Title Page

-

Cooperative Name

-

Location

-

Truck Number and Type (digger, bucket, etc.)

- Main Facility

- Outpost

-

Conducted on

-

Prepared by

Section 9: Diggers, Buckets, Etc. (Over 10,000 Lbs. GVWR)

-

All digger derricks, aerial devices, and other commercial vehicles over 10,000 lbs. (GVWR) have six documents: insurance card, registration form, operator's manual, accident reporting guidelines, daily post trip inspections, and annual DOT meetings.

-

Commercial vehicles over 10,000 ibs. GVWR are well maintained.<br>

-

Commercial vehicles are equipped with the proper work zone safety equipment.<br>

-

Roadside emergency triangular markers are on all of these vehicles.

-

Head lights, clearance lights, and strobe lights, and hazard warning lights in safe working condition.

-

Body, jib, and boom winch mechanisms, cables, ropes, mounting, and controls are properly matched for the intended use and maintained in good condition.

-

Appropriate vehicle grounding and/or barricading equipment is available and in good condition.

-

Vehicle ground cables are individually marked with a method of unique identification and date of most recent test.

-

Shovels, pry bars, tamps, ground rod drivers, sledges, chains, other heavy tools and materials are properly stored/secured in these utility vehicles.

-

At Least two effective wheel chocks are provided per large truck, properly placed in accordance with safety manual, and properly stowed on each truck when not in use.

-

Substantial outrigger pads are provided for all equipment outrigger legs, are properly used in accordance with manufacturer's requirements, and are properly stored on the vehicle when not in use.

-

Manufacturer's identification, capacity ratings, warning signs, and equipment control placards for digger derrick and aerial basket devices are in place and in good condition

-

Daily operational inspections are conducted before these vehicles leave the facility.

-

Dielectric tests for these utility vehicles meets/exceeds applicable OSHA/ASTM/ANSI standards and results are available on or in each vehicle.<br> RESAP wants to ensure a system satisfy OSHA requirements by conducting an annual test but promotes using a semi-annual (6months) dielectric test that exceeds the OSHA requirement.

-

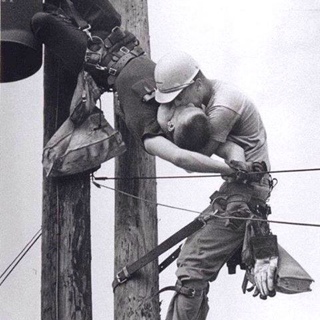

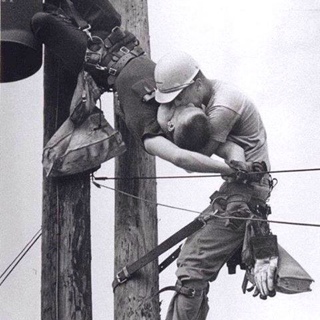

Handline or other self rescuing device is kept inside the bucket while work is being preformed.

-

Hydraulic lines and tools are free of damages cracks and leaks.

-

Live line tools are properly stored and maintained.

-

Live line tools have are labeled with the most recent test date.

-

Rubber guts and blankets are properly stored and maintained.

-

Rubber guts and blankets are stamped with most recent test dates.

-

Mac's (insulated jumpers) are properly stored and maintained.

-

Rubber gloves and sleeves are stored properly and in good condition.

-

Harnesses and fall protection are properly stored and in good condition.

-

Lanyards are stored in a bin or fixed to harness, and kept out of weather and other elements.

-

FR or arc rated clothing is in good condition and free of stains, rips, or tears.

-

Slings and lifting chains are in good condition and labeled with legible tags with weight ratings.

-

Strap hoists are well maintained.

Section 9: Summary

-

Additional comments or concerns.

Safety Personnel Signature

-

Add signature