Title Page

-

Performed by

Hegla Galactic Cutter PM - ONCE PER SHIFT

-

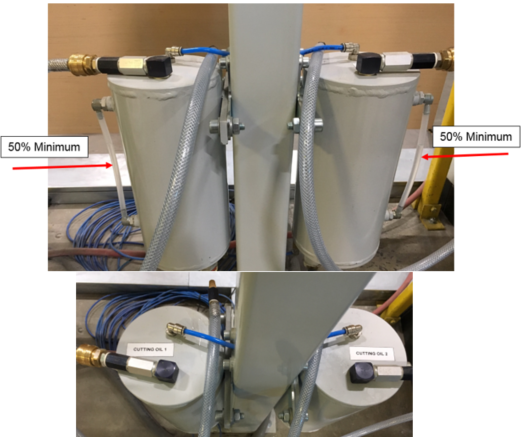

Cutting Oil Level : Minimum 1/2 Full

-

Verify that cutting oil level is 1/2 full at minimum.

-

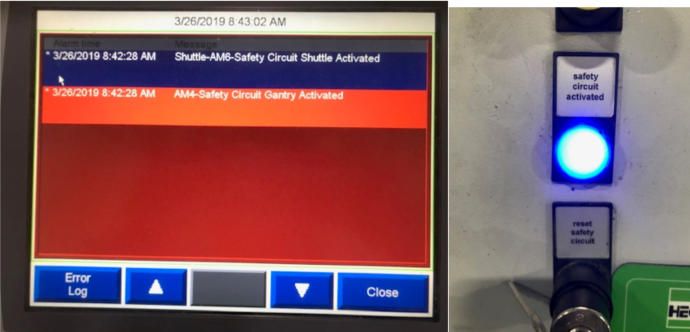

Verify all Safety Features (e.g. barriers, warning signals, etc.) are functioning

-

Verify that all safety features are functioning.

-

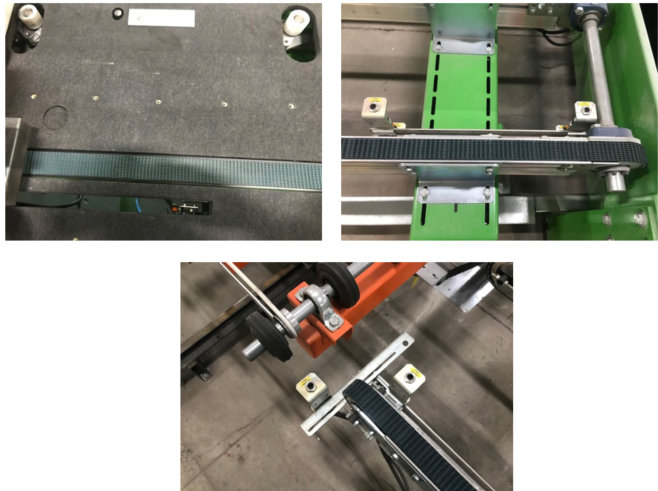

Blow off cutting table/breakout table felts thoroughly prior to shift start

-

Blow off cutting/breakout table felts thoroughly prior to shift start.

-

Clean all sensors with a lint free cloth. (Do not damage or shift sensors.)

-

Clean all sensors with a lint free cloth.

-

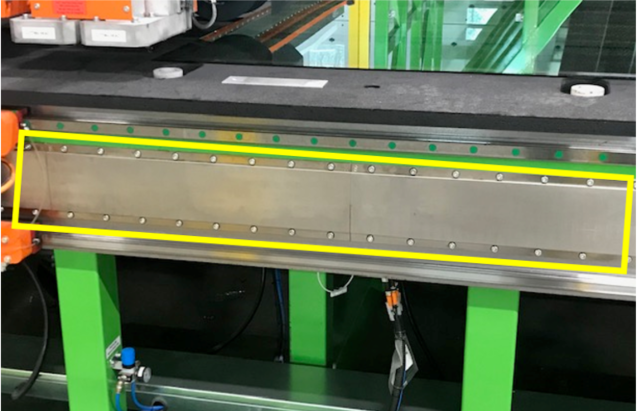

Clean and keep permanent magnets free of contamination. Use no more than glass cleaner as a cleaning agent and keep credit cards, phones, flash drives, etc. away from magnets as this will cause failure. These items should be placed in container hanging on glass wall before entering.

-

Clean and keep permanent magnets free of contamination using no more than glass cleaner as cleaning agent.

-

Check air dryer cylinder at corner of cutting table. Drain any moisture. Pressure should be at 6-8 bar.

-

Check air cylinder to verify that pressure is between 6-8 bar and drain any moisture.

-

Change cutter wheel and axle.