1

- Library or Community Services - Category 2

- Manufacturing, Sign Making - Cate 3

- Marketing, information, media and telecommunications (Interact with public)- Category 2

- Marketing, information, media and telecommunications (Not public facing) - Category 1

- Mining - Cate 3

- Painting or Plastering - Cate 3

- Pest Control - Cate 3

- Plumbing - Cate 3

- Postal Operations (Mail delivery and freight) - Cate 3

- Professional, managerial, clerical or administrative work - Government, office or other administrative setting - Cate 1

- Professional, managerial, clerical or administrative work - High risk location (i.e. Warehouse, Manufacturer, etc) - Cate 2

- Professional, managerial, clerical or administrative work - Public facing office - Cate 2

- Public Safety - Security, Correctional Services - Cate 3

- Rental, Hiring and Real Estate Services - Category 2

- Sports and Recreation - Category 2

- Transport, Logistics, Professional Drivers, Water Carters, Oil/Gas Tankers - Cate 3

- Warehouse / Stores Operations - Cate 3

- Waste Management, Industrial Cleaning or Hazardous Chemicals Manufacturing - Cate 3

- Water Treatment Operations - Cate 3

- Other

-

3.7 Equipment, tools and plant to be used (Please list or provide a photo of all plant/equipment/machinery/tools to be used):

- General office equipment: Computer, printer, desk phone, stationary (stapler, pens, paper, hole punch, etc)

- Specialised office equipment (i.e. Drill punch, laminator, guillotine, document binder)

- Hand tools

- Powered / electric hand tools

- Machinery (i.e. lathes, manufacturing equipment, robotic arms, etc).

- Mobile plant (i.e. Forklift, excavator, elevated work platform, etc)

- Motor vehicle for business purposes (this does not include commuting to/from work)

- Other

- Not Applicable

-

Please describe:

-

Please describe or provide a photo of the tools / equipment above:

-

Select the controls in place:

- See attached photographic evidence / documentation attached via email with this completed WHS Profile to WHSAction@maxima.com.au

- Iso – workers separated either by distance or physical barrier. For example: constructing a booth from which the plant can be operated remotely.

- Eng - a permanently fixed guard for areas not required to be accessed during use, maintenance or cleaning (i.e. distance guards on a feed chute)

- Eng - an interlock guard for areas requiring access during operation, maintenance or cleaning, that is connected to the plant's operating controls, so the plant can't operate when the guard is open or be removed/opened until all moving parts (i.e.cutting blade) have stopped.

- Eng - a fixed guard, which can only be altered or removed with a tool not normally available to the operator

- Eng - a presence sensing system which detects when a person (or part of someone’s body) enters the danger zone and stops a machine. (i.e. Photoelectric light beams, laser scanners and foot pressure mats, etc)

- Eng - Captive key system

- Eng - Critical safety systems/ high integrity fail-safe control, etc

- Admin - Safe Work Procedure / SWMS / JSA provided to workers prior to use

- Admin - Lock out/tag-out procedures to ensure the plant is isolated from all energy sources and cannot be operated while maintenance or cleaning work is being done. This must be done before accessing any parts of the plant for maintenance or cleaning work.

- Admin - Training, information and instruction to workers who use the plant.

- Admin - Supervision

- Admin - Work Group / Spotter / Work Colleague

- Admin - Consultation with workers on the plant and work processes being used.

- Admin - Signage to warn people of a hazard (i.e. a pinch point)

- PPE - Hearing protection

- PPE - Protective clothing (i.e. 100% cotton, high vis)

- PPE - Respirator (half face, full, dust mask)

- PPE - Gloves

- PPE - Safety Glasses / Eye protection

- Other

- No controls in place

-

Describe what other controls are in place:

-

Review all applicable Codes of Practice (i.e. Managing risks of plant in the workplace, Abrasive Blasting, Spray painting and powder coating, Welding processes, Excavation work, Demolition work, Construction work, etc) and their recommended controls, and raise an action for implementation if required.

-

Select the controls in place for motor vehicle use:

- See attached photographic evidence / documentation attached via email with this completed WHS Profile to WHSAction@maxima.com.au

- Additional lights mounted for fog or low light conditions

- Air-conditioned vehicle

- Compliance / assurance activities to ensure vehicle is properly maintained, has in-date safety equipment, driver licence is still valid, etc

- Conduct vehicle familiarisation training with new makes and models which also includes setting up the vehicle to be ergonomic

- Documented Journey Management Plan / Procedure with planned routes and times, hazards identified, contact numbers, time of departure and estimated arrival, dedicated person to follow up if destination not reached by estimated time

- Documented procedure / policy on the safe use of vehicles that highlights applicable driving hazards, includes fatigue management / recommended driving lengths or distances.

- Driver behaviour consequence matrix / discipline procedure

- Driver training

- Drivers licence is checked as part of induction process

- Emergency response procedure / JSA for driving

- Expectations of driving behaviour communicated (i.e. during induction or prior to driving)

- Fatigue management system (i.e. driver eye-monitoring or IVMS that notifies when driving time without break has been exceeded)

- GPS Tracking

- In vehicle monitoring system (IVMS) / duress button or system that alerts of injury

- Informal journey management plan (i.e. work schedule management (allocated times to be at each location), buddy system/call in procedure at beginning and end of each day)

- Informal understanding that there is no driving in adverse weather conditions / no work or office work is conducted during adverse weather

- Items are restrained either by being kept outside of the driver cabin (i.e in the boot or tray of vehicle) or the use of cargo nets or seat belts.

- Kilometers driven are monitored

- Leased vehicles (maintenance and repairs are tracked and managed externally)

- Minimum licence requirements (e.g.2nd year of P Plates)

- Mobile phone use policy (i.e. not allowed to use whilst driving) or Bluetooth connection with steering wheel mounted answer button or similar

- Motor vehicle maintenance schedule

- New vehicles (less than 1 year)

- No driving outside of usual business hours (i.e. only during the day, not at dawn, dusk or night)

- No lone driving

- Private vehicle use process. Ensuring vehicle details such as the vehicle is registered, insured for work purposes, vehicle is roadworthy / appropriately serviced, valid drivers licence

- Regular vehicle inspections

- Satellite phone

- Sun glasses to reduce glare and avoid objects from entering eye

- Sun visor to reduce glare

- Undocumented procedure / understanding of safe vehicle use and requirement for vehicles to be road worthy

- Vehicle specifications defined, including minimum safety standards required

- Other

- No controls in place

-

Describe what other controls are in place:

-

A Maxima WHS Consultant may contact you for further information or to schedule a workplace inspection and risk assessment.

4. Hazards in the workplace

-

Will the Job/Task require our worker to undertake or be exposed to any of the following? (select all that apply):

-

Biological materials (human waste, needle stick injury, blood, etc)

-

Select the controls in place:

-

Describe what other controls are in place:

-

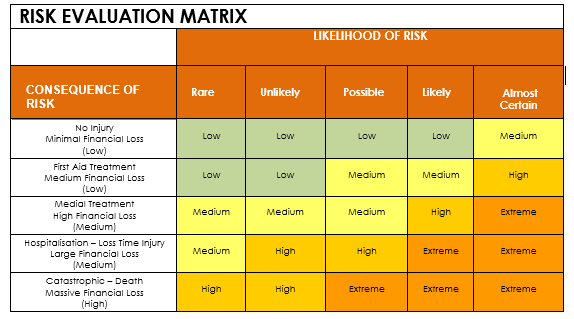

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Confined Spaces

-

Select the controls in place:

-

Describe what other controls are in place:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Conveyor belt use

-

Select the controls in place:

- See attached photographic evidence / documentation attached via email with this completed WHS Profile to WHSAction@maxima.com.au

- Iso – workers separated either by distance or physical barrier. For example: constructing a booth from which the plant can be operated remotely.

- Eng - a permanently fixed guard for areas not required to be accessed during use, maintenance or cleaning (i.e. distance guards on a feed chute)

- Eng - an interlock guard for areas requiring access during operation, maintenance or cleaning, that is connected to the plant's operating controls, so the plant can't operate when the guard is open or be removed/opened until all moving parts (i.e.cutting blade) have stopped.

- Eng - a fixed guard, which can only be altered or removed with a tool not normally available to the operator

- Eng - a presence sensing system which detects when a person (or part of someone’s body) enters the danger zone and stops a machine. Photoelectric light beams, laser scanners and foot pressure mats are examples of these safety guards. They rely on sensitive trip mechanisms and the machine being able to stop quickly.

- Admin - Safe Work Procedure / SWMS / JSA provided to workers prior to use

- Admin - Lock out/tag-out procedures to ensure the plant is isolated from all energy sources and cannot be operated while maintenance or cleaning work is being done. This must be done before accessing any parts of the plant for maintenance or cleaning work.

- Admin - Training, information and instruction to workers who use the plant.

- Admin - Supervision

- Admin - Consultation with workers on the plant and work processes being used.

- Admin - Signage to warn people of a hazard (i.e. a pinch point)

- Personal protective equipment (i.e. gloves)

- Other

- No controls in place

-

Describe what other controls are in place:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Electricity or electrical shock hazards

-

Select the controls in place:

- See attached photographic evidence

- Lock out / Tag Out Process

- Safety Switches

- Testing and Tagging completed regularly

- Visual inspection of cords and electrical equipment.

- Other

- No controls in place

-

Describe what other controls are in place:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Falling objects

-

Select the controls in place:

- See attached photographic evidence / documentation attached via email with this completed risk assessment to WHSAction@maxima.com.au

- Iso - Designated walkways

- Iso - Barricading

- Eng - Speed restricted plant

- Admin - communication between work group

- Admin - Risk and controls covered during induction

- Admin - Mobile plant operator skills and capabilities are assessed prior to operating any plant (i.e. VOC)

- Admin - Mobile plant licensing & training

- Admin - Training - load restraint / packing

- Admin - Supervision

- Admin - Safe work procedures / JSA / SOP / SWMS

- Admin - Traffic management plan (including speed limit signage)

- PPE - Drop nets

- PPE - Hard hat

- Other

- No controls in place

-

Describe what other controls are in place:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Fast pace

-

Select the controls in place:

- See attached photographic evidence / documentation attached via email with this completed WHS Profile to WHSAction@maxima.com.au

- Adequate training on how to conduct work with plant / equipment driving pace

- Alternative work is available during low work activity

- Documented procedure / work instruction

- Job rotation

- More workers are scheduled during peak times

- Plant / machinery speed has been reduced to an acceptable level

- Regular breaks

- Short time exposure

- Other

- No controls in place

-

Describe what other controls are in place:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Fatigue

-

Select the controls in place:

- See attached photographic evidence / documentation attached via email with this completed WHS Profile to WHSAction@maxima.com.au

- Certain amount of hours break required between shifts

- Covered during induction

- Documented fatigue management procedure

- Fatigue awareness/management training

- Fatigue toolbox talk

- Informal arrangement where worker starts later the next day / has time off

- Supervisor / team members look out for signs of fatigue in colleagues

- Supervisor actively encourages workers to speak up if feeling fatigued

- Time off in lieu (TOIL) process (formalised)

- Other

- No controls in place

-

Describe what other controls are in place:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Hazardous Chemicals - Use / Store / Manufacture / Transport by worker

-

Attach photos below of:

1. The hazardous substances / chemicals or materials present in their storage area;

2. Any PPE, spill clean up or spill containment kits and their contents; and

3. Safety Data Sheets and their location.

Review the changes to workplace chemical laws and any applicable guidance materials under GHS 7: https://www.safeworkaustralia.gov.au/collection/ghs-7-guidance-material

NOTE: Users should not accept hazardous chemicals manufactured or imported on or after 1 January 2023 unless they are classified and labelled in accordance with GHS 7 and have SDS prepared in accordance with GHS 7. -

List or photograph the type of chemicals or substances the worker may use / handle / come into contact with:

- See attached photographic evidence

- Aerosols

- Fertilisers

- Fuels

- Greases

- Lubricants

- Oils

- Paints

- Gases

- Poisons

- Pesticides

- Non hazardous substances

- Other

-

The other types of chemicals / substances the worker may come into contact with:

-

Select the controls in place and or provide photographic evidence:

- See attached photographic evidence of controls in place

- Substitution - Alternative non-hazardous chemicals are used where possible

- Isolation - distancing workers from hazardous chemicals and any potential hazards generated by their use (i.e. operations with chemicals confined to one room with restricted access; plant with a positive pressure cabin that prevents airborne contaminants from entering)

- Eng - Adequate ventilation or extraction in place (by natural, forced or mechanical means)

- Admin - Worker has no direct contact or interaction with chemicals as part of their usual work tasks.

- Admin - Spill containment procedure / emergency plan (i.e. Spill kits, Bunded areas, isolated drain and containment system, adequate fire fighting equipment for the substances on site, etc)

- Admin - Chemicals and substances are stored and labelled correctly (i.e. All items are clearly identified with labels not faded / damaged, as per GHS standard; Containers are not broken or leaking; Stored in bunded area / chemical cabinet with appropriate signage, not with other chemicals that could cause a reaction, out of direct sunlight / away from heat, etc)

- Admin - Current Safety Data Sheets available for all hazardous chemicals or substances / Maintain a register and manifest and providing notification to regulator of manifest quantities (if required).

- Admin - Documented procedures in place (i.e. SOPs, SWMS, JSA, work instructions, etc)

- Admin - Eating, drinking and smoking in areas where hazardous chemicals are used, stored or handled is prohibited

- Admin - Health monitoring for workers

- Admin - Job rotation / short term exposure

- Admin - Purchasing policy (i.e. only able to purchase approved chemicals / substances, purchase premixed chemicals or smaller quantities, purchasing quantity limits, risk of physical or chemical reaction identified, etc)

- Admin - Regularly cleaning of areas and or maintenance schedule for engineered controls

- Admin - Suppression methods (i.e. vacuuming or wetting areas to suppress dust)

- Admin - Supervision

- Admin - Training and instruction

- Admin - Washing facilities for rinsing off chemicals (i.e. hand washing stations, showers, laundering of used clothes by host, etc)

- Admin - Warning Signage

- PPE - Use of appropriate PPE required and available to worker.

- Other

- No controls in place

- Safety Data Sheet/s are out of date or not available to worker

-

Please describe what other controls are in place:

-

Review all applicable Codes of Practice (i.e. Managing risks of hazardous chemicals in the workplace, Labelling of workplace hazardous chemicals, etc) and raise an action to consider and implement additional controls to reduce the level of risk.

-

What is the residual risk of injury through the contact, inhalation, ingestion and or physical reaction of hazardous chemicals or substances?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Hazardous Chemicals - Stored on site, but worker would not have any contact with under usual work conditions.

-

Attach photos below of:

1. The substances / chemicals or materials present in their storage area;

2. Any PPE, spill clean up or spill containment kits and their contents; and

3. Safety Data Sheets and their location.

Review the changes to workplace chemical laws and any applicable guidance materials under GHS 7: https://www.safeworkaustralia.gov.au/collection/ghs-7-guidance-material

NOTE: Users should not accept hazardous chemicals manufactured or imported on or after 1 January 2023 unless they are classified and labelled in accordance with GHS 7 and have SDS prepared in accordance with GHS 7. -

List or photograph the type of chemicals or substances the worker may use / handle / come into contact with:

- See attached photographic evidence

- Aerosols

- Fertilisers

- Fuels

- Greases

- Lubricants

- Oils

- Paints

- Gases

- Poisons

- Pesticides

- Non hazardous substances

- Other

-

The other types of chemicals / substances the worker may come into contact with:

-

Select the controls in place and or provide photographic evidence:

- See attached photographic evidence of controls in place

- Substitution - Alternative non-hazardous chemicals are used where possible

- Isolation - distancing workers from hazardous chemicals and any potential hazards generated by their use (i.e. operations with chemicals confined to one room with restricted access; plant with a positive pressure cabin that prevents airborne contaminants from entering)

- Eng - Adequate ventilation or extraction in place (by natural, forced or mechanical means)

- Admin - Worker has no direct contact or interaction with chemicals as part of their usual work tasks.

- Admin - Spill containment procedure / emergency plan (i.e. Spill kits, Bunded areas, isolated drain and containment system, adequate fire fighting equipment for the substances on site, etc)

- Admin - Chemicals and substances are stored and labelled correctly (i.e. All items are clearly identified with labels not faded / damaged, as per GHS standard; Containers are not broken or leaking; Stored in bunded area / chemical cabinet with appropriate signage, not with other chemicals that could cause a reaction, out of direct sunlight / away from heat, etc)

- Admin - Current Safety Data Sheets available for all hazardous chemicals or substances / Maintain a register and manifest and providing notification to regulator of manifest quantities (if required).

- Admin - Documented procedures in place (i.e. SOPs, SWMS, JSA, work instructions, etc)

- Admin - Eating, drinking and smoking in areas where hazardous chemicals are used, stored or handled is prohibited

- Admin - Health monitoring for workers

- Admin - Job rotation / short term exposure

- Admin - Purchasing policy (i.e. only able to purchase approved chemicals / substances, purchase premixed chemicals or smaller quantities, purchasing quantity limits, risk of physical or chemical reaction identified, etc)

- Admin - Regularly cleaning of areas and or maintenance schedule for engineered controls

- Admin - Suppression methods (i.e. vacuuming or wetting areas to suppress dust)

- Admin - Supervision

- Admin - Training and instruction

- Admin - Washing facilities for rinsing off chemicals (i.e. hand washing stations, showers, laundering of used clothes by host, etc)

- Admin - Warning Signage

- PPE - Use of appropriate PPE required and available to worker.

- Other

- No controls in place

- Safety Data Sheet/s are out of date or not available to worker

-

Please describe what other controls are in place:

-

Review all applicable Codes of Practice (i.e. Managing risks of hazardous chemicals in the workplace, Labelling of workplace hazardous chemicals, etc) and raise an action to consider and implement additional controls to reduce the level of risk.

-

What is the current level of risk from an incident involving the hazardous chemicals or substances on site?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Hazardous manual tasks (i.e. computer work)

-

Select how the hazard could occur:

- Please see attached photo of risk assessment / standard operating procedure or hazards

- Continued use of any hand tool, plant or equipment for prolonged time without adequate time to recover.

- Cumulative damage to workers body tissue (i.e. muscles weakened over time due to repetitive use)

- Exposure to wind forces or adverse weather conditions may increase force required to handle items, particularly those that are large and or flexible during sudden gusts of wind)

- Handling animals

- Handling people

- High job demands

- Inadequate workplace training

- Inappropriate lighting (i.e. low or high levels, glare, reflection may lead to awkward or sustained postures to improve vision or avoid glare)

- Incorrect or inappropriate PPE (i.e. Gloves that get slippery in humid environments)

- Increased work pace to meet deadline / time constraints

- Limited resources and guidance available (i.e. PPE or equipment)

- Limited staff numbers

- Load is difficult to grip because of unsuitable handles, handholds or surface textures

- Maintaining an awkward posture while carrying a load for a sustained period of time

- Operating heavy hand tools, particularly for long periods of time (i.e. 3 kg power drill used unsupported)

- Operating plant, tools or equipment that deliver impacts (i.e. hammers, hammer drills, nail guns)

- Operating tools or equipment with the heaviest part in front of the wrist; handle diameter is too large, too small or too short; handle orientation does not place wrist in a handshake position; or cannot be used by either hand (i.e. right-handed design)

- Organisation of work (poorly scheduled / arranged)

- Poor housekeeping (i.e. obstructions in walkway, cleaning practices)

- Poorly designed mobile plant (i.e. operator controls, seating, etc)

- Poorly maintained or irregularly serviced tools, plant or equipment with potential to increase the force required to operate (i.e. blunt drill bits, an unsharpened knife, triggers/buttons/levers required to push/pull)

- Shift arrangements / fatigue

- Slippery, uneven or unsuitable floor surfaces (i.e. required to push heavy trolley over carpet / gravel)

- The size, shape and weight of the load (i.e. large, bulky or heavy load that cannot be held close to the body, has asymmetrical sides or puts an uneven force on the spine)

- Unstable or unwieldy loads which may create sudden or high muscle force

- Using unsuitable tools for the task

- Work area design and layout (i.e. positioning / height or width of workbenches, conveyors, furniture, fittings and the equipment used)

- Worker lacking skill or experience for job task

- Worker physical characteristics (i.e. mismatch between worker and task; mismatched heights and strength of workers carrying out a team lift)

- Workers unable to influence routines/organisation of work, workload / pace, work methods, etc.

- Working in a hot, cold or humid environment

- Other

-

Please describe:

-

Select the controls in place:

- See attached photographic evidence / documentation attached via email with this completed WHS Profile to WHSAction@maxima.com.au

- Adjustable height desk / standing desk

- Adjustable seating

- Changed the work process so that loads do not have to be lifted or moved by hand

- Covered during induction

- Footrest

- Frequent short rest breaks, job rotation and or a mixture of repetitive and none repetitive tasks

- Mechanical aid (i.e. trolley)

- Multiple person lift

- Pre-employment medical

- Safe work procedure / SOP / JSA / SWMS

- Signage / Label

- Smaller containers to reduce the weight of the load

- Supervision

- Toolbox talk

- Tools with comfortable none slip handles

- Training in safe manual handling techniques

- Other

- No controls in place

-

Please describe:

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

Hot / cold work environments (i.e. cold air conditioning, near heat generating equipment)

-

Select the controls in place:

- See attached photographic evidence / documentation attached via email with this completed WHS Profile to WHSAction@maxima.com.au

- Air-conditioned work area

- Building is insulated and or sources of radiant heat/cool (i.e. pipework) are cladded or enclosed

- Cool shaded or air-conditioned area to take break when required at or near work location

- Cooling neck / wrist bands

- Covered during induction

- Documented heat/cold stress procedure

- Heavy or strenuous work is scheduled for cooler times of the day or year

- Hot machinery or surfaces are isolated using shields, barriers and guards (i.e. around a furnace)

- Informal procedure for managing heat/cold stress (verbal / understanding) that is actively encouraged by Supervisor

- Light breathable clothing

- Local exhaust ventilation used to remove heated air or steam

- No lone work, one or more workers to look out for heat/cold stress signs

- Plant is allowed to cool down prior to use

- Protective clothing (cold): Jackets, long warm pants, enclosed shoes, gloves, head wear (i.e. beanie)

- Protective clothing (heat): long sleeved shirts, long pants, wide brim hat/hard hat visor, enclosed shoes

- Regular breaks / work-rest schedules

- Rotate tasks

- Safe work procedures / JSA / SWMS / SOPs

- Shaded areas or able to erect shade to work under

- Targets and work rates are modified during hot/cold days / seasons to reduce physical exertion

- Task specific PPE (i.e. welders mask, fire-resistant clothing, gloves, apron, etc)

- Toolbox talk (i.e. given at the start of summer/winter or on expected hot/cold days)

- Use of automated equipment or processes to access hot locations.

- Use of plant or other equipment to reduce manual labour.

- Warning signs for hot / cold equipment, plant or areas

- Water available at work location

- Where possible, workers do the work elsewhere (i.e. prefabricate materials in air conditioned factories)

- Wide brim hat

- Work is organised to minimise physically demanding tasks, for example conduct work at ground level to minimise climbing up and down stairs or ladders

- Workers are encouraged to pace themselves and manage work schedule.

- Workplace has good air flow (i.e. fans, windows, whirly birds and/or vents).

- Other

- No controls in place

-

Describe what other controls are in place:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Loud noise levels which exceed the regulated standard in the general work environment (i.e. large crowd in a hall, using a phone headset, etc)

-

Select the controls in place and provide photographic evidence:

- See attached photographic evidence / documentation attached via email with this completed WHS Profile to WHSAction@maxima.com.au

- Cease work directive if area gets too loud

- Hearing protection

- Induction - risks and locations of loud areas discussed during induction

- Job / Task Rotation

- Noise maps

- Open air area

- PPE / Warning Signage

- Pre-employment medical hearing check

- Regular hearing tests

- Request no / little talking / noise whilst conducting task

- SOPs / JSAs / Risk Assessments

- Other

- No controls in place

-

Describe what other controls are in place:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

Multiple PCBU's / businesses operating in the same work area

-

Select the controls in place:

- See attached photographic evidence / documentation attached via email with this completed Self-Assessment to WHSAction@maxima.com.au

- Clearly defined or known work area boundaries (i.e. Always allocated the same work space, barricades, ground markings, signage, maps)

- Covered during induction

- Covered during job task training

- Noticeboard alerts

- Permit to work system / work approval process / simultaneous operations procedure

- Safe work procedures / JSA / SWMS

- Supervisor communicates key works that could impact that worker

- Toolbox / Prestart meeting with a representative for each work / all workers each morning

- Other

- No communication strategies in place

-

Other controls in place are:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-

On or near water

-

Select the controls in place:

- See attached photographic evidence / documentation attached via email with this completed Self-Assessment to WHSAction@maxima.com.au

- Barricading / no exposed edges

- Fall protection

- Flat / calm bodies of water (i.e. dam, etc)

- Life jackets

- Safe operating procedures / SWMS / JSA, etc

- Supervision

- Training and instruction

- Travel at slow speed

- Warning label / signage

- Water rescue devices (i.e. lifesaver)

- Other

- No controls in place

-

Other controls in place are:

-

What is the current risk?

-

Raise an action to consider and implement controls to reduce the level of risk.

-

What is the residual risk?

-

Raise an action to consider and implement additional controls to reduce the level of risk.

-