Title Page

-

Opportunity Nummer

-

Opportunity Name

-

Erstellt am

-

Erstellt von

Contact

OEM-Customer

-

OEM-Customer

-

Name and address of end customer

-

Pre-commissioning

-

OEM customer contact for installation planning

-

Contact details

-

Function/Department

-

Email-Adress

-

Telephone number

-

Mobile number

-

Contact person of the Domino service technician<br>As above

-

Name

-

Contact details

-

Function/Department

-

Email-Address

-

Telephone number

-

Mobile number

-

Adresse der Vor-Inbetriebnahme

Endkunde

-

Contact person for installation planning Name

-

Contact details

-

Function/Department

-

Email-Adress

-

Telephone number

-

Mobile number

-

Contact person of the Domino service technician<br>As above

-

Name

-

Contact details

-

Function/Department

-

Email-Address

-

Telephone number

-

Mobile number

-

Abweichende Anschrift des Installationsortes

-

Address of the installation site

Task description

Complexity of the order

-

Level of integration

- 1 - standard product

- 2 - Level 1 incl. standard software

- 3 - Level 2 including QD-Datalink or QD Client-Server installation

- 4 - Solution products and/or QD unit/simple special software

- 5 - Complex order

-

Erläuterung zu den Integrationsleveln anzeigen

-

Level 1

Only Domino standard products are included in this order

E.g. simple tape installation with inkjet

- VKAD is fully responsible for the ILC preparation

- Support from the PcT was and is not required

- The integration or installation can be carried out by a "simply" trained technician

Level 2

This order includes only Domino standard products including Domino standard software (QD Lite or Standard)

For example, a Domino printer must be installed in conjunction with QuickDesign (Lite or Standard)

- VKAD is fully responsible for the ILC preparation

- Support from the PcT was and is not required

- The integration or installation can be carried out by a trained technician who has basic knowledge of the printer technology and software

Level 3

This order includes Domino standard products including Domino standard software which requires a database connection and more (Datalink or OD standard as client-server installation)

For example, a Domino printer must be connected to a complex database in conjunction with QuickDesign (Datalink or QD Standard as client-server installation)

- This order includes Domino standard products including more complex I/O or data connection to third party systems (e.g. Cable and Wire, Eier, Weihenstephan, ...)

For example, a Domino printer must communicate with a MOBA

- VKAD is fully responsible for the ILC preparation

- A product support by the PcT was and is required, the product supporter must be stored in the ILC

- The integration or installation can be carried out by a trained technician who has basic knowledge of the printer technology and software.

- If necessary, support must be provided by the PcT

- The support costs (on-site, remote, ...) must be clarified in advance by VKAD with the PcT.

- Possible external suppliers must be taken into account

- The planner arranges appointments with the product supporter and possible suppliers

Level 4

In this order are only Domino-Solution-Products and/or QD Units/ simple special software

E.g. a Domino Solution printer and/or QD Unite must be requested/edited from DPA or DLG or special software must be programmed for the application

- VKAD is fully responsible for the ILC creation and can hand over to a product specialist

- Support from the PcT is required and a product specialist is appointed

- The product specialist must be stored in the ILC

- Support by the product specialist during the entire IBN process

- The integration or installation can be carried out by a trained technician, the planning is done in coordination with the product specialist

- The necessary qualification of the technician and the support effort (on-site, remote, ...) by the PcT is coordinated between product specialist and THD/RSL

- PcT starts the arrangement with THD/RSL during the order check

- Possible external suppliers must be taken into account

- The final appointments with the customer, technicians, product support and possibly suppliers are made by the planner

Level 5

(All level 5 must be approved by THG)

In this order, more complex interrelationships of the order are to be considered

E.g. external suppliers (e.g. order volume larger than domino share) have to be considered, very high order volume where IBN planning is running over a long period of time (multiple locations and/or multiple technologies)

- VKAD is fully responsible for the creation of the ILC and can hand it over to a project manager

- A project manager from the PcT is appointed

- The integration or installation can be carried out by a trained technician, the planning is done in coordination with the project manager

- Responsibility for the whole IBN process is with the project manager

*** Translated with www.DeepL.com/Translator (free version) ***

Environmental conditions

-

Ambient temperature

- Ax-Serie, MJ2: 5 bis 45°C

- C-, F-Serie: 5 bis 35°C

- D-, M-, V-Serie: 5 bis 40°C

- G-Serie: 0 bis 50°C

- < 0°C, 5°C

- > 35°C, 40°C, 45°C

-

The selected ambient temperature is outside the technical machine specification. Please specify ambient temperature in °C

-

Ambient conditions

-

Please indicate relative humidity in %.

-

Power supply

Marking parameters

-

Production: maximum ... Hours / ... Shifts

-

Production location / line description / -part

-

Plant and process description

-

Installation location

-

Marking of

-

Composition of the marking

-

Position of the marking

-

Condition of the product during marking

-

Picture of a labelled product

-

Task description and solution proposal

-

Is it a trial installation

-

General condition for the trial

-

Agreed objective of the trial

Bemusterung

-

Sampling in sample department createt

-

SF Sample Number and/or SF Sample Link

Peripheral equipment

Product movement

-

Product movement

-

Maximum speed of line

-

Encoder pulses

-

Details

-

Maximale Geschwindigkeit der Linie

-

Drehgeber wird bereitgestellt durch

-

Montage mit

- Reibrad federgelagert

- Reibrad starr

- RS008 - Flex(K-)Kupplung 10mm x 10mm an Welle

- 13403 - Wellenkupplung für Drehimpulsgeber 10mm x 10mm

- DIG Dummy

- Regelgetriebe

-

Foto der Montageposition des Drehgebers

-

Drehgeber wird installiert durch

-

Stillstandszeit des Produktes zur Kennzeichnung (in Sek.)

-

Note on installation of the encoder or product movement

Product detection

-

Print trigger

- Light barrier (with reflector)

- Light sensor (without reflector)

- Initiator inductive

- Initiator Capacitive

- Potential-free contact

- Pushbutton/ switch

- Z-Pulse Encoder

- Internal, e.g. Continuous Printing Pack, PLC

- Communication protocol

-

Photo of mounting position of print trigger

-

Note on Installing of print trigger or product detection

Data connection and layout creation

-

Integration of the printer into a network

-

Details

-

Art der Datenkommunikation

-

Kommunikationsprotokoll

-

Software zur Layouterstellung

-

Details

Signal connection

-

Line stop in case of alarm messages or other signal exchange

-

Details

Plug systems

-

Provision of connector system, e.g. for backup system or connection to several lines

-

Details

Marking system

Selection of marking system

-

Technology

- Ax-Serie

- C-Serie

- G-Serie

- Laser

- M-Serie

- Macrojet 2

- V-Serie

V-Serie

-

Type of printer

- V120i (32mm - without cassette - no compressed air required)

- V230i (32mm - mit Kassette - kein Druckluft nötig)

- V230i (53mm - mit Kassette - kein Druckluft nötig)

- V320i (53mm - mit Kassette - Druckluft nötig)

- V320i (128mm - mit Kassette - Druckluft nötig)

- V320i auf Verfahrachse

-

Use of an existing bracket

-

Adapter plates for

-

Details

-

Existing printer type

-

Rahmen benötigt

-

Welcher

- OM

- Window Bracket

- Web Positioning System

- IM

- L Bracket

- Sonderbracket

-

Etikettierer

-

Druckluft 6-8 bar (trocken+ölfrei) verfügbar

-

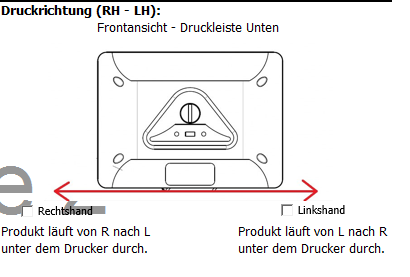

Druckrichtung

-

Provision of the ribbon by

-

Touchpanel/Touchscreen

- kein

- Touchpanel (gross)

- Touchpad (klein)

- Netzteil Touchpad (z.B. bei V320)

-

Cabling of TouchPanel longer than 3 m (max 7 meters) ?

-

Distance touch screen - printer (m)

-

Distance touch screen - machine (m)

-

Photo of installation location of printing unit

-

Type of machine (tubular bags, labelers etc.)

-

Camera processing

-

Grading

-

Special features of the readability and adhesion

Laser

-

Industry

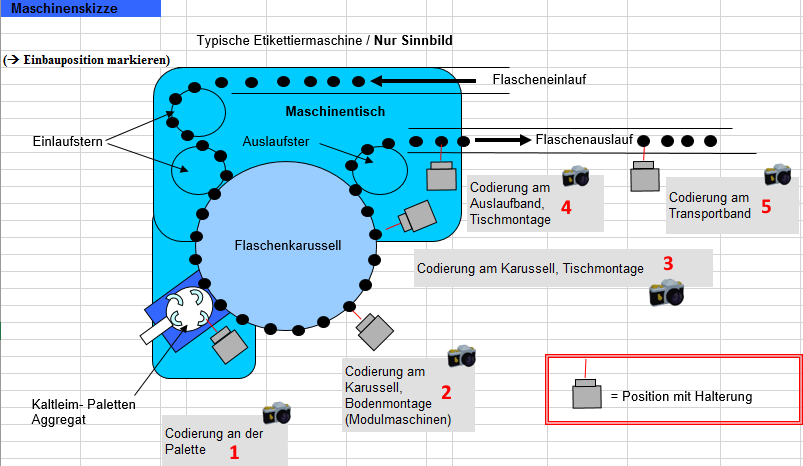

Etima

-

Possible marking positions

-

Marking position

-

Height adjustable aggregate

-

Labelling direction

- Right turning

- Left turning

- Heineken curve

-

Hersteller der Maschine

-

Hersteller

-

Modellbezeichnung/Kommissionsnummer

-

Regelgetriebe mit freier Aufnahme für Drehgeber des Kennzeichnungssystems vorhanden

-

Geschw. Palette

-

Zeigt Datierfeld nach aussen

-

Datenanbindung (Serial Conditional Printing)

-

Photo of the position of the print head

-

Performance bottle/hour

-

Label material

-

Coding field size

-

Print direction

- parallel (horizontal)

- 90° to running direction (vertical)

-

Bottle types (glass, PET, disposable, reusable, plantbottle)

-

Laser wavelength

-

Coding position on bottle

Getränkeindustrie

-

Datenanbindung (Serial Conditional Printing)

-

Foto der Position des Druckkopfes

-

Leitstung FL/Stunde

-

Etikettenmaterial

-

Datierfeldgröße

-

Druckrichtung

- parallel (horizontal)

- 90° to running direction (vertical)

-

Flaschensorten (Glas, PET, Einweg, Mehrweg, Plantbottle)

-

Laser Wellenlänge

-

Datierposition auf der Flasche

-

Conduit length (between scan head and controller)

-

Conduit length between scan head and controller

-

Photo of installation location of control

-

Supply of compressed air

- 4-7 bar tech. Compressed air by customers

- Montage Air Chiller

-

Extraction unit is provided by

- Domino

- Customer

- OEM

- Not required

-

Suction chamber [Include in scope of delivery]

- L015356ATO - suction chamber for 10mm scan head with 80mm optics

- L015357ATO - suction chamber for 10mm scan head with 100mm optics

- L015358ATO - suction chamber for 10mm scan head with 120mm optics

- L015359ATO -suction chamber for 10mm scan head with 150mm optics

- L015360ATO - Suction chamber for 10mm scan head with 200mm optics

- Other

-

Details of the suction chamber

-

Installation of the suction chamber by

-

Photo of the installation site of the suction unit/suction chamber

-

Installation of the suction chamber by

-

Foto des Installationsortes der Absaugung/Absaugkammer

-

Planning and supply of laser safety enclosure by

-

Interlock version in the machine

-

Notes on the interlock connection

-

Installation of laser safety enclosure by

-

Laser protection classification class 1, according to BGV B2/OStrV, per device, incl. complete documentation and certificate by Domino

-

Water cooler required

-

Type

-

Installation of water cooling by

-

Photo of the chiller installation site

Ax-Serie

-

Nozzle size

-

Conduit length

Ax-Serie - Weitere Informationen

-

Cleaning with high pressure cleaner

-

Multiple printers on one touch panel?

-

Cable length between touch panel and printer

-

Kabellänge zwischen Touch Panel und Drucker

-

Ink type

-

Photo of printhead installation location

Domino Cloud Interface (DCI)

-

Domino Cloud Interface

-

Type of installation

-

Connected: Several printers connected via a DCI with DCI as network participant to switch and/or printer or to QuickDesign. Cloud over 3G or customer LAN.<br><br>Stand Alone: One DCI per printer, no networking or QuickDesign connection. Cloud over 3G or customer LAN.

-

Printer:

- EPT022075 Comms Pack for Printer

- EPT041081 Port in printer

Order separately:

- EPT028998 - DCI (Rev.2) E.U. SIM, incl. EPT040473

- EPT028420 DCI housing IP66

If data connection desired:

Order for any printer:

- EPT028315 Ethernet cable Printer 5m

If necessary, a switch with accessories for networking at the customer's, if not provided by the customer!

All required parts are listed in the scope of delivery (QQ)] -

Drucker enthält:

- EPT022075 Comms-Pack für Drucker

- EPT041081 Port im Drucker

Zusätzlich bestellen:

- 1x EPT028998 - DCI (Rev.2) E.U. SIM, inkl. EPT040473

- 1x EPT042202 DCI Netzteil

- 1x RS003 RJ45 Kabel Standard 1m

- 1x EPT028420 DCI-Gehäuse IP66

Für jeden Drucker bestellen:

- EPT028315 Ethernet-Kabel Drucker 5m

Ggf. noch Switch mit Zubehör für Vernetzung beim Kunden, wenn nicht bauseits zur Verfügung gestellt!

[Alle benötigten Teile im Lieferumfang aufführen] -

Vernetzt. Rev. 1 empfohlen<br>Mehrere Drucker über ein DCI mit DCI als Netzwerkteilnehmer an Switch und/oder Drucker vernetzt bzw. an QuickDesign. Cloud über 3G oder Kunden-LAN.<br><br>Stand Alone (Rev. 2 empfohlen)<br>Ein DCI je Drucker, keine Vernetzung oder QuickDesign-Anbindung. Cloud über 3G oder Kunden-LAN.

-

Einmalig bestellen:

1x EPT028998 - DCI (Rev.2) E.U. SIM, inkl. EPT040473

1x EPT028420 DCI-Gehäuse IP66

1x EPT042202 DCI Netzteil

1x RS003 RJ45 Kabel Standard 1m

Für jeden Drucker bestellen:

- EPT022075 Comms-Pack für Drucker

- EPT028315 Ethernet-Kabel Drucker 5m

Ggf. noch Switch mit Zubehör für Vernetzung beim Kunden, wenn nicht bauseits zur Verfügung gestellt!

[Alle benötigten Teile im Lieferumfang aufführen] -

Für jeden Drucker bestellen:

- EPT028998 - DCI (Rev.2) E.U. SIM, inkl. EPT040473

- EPT028420 DCI-Gehäuse IP66

- EPT041081SP Port im Drucker

Falls Datenanbindung gewünscht:

Für jeden Drucker bestellen:

- EPT028315 Ethernet-Kabel Drucker 5m

Ggf. noch Switch mit Zubehör für

Vernetzung beim Kunden, wenn nicht bauseits zur Verfügung gestellt!

[Alle benötigten Teile im Lieferumfang aufführen] -

Rev. 2 zu Rev. 1<br>Z.B. nachträglich mehrere Drucker über ein DCI oder Vernetzung bzw. QuickDesign Anbindung.<br>Cloud über 3G oder Kunden-LAN.<br><br>Rev. 1 zu Rev. 2<br>Z.B. Netzteil nicht erwünscht, Auflistung für ein DCI je Drucker, keine Vernetzung oder QuickDesign-Anbindung. Cloud über 3G oder Kunden-LAN.

-

Einmalig bestellen:

1x EPT042202 DCI Netzteil

1x RS003 RJ45 Kabel Standard 1m

Für jeden Drucker bestellen:

- EPT022075ATO Comms-Pack für Drucker

- EPT028315 Ethernet-Kabel Drucker 5m

Ggf. noch Switch mit Zubehör für Vernetzung beim Kunden, wenn nicht bauseits zur Verfügung gestellt!

[Alle benötigten Teile im Lieferumfang aufführen] -

Für jeden Drucker bestellen:

- EPT040473 Kabel

- EPT041081SP Port im Drucker

Falls Datenanbindung gewünscht:

Für jeden Drucker bestellen:

- EPT028315 Ethernet-Kabel Drucker 5m

Ggf. noch Switch mit Zubehör für Vernetzung beim Kunden, wenn nicht bauseits zur Verfügung gestellt!

[Alle benötigten Teile im Lieferumfang aufführen]

M-Serie

-

Labeller type

Product

-

Type of product

- Keg

- Bottle

- Carton

- Can

- Pallet

- Shrink wrap

- Other

-

Specify the product

-

Minimum weight of product (kg)

-

Surface finish of the product

- Dry

- Frozen

- Dusty

- Warm

- Wet

- Other

-

Specify the surface finish of the product

-

Dimension of the product (width x depth x height in mm, in running direction)

-

Product variation

Label

-

Label

- Standard white rectangular paper label

- No Standard

-

If not standard white rectangular paper label on opaque carrier material

-

Type of label

-

Type of label material

-

Type of label material

-

Shape of label

-

Shape of label

-

Color of label

-

Colour of carrier material

-

Label gap detection

- Black stamp

- Gap

- Notch

- Transparent

- Transparent/Black stamp

- Other

-

Label gap detection

-

Type of information to be printed

-

-

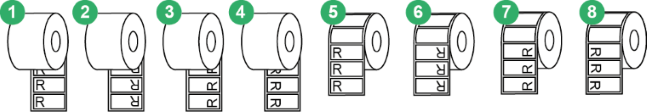

Select image

- 1 - Inside

- 2 - Inside

- 3 - Inside

- 4 - Inside

- 5 - Outside

- 6 - Outside

- 7 - Outside

- 8 - Outside

-

Label roll pattern

-

Notes on the sample label roll

Barcode

-

Barcode

-

Send barcode data to

-

Barcode-Typ

- EAN 13

- UPC

- Code 39

- Code 128

- GS1 128

- 2of5 Interleaved

- DataMatrix

- QR Code

- PDF417

-

Barcode alignment on the label

-

Barcode Resolution

- 0.1mm (4mils)

- 0.2mm (8 mils)

- 0.3mm (12 mils)

- 0.4mm (16 mils)

- 0.5mm (20 mils)

- 0.6mm (24 mils)

- 0.7mm (28 mils)

- 0.8mm (32 mils)

- 0.9mm (36 mils)

- 1.0mm (40 mils)

-

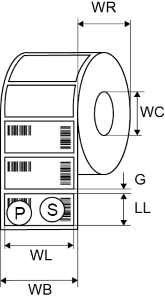

Label roll

-

WR = Roller diameter (mm)

-

WC = core diameter (mm) if not 76 mm

-

G = Distance between labels

-

Label size(s) in mm (width (WL), length (LL), width (WB))

-

Supply of labels by

-

Supply of ribbon by

-

Notes

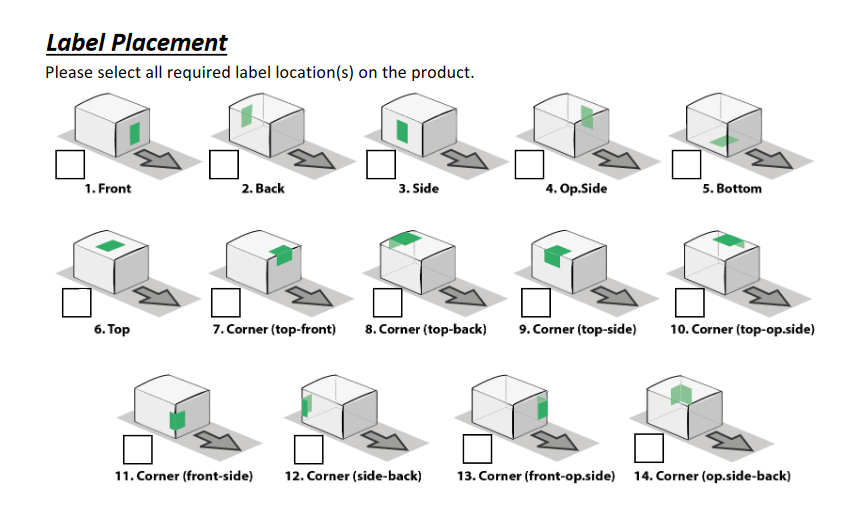

Placement of labels

-

-

Desired label positions on the product

- 1.

- 2.

- 3.

- 4.

- 5.

- 6.

- 7.

- 8.

- 9.

- 10.

- 11.

- 12.

- 13.

- 14.

-

-

Alignment of the applied labels on the product

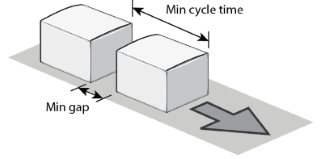

Performance

-

-

Maximum number of products/min

-

Maximum number of labels per product

-

Number of stops for applying labels

-

Minimum distance between products (mm)

-

Minimum cycle time (sec.)

-

Type of conveyor belt

-

Specify type of conveyor belt

-

Conveyor speed (meter/min.)

-

Pitch (°) if not 0

-

Redundancy (Master-Slave)

-

Slave-Configuration

-

Remarks - Label Placement / Performance

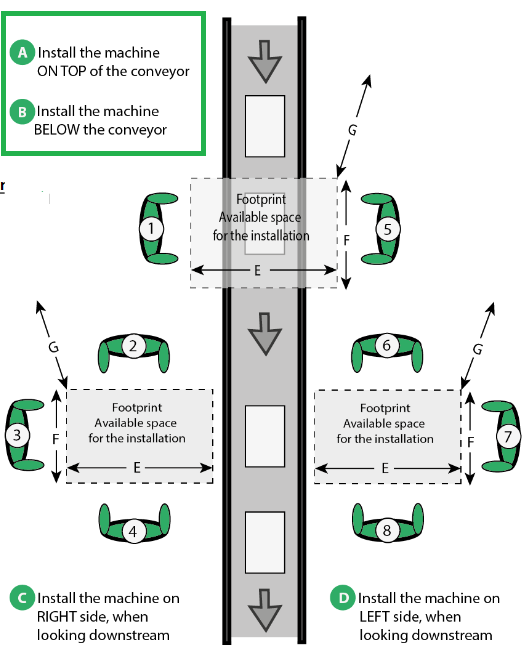

M-Series Installation Location, Operator Side, and Product Position

-

-

Type of installation of the machine

-

Installation location of the machine

-

Version of the M-Series

-

Applikator Type

-

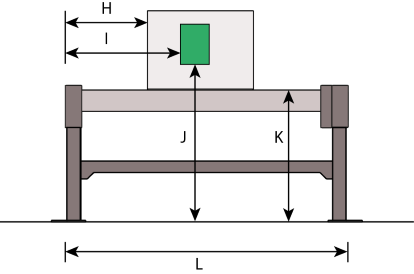

Product position

Hint! Labelling machine on the left side of the picture. -

H = Max. Distance from the conveyor side to the product (mm)

-

I = Minimum distance from the side to the next edge of the label (mm)

-

J = Height from bottom to bottom of label (mm)

-

K = Height above conveyor floor (mm)

-

L = Total width of the conveyor (mm)

-

Notes

-

Photo of the installation site

Integration

-

Apply Signal Source

-

Describe the signal source of the application

-

Pusher signal source (if separate pusher)

-

Describe the Pusher Signal Source

-

Safety interface input

-

Gehäuse

-

3-Seiten-Funktionalität

-

Bedienung

-

Drehrichtung

-

Klimakit

-

Eingangsspannung

-

Integrierter Checkscanner

-

Optionen [Alle benötigten Teile im Lieferumfang aufführen]

- MT38248 - Funktion zur Etikettenprüfung

- MT40580 - Integriertes Touchpanel Aluminium

- MT40581- Integriertes Touchpanel Edelstahl

- MT39998 - Zweikreisige Not-Aus-Option

-

Weitere Wünsche oder Bedürfnisse

-

Gesondertes, komplettes SRS notwendig

G-Serie

-

Distance between print head positions (cable length)

-

Print height at the particular print position

-

Number of print head groups

-

More than 2 print head groups require G320i unlock code

-

Ink type

-

Photo of the installation location of the controller

-

Photo of possible printhead installation locations

C-Serie

-

Printer design

Print head 1

-

Ink system size

-

Print head type

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Conduit length

-

Anzahl Druckköpfe

Druckkopf 1

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 1

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 2

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 1

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 1

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 2

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 1

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 2

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 3

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 1

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 2

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 3

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

Druckkopf 4

-

Druckkopf

- C1000

- C1000x

- C3000

- C3000x

- C6000

- C6000i

- C6000MF

- C6000V

-

Schlauchlänge

-

Ink type

- 952BK black, Mineral oil free ink

- 901BKS black, oil based printing ink

- 902RD red, oil based ink

- 903GR green, oil based ink

- 904BL blue, oil based printing ink

- TCN Ink

-

Version mains cable

- Europa 230V

- Europa 110V

- USA

- UK

- AUS/NZ

- Ohne Stecker

-

Manual Language

- Deutsch

- Englisch

- Argentinian (Spanish)

- Br-Portuguese

- Chinese Simple

- Niederländisch

- Französisch

- Italienisch

- Koreanisch

- Polnisch

- Japan

- Spanisch

- Russisch

-

Starter Pack

-

Photo of the printhead installation location

Macrojet 2

Print head 1

-

Conduit length

-

Nozzle

-

Print height

-

Druckhöhe

2 Druckköpfe

-

Druckkopf Konfiguration

Druckkopf 1

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

Druckkopf 2

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

Druckkopf 1

-

Schlauchlänge

-

Düse: 16 Tropfen

-

Druckhöhe

Druckkopf 2

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

3 Druckköpfe

-

Druckkopf Konfiguration

Druckkopf 1

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

Druckkopf 2

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

Druckkopf 3

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

Druckkopf 1

-

Schlauchlänge

-

Düse: 16 Tropfen

-

Druckhöhe

Druckkopf 2

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

Druckkopf 3

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

4 Druckköpfe

-

Druckkopf Konfiguration: 4 x 7 Tropfen

Druckkopf 1

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

Druckkopf 2

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

Druckkopf 3

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

Druckkopf 4

-

Schlauchlänge

-

Düse: 7 Tropfen

-

Druckhöhe

-

Ink type

- BK8201

- BL8302

- RD8303

- CL8510

- BK8601

- YL8805

- BK8101

- RD8103

- BL8402

- BK8001

- GR8004

- BK8701

- BL8702

- GR8304

- BK8981

- Drytest

- Washtest - MEK

- Washtest - Ethanol

- Washtest - Water

-

Software

- 50 texts/40 characters (51081)

- 40 texts/200 characters (51082)

-

Charakter Satz 1 [In der Regel: 41943]

- Standard 16x10 & 7x5 (41943)

- Deutsch 16x10 & 7x5 (42546)

- Standard 12x10 & 5x5 (43672)

- Arabisch (43671)

- Dänisch, Norwegisch 16x10 & 7x5 (43650)

- Standard 5x5 C1/2, 6, 9 Changed (43606)

-

Character Set 1 [Usually: 41943]

- Standard 16x10 & 7x5 (41943)

- Deutsch 16x10 & 7x5 (42546)

- Standard 12x10 & 5x5 (43672)

- Arabisch (43671)

- Dänisch, Norwegisch 16x10 & 7x5 (43650)

- Standard 5x5 C1/2, 6, 9 Changed (43606)

-

Power supply

-

Power cord design

-

Language Pocket Guide

-

Language Maintenance manual

- Englisch

- Chinesisch

- Dänisch

- Französisch

- Italienisch

- Russisch

- Spanisch

-

Language PT64 manual

- German

- Englisch

- French

- Dutch

- Spanisch

- Italien

-

Starter Pack

Other information

-

Other information that may affect the order and the installation.

Installation work, training and production support

Installation work

-

To ensure a smooth and effective installation, the Domino service technician requires unrestricted access to the production line and installation site.

-

Access to production line and installation site

-

Details on restrictions during installation and notes for scheduling

-

Mechanical installation of the brackets for the marking components (print head, controller, etc.) by

-

Mechanical installation of the marking components (print head, laser head, controller, etc.) on the appropriate bracket by means of

-

Cable installation between the marking components through

-

Cable installation for signal exchange with the customer's machine and connection of the signals by means of

-

The signal interface to customer machine can only be established in cooperation with the customer!

-

Notes on the installation work

-

Support of service technician by customer's personnel during installation

-

Nature of support

- Elektriker

- Mechaniker

- Maschinenführer

- Helfer

-

Scope of assistance

-

Notes on customer support

Training and production support

-

Training, beyond the instruction of the unit, desired

-

Type of training [Please specify in scope of delivery]

- Bediener-Schulung, 1 Tag im Schulungscenter

- Techniker-Schulung, 2 Tage im Schulungscenter

- Bediener-Schulung, 1 Tag beim Kunden

- Techiker-Schulung, 2 Tage beim Kunden

-

Production support by a Domino service technician

-

Number of days of production support [Please specify in scope of delivery]

Aftermarket

SafeGuard

-

Agreements on the subject of maintenance or SafeGuard contracts

- Ja, SafeGuard im Auftrag enthalten

- Ja, SafeGuard wird gesondert bestellt

- Ja, Wartungsvertrag im Auftrag enthalten

- Ja, Wartungsvertrag wird gesondert bestellt

- Ja, noch keine Entscheidung

- Nein

-

Comments

-

Soll das Thema durch das Aftersales-Team weiter verfolgt werden

-

Name des Ansprechpartners beim Kunden

-

Erläuterung