Title Page

-

Document No

-

Audit Title

-

Client / Site

-

Conducted on

-

Conducted by

-

Location

-

Other participants

-

Job description

-

Prior to job commencement assess job tasks and working environment

-

Check mandatory PPE, it's suitability and condition

Select appropriate JHAs applicable to above described task(s)

-

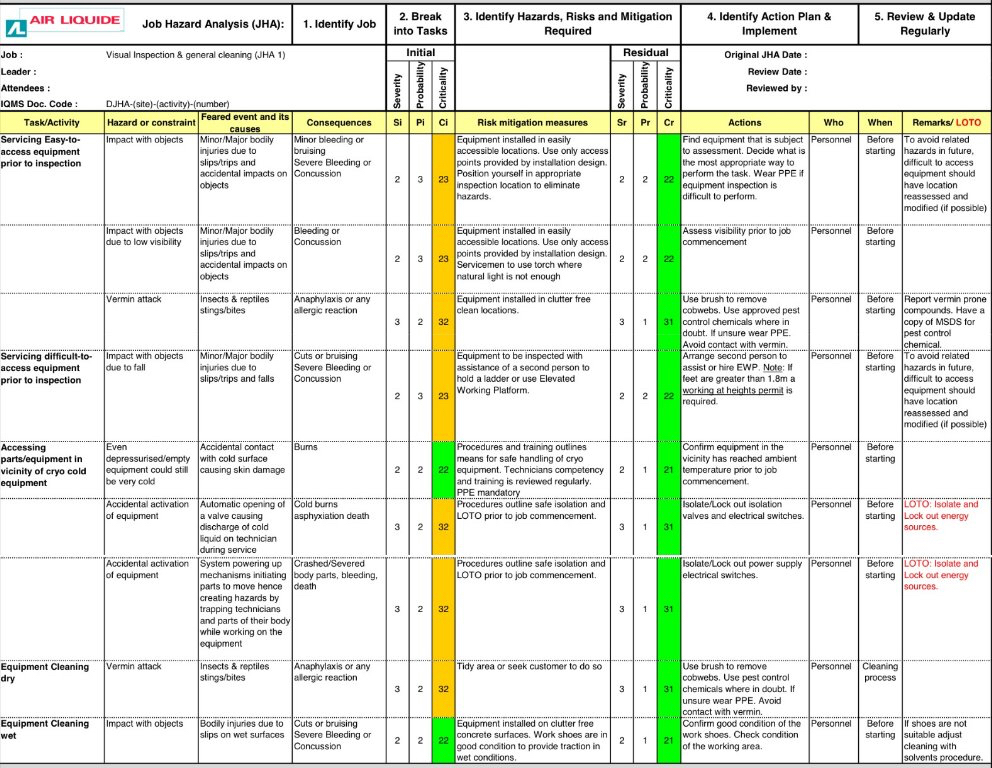

JHA 1 - Visual inspection and general cleaning

-

LOTO - If required isolate (and lock out) main isolation valve and/or electrical switch and other equipment's mechanisms

-

Check if light and visibility is suitable for the job

-

Check access. Ask for assistance and use suitable equipment for accessing out of reach areas

-

Check nearby equipment temperature has normalised (ambient condition achieved)

-

Check for pest and vermin, use chemicals and brushes to avoid contact

-

-

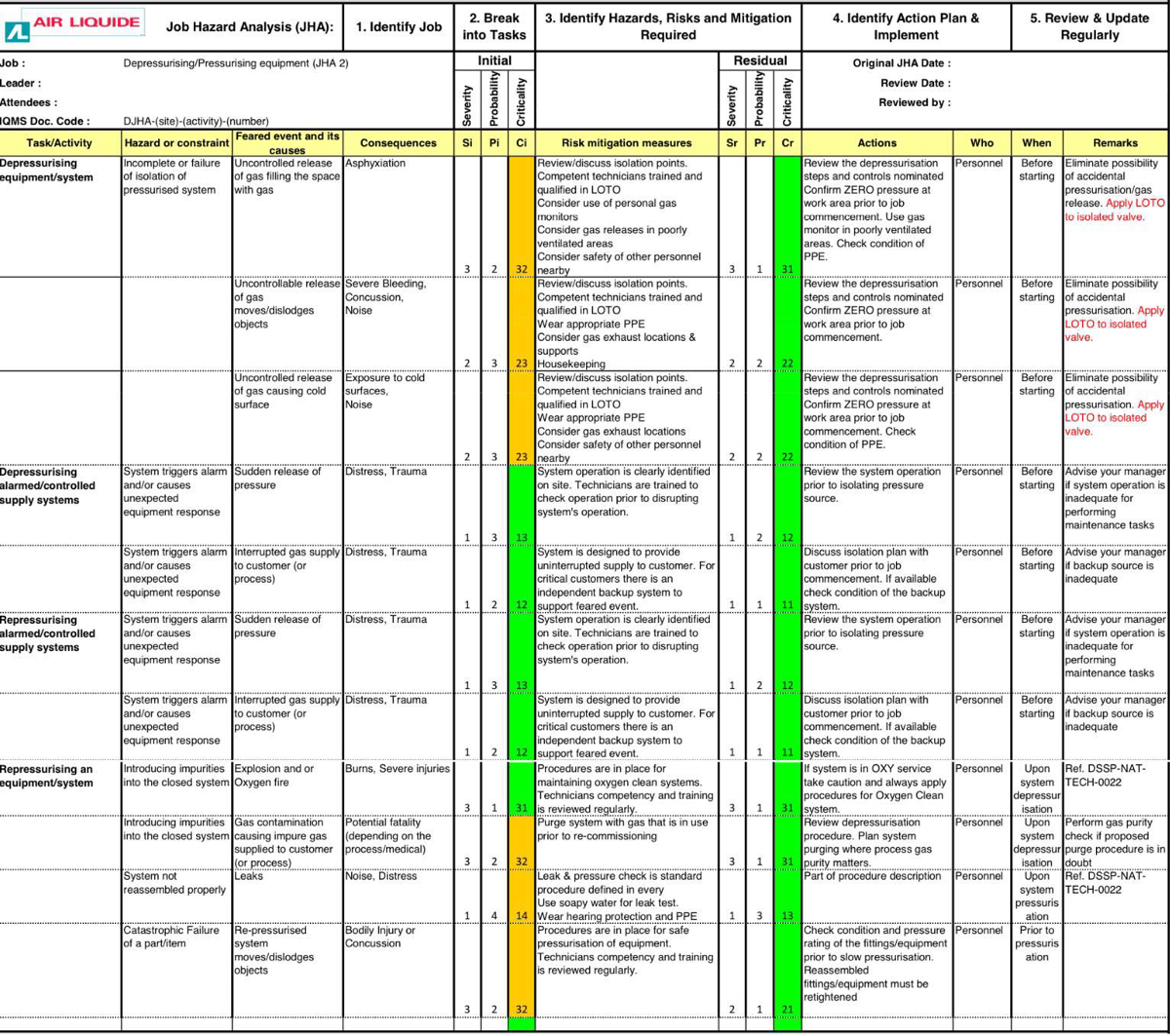

JHA 2 - Depressurising/Repressurising equipment

-

Review operation, discuss/confirm isolation plan and depressurisation steps. If poorly ventilated consider using gas monitor

-

LOTO - Isolated valve/equipment is locked and tagged

-

If present check level and condition of backup source. Is it active?

-

Upon equipment depressurising confirm ZERO pressure has been achieved

-

If oxygen clean system, apply only OXY clean procedures

-

If required purge system thoroughly

-

Check condition of the fittings/equipment prior to SLOW re-pressurising. Re-tighten and check for leaks.

-

-

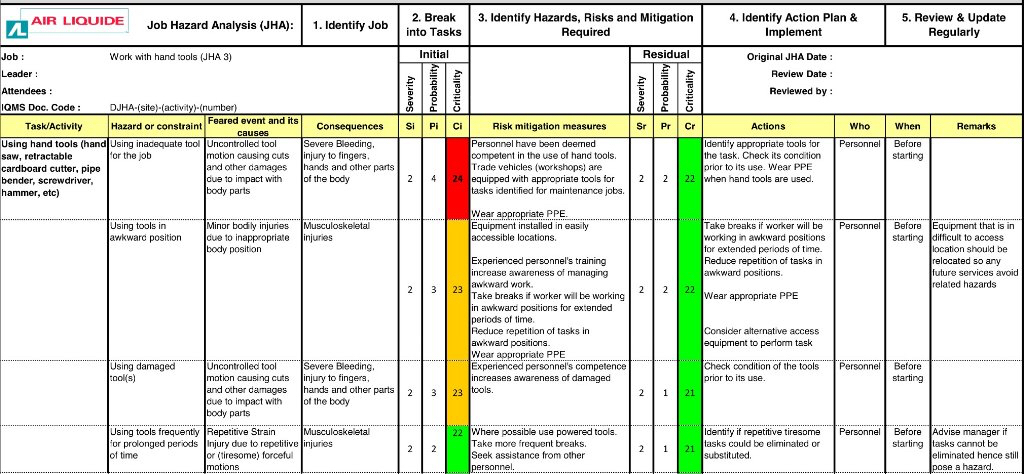

JHA 3 - Working with hand tools

-

Identify and use only the appropriate tools for the task. Check tools condition

-

If job task require workings in awkward position reassess the task and/or take regular breaks

-

-

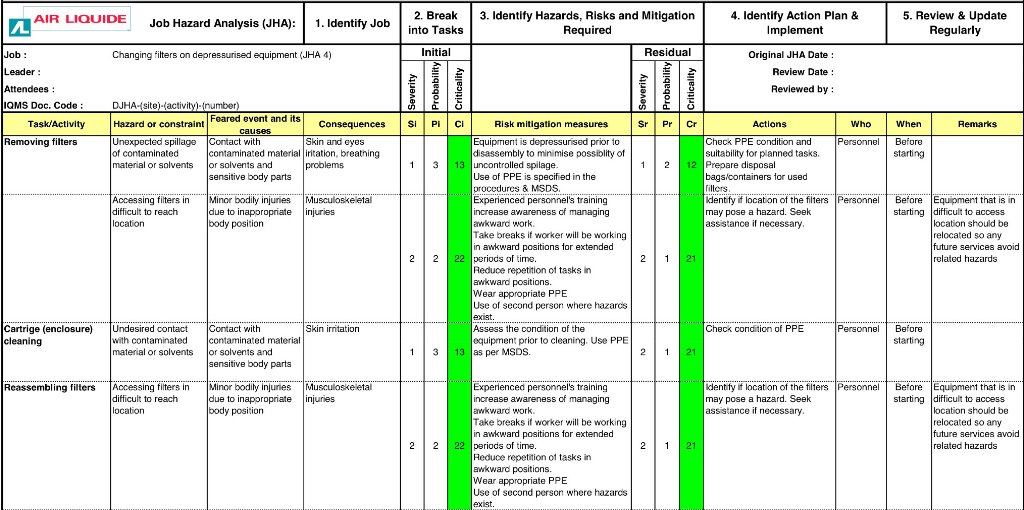

JHA 4 - Change filters on depressurised equipment

-

Prepare bags for disposing used filters. Seek assistance if necessary

-

-

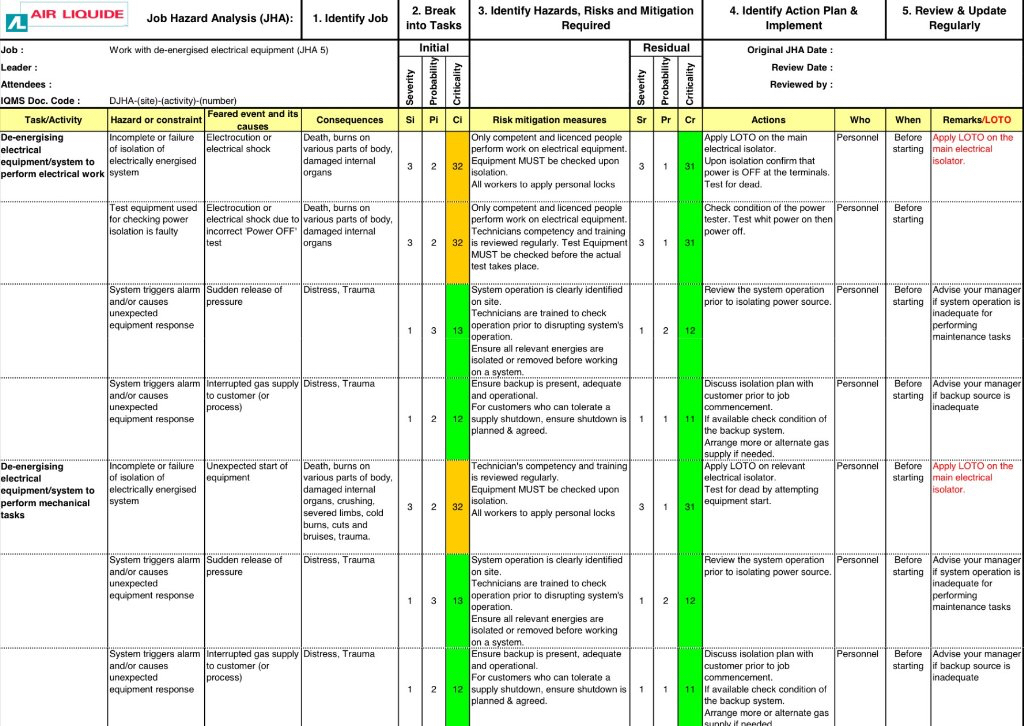

JHA 5 - Working with de-energised electrical equipment

-

Plan power isolation. Review/discuss system operation prior to isolating power source. If available check system backup.

-

LOTO - Apply lock and tag on main electrical isolator

-

Check power tester, power ON then OFF. Test system terminals for power OFF

-

-

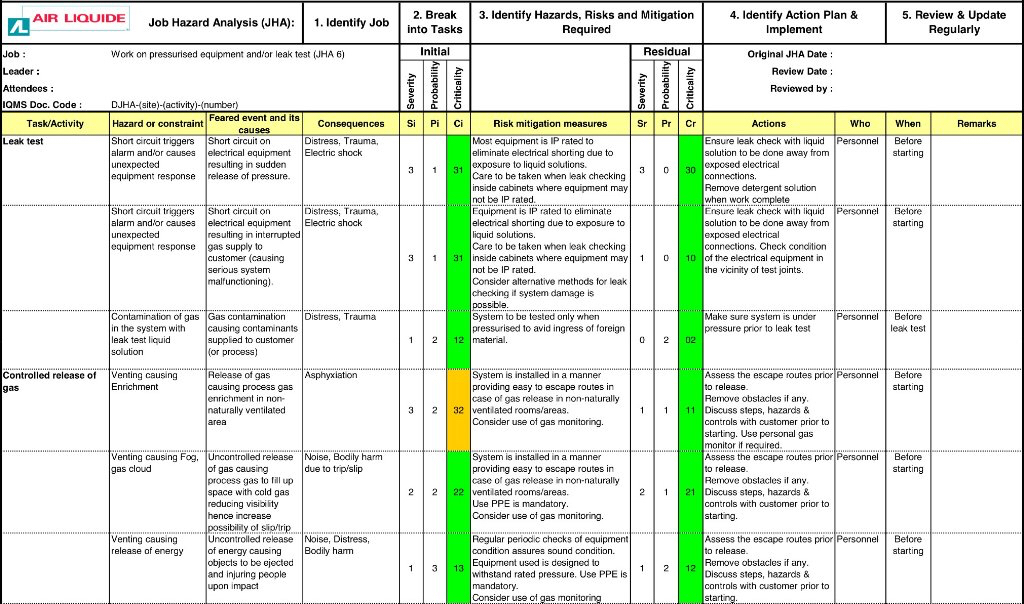

JHA 6 - Working on pressurised equipment and/or leak test

-

If leak test is required, ensure leak check with liquid solution to be away from electrical contacts

-

If leak test is required, avoid contamination by ensuring system is pressurised prior to leak test

-

Assess system operation. Review/discuss hazard and controls in an event of unexpected release of gas in the working area

-

-

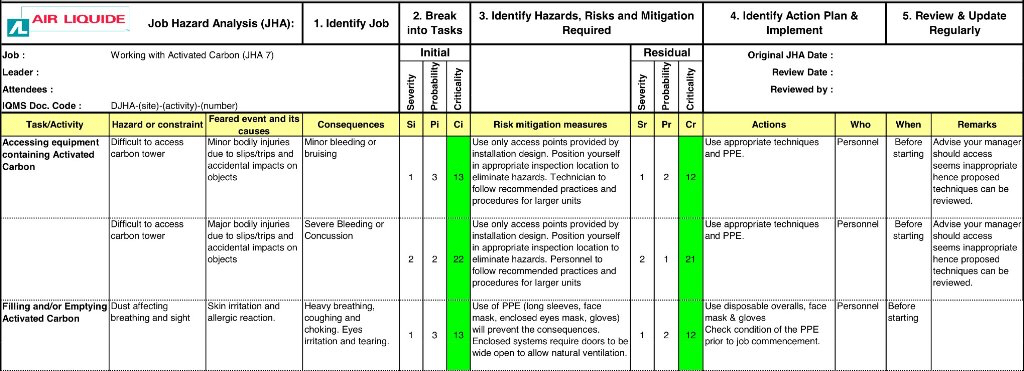

JHA 7 - Working with activated carbon

-

Consider using industrial vacuum sucker for removing and/or filling activated carbon

-

To avoid dust particles use disposable overalls, face mask and gloves

-

-

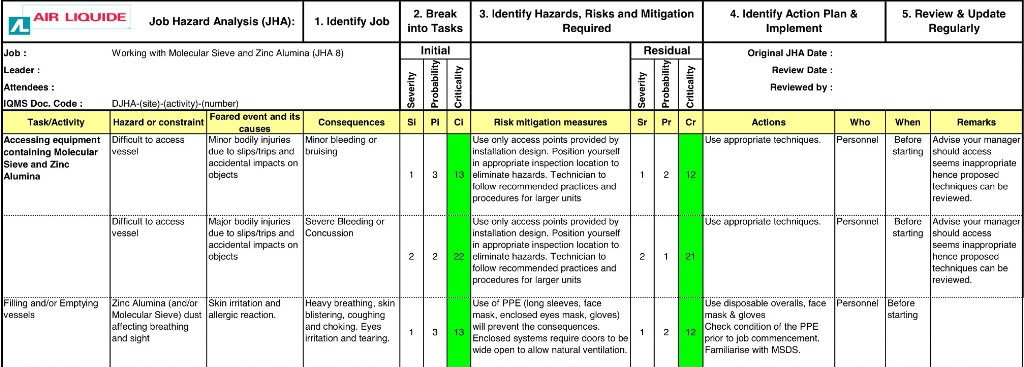

JHA 8 - Working with Molecular Sieve and Zinc Alumina

-

Consider using industrial vacuum sucker for removing and/or filling Molecular Sieve and Zinc Alumina

-

Familiarise with MSDS. To avoid dust particles (Molecular Sieve/ Zinc Alumina) use disposable overalls, face mask and gloves

-

-

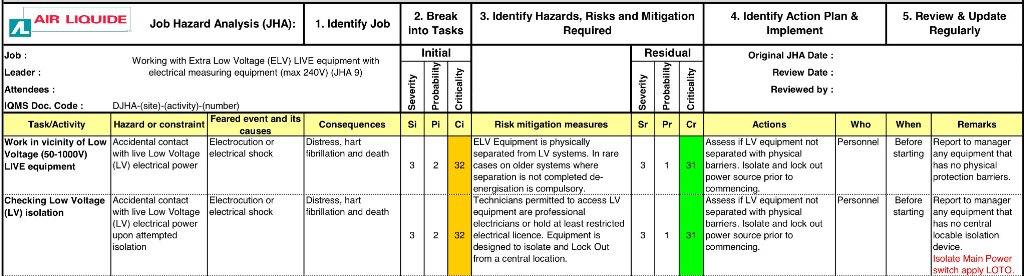

JHA 9 - Working with Extra Low voltage LIVE equipment and electrical measuring equipment (max 240V)

-

If low voltage (50-10000 V) equipment is not separated with physical barrier isolate and lock power source

-

-

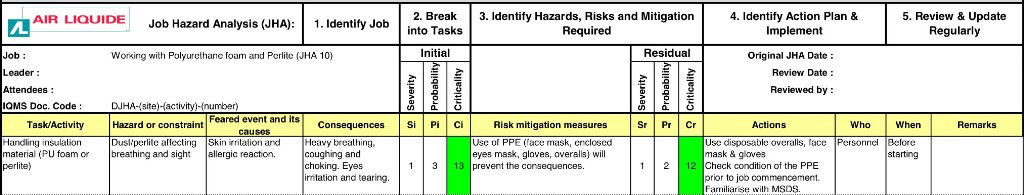

JHA 10 - Working with perlite and foam insulation

-

Familiarise with Perlite/Foam MSDS. Consider using overalls, face mask and gloves

-

-

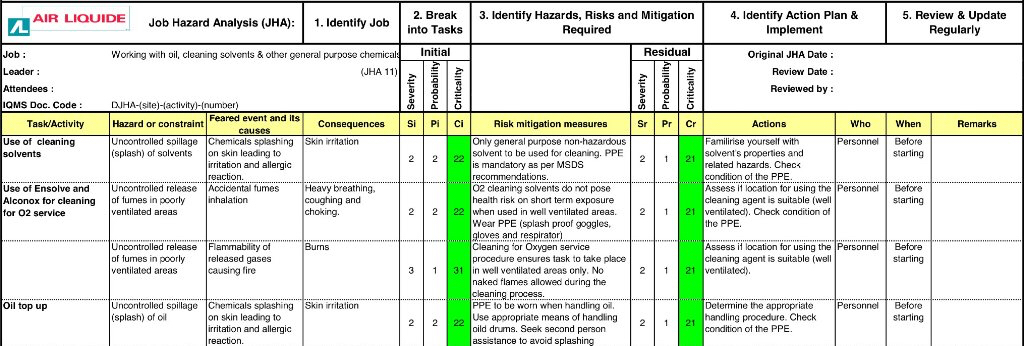

JHA 11 - Working with oil, cleaning solvents and other general purpose chemicals

-

Familiarise with solvent's MSDS and assess its suitability for use on site and equipment. Consider appropriate safety and environment impact practices

-

-

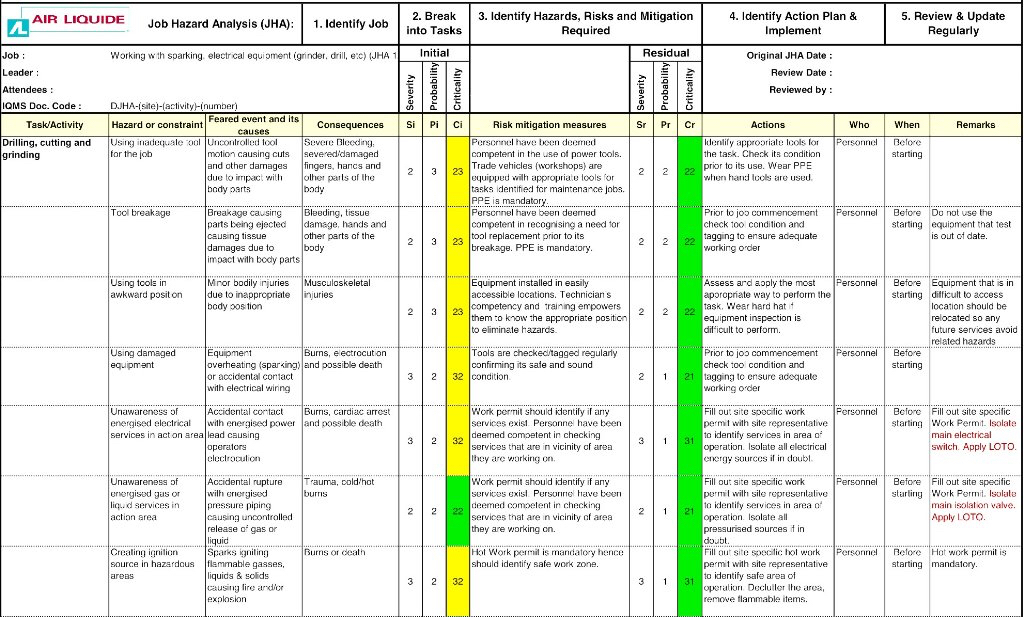

JHA 12 - Working with sparking electrical equipment ( grinder, drill, etc)

-

Identify and use only appropriate power tools for the task. Check tools condition and task

-

LOTO - If required, isolate (lock out) energised services in the area that could accidentally get damaged during use of tools

-

Hot work permit (HWP) is mandatory when working with power tools that generate sparks. Follow HWP instruction

-

-

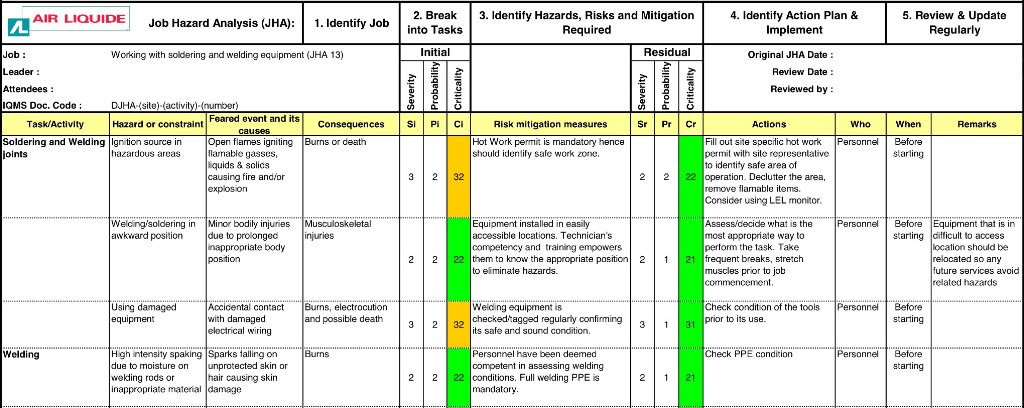

JHA 13 - Working with welding and soldering equipment

-

Hot work permit (HWP) is mandatory when working with soldering/welding tools. Follow HWP instruction

-

Review/Discuss job tasks to decide on appropriate soldering/welding technique. Take breaks as necessary

-

Identify and use only the appropriate soldering/welding tools for the task. Check tools condition

-

-

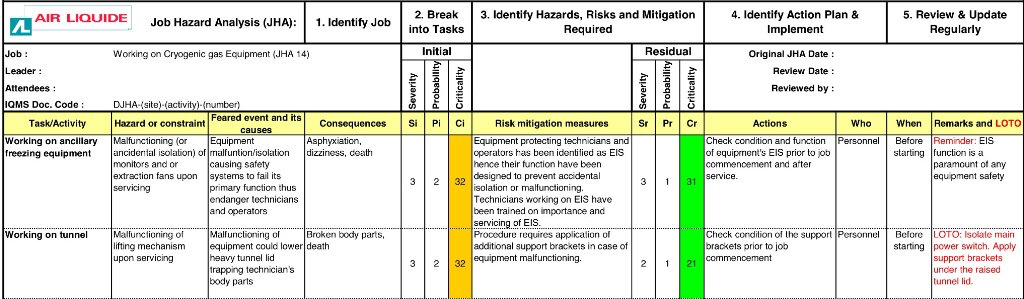

JHA 14 - Working on cryogenic freezing equipment

-

Check the function of the gas monitor in the room. Use personal gas monitor as a backup.

-

LOTO - For freezing tunnels only, use support brackets to secure lid in open position

-

-

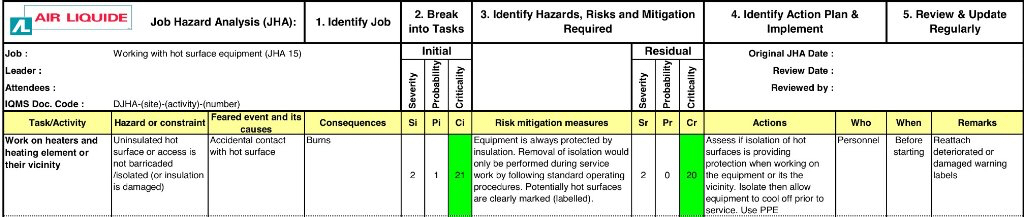

JHA 15 - Working with hot surface equipment

-

Assess isolation and current condition of hot surfaces on site. If hot, isolate and allow to cool off prior to job commencement

-

-

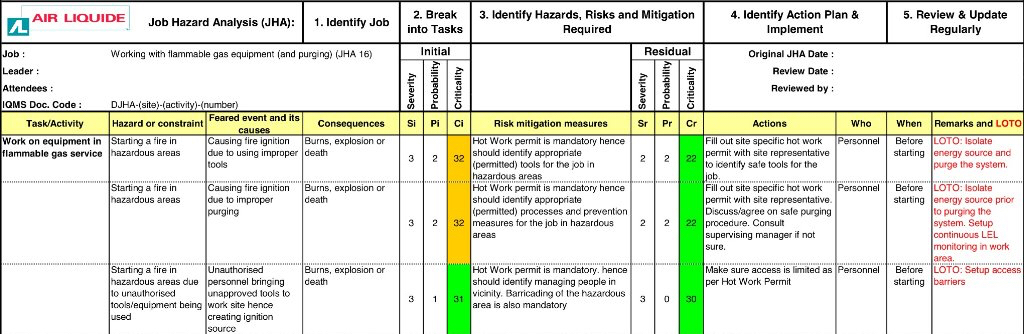

JHA 16 - Working with flammable gas equipment (purging included)

-

Hot work permit (HWP) is mandatory when working with flammable gas equipment. Follow HWP instructions

-

LOTO - Isolate valves (lock out), vent and purge with nitrogen in safe location. Use personal LEL monitor

-

Setup barriers to limit access to hazardous area

-

-

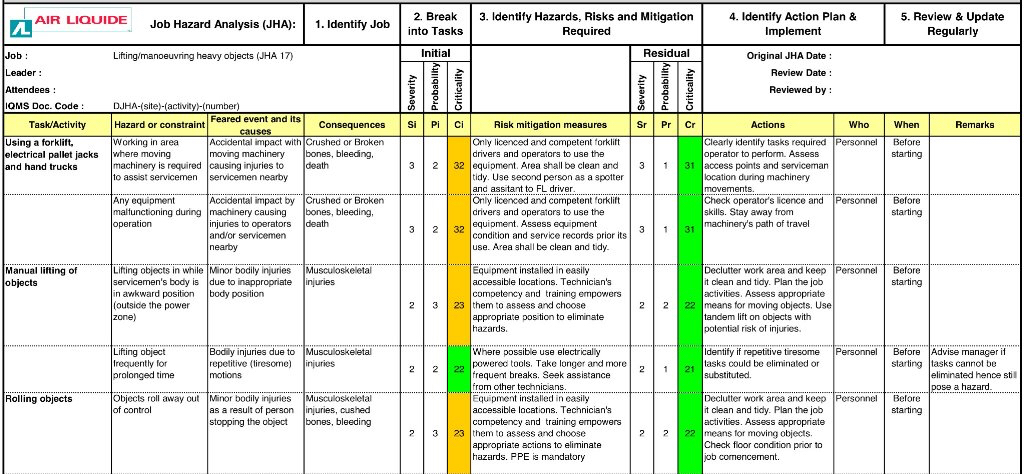

JHA 17 - Lifting/Manoeuvring heavy objects

-

Assess/Discus/Identify lifting tasks machinery operator is required to do. Identify paths of travel.

-

If applicable, check machinery operator's licence and assess its competency

-

De clutter and clean up work area. Check floor condition

-

Identify heavy lifting tasks where tandem lift is required. If required, take regular breaks

-

-

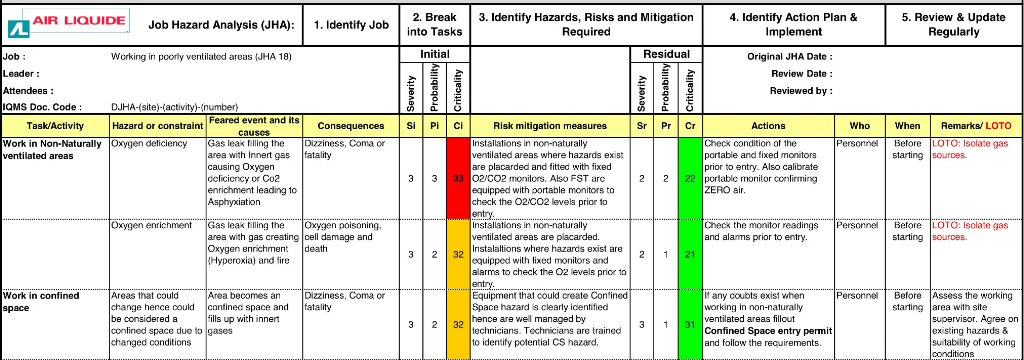

JHA 18 - Working in poorly ventilated areas

-

LOTO - If poorly ventilated consider isolating gas sources (lock out) that could lead to potential gas accumulation

-

If required, check portable gas monitor condition. Calibrate ZERO air

-

-

Other hazards and mitigation measures

-

NOTE: Should there be a task that is not covered in JHA listing describe the task and assess hazards and mitigation measures.

-

Have relevant departments/personnel been consulted

-

Completed by

-

Approved by