Title Page

-

Auditor

-

Conducted on

-

Package Serial Number

-

Package Model

-

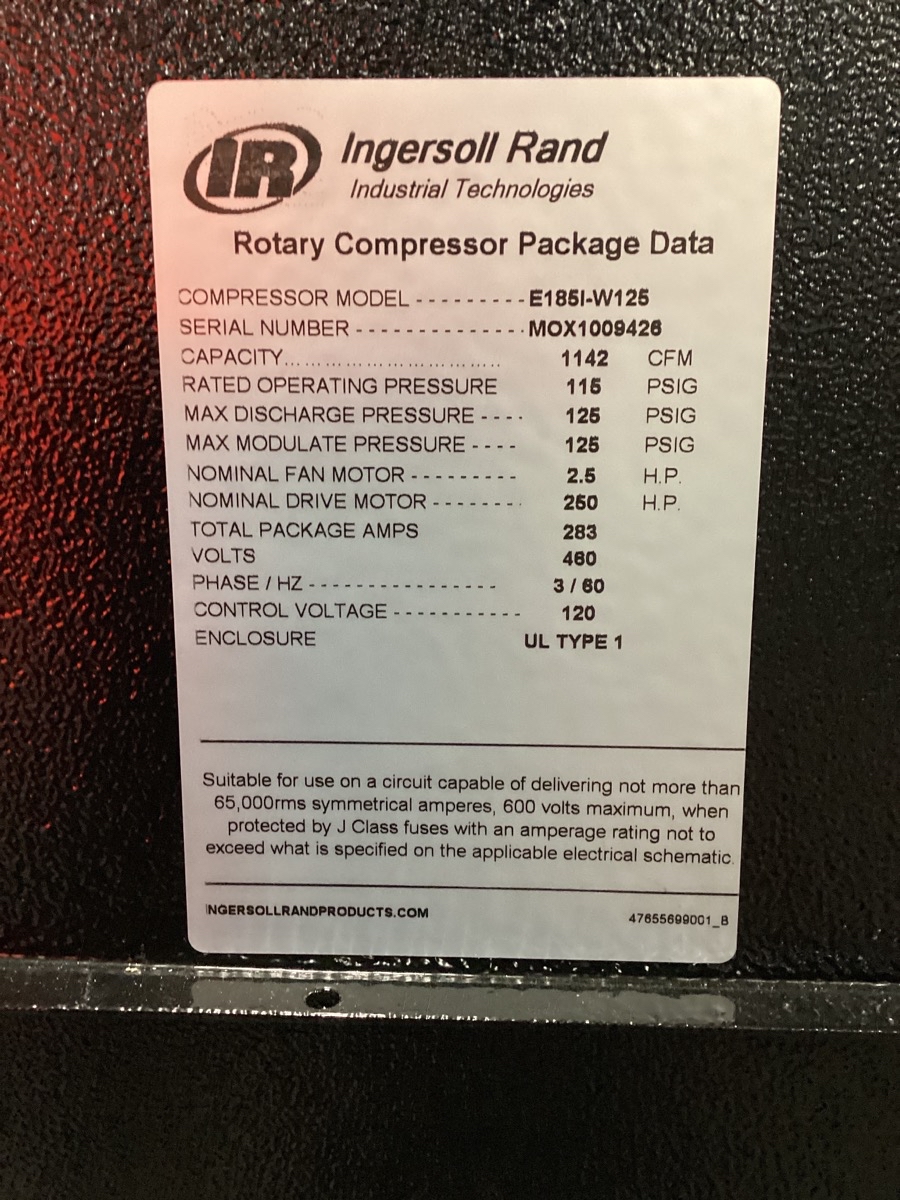

Compressor Package Data Plate EXAMPLE PHOTO

-

Take photo of compressor package data plate on exterior of compressor

Inspection Checklist

-

Exterior of compressor is clean and free of any damage/paint imperfections

-

Provide photos of the exterior damage/paint imperfections/cleanliness

-

Provide photos of all 4 sides of the machine with doors closed

-

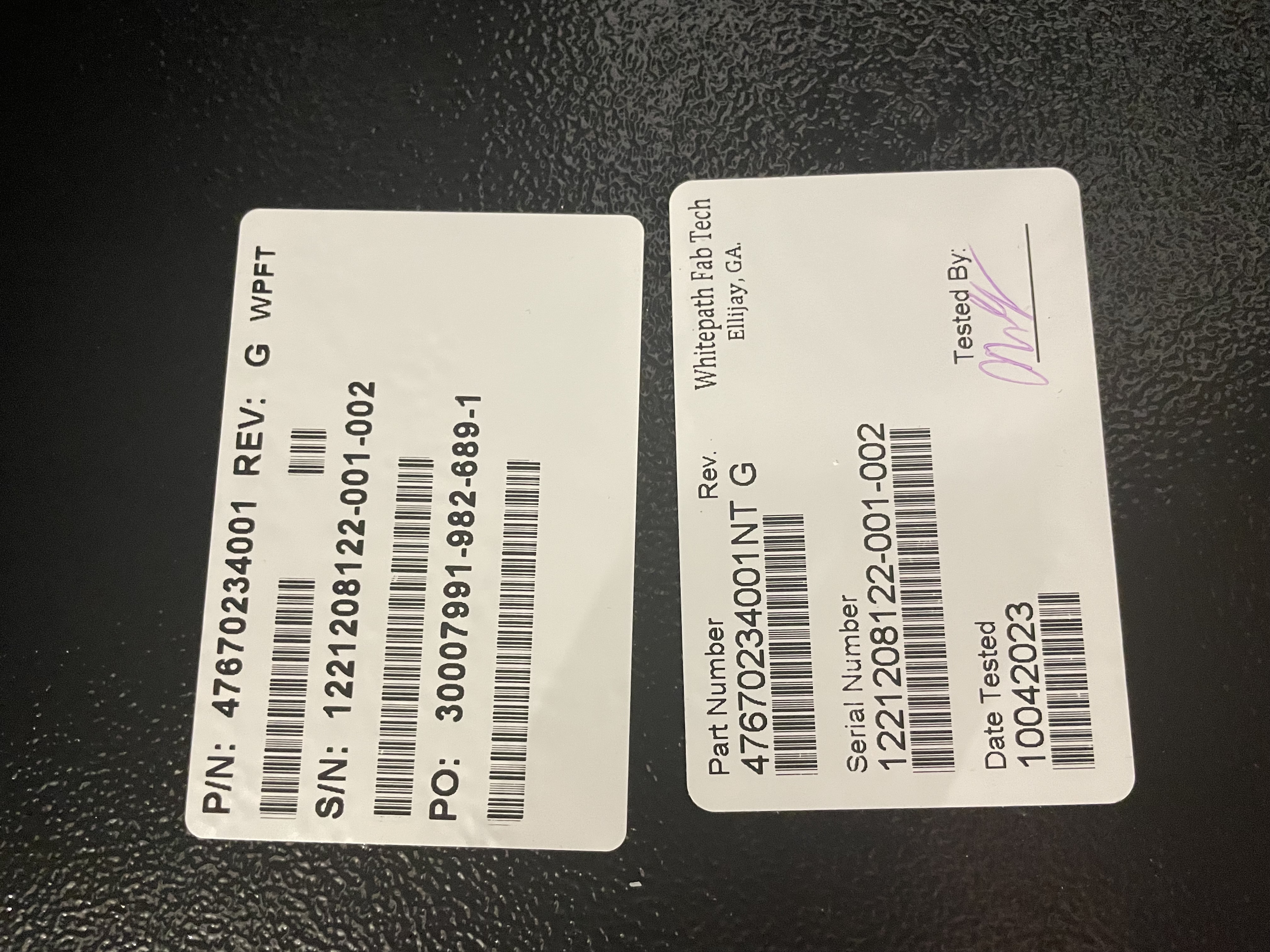

White Path Label EXAMPLE PHOTO

-

Take photo of white path label inside starter box

-

White Path Inspection Label EXAMPLE PHOTO

-

Take photo of white path inspection label inside starter box

-

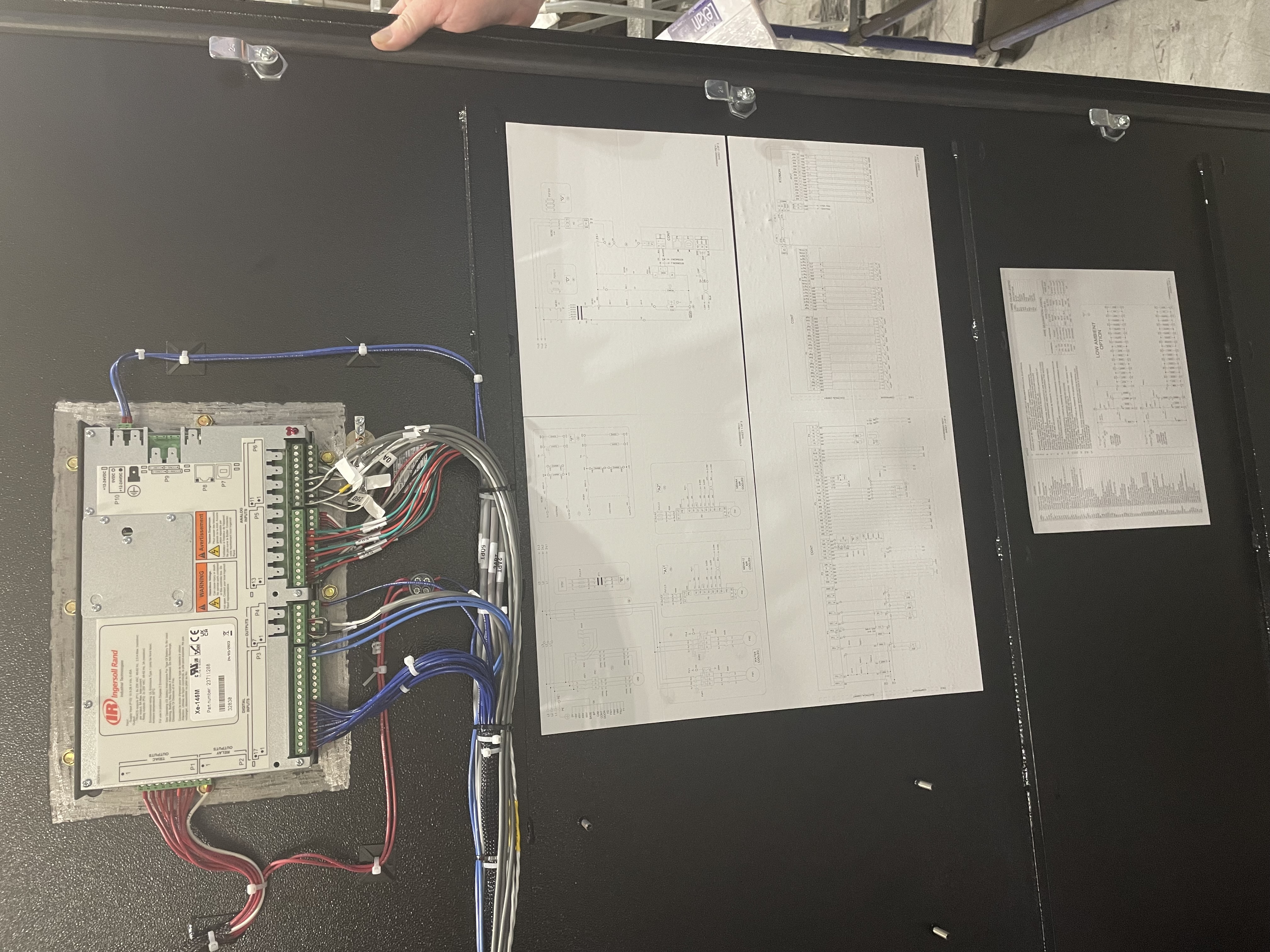

Starter Box Door with Wiring Schematic EXAMPLE PHOTO

-

Take photo of starter box door and wiring schematic

-

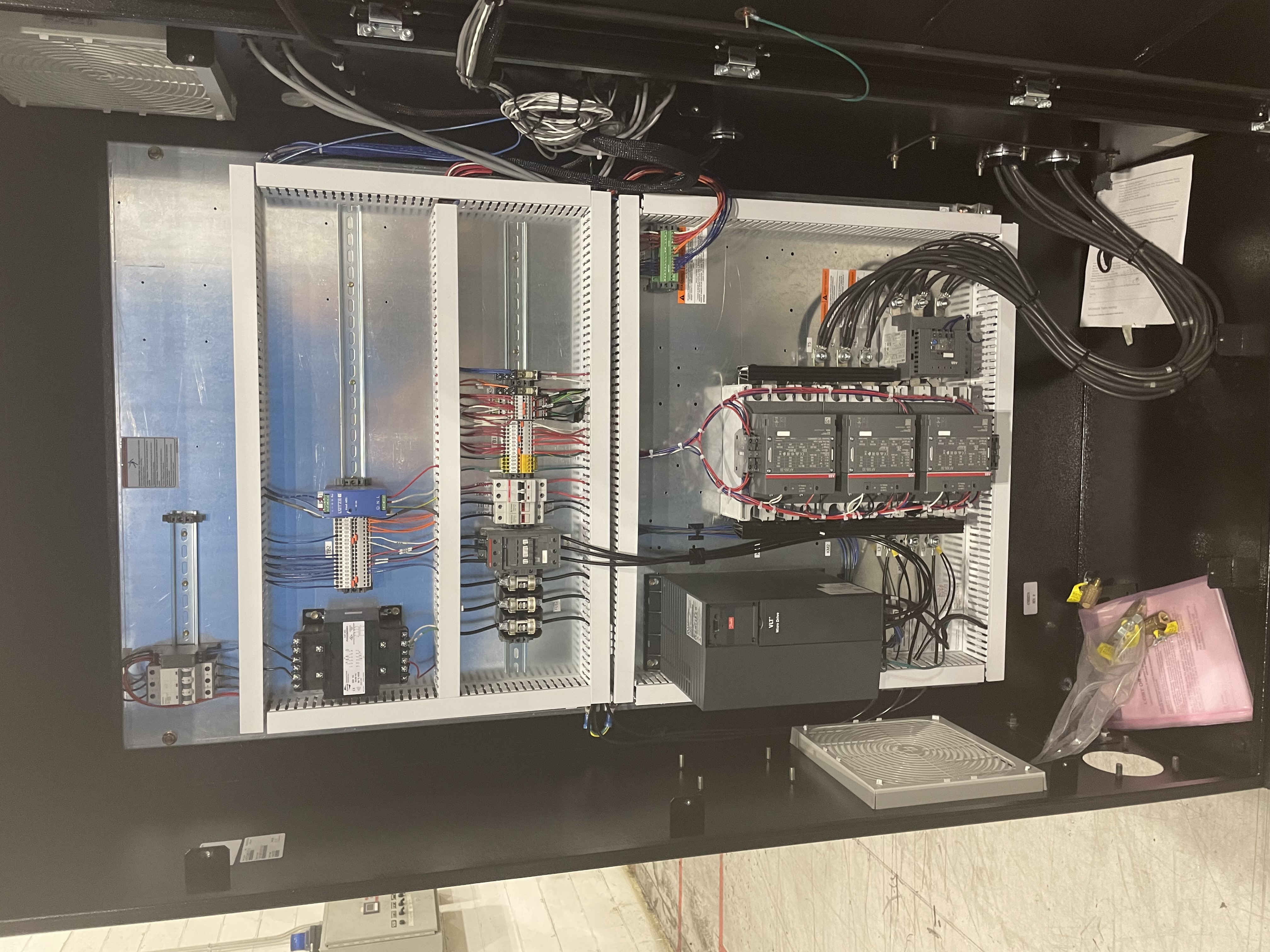

Interior of starter box EXAMPLE PHOTO

-

Photograph the interior of the starter box

-

Randomly check to ensure all wires are securely fastened inside starter box as well as no tight wires

-

Wires are neat, organized, zip tied, etc.. inside starter box

-

All ports sealed inside starter box

-

All glands connected to starter box are tight

-

Inside of machine is clean. No dirt, dust, leaks, etc.

-

All nuts and bolts are tight with torque marks where required

-

All pipes are tight and not touching

-

Pipes/wires have a correct or appropriate bend radius

-

All solenoids are secure

-

No components, wires, etc.. hanging below the base

-

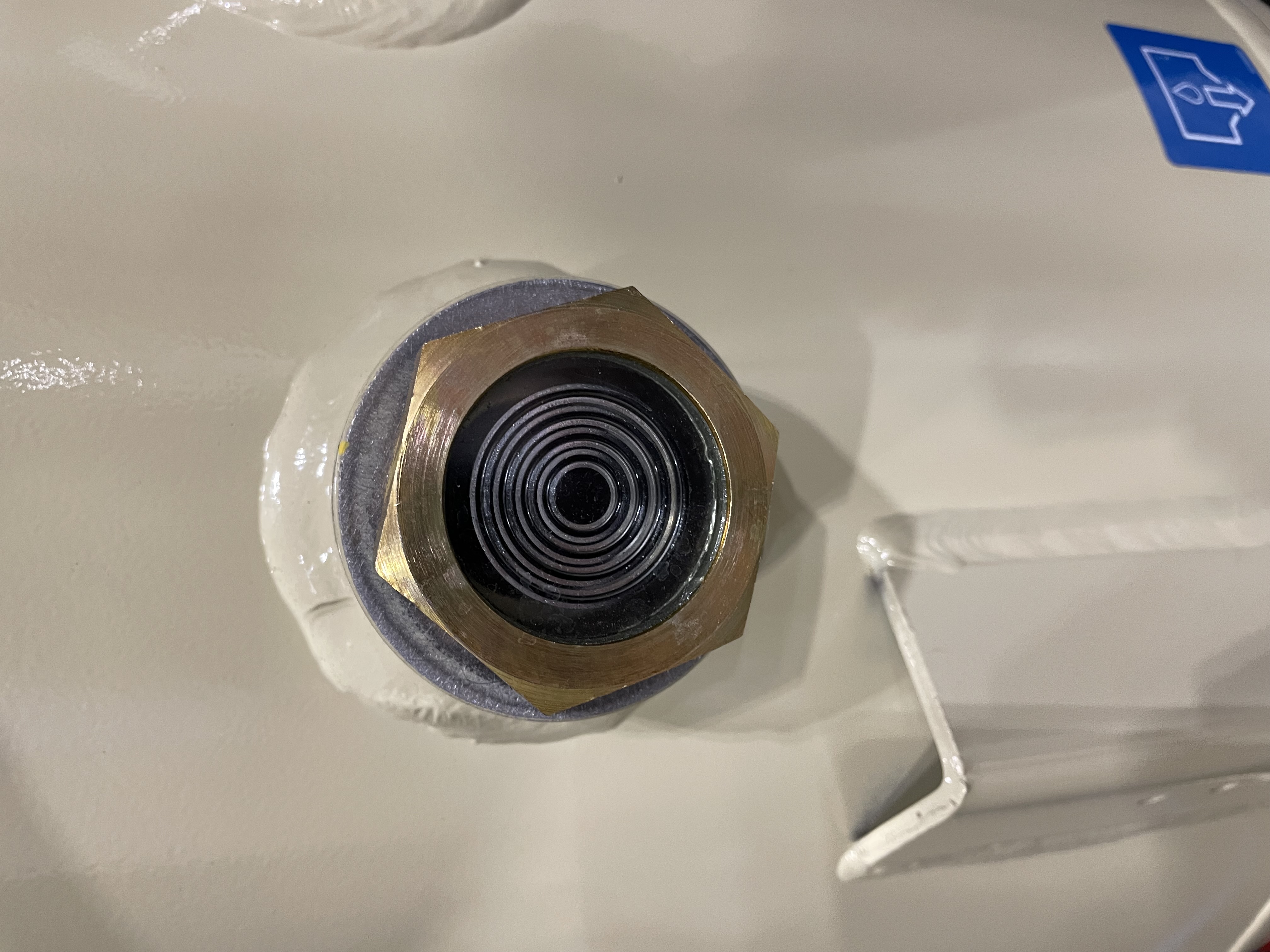

Oil Level Site Glass EXAMPLE PHOTO

-

Take photo of oil level in site glass to verify it is at the proper level

-

Take photo of inside of machine through each panel door

-

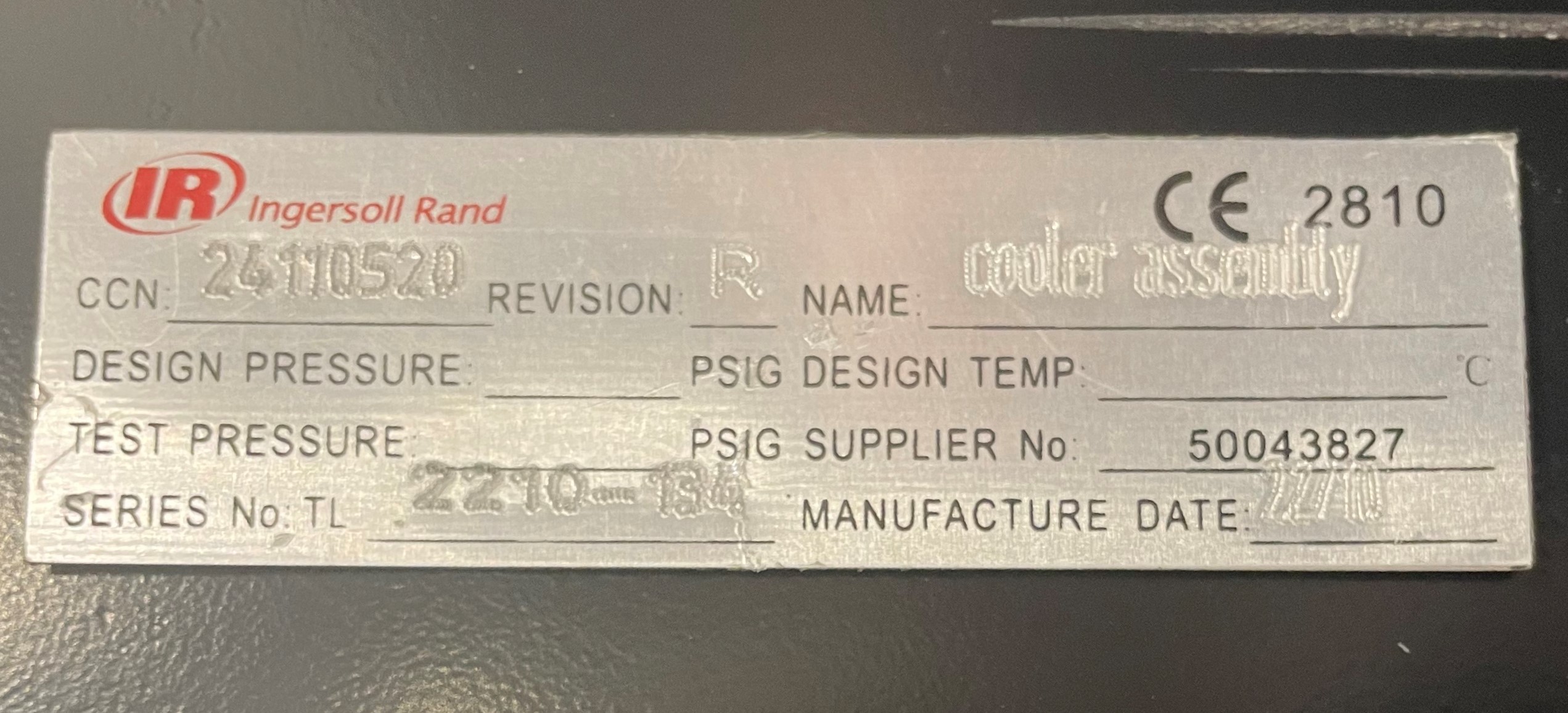

Cooler Data Plate EXAMPLE PHOTO

-

Take photo of cooler data plates

-

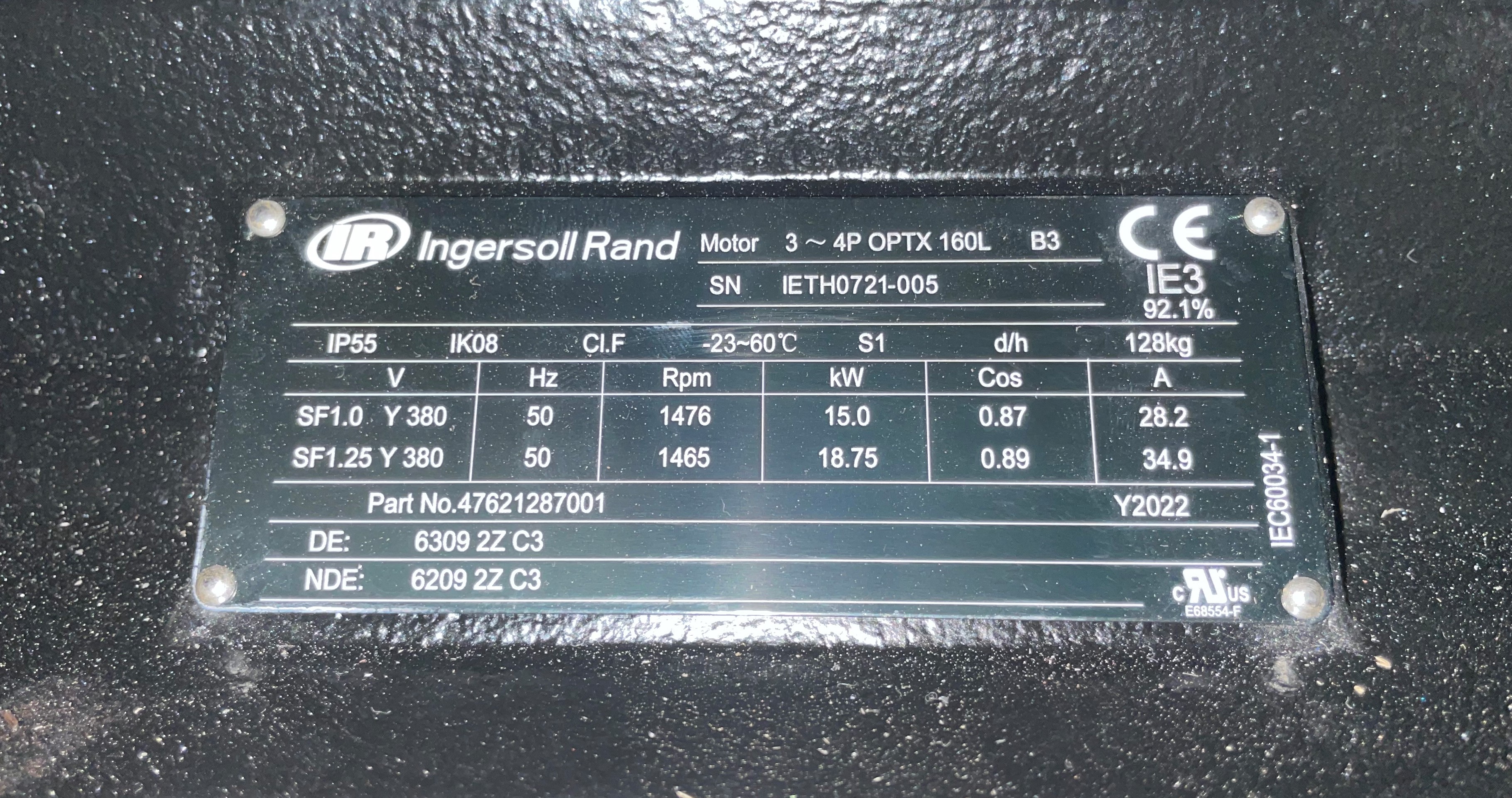

Main Drive Motor Data Plate EXAMPLE PHOTO

-

Take photo of main drive motor data plate

-

Fan Motor Data Plate EXAMPLE PHOTO

-

Take photo of fan motor data plates

-

Audit Complete: Place green dot on tag at starter box

-

Sign off on completed audit