Information

-

Site conducted

-

Client

- Queensland Urban Utilities

- Unity Water

- Watercorp

- Sydney Water

- Gold Coast City Council

- Sunshine Coast Regional Council

- Ballina Regional Council

- Other

-

Site / Project

-

Conducted on

-

Completed By

-

Location

-

Enter address if not identified

Site Control

-

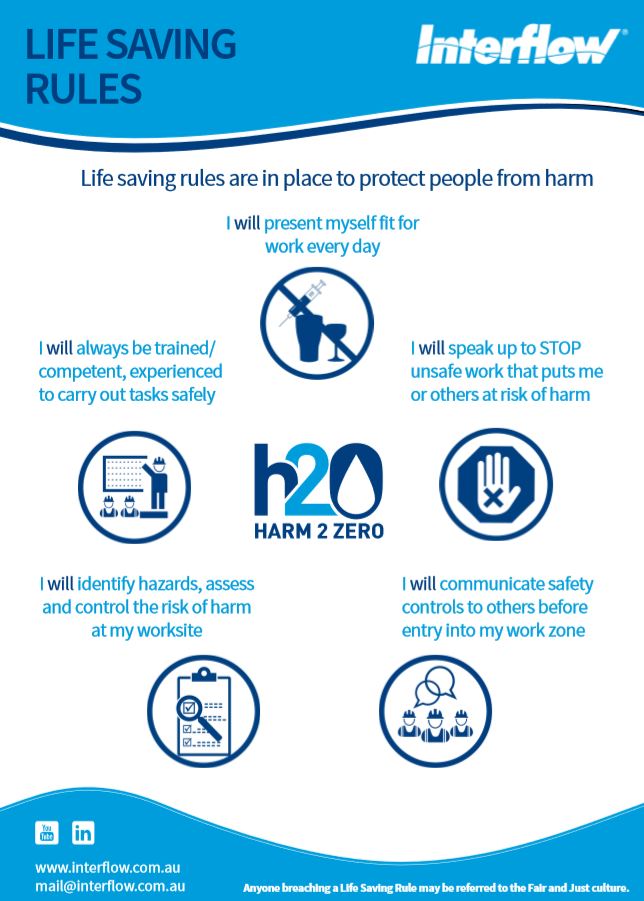

Are all aware of Interflow's LIFE SAVING RULES?

-

Personnel Details

-

Identified Workgroup

- Lining Crew

- Cutting Crew

- Dig Up Crew

- Cleaning Crew

- Subcontractor

- Other

- Interfit

-

SNRP Details

-

Interflow Worker(s) Details

-

Contractor(s) Details

Safety Conversation/ Safety Share/ Alerts or L2BL communicated

-

undefined

Work Pack Risk Assessment

-

All roles and responsibilities have been identified, communicated and are understood?

-

Work Pack has been completed in full consultation with all - includes Subcontractors i.e. Traffic Controllers?

-

Work Method Statements have been correctly identified for the scope of work and can be validated as having been reviewed in full by all members of the work group

Identify any High Risk Work Activities and verify a SWMS and Controls have been implemented to mitigate risk.

-

undefined

- Confined Space Entry

- Excavation and Trenching

- Electrical Safety

- Use of Hazardous Chemicals

- Working at Height

- Hazardous Manual Tasks - i.e. Lifting and Pulling

- Use of Plant and Equipment - i.e. Vehicle Loading Crane (VLC)

- Working Adjacent to the Roadway - Traffic Management

- Energy Isolation - Lock Out/ Tag Out

- Working Adjacent to Water

- Lone Worker

- Demolition Works

- Scaffolding

- Asbestos Removal or Handling

- Use of High Pressure Equipment

-

Additional Notes on Implemented Controls

Critical Safety Essentials

-

No. 1 - Excavation and Trenching

-

-

Are personnel involved in excavation and trenching trained and competent to understand the hazards and controls associated with excavation and trenching?

-

-

Prior to any excavation and trenching activity, has an Excavation and Trenching Permit being completed and authorised by a competent person?

-

-

Are underground services identified, positively located, marked and where possible isolated before breaking ground?

-

-

Has in ground service locations being communicated to all relevant stakeholders prior to the work activity commencing?

-

-

Excavations > 1.5 are planned and include controls such as benching, battering or shoring?

-

-

Is there safe means of access/ egress being implemented and maintained for all excavations and trenches that workers need to enter?

-

-

Has material/ spoil being removed during the excavation and trenching to reduce the potential of collapse?

-

-

Are barriers, covers, exclusion zones, edge protection, lighting and/or signage provided to prevent people, plant, objects and equipment falling into excavations and trenches?

-

-

Are controls in place to prevent the accumulation of fumes and gases within excavations and trenches.

-

-

Are excavations and trenches inspected by a competent person before each working shift and after rainfall, or other events which could impact ground stability or introduce further hazards?

-

-

Are spotters must be in place during excavation and trenching in the vicinity of underground/ overhead services?

-

-

No. 2 - Confined Space

-

-

Are all personnel involved in confined space entries trained in NWP219A or RIIWHS202A, and carry the confined space training ticket?

-

-

Has a Confined Space entry permit been completed prior to a confined space entry?

-

-

Is the confined space opening greater than 450mm in diameter or 400 x 450 if rectangle?

-

-

Is the Responsible and the Stand By person(s) in the vicinity of the confined space and have they been nominated on the confined space permit?

-

-

Has a physical exclusion zone including confined space warning signs established around the confined space opening to prevent unauthorised entry.

-

-

Has the gas detector bump test result been recorded on the confined space permit?

-

-

Has the immediate surround of the confined space been gas tested before the confined space cover i.e. 'Manhole lid' is removed?

-

-

Has the open access chamber lid been removed approx. 200mm and re test using with a calibrated equipment prior to entry?

-

-

Are personnel inside the immediate exclusion zone hooked up to a rated anchor point or is the access chamber opening covered up.

-

-

Has the rescue equipment (tripod, harness, wire winch, winch / rope set inspected, in date and set up prior to confined space entry?

-

-

Is the confined space continually gas monitored during entry?

-

-

Is a rescue plan in place and understood by the crew before any entry into a confined space?

-

-

Is a Stand-By person in the vicinity of the confined space during entry.

-

-

Does the responsible person sign off on the confined space permit when the site has been returned to Pre- entry condition and the access chamber lid is in place?

-

-

Has a 'Non - person entry' record nominating the 'Responsible Person', been completed for each confined space that is opened?

-

-

For 'Inspection Only' has the lid been removed 200mm and 'no person or equipment', is in the confined space?

-

-

No. 3 - Underground and Overhead Services

-

-

Are personnel involved in works in and around Underground and Overhead services trained and competent to understand the hazards and controls associated with the task to be undertaken?

-

-

Where necessary, has a permit been completed and authorised by a competent person?

-

-

Have underground services been identified, located, marked and where possible isolated before breaking ground by using the 4P method?

-

-

Has in ground service locations being communicated to all relevant stakeholders prior to the work activity commencing?

-

-

Has a dedicated safety observer to observe clearances and provide direction to the operator been made available?

-

-

Are barriers, covers, exclusion zones, edge protection, lighting and/or signage provided to prevent people, plant, objects and equipment contacting Underground and Overhead services?

-

-

Has all Overhead and Underground essential services been identified or exposed and clearly marked?

-

-

Have exclusion zones of Live Overhead Line Equipment (OHLE) or live electrical services been clearly set-up?

-

-

If any infrastructure asset is damaged are you able to immediately locate the asset owners contact details?

-

-

No. 4 - Crane and Lifting Operations

-

-

Are persons trained and verified as competent for Vehicle Loading Cranes (VLC) and lifting operations

-

-

Are safe operating manual / manufacturer’s instructions specific to the crane in an easily accessible location?

-

-

Has a pre-use inspection of lifting equipment been carried out?

-

-

Are site hazard assessments and lifting plans in place?

-

-

Are exclusion zones established to prevent unauthorised access to the operating area?

-

-

Are Emergency Stop buttons fitted on each VLC pendant and operational?

-

-

Are daily pre-start inspections and/or function tests completed?

-

-

Are Crane Load Charts legible and understood?

-

-

Has the VLC been fitted with an overload warning system?

-

-

Are all Danger and Warning signage clearly visible and legible?

-

-

Are all Wheel chocks being used on front and rear wheels when in use?

-

-

Are the outriggers fully extended on each side when is use/ supported by correct Dunnage/composite pads?

-

-

No. 5 - Lock Out Tag Out and Asset Isolation and Flow Management

-

-

Is evidence of client specific training for those personnel involved in managing or isolating flow?

-

-

Has a personal Lock Out and Tag Out device installed on the isolated asset (i.e. main control valve or similar) to prevent inadvertent activation of the isolated asset?

-

-

Have personnel that are responsible for Locking Out/ Tagging Out a client’s asset/s received information, training or instruction as to the LOTO process from the asset owner?

-

-

Has a Hazard Identification Risk Assessment (HIDRA) been documented and defines all possible significant inrush and inundation locations either up or down stream?

-

-

Have the control measures that are identified within the Hazard Identification Risk Management (HIDRA) been implemented following the Hierarchy of Control?

-

-

Have double Isolations been implemented where access to a confined space is required?

-

-

Has the client provided appropriate permission and approval to commence work?

-

-

Has monitoring of adverse weather conditions been carried out and verified that could impact on the immediate work area?

-

-

Have Emergency Rescue plans been documented, established, trialed and approved based on potential inrush and inundation scenarios?

-

-

Are Emergency Rescue plans been communicated to all persons on site?

-

-

Are all persons clear on the monitoring of the control measures and discussed at the pre-starts?

-

-

No. 6. - Mobile Plant

-

-

Are personnel involved in the operation of powered mobile plant trained, verified, competent and where required licensed to operate powered mobile plant?

-

-

Are powered mobile plant operators approved and authorised for use?

-

-

Have powered mobile plant and vehicle operators completed a prestart and/or daily check to confirm safe working order?

-

-

Are tasks planned to eliminate or separate operating plant from people. Where persons are required to work near powered mobile plant, have effective communications being established and maintained between powered mobile plant and work crews controlling the site?

-

-

Have all powered mobile plant and vehicles been inspected, serviced and maintained in accordance with manufacturers and/or supplier recommendations?

-

-

Has a Plant Risk Assessment been completed by a competent authorised person for powered mobile plant and available on the powered mobile plant?

-

-

Are seat belts worn by the operator/s (where fitted)?

-

-

Is powered mobile plant when not in use is parked on fundamentally stable ground?

-

-

Are unattended vehicles/ powered mobile plant have wheels chocked when parked on site?

-

-

Does unattended powered mobile plant have the ignition key removed when unattended.

-

-

Do the mobile plant operators know they are not to use mobile phones when operating plant.

-

-

Are spotters in place during the reversing of powered mobile plant.

-

-

No. 7 - Fall Prevention

-

-

Is the edge protection in place when workers access the rear of the truck tray?

-

-

Are walkways in and on trucks clear of tools, materials and equipment to prevent falls?

-

-

Are the truck steps hand rails in place to provide three points of contact?

-

-

Are Personnel working inside the immediate confined space exclusion zone connected to a rated anchor point either a Tri-Pod or Gantry to prevent fall?

-

-

Are maintenance holes covered with a grate when not in use?

-

-

Do open pits, excavations and or trenches have adequate edge protection/ barriers?

-

-

Are tools, materials and equipment secured when lifting and lowering?

-

-

When tools, materials and equipment are being lifted or lowered, is there an exclusion zone established within the fall zone?

-

-

Are hoses and cables covered and are signs in place to advise pedestrians?

-

-

Are temporary water lines placed inside a ramp when they are located over a pedestrian walkway?

-

-

No. 8 - Electrical Safety with Metallic Water Pipework

-

-

Has the Current Split Neutral Integrity Test (CSNI test) been completed for the proposed work area?

-

-

All workers involved in carrying out work on metallic water mains/services are trained in National Unit of Competency -NWPNET003 - Control electrical risk on metallic pipes?

-

-

Is the personal protective equipment (Insulated Electrical Gloves) being worn to prevent the potential of an electrical shock when working with metallic pipework?<br><br>

-

-

A minimum of two essential control measures are being used before and during the work.<br>1st Essential control - Insulated Electrical Gloves being worn (and outers where required). <br>2nd Essential control - Bridging conductors used. <br>

-

-

Are workers able to demonstrate the glove inspection process (i.e. inflated before use) and are worn during the initial set up through to the completion of work and removal of bridging conductors?

-

-

Workers are able to demonstrate the pre-start continuity test of the bridging conductors?

-

-

Are the bridging conductors within the inspection test date (test tag sticker)?

-

-

Are bridging conductors clean (no dirt, mud or oxidation) and in good order?<br><br>

-

-

Is the metallic water pipework mechanically cleaned to ensure an adequate connection between bridging conductor connection and pipework?<br><br>

-

-

Is the Plumb Guard inspection and recalibration in date?<br><br>

-

-

Is the Plumb guard monitored throughout the duration of work to ensure that no electricity or voltage greater than 5 volts (5v) is detected within the pipework?<br><br>

-

-

Is the voltage monitored and recorded for each premises throughout the duration of works?<br><br>

-

-

No. 9 - Traffic and Road Safety

-

-

Approved Traffic Management Plans / Control Plans in place?

-

-

Are personnel involved in developing roadside / work zone Traffic Management Plans (TMPs) or Traffic Control Plans (TCPs) trained and accredited?

-

-

Are roadside Traffic Controllers trained and accredited?

-

-

Are all Traffic Management Permits (where required) and Plans correctly authorised and approved prior to the commencement of work?

-

-

Are designated pedestrians access points physically separated from operating plant/ vehicles?

-

-

Are Traffic Management / Control Signage serviceable, positioned and maintained in accordance with a Traffic Management Plans?

-

-

Do Traffic Management Plans identify vehicle routes, Go/ No Go Zones, directions, access/ egress points and parking areas on static construction worksites?

-

-

Are the Loading and unloading zones clearly delineated and consider the position of vehicles relative to live traffic along with pedestrian thoroughfare and overhead hazards?

-

-

Are permanent and temporary parking areas clearly defined?

-

-

Are operators that reverse plant/ vehicles in restricted access/space or in public areas accompanied by a spotter/ or a guide?

-

-

Is the designated parking, loading and unloading worksite area adjacent to live traffic well lit?

-

-

Are vehicles working on or near roads/ public areas have the warning beacon lighting activated throughout the duration of works?

-

-

Are traffic management controls measures continually monitored?

-

-

No. 10 - Working on or Near Water

-

-

Is there evidence a formal Hazard Identification Risk Assessment has been completed prior to work commencing?

-

-

Do the controls on site consider the Hierarchy of Control?

-

-

Are exclusion zones, edge protection/ barriers being used to prevent equipment, falls into or un-authorised access to water hazards?

-

-

Have all persons on site been advised that Lone Work is not permitted?

-

-

Has the water vessel been inspected prior to use?

-

-

Has the Life Saving equipment been inspected and manufacturers label clearly identified?

-

Is life-saving equipment readily available and positioned accordingly?

-

-

Are personnel wearing life saving equipment trained in the fitting, use, inspection and maintenance of that life saving equipment?

-

-

Roles and responsibilities for emergency management plan clearly understood, the emergency rescue plan has been rehearsed?

-

-

All emergency / life saving equipment identified as serviceable, currently tested and tagged (if required) and positioned appropriately?

-

-

Electrical power tools are currently tested and tagged and protected by an RCD?

-

-

Operating water vessels are registered and operated by a licensed, competent operator?

-

Completed by

- Add Person

-

Add signature