Title Page

-

Customer

-

Work Order#

-

Date

-

Job Location

-

Nearest Medical Facility

-

Customer Task Mgr/PM

-

Customer Phone#

-

Foreman/CL

-

GF

-

Competent Person

-

Outdoor Temp

-

Is the Temp over 95 degrees?

-

Please fill out the Extreme Heat Stress Prevention Plan

-

Or upload a photo of the paper copy

-

Wind Speed

-

Precipitation

-

Work Type

-

Work Type

Critical Job Tasks/ Hazards / Preventative measures/barriers

-

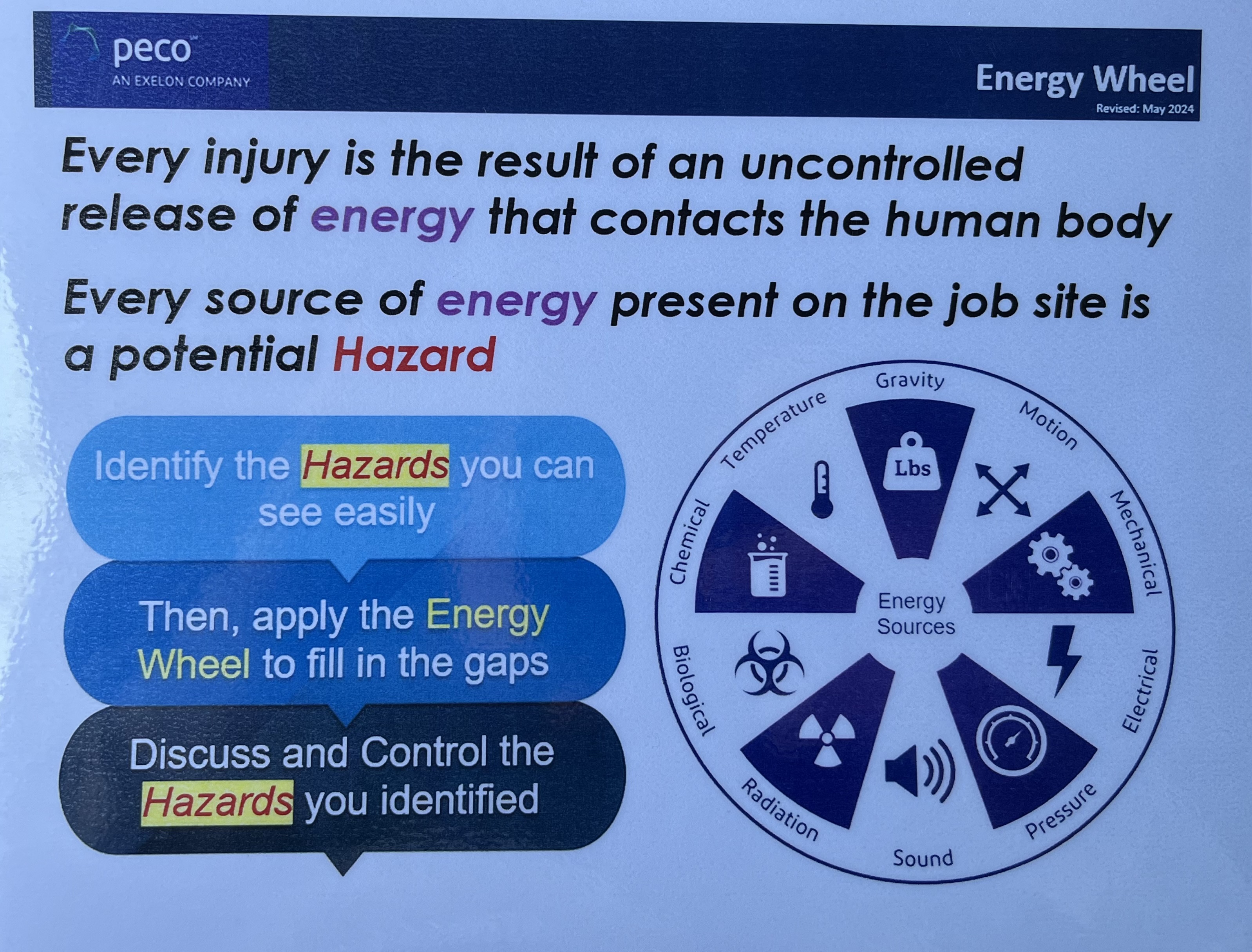

Before filling out the Critical Job Tasks please refer to the Energy wheel to identify all hazards you may encounter

-

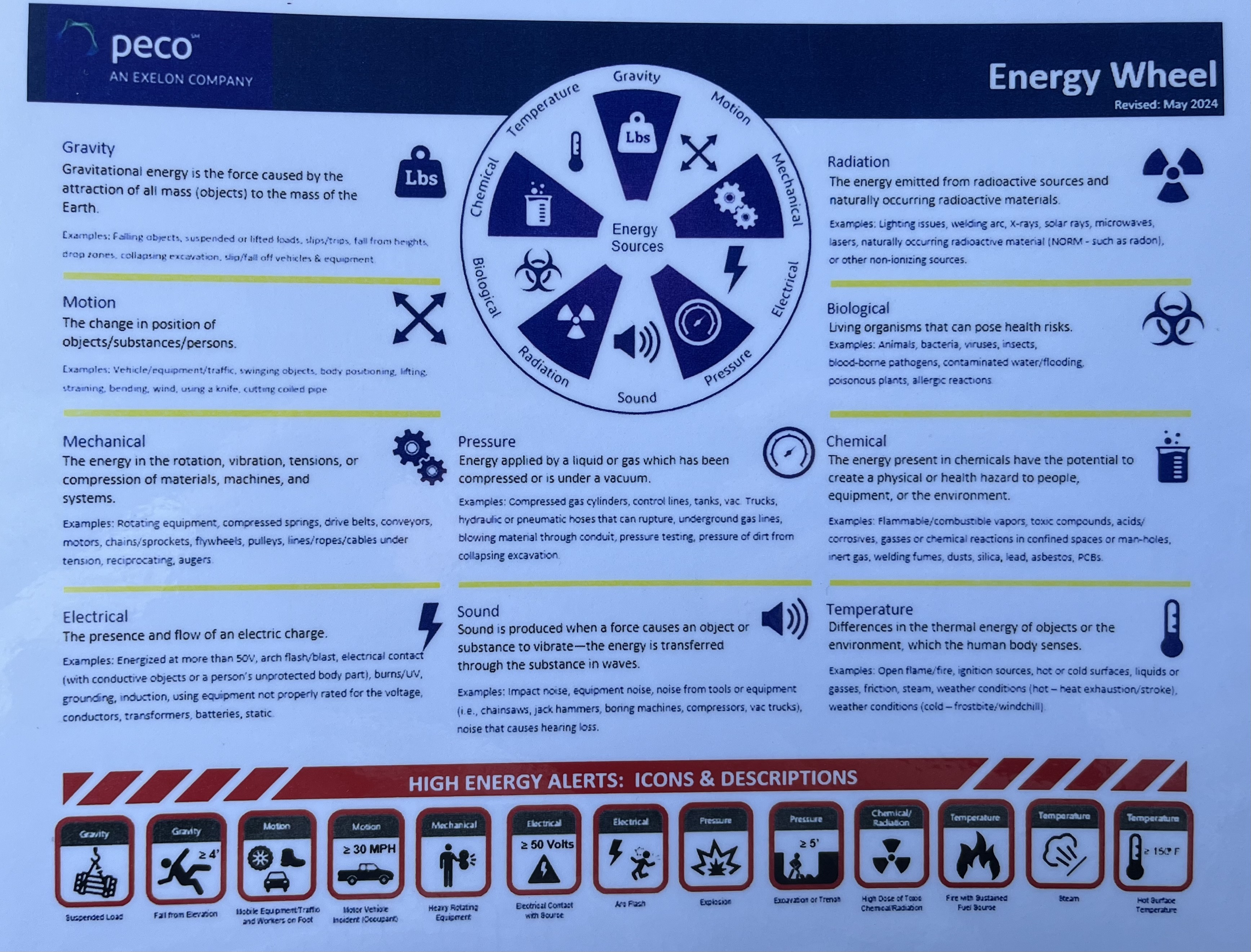

Energy wheel

-

Energy wheel definitions

-

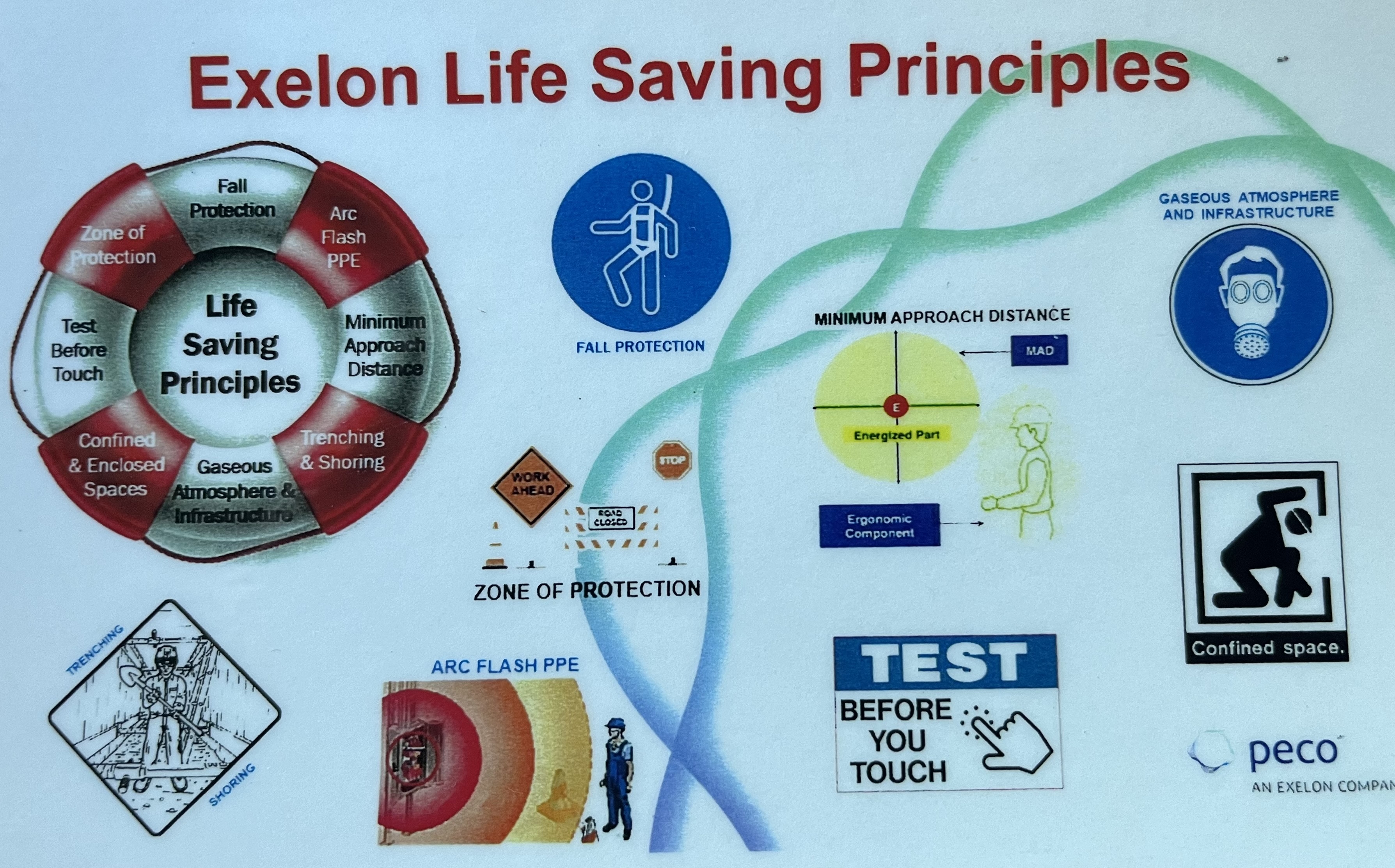

Lifesaving principles

-

1. Critical Job Task / Hazard

-

Preventative Measures/Barrier

-

2. Critical Job Task / Hazard

-

Preventative Measures/Barrier

-

3. Critical Job Task / Hazard

-

Preventative Measures/Barrier

-

4. Critical Job Task / Hazard

-

Preventative Measures/Barrier

-

Identify Hold Points

Work Area Protection

-

Is work area Protection Required for your task?

-

Have you called Penn Dot traffic managment?

-

Please call Penn Dot Traffic Managment before any work on state roadways

-

State and/or Township Rd Permit #

-

Do you have a copy of the permit on site?

-

OBTAIN A PERMIT BEFORE WORK BEGINS ON ROADWAY!!

-

Following Traffic Control Plan?

-

Traffic Flow

-

MUTCD Tad #

-

Approx. # of Cones Placed

-

# of Signs Placed

ZONE OF PREOTECTION (ZOP)

-

Is ZOP required for your work?

-

Primary Voltage

-

Secondary Voltage

-

Minimum Approach Distance

-

Line/Feeder/Circuit #

-

Clearance / Admin Orders Reviewed # is

-

3-Part Communication w/ Designated Authority

Live Until Proven Dead!!

-

Are you Preforming Lock Out Tag Out today?

-

Types of tags

-

Tags Recoreded

-

Equipment #'s Recorded

-

Number of Grounds

-

Master Ground Loc.

-

Undispatched Grounds

-

Tested & Grounded

-

LOTO / Hold Off / Tags Placed

-

ZOP Established

-

Crew Understands ZOP

-

Potential Backfeed Identified

Job Brief sheet 2

Excavation

-

Are you excavating today?

-

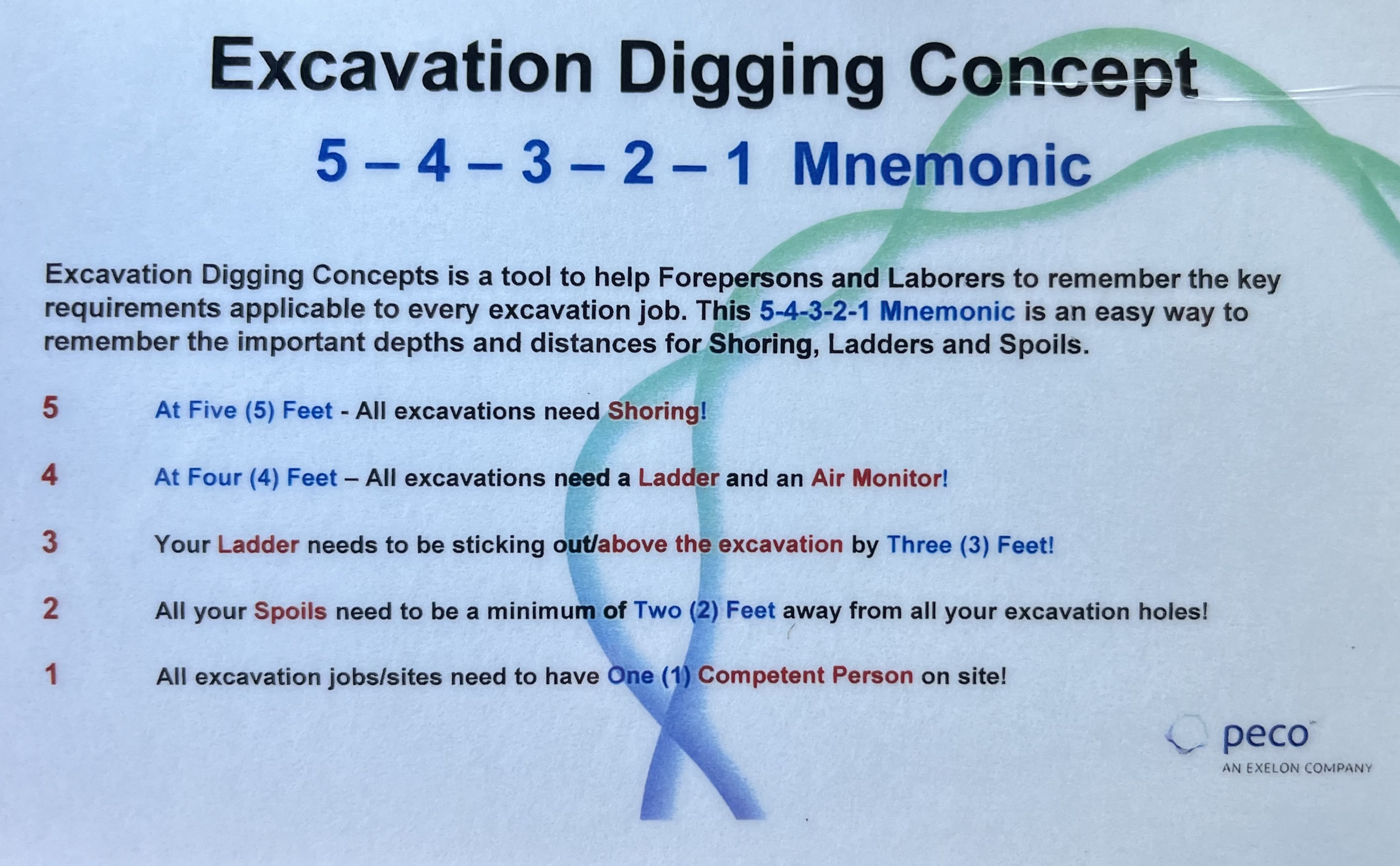

Please refer the Excavation Digging Concept 5) At Five (5) Feet- All excavations need a ladder, shoring and air monitoring 4) At Four (4) Feet- All Excavations need a Ladder and periodic air monitoring 3) Your Ladder needs to be sticking out/above the excavation by Three (3) Feet 2) All Spoils need to be a minimum of Two (2) Feet away from all your excavation holes 1) All excavation jobs/sites need to have One (1) Competent person on site

-

One Call Number

-

Please attach OneCall ticket by photo or PDF

-

Have you inspected the area for unmarked facilities?

-

What facilities are in your work area?

- Electric

- Gas

- Telecommunications

- Water

- Sewer

- Other

-

What other facilities have you found?

-

Have you secured unattended Excavations?

-

Check what applies to your job site below

-

Soil Type

-

Estimated Depth of Excavation

-

Excavation Protection System Used for Excavation of 5 ft. or Greater that Meets Soil Type:

-

Ladder in Excavation at 4 ft. and Every 25 ft.

-

Water Accumulation Controlled

-

Engineer Approved Plan for Excavation in Excess of 20 ft. on Site

CONFINED/ENCLOSED SPACE

-

Will the Job Require Confined Space Entry

-

Will a Permit be Required

-

Attendant Name

-

Percent Oxygen

-

Percent Oxygen (Mid-Shift)

-

Emergency Retrieval System Readily Available

-

Space is Barricaded to Prevent Fall In

-

Blower Readily Available to Force Air Ventilate

-

Arc Blanket Utilized

PPE

-

All basic PPE Worn? (HARD HAT,SAFETY GLASSES, HIGH VIZ VEST/CLOTHING, WORK GLOVES & SAFETY TOED BOOTS)

-

FR Clothing

-

2nd layer FR

-

Primary Gloves

-

Sleeves

-

Other

Electrical Hazards

-

Inspect all Rubber Goods

-

Rubber Properly Placed

-

Inspect All Live Line Tools

-

Equipment Checked/Calibrated

-

Inspect Pole Condition

-

Equipment Grounded

-

System Neutral

-

Pole Ground

-

Anchor

-

Screw Ground

-

Directional Drill Strike Alert

-

Other

-

Why?

-

Induction Sources Identified

-

Step/Touch Potential Identified

-

Flag/Visual Ground Marker

-

LOFFA Set Properly

Site Conditions/Environmental

-

Site Walk Down Complete

-

Uneven Surfaces

-

Ice/Mud/Snow

-

Pinch Points Identified

-

Leaking Equipment

-

Working Near a Wetland

-

Poison Ivy/Oak

-

Wild Life Concerns

-

PCB Contaminants Presents

-

Emergency Escape Plan

-

Location to meet?

-

Proper Dewatering

-

Fire Protection Tools Checked

-

Hydration Monitor - Aware of Heat Illness Plan

Vehicle/ Equipment

-

Pre-Trip Inspection

-

360 Walk Around

-

Use of Spotter

-

Operator Wearing Seatbelt

-

Line of Fire Identified

-

Load Properly Secured

-

Equipment Barricaded

-

Public Protected

-

Qualified Operator / Rigger

-

Rigging Inspected

Mid-Shift/ Scope of Work Change

-

Has a Mid-Shift Scope Change occurred?

-

What has changed?

Discussions

-

Weekly Discussion Tool

-

Attach weekly discussion form

-

Recent Bulletins

-

Industry News

RULES TO DIG BY

CHECK that the One-Call ticket is correct

-

Verify Address, scope, and area of your proposed excavation

CHECK the lawful start date and time.

-

Verify excavation does not begin prior to the lawful start date & time

-

48 hours (Illinois) & 72 hours (Pennsylvania)

-

A 2 hour waiting period exists for emergent locate requests (after 2 hours you must make another call attempt) Except for emergent requests, these waiting periods are exclusive of Saturday, Sunday, and One-Call holidays

-

Work must begin within 14 days (Illinois) & 10 days (Pennsylvania)

-

One-Call law allows deviation from these rules in isolated emergencies provided prudent digging techniques are utilized

CHECK for completeness and accuracy of locates

-

Investigate and ensure facilities are marked near equipment (i.e. transformers, pedestals, splice boxes, down-feeds, meters, & etc.) within your extent of work

-

Evaluate available maps & work orders to determine if marks exist, as they would be expected

-

Verify if all One-Call utilities, municipalities, and private facility owners have located their facilities

-

"All clear" marks or notifications should exist for those utilities that do not have facilities in the specified area of excavation

-

When utilizing One-Call, never waive the "all clear" call back from utilities

LOOK for previous marks on sidewalks, curbs & roads

-

Evaluate the potential for human error or oversight by reviewing the area for fading marks from previous locate requests

-

If fading marks are found evaluate the potential for a miss-marked facility

USE appropriate maps, work orders, and prints prior to construction

-

Evaluating maps, work orders, and prints will help determine if the marks found in the field are accurate

HAND DIG when working within 24 inches of locates or equipment to verify the underground facility's location

-

EED has created the standard of a 4-foot tolerance zone. (24 inches either side of a mark)

-

Tolerance zones are created due to the technical difficulty of locating buried facilities. The actual location of these facilities can vary to any portion of this zone.

-

Mechanical excavation within the tolerance zone requires visual identification of all facilities

-

One mark doesn't mean one facility

-

Secure the excavation when unattended

NEVER use powered equipment in the tolerance zone such as trenchers, backhoes and augers until you have verified that the mark is accurate

-

Once you determine what facilities exist, create a safe work plan to avoid them

-

The tolerance zone is noted as the 24" area on either side of a mark.

-

While using mechanical means to excavate, you are expected to utilize practices, such as "chipping in". This term amounts to digging outside the marks and using hand tools to loosen earth over marks into the excavation site

NEVER ASSUME:

-

That the facility route is in a straight line

-

That locating marks are accurate

-

That utilities are buried at proper depth

-

That no marks means no utilities

A DIG TICKET is not a license to dig

-

TICKET is not a license to dig All information in this guideline combined and applied provides a safer opportunity to excavate

-

Your evaluation of the information and existing field conditions are determining factors when beginning to excavate

RESPECT all One-Call marks.

-

Refer to the One-Call law

-

It's part of your safe excavation practices

-

NOTE: Prudent Digging includes the strict adherence to all Exelon procedures and One Call Laws, the proper application and use of all approved tools as defined in this procedure as applicable, maintenance of the marks and the protection and support of uncovered facilities. The use of powered equipment shall only begin after the exact location of all facilities and visual identification of all facilities within the 24" tolerance zone have been identified and a safe work plan has been created to avoid the facilities. The safe work plan's responsible party would be On-site Supervision who would identify all potential hazards including but not limited to those referenced in this procedure and documented on the Job Brief.

-

ATTACHED IS THE PECO RULES TO DIG BY

Please Write Your Own Name After Being Briefed

-

Name, Role & Signiture