Title Page

-

Site conducted

-

Conducted on

-

Address

-

Prepared by

-

Certificate Number: 224840A

-

Certificate Number: 137870A

-

Certificate Number:

FURNACE

-

Make of Furnace:

- Goodman

- Trane

- Comfortmaker

- York

- American Standard

- Frigidaire

- Ameristar

- OTHER

-

Type Make of Furnace

-

Model Number:

-

Furance Serial Number:

-

BTU Input Rating:

- 40,000

- 50,000

- 60,000

- 70,000

- 80,000

- 90,000

- 100,000

- Other

-

undefined

-

Year Installed:

-

Access Tee installed

-

Size of Port Installed

-

Thermostat Make:

-

undefined

-

Thermostat Model:

-

undefined

-

Thermostat

-

inform DCC and take note here

-

Automatic gas/fuel control valve assembly

-

inform DCC and take note here

-

System operating pressure

-

inform DCC and take note here

-

Operation of safety limit controls

-

inform DCC and take note here

-

Flame spreader

-

inform DCC and take note here

-

Flow switch

-

inform DCC and take note here

-

Clean & adjust burner orifices

-

inform DCC and take note here

-

Gas regulator

-

inform DCC and take note here

-

Thermocouple

-

inform DCC and take note here

-

Perform necessary adjustments to achieve peak performance

-

inform DCC and take note here

-

Efficiency (%)

-

Gas piping to appliance

-

inform DCC and take note here

-

Automatic vent damper & motor

-

inform DCC and take note here

-

Lube pumps and motors

-

inform DCC and take note here

-

Check and clean venting, flue and fresh air intake

-

inform DCC and take note here

-

Perform CO/Combustion efficiency test (heat exchanger and flues)

-

inform DCC and take note here

-

Check and clean blower motor, wheel and fan

-

inform DCC and take note here

-

Check and clean Heat Exchanger

-

inform DCC and take note here

-

Fan belt tension

-

inform DCC and take note here

-

Fan alignment

-

inform DCC and take note here

-

Electric ignition system

-

inform DCC and take note here

-

Check all electrical connections for tightness and cleanliness (clean and tighten where necessary)

-

inform DCC and take note here

-

Inspect 636 PVC exhaust/intake piping to exterior of RHU

-

inform DCC and take note here

-

Inspect furnace condensate lines and inspect condensate pump

-

inform DCC and take note here

-

Low voltage fuse

-

inform DCC and take note here

-

Relays

-

inform DCC and take note here

-

Replace Air filter

-

Size of filter

-

Additional Notes:

HUMIDIFIER

-

Is there a Humidifier

-

Make

-

Model

-

Humidistat

-

inform DCC and take note here

-

Clean Humidifier tray, float and pad.

-

inform DCC and take note here

-

Additional Note

HOT WATER TANK

-

Make of HWT

- Rheem

- John Wood

- Bradford White

- GSW

- AO Smith

- Other

-

Type Make of HWT

-

Type

-

BTU Input Rating

-

undefined

-

Year Installed

-

HWT Serial Number

-

Access Tee installed

-

Size of Port Installed

-

Automatic gas/ fuel control valve assembly

-

inform DCC and take note here

-

Gas / fuel regulator

-

inform DCC and take note here

-

Thermocouple

-

inform DCC and take note here

-

Inspect and clean intake screen on bottom of tank.

-

inform DCC and take note here

-

Perform CO/Combustion efficiency test (heat exchanger and flues)

-

inform DCC and take note here

-

Gas piping to appliance.

-

inform DCC and take note here

-

Electric ignition system

-

inform DCC and take note here

-

Check all electrical connections for tightness and cleanliness (clean and tighten where necessary).

-

inform DCC and take note here

-

Temperature set to maximum 40 C

-

inform DCC and take note here

-

Thermostat

-

inform DCC and take note here

-

Relief tube extends to 300mm off floor

-

inform DCC and take note here

-

Venting and fresh air intake

-

inform DCC and take note here

-

Manually operate HWT pressure relief valve

-

inform DCC and take note here

-

Perform necessary adjustments to achieve peak performance

-

inform DCC and take note here

-

Additional Notes:

SMOKE & CO DETECTORS

-

Smoke Detector

-

Quantity

Model

-

Model Number

-

Type Model Number

-

Replace By

-

CO Detector

-

Quantity

Model

-

Model Number

-

Type Model Number

-

Replace By

-

Smoke & CO Combination Detector

-

Quantity

Model

-

Model Number

-

Type Model Number

-

Replace By

-

Garage or Other location

-

Quantity

Model

-

Model Number

-

Type Model Number

-

Replace By

-

AA Quantity:

-

AAA Quantity:

-

9V Quantity:

-

Attached Garage?

-

Condition of Detectors on arrival?

-

inform DCC and take note here

-

Clean all detectors & vent holes free of obstructions.

-

inform DCC and take note here

-

Interconnection between detectors?

-

inform DCC and take note here

-

Verification of all detectors in power failure mode?

-

inform DCC and take note here

-

Reinstalled any detectors that have been removed and securely fastened to wall/ceiling?

-

Please inform DCC immediately !!!

-

Is there a disconnect switch between breaker and alarm?

-

Additional Notes:

DRYER VENT

-

Clean & Re-installed

-

Please inform DCC

SUMP PUMP

-

Does this unit have a sump?

-

Manufacturer’s instructions available (On Site ?)

-

Clean sump pit

-

inform DCC and take note here

-

Check and clean sump float, relocate float for proper operation in sump hole if required

-

inform DCC and take note here

-

Flush sump pit

-

inform DCC and take note here

-

Lubricate as required

-

inform DCC and take note here

-

Verify operation of check valves - clean as necessary

-

inform DCC and take note here

-

Check discharge piping condition and connections, tighten/secure as necessary

-

inform DCC and take note here

-

Pump discharges adequate distance from foundation wall

-

inform DCC and take note here

-

Sump pit covered

-

inform DCC and take note here

-

Clean pump including screen(s)

-

inform DCC and take note here

-

Check electrical wiring and connections – tighten/secure as necessary

-

inform DCC and take note here

-

Sump pump operates as intended

-

inform DCC and take note here

-

Additional Notes

ELECTRICAL PANEL

-

Year Installed

-

Amperage

-

Available Slots

BACKWATER CHECK VALVE

-

Backwater Check Valve in Unit?

-

Manufacturer:

-

Year Installed:

-

Model:

-

Valve Location:

-

Manufacturer's Instructions Availble on Site?

-

Inpect body and gate for debris

-

inform DCC and take note here

-

Clean and flush valve body and gate

-

inform DCC and take note here

-

Inspect and confim propoer operation

-

inform DCC and take note here

-

Test Valve for proper operation

-

inform DCC and take note here

-

Alert occupants of its presence and operation, Contact CFHA if Required.

-

Back valve operates as intended

-

inform DCC and take note here

-

Inspect and Clean Floats as necessary

-

inform DCC and take note here

-

Additional Notes:

TANKLESS WATER HEATER

-

Boiler system in Unit?

-

Manufacturer:

-

Type Manufacturer here

-

Model:

-

Year Installed:

Total Batteries Replaced

-

AA

-

9V

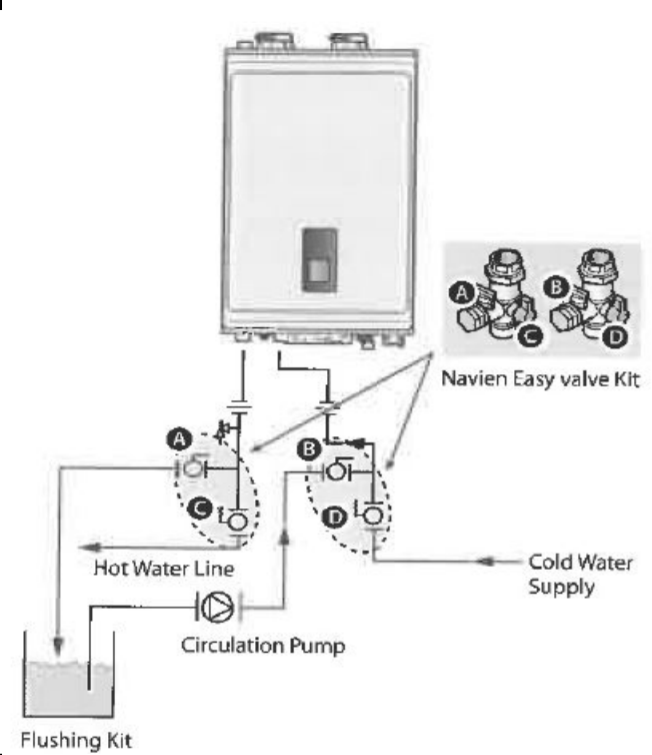

Before flushing gather the following items:

-

* Refer to Annex C in Boilers Manufacturers Maintenance Manual for further details and diagram below of steps to complete flushing of system.

-

A 5 galon bucket, cleaning solution with water, 3 hoses, and a water circulation pump. - OK

-

1. Press the Power button on the front panel to turn off boiler.

-

2. Disconnect the power supply to the boiler.

-

3. Close the "C" and "D" valves on the supply and return water lines.

-

4. Connect one tube to the "A" valve and place the free end on the bucket.

-

5. Connect one of the tubes to the circulation pump outlet and the return water line at the "B" valve.

-

6. Connect one tube to the circulation pump inlet and place the free end in the bucket.

-

7. Pour the cleaning solution into the bucket.

-

8. Open both "A" and "B" valves.

-

9. Turn on the circulation pump and allow the solution to circulate through the boiler for at least 45 minutes.

-

10. Rinse the cleaning solution from the boiler:<br><br>a. Remove the free end of the drain tube from the bucket and place it in the condensate drain or laundry tub (whereever the boiler drains).<br>b. Close the "B" valve and open the "D" valve. Do not open the "C" valve yet.<br>c. Allow the water to flow through the boiler for 5 minutes.<br>Close the "A" valve and open the "C" valve.

-

11. Disconnect all tubes.

-

12. Remove the strainer from the boiler and clean out any residue.

-

13. Reinsert the filter and ensure the filter cap is securely tightened.

-

14. Reconnect the power supply to the boiler.

-

15. Press the Power button on the front panel to turn on the boiler.

-

16. Ensure the boiler is operating normally for a few minutes before leaving the residence.

-

17. Clean and rinse out condensate trap.

-

Additional Notes:

HRV / ERV

-

Air Exchanger (HRV/ERV) in Unit?

-

HRV/ERV

-

Manufacturer:

-

Model:

-

Year Installed:

-

Manufacturer's Instructions Availble on Site?

-

Cleaned or replaced filters?

-

Clean recovery core

-

Clean wheels/blades

-

Clean blower motor

-

Clean condensation tray

-

Oil components as per manufacturer instructions

-

Wipe down entire unit inside and out

-

Clean exterior intake and exhaust hoods and grilles

-

Clean all interior exhast grilles (fully ducted only)

-

Clean as necessary, ducting between unit & exterior intake & exhaust hoods

-

Checked controls

-

Checked all operating modes

-

Balanced HRV given exisitng house ventilation systems

-

Air exchanger installation conforms to manufacturers requirements?

-

Air exchanger operates as intended?

-

inform DCC and take note here

-

Additional Notes:

INSPECTION VERIFICATION

-

Inspector Signature