Information

-

MONTHLY WORKSHOP CHECKLIST

-

INSTRUCTION

Please use the Workshop checklist below to conduct your monthly Workplace Hazard Inspection. Once the Inspection is completed please summarise the unresolved hazards on the Workplace Hazard Inspection Summary Sheet and forward a copy to your Portfolio/Regional Manager and a copy to the OSH Coordinator. -

Inspected By:

-

Date:

-

Area Inspected: WORKSHOP CHECKLIST

-

CAMPUS:

-

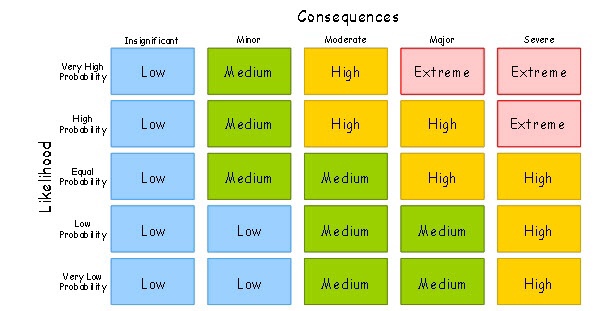

Risk Priority Rating:

X - Extreme Risk - extremely urgent, action IMMEDIATELY

H - High Risk - urgent, action AS SOON AS POSSIBLE

M - Medium Risk - action within ONE WEEK

L - Low Risk - not urgent, action within ONE MONTH -

Fire, Emergency and First Aid

FIRE.EMERGENCY AND FIRST AID

-

1. Emergency / Evacuation plans and instructions - available to all staff, and appropriately displayed.

-

2. Fire Extinguishers - are clearly marked in relation to type of fire use? Clear access (1m) kept to all fire fighting equipment?

-

3. Fire extinguishers / hoses / blankets - serviced and tagged every 6 months?

-

4. Exit Doors - clear access kept and easily opened from the inside? Adequate exit direction notices / signs clearly visible.

-

5. Flammable materials – are they stored and handled away from heat in a manner that there is no risk of fire?

-

6. First aid – access to kits, suitably stocked, signage for all treatments, kept clean, tidy and contents checked regularly. Gloves are included for first aid, blood injuries and biohazard procedures?

-

7. First aid training – do staff have current first aid certificate Is there a current list of First Aiders displayed

-

8. Eyewash – are eyewash facilities available where required?

Summary Fire, Emergency & First Aid

WORKPLACE HAZARD INSPECTION SUMMARY SHEET - Fire, Emergency and First Aid

-

Please complete the Workplace Hazard Inspection Summary Sheet and forward it to your Portfolio / Regional Manager and OSH Coordinator together with the above complete Inspection Checklist.

(Acknowledgement: Northern Territory Government, Department of Education and Training in the development of this Checklist.) -

UNRESOLVED HAZARD

-

RISK RATING

- LOW

- MEDIUM

- HIGH

- EXTREME

-

RECOMMENDED CONTROLS

-

BY WHOM

-

BY WHEN

-

INSPECTED BY: (Signature)

-

DATE:

-

PORTFOLIO / REGIONAL MANAGER ( Signature)

-

DATE:

-

OSH COORDINATOR (Signature)

-

DATE:

-

OSH COMMITTEE CHAIR (Signature)

-

DATE:

Floor, Walkways and Trip Hazards

FLOOR, WALKWAYS AND TRIP HAZARDS

-

34. Clear access – are all walkways, entries and exits kept clear of all trip hazards, with walkways a minimum one meter wide?

-

35. Mobility Impaired –access available to relevant areas?

Summary - Floor, Walkways & Trip Hazards

WORKPLACE HAZARD INSPECTION SUMMARY SHEET - Floor, Walkways and Trip Hazards

-

Please complete the Workplace Hazard Inspection Summary Sheet and forward it to your Portfolio / Regional Manager and OSH Coordinator together with the above complete Inspection Checklist.

(Acknowledgement: Northern Territory Government, Department of Education and Training in the development of this Checklist.) -

UNRESOLVED HAZARD

-

RISK RATING

- LOW

- MEDIUM

- HIGH

- EXTREME

-

RECOMMENDED CONTROLS

-

BY WHOM

-

BY WHEN

-

INSPECTED BY: (Signature)

-

DATE:

-

PORTFOLIO / REGIONAL MANAGER ( Signature)

-

DATE:

-

OSH COORDINATOR (Signature)

-

DATE:

-

OSH COMMITTEE CHAIR (Signature)

-

DATE:

Storage and Manual Handling

STORAGE AND MANUAL HANDLING

-

9. House keeping – all areas clean, tidy, and free of clutter?

-

10. Shelving - are free standing shelves and cupboards secured to ensure stability, and are items stored at a suitable height and within shelving width?

-

11. Containers – are there suitable containers used for storage, and are they suitably labelled

-

12. Gas Cylinders –pressurised cylinders stored correctly?

-

13. Manual handling – are staff aware of precautions / techniques to take when lifting or moving objects.<br>

Summary - Storage & Manual Handling

WORKPLACE HAZARD INSPECTION SUMMARY SHEET - Storage & Manual Handling

-

Please complete the Workplace Hazard Inspection Summary Sheet and forward it to your Portfolio / Regional Manager and OSH Coordinator together with the above complete Inspection Checklist.

(Acknowledgement: Northern Territory Government, Department of Education and Training in the development of this Checklist.) -

UNRESOLVED HAZARD

-

RISK RATING

- LOW

- MEDIUM

- HIGH

- EXTREME

-

RECOMMENDED CONTROLS

-

BY WHOM

-

BY WHEN

-

INSPECTED BY: (Signature)

-

DATE:

-

PORTFOLIO / REGIONAL MANAGER ( Signature)

-

DATE:

-

OSH COORDINATOR (Signature)

-

DATE:

-

OSH COMMITTEE CHAIR (Signature)

-

DATE:

Workshop Management and Practices

WORKSHOP MANAGEMENT AND PRACTICES

-

14. Floor surfaces – kept clean, tidy and in good condition?

-

15. Periodic Inspection - are all hand tools (including hand power and pneumatic tools) and equipment, inspected periodically for wear and tear, and is there a replacement procedure for damaged hand tools? Are appropriate guards fitted where required?

-

16. Training - are students instructed in the correct use of all hand tools?

-

17. Tools - are appropriate hand tools supplied / used for the job?

-

18. Lighting – Is there adequate lighting

-

19. Workstations/benches – are work heights appropriate?

-

20. Personal Protective Equipment - – Is the correct PPE provided, inspected, maintained and stored appropriately for all areas of the workplace

-

21. Housekeeping- all tools, equipment and materials stored adequately?

-

22. Extraction systems – is there an adequate system in place, and are dust/particles disposed of regularly?

-

23. Switches - are all machine switches, emergency stops etc in easy safe reach?

-

24. Walkways - are floors clearly marked with walkways and machine operating danger areas in workshops?

-

25. Welding Shields – are adequate shields supplied and maintained?

-

26. Standard Operating Procedures (SOPs) - have been developed / documented for all tasks carried out, and, if applicable, attached to the equipment? (Includes welding, hydraulic systems, air compressors and gas cylinders etc

-

27. Authorisation - do only competent and authorised personnel use equipment

-

28. Maintenance – is there a procedure to report all machine / workshop problems? Maintenance schedule in place

-

29. Machine Lock Out’s – are they fitted to prevent unauthorised usage (where required)?

-

30. Licensing/Authorisation – is the student licensed to operate their respective machine

-

31. Welding - does the following equipment comply with requirements?<br> Cylinders chained/secured?<br> Flammable/combustible materials removed /minimised?<br> Appropriate shielding and PPE available?<br> Equipment serviced and maintained regularly?

-

32. Steps/Ladders - are all steps/ladders maintained?

-

33. Warning Signs – are metal ladders marked with warnings not to use near electrical plant?

Summary - Workshop Mgmt & Practices

WORKPLACE HAZARD INSPECTION SUMMARY SHEET - Workshop Management and Practices

-

Please complete the Workplace Hazard Inspection Summary Sheet and forward it to your Portfolio / Regional Manager and OSH Coordinator together with the above complete Inspection Checklist.

(Acknowledgement: Northern Territory Government, Department of Education and Training in the development of this Checklist.) -

UNRESOLVED HAZARD

-

RISK RATING

- LOW

- MEDIUM

- HIGH

- EXTREME

-

RECOMMENDED CONTROLS

-

BY WHOM

-

BY WHEN

-

INSPECTED BY: (Signature)

-

DATE:

-

PORTFOLIO / REGIONAL MANAGER ( Signature)

-

DATE:

-

OSH COORDINATOR (Signature)

-

DATE:

-

OSH COMMITTEE CHAIR (Signature)

-

DATE:

Electrical

ELECTRICAL

-

36. Electrical register - is one kept of all electrical items, tagged, tested & updated?<br>- portable items every 12 months<br>- non-portable items every 5 years

-

37. Electrical power boards or equivalent – do they have overload cut off switch? Are double adapters removed from workplace?

-

38. Electrical – are plugs, sockets, switches, extension leads kept in good condition and maintained regular

-

39. Electrical - walkways clear of leads etc?

Summary - Electrical

WORKPLACE HAZARD INSPECTION SUMMARY SHEET - Electrical

-

Please complete the Workplace Hazard Inspection Summary Sheet and forward it to your Portfolio / Regional Manager and OSH Coordinator together with the above complete Inspection Checklist.

(Acknowledgement: Northern Territory Government, Department of Education and Training in the development of this Checklist.) -

RISK RATING

- LOW

- MEDIUM

- HIGH

- EXTREME

-

RECOMMENDED CONTROLS

-

BY WHOM

-

BY WHEN

-

INSPECTED BY: (Signature)

-

DATE:

-

PORTFOLIO / REGIONAL MANAGER ( Signature)

-

DATE:

-

OSH COORDINATOR (Signature)

-

DATE:

-

OSH COMMITTEE CHAIR (Signature)

-

DATE:

Hoists and Lifting Equipment

HOISTS AND LIFTING EQUIPMENT

-

40. Authorisation - do only authorised, competent people use hoists?

-

41. Limit Devices - do you have limit devices on overhead hoists to stop hook travel at lowest and highest points of safe travel?

-

42. Holding devices - are there automatic stopping and holding devices on hoists to suspend elevated loads during interruptions to power? Are hoists marked with load capacities?

-

43. Clear Direction of Travel – do controls clearly show direction of travel?

-

44. All equipment and accessories – is regularly inspected, certified, maintained and registered

-

45. Packing - is packing used to prevent damage to lifting slings or loads?

Summary -Hoists & Lifting Equipment

WORKPLACE HAZARD INSPECTION SUMMARY SHEET - Hoists and Lifting Equipment

-

Please complete the Workplace Hazard Inspection Summary Sheet and forward it to your Portfolio / Regional Manager and OSH Coordinator together with the above complete Inspection Checklist.

(Acknowledgement: Northern Territory Government, Department of Education and Training in the development of this Checklist.) -

RISK RATING

- LOW

- MEDIUM

- HIGH

- EXTREME

-

RECOMMENDED CONTROLS

-

BY WHOM

-

BY WHEN

-

INSPECTED BY: (Signature)

-

DATE:

-

PORTFOLIO / REGIONAL MANAGER ( Signature)

-

DATE:

-

OSH COORDINATOR (Signature)

-

DATE:

-

OSH COMMITTEE CHAIR (Signature)

-

DATE:

Rotating Devices

ROTATING DEVICES (Grinding / Linishers / Lathes

-

46. Emergency Stop – are emergency stop facilities fitted on spinning or rotating devices?

-

47. Grinders – are work rests adequately adjusted to the wheel, and are guards fixed as per manufacturers recommendations? Are abrasive wheels “ring tested” before installation to ensure they are not fractured? (Test each new grinding wheel prior to installation by suspending on a screwdriver, cord or similar, tap wheel lightly with a metal object – a clear ring should be heard

-

48. Ventilation/Extraction - is there adequate particle extraction available and is it regularly maintained?

-

49. Lighting – Are only incandescent globes used over lathes and other variable speed devices? (fluorescent tubes may make rotating parts appear to be standing still or rotating slowly through a strobe effect

Summary - Rotating Devices

WORKPLACE HAZARD INSPECTION SUMMARY SHEET - Rotating Devices

-

Please complete the Workplace Hazard Inspection Summary Sheet and forward it to your Portfolio / Regional Manager and OSH Coordinator together with the above complete Inspection Checklist.

(Acknowledgement: Northern Territory Government, Department of Education and Training in the development of this Checklist.) -

RISK RATING

- LOW

- MEDIUM

- HIGH

- EXTREME

-

RECOMMENDED CONTROLS

-

BY WHOM

-

BY WHEN

-

INSPECTED BY: (Signature)

-

DATE:

-

PORTFOLIO / REGIONAL MANAGER ( Signature)

-

DATE:

-

OSH COORDINATOR (Signature)

-

DATE:

-

OSH COMMITTEE CHAIR (Signature)

-

DATE:

Chemicals

CHEMICALS

-

50. Chemical Register – are all chemicals clearly labelled, listed, adequately stored, and registered regularly?

-

51. MSDS – are Material Safety Data Sheets available for all workplace chemicals?

-

52. Oily rags – are stored in steel bins with tight fitting lids

-

53. Training – is suitable training on workplace chemicals given to staff and students

-

54. Spill Control - procedures in place for chemical spills?

Summary - Chemicals

WORKPLACE HAZARD INSPECTION SUMMARY SHEET - Chemicals

-

Please complete the Workplace Hazard Inspection Summary Sheet and forward it to your Portfolio / Regional Manager and OSH Coordinator together with the above complete Inspection Checklist.

(Acknowledgement: Northern Territory Government, Department of Education and Training in the development of this Checklist.) -

RISK RATING

- LOW

- MEDIUM

- HIGH

- EXTREME

-

RECOMMENDED CONTROLS

-

BY WHOM

-

BY WHEN

-

INSPECTED BY: (Signature)

-

DATE:

-

PORTFOLIO / REGIONAL MANAGER ( Signature)

-

DATE:

-

OSH COORDINATOR (Signature)

-

DATE:

-

OSH COMMITTEE CHAIR (Signature)

-

DATE: