Title Page

-

Site conducted

-

Branch

- Accrington

- Birmingham

- Bury St Edmunds

- Crawley

- Crayford

- Darlington

- Exeter

- Gloucester

- Milton Keynes

- Newbury

- Wales

- Nottingham

- Warrington

- Wombwell

- Services

-

Inspector

-

Contract Number

-

Date

-

Location

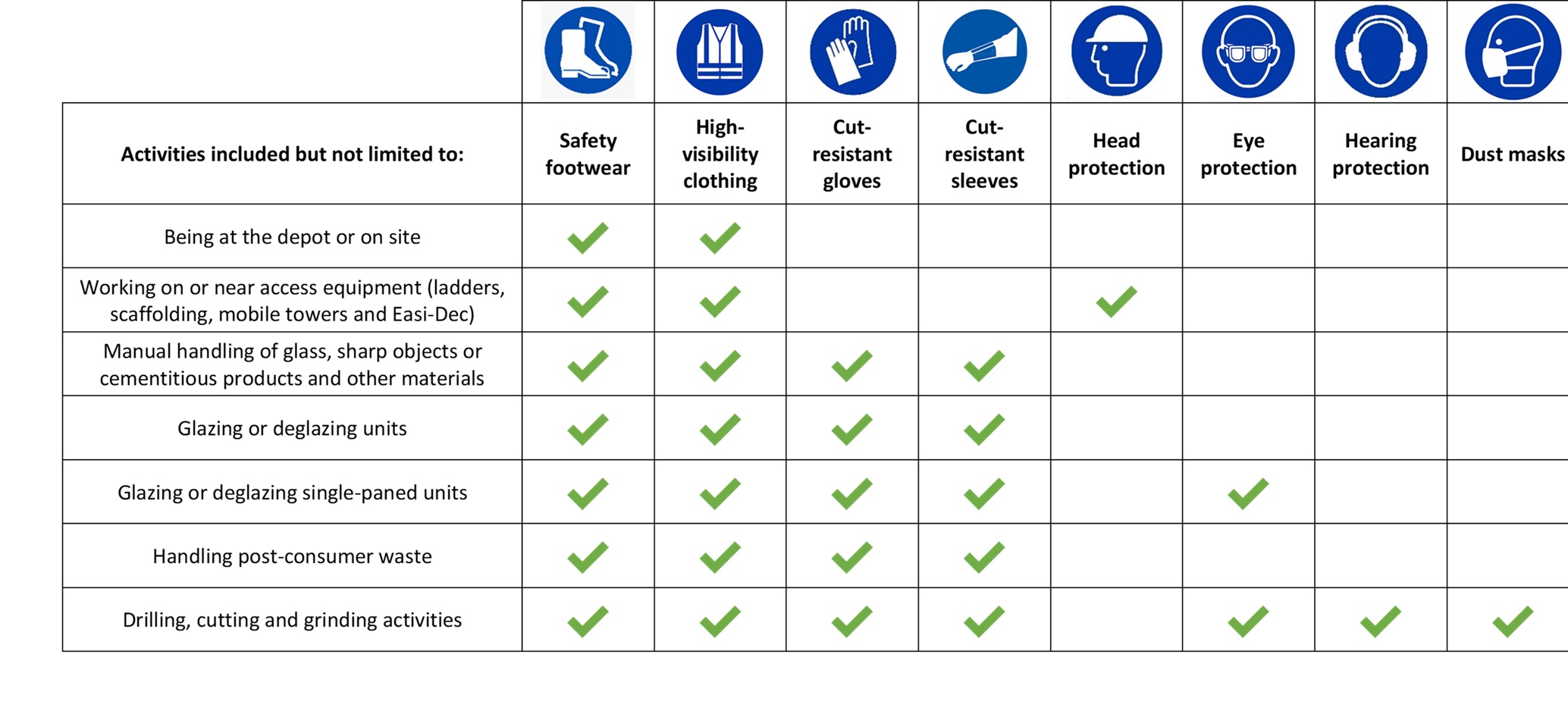

Risk Assessment

-

Has an onsite risk assessment been carried out?

-

STOP WORK IMMEDIATELY: Advise lead installer to carry out on site risk assessment. Assist with the risk assessment process and provide guidance on completing the form. Once this is complete the work may commence providing all necessary controls identified by the risk assessment are in place. (see completed risk assessment example)

-

Risk Assessment - Comment

-

Surveyor

-

Is the work being carried out segregated from other persons within the property?

-

INTERVENTION REQUIRED: Advise personnel the requirement to segregate work areas from other persons during works

Company vehicle

-

Please state how many vehicles on site are being inspected

Vehicle 1

-

Vehicle 1: Driver Name

-

Vehicle 1: Registration Number

-

Vehicle 1: Items stored on vehicle

- PCW

- New frames

- N/A

- Empty vehicle

-

Vehicle 1: Equipment on vehicle

- Ladder

- Stepladders

- Hop up

- Standoff

- Ladder spurs

- Trestle

- Hazard warning sign

- Window bar

- N/A

-

Vehicle 1: Is access equipment stored securely on the vehicle?

-

Vehicle 1: Is the vehicle parked in a safe location? e.g. not obstructing public footpaths or highways.

-

Vehicle 1: Parking issue

- Yellow lines

- Permit required

- Red route

- Local bylaws

-

Comment

-

Vehicle 1: Is a first aid kit with eye wash available, fully stocked and all items in date within the vehicle?

-

Vehicle 1: First aid kit issue

-

Vehicle 1: Please select the missing items

- Sterile cleaning wipes

- Adhering dressing pads

- Burn dressing

- Dressing

- Triangular bandages

- Clothing cutting scissors

- Nitrile gloves

- Revive-aid

- Plasters

- Emergency booklet

- Eye wash

- Surgical tape

- Face shield

- Conforming bandages

- Foil blanket

-

Vehicle 1: Are safety signs on display in prominent positions?

-

Vehicle 1: Safety Sign - Issue

-

Is there a waste carriers licence available in the vehicle

Vehicle 1

-

Vehicle 1: Driver Name

-

Vehicle 1: Registration Number

-

Vehicle 1: Items stored on vehicle

-

Vehicle 1: Equipment on vehicle

- Ladder

- Stepladders

- Hop up

- Standoff

- Ladder spurs

- Trestle

- Hazard warning sign

- Window bar

- N/A

-

Vehicle 1: Is access equipment stored securely on the vehicle?

-

Vehicle 1: Is the vehicle parked in a safe location? e.g. not obstructing public footpaths or highways.

-

Vehicle 1: Parking issue

- Yellow lines

- Permit required

- Red route

- Local bylaws

-

Comment

-

Vehicle 1: Is a first aid kit with eye wash available, fully stocked and all items in date within the vehicle?

-

Vehicle 1: First aid kit issue

-

Vehicle 1: Please select the missing items

- Sterile cleaning wipes

- Adhering dressing pads

- Burn dressing

- Dressing

- Triangular bandages

- Clothing cutting scissors

- Nitrile gloves

- Revive-aid

- Plasters

- Emergency booklet

- Eye wash

- Surgical tape

- Face shield

- Conforming bandages

- Foil blanket

-

Vehicle 1: Are safety signs on display in prominent positions?

-

Vehicle 1: Safety Sign - Issue

-

Is there a waste carriers licence available in the vehicle

Vehicle 2

-

Vehicle 2: Driver Name

-

Vehicle 2: Registration Number

-

Vehicle 2: Items stored on vehicle

-

Vehicle 2: Equipment on vehicle

- Ladder

- Stepladders

- Hop up

- Standoff

- Ladder spurs

- Trestle

- Hazard warning sign

- Window bar

- N/A

-

Vehicle 2: Is access equipment stored securely on the vehicle?

-

Vehicle 2: Is the vehicle parked in a safe location? e.g. not obstructing public footpaths or highways.

-

Vehicle 2: Parking issue

- Yellow lines

- Permit required

- Red route

- Local bylaws

-

Comment

-

-

Vehicle 2: Is there an installer's handbook present on the vehicle? (Please refer to the photo of the manual below)

-

Please ensure to create an action for the branch to provide an installer handbook for this vehicle

-

Vehicle 2: Is a first aid kit with eye wash available, fully stocked and all items in date within the vehicle?

-

Vehicle 2: First aid kit issue

-

Vehicle 2: Please select the missing items

- Sterile cleaning wipes

- Adhering dressing pads

- Burn dressing

- Dressing

- Triangular bandages

- Clothing cutting scissors

- Nitrile gloves

- Revive-aid

- Plasters

- Emergency booklet

- Eye wash

- Surgical tape

- Face shield

- Conforming bandages

- Foil blanket

-

Vehicle 2: Are safety signs on display in prominent positions?

-

Vehicle 2: Safety Sign - Issue

-

Is there a waste carriers licence available in vehicle 2?

Vehicle 1

-

Vehicle 1: Driver Name

-

Vehicle 1: Registration Number

-

Vehicle 1: Items stored on vehicle

- PCW

- New frames

- N/A

- Empty vehicle

-

Vehicle 1: Equipment on vehicle

- Ladder

- Stepladders

- Hop up

- Standoff

- Ladder spurs

- Trestle

- Hazard warning sign

- Window bar

- N/A

-

Vehicle 1: Is access equipment stored securely on the vehicle?

-

Vehicle 1: Is the vehicle parked in a safe location? e.g. not obstructing public footpaths or highways.

-

Vehicle 1: Parking issue

- Yellow lines

- Permit required

- Red route

- Local bylaws

-

Comment

-

Vehicle 1: Is a first aid kit with eye wash available, fully stocked and all items in date within the vehicle?

-

Vehicle 1: First aid kit issue

-

Vehicle 1: Please select the missing items

- Sterile cleaning wipes

- Adhering dressing pads

- Burn dressing

- Dressing

- Triangular bandages

- Clothing cutting scissors

- Nitrile gloves

- Revive-aid

- Plasters

- Emergency booklet

- Eye wash

- Surgical tape

- Face shield

- Conforming bandages

- Foil blanket

-

Vehicle 1: Are safety signs on display in prominent positions?

-

Vehicle 1: Safety Sign - Issue

-

Is there a waste carriers licence available in the vehicle

Vehicle 2

-

Vehicle 2: Driver Name

-

Vehicle 2: Registration Number

-

Vehicle 2: Items stored on vehicle

- PCW

- New frames

- N/A

- Empty vehicle

-

Vehicle 2: Equipment on vehicle

- Ladder

- Stepladders

- Hop up

- Standoff

- Ladder spurs

- Trestle

- Hazard warning sign

- Window bar

- N/A

-

Vehicle 2: Is access equipment stored securely on the vehicle?

-

Vehicle 2: Is the vehicle parked in a safe location? e.g. not obstructing public footpaths or highways.

-

Vehicle 2: Parking issue

- Yellow lines

- Permit required

- Red route

- Local bylaws

-

Comment

-

-

Vehicle 2: Is there an installer's handbook present on the vehicle? (Please refer to the photo of the manual below)

-

Please ensure to create an action for the branch to provide an installer handbook for this vehicle

-

Vehicle 2: Is a first aid kit with eye wash available, fully stocked and all items in date within the vehicle?

-

Vehicle 2: First aid kit issue

-

Vehicle 2: Please select the missing items

- Sterile cleaning wipes

- Adhering dressing pads

- Burn dressing

- Dressing

- Triangular bandages

- Clothing cutting scissors

- Nitrile gloves

- Revive-aid

- Plasters

- Emergency booklet

- Eye wash

- Surgical tape

- Face shield

- Conforming bandages

- Foil blanket

-

Vehicle 2: Are safety signs on display in prominent positions?

-

Vehicle 2: Safety Sign - Issue

-

Is there a waste carriers licence available in vehicle 2?

Vehicle 3

-

Vehicle 3: Driver Name

-

Vehicle 3: Registration Number

-

Vehicle 3: Items stored on vehicle

- PCW

- New frames

- N/A

- Empty vehicle

-

Vehicle 3: Equipment on vehicle

- Ladder

- Stepladders

- Hop up

- Standoff

- Ladder spurs

- Trestle

- Hazard warning sign

- Window bar

- N/A

-

Vehicle 3: Is access equipment stored securely on the vehicle?

-

Vehicle 3: Is the vehicle parked in a safe location? e.g. not obstructing public footpaths or highways.

-

Vehicle 3: Parking issue

- Yellow lines

- Permit required

- Red route

- Local bylaws

-

Comment

-

-

Vehicle 3: Is there an installer's handbook present on the vehicle? (Please refer to the photo of the manual below)

-

Please ensure to create an action for the branch to provide an installer handbook for this vehicle

-

Vehicle 3: Is a first aid kit with eye wash available, fully stocked and all items in date within the vehicle?

-

Vehicle 3: First aid kit issue

-

Vehicle 3: Please select the missing items

- Sterile cleaning wipes

- Adhering dressing pads

- Burn dressing

- Dressing

- Triangular bandages

- Clothing cutting scissors

- Nitrile gloves

- Revive-aid

- Plasters

- Emergency booklet

- Eye wash

- Surgical tape

- Face shield

- Conforming bandages

- Foil blanket

-

Vehicle 3: Are safety signs on display in prominent positions?

-

Vehicle 3: Safety Sign - Issue

-

Is there a waste carriers licence available in vehicle 3?

Work at Height

-

Is work at height equipment present or in use on site?

-

Select all Access Equipment present

- Ladder

- Stepladder

- Hop-Up Platform

- Traditional Scaffold

- Trestles

- Easi-Dec

- Window bar

- Mobile tower

-

All users of scaffolding must have completed the work at height element of the part 1 induction and ladder safety test.

-

Are installers using the scaffold safely?

-

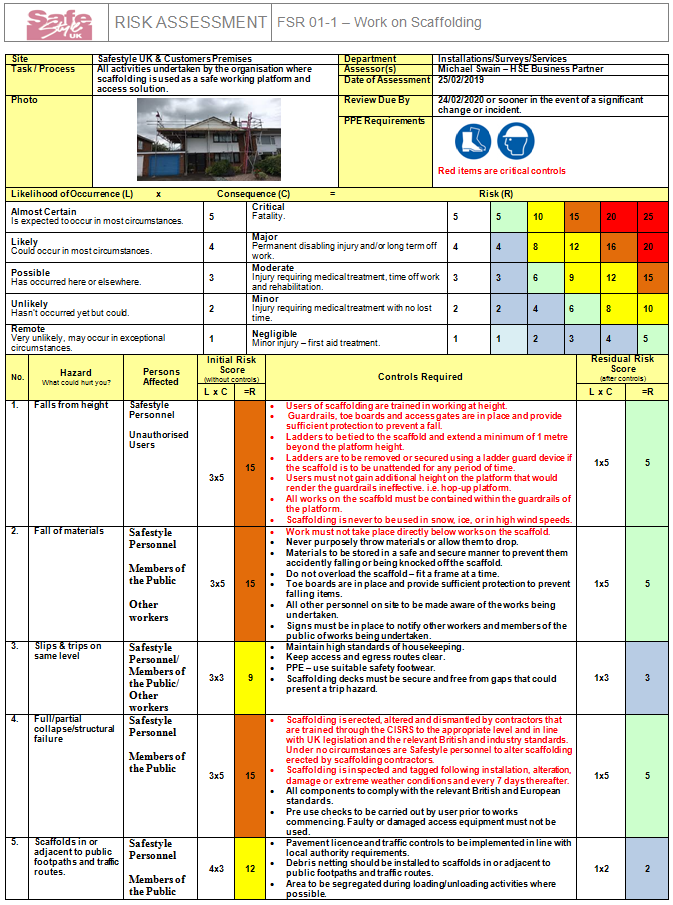

STOP WORK IMMEDIATELY: Discuss the attached risk assessment for work on scaffolding with the personnel on site. Work must not commence until all personnel confirm they understand the controls set out within this assessment.

-

Comment

-

Is the scaffolding safe to use?

-

Please start a scaffold audit: https://app.safetyculture.com/inspection/new?templateId=template_6958429923a54ae495ae44ad823e4e2c

-

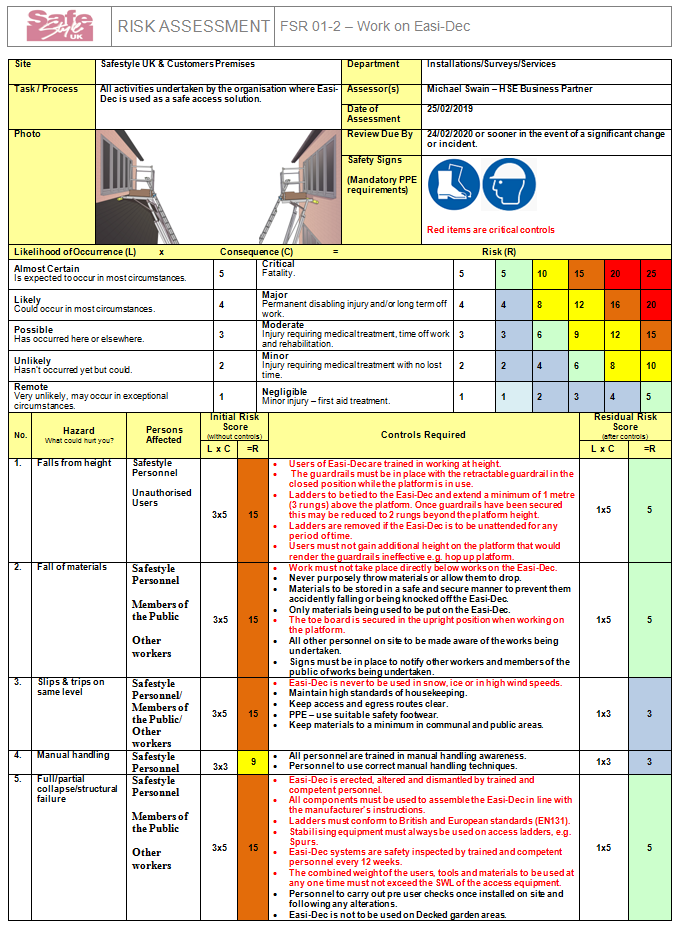

Any person who is required to erect, alter or dismantle Easi-Dec systems must be formally trained and hold a valid user certification and a legible copy of the manufacturers instructions must be readily available on site.

-

Has the Easi-Dec been formally inspected within the last 6 months?

-

STOP WORK USING EASI-DEC IMMEDIATELY: Easi-Dec equipment to be returned to branch for periodic safety inspection

-

Comment

-

Is the user Easi-Dec trained?

-

STOP WORK USING EASI-DEC IMMEDIATELY: Investigation required to identify how access equipment was issued to untrained personnel

-

Comment

-

Is the Easi-Dec free from damage and defects?

-

STOP WORK USING EASI-DEC: Contact branch management to arrange remedial works to be carried out. Work must not commence until remedial actions have been completed

-

Comment

-

Is a copy of the manufacturers instructions available on site for Easi-Dec?

-

ACTION REQUIRED: Installer to obtain manufacturers instructions from branch manager

-

Comment

-

Has the Easi-Dec been installed correctly as per the manufacturers instructions?

-

STOP WORK USING THE EASI-DEC: Advise personnel to dismantle the Easi-Dec and re-assemble in line with the manufacturers instructions

-

Comment

-

Is the Easi-Dec suitable for the work being carried out

-

Please provide details

-

Is the Easi-Dec being used safely?

-

STOP WORK IMMEDIATELY: Discuss the attached risk assessment for work on Easi-Dec with the personnel on site. Work must not commence until all personnel confirm they understand the controls set out within this assessment.

-

Comment

-

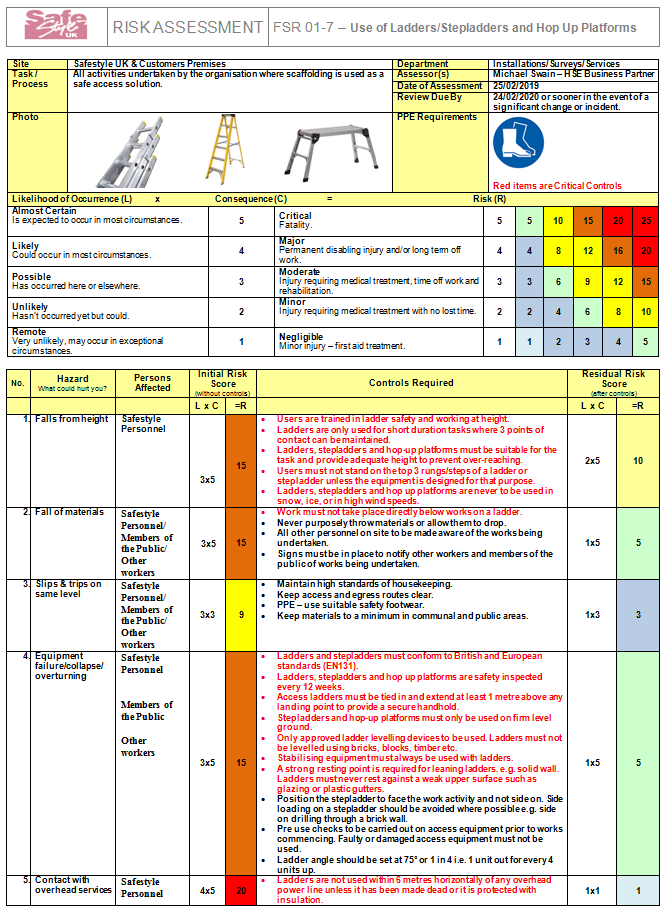

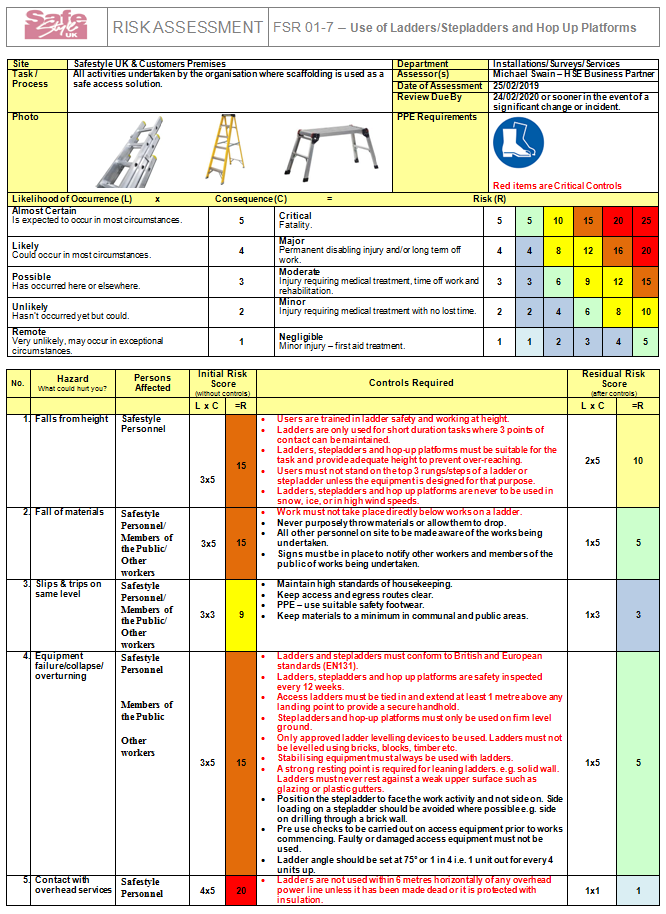

All users of ladders must have completed the work at height element of the part 1 induction and ladder safety test.

-

Is the ladder the correct class (e.g. EN131) and has it been formally inspected within the last 6 months?

-

ACTION REQUIRED: Ladder to be removed from service. Advise personnel that further use will result in a non-conformance being raised

-

Comment

-

Is the ladder fitted with suitable stabilizing devices at the top and base of the ladder?

-

ACTION REQUIRED: Advise personnel to fit stabilising devices to the ladder before work on the ladder commences

-

Comment

-

Is the ladder set up correctly?

-

STOP WORK IMMEDIATELY: Discuss the attached risk assessment for work on ladders with the personnel on site. Work must not commence until all personnel confirm they understand the controls set out within this assessment.

-

Comment

-

Is the ladder suitable for the work being carried out

-

Please provide details

-

Is the ladder being used safely?

-

STOP WORK IMMEDIATELY: Discuss the attached risk assessment for work on ladders with the personnel on site. Work must not commence until all personnel confirm they understand the controls set out within this assessment.

-

Comment

-

All users of stepladders must have completed the work at height element of the part 1 induction and ladder safety test.

-

Is the stepladder the correct class (e.g. EN131) and has it been formally inspected within the last 6 months?

-

ACTION REQUIRED: Stepladder to be removed from service. Advise personnel that further use will result in a non-conformance being raised

-

Comment

-

Is the stepladder set up correctly?

-

STOP WORK IMMEDIATELY: Discuss the attached risk assessment for work on stepladders with the personnel on site. Work must not commence until all personnel confirm they understand the controls set out within this assessment.

-

Comment

-

Is the stepladder suitable for the work being carried out

-

Please provide details

-

Is the stepladder being used safely?

-

STOP WORK IMMEDIATELY: Discuss the attached risk assessment for work on stepladders with the personnel on site. Work must not commence until all personnel confirm they understand the controls set out within this assessment.

-

Comment

-

-

Is the hop-up platform in safe working order?

-

ACTION REQUIRED: Hop-up platform to be removed from service. Advise personnel that further use will result in a non-conformance being raised

-

Comment

-

Is the hop-up suitable for the work being carried out

-

Please provide details

-

Is the hop-up platform being used safely?

-

STOP WORK IMMEDIATELY: Discuss the attached risk assessment for work on hop-up platforms with the personnel on site. Work must not commence until all personnel confirm they understand the controls set out within this assessment.

-

Comment

-

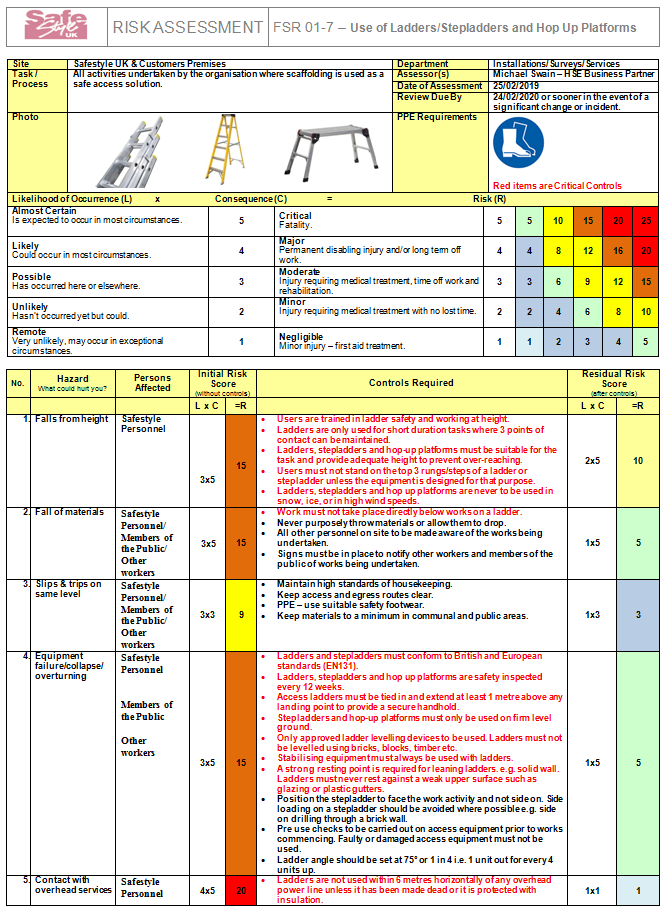

Any person who is required to erect, alter or dismantle mobile towers must be formally trained and hold a valid PASMA user certification and a legible copy of the manufacturers instructions must be readily available on site, however, copies of these can be obtained through the PASMA mobile app which is available on Android and IOS mobile devices.

-

Is the user trained to erect mobile towers? e.g. PASMA user trained

-

STOP WORK USING MOBILE TOWER IMMEDIATELY: Investigation required to identify how access equipment was issued to untrained personnel

-

Comment

-

Is the mobile tower free from damage and defects?

-

STOP WORK USING MOBILE TOWER: Contact branch management to arrange remedial works to be carried out. Work must not commence on the mobile tower until remedial actions have been completed

-

Comment

-

Is a copy of the manufacturer's instructions available on site for the mobile tower?

-

ACTION REQUIRED: Installer to download PASMA mobile app and access manufacturers installation instructions

-

Comment

-

Has the mobile tower been installed correctly as per the manufacturer's instructions?

-

STOP WORK USING THE MOBILE TOWER: Advise personnel to dismantle the tower and re-assemble in line with the manufacturer's instructions

-

Comment

-

Is the mobile tower suitable for the work being carried out

-

Please provide details

-

Is the mobile tower being used safely?

-

STOP WORK IMMEDIATELY: Discuss the attached risk assessment for work on mobile towers with the personnel on site. Work must not commence until all personnel confirm they understand the controls set out within this assessment.

-

Comment

Team(s) on Site

-

Please state how many teams there are on this site

Team 1 Information

-

Team 1 Lead installer name

-

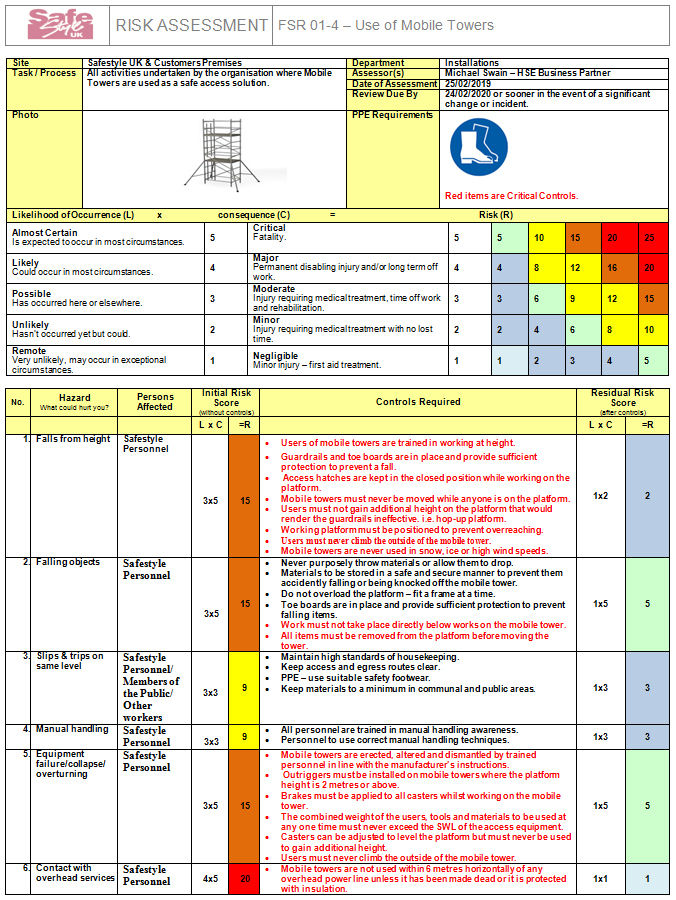

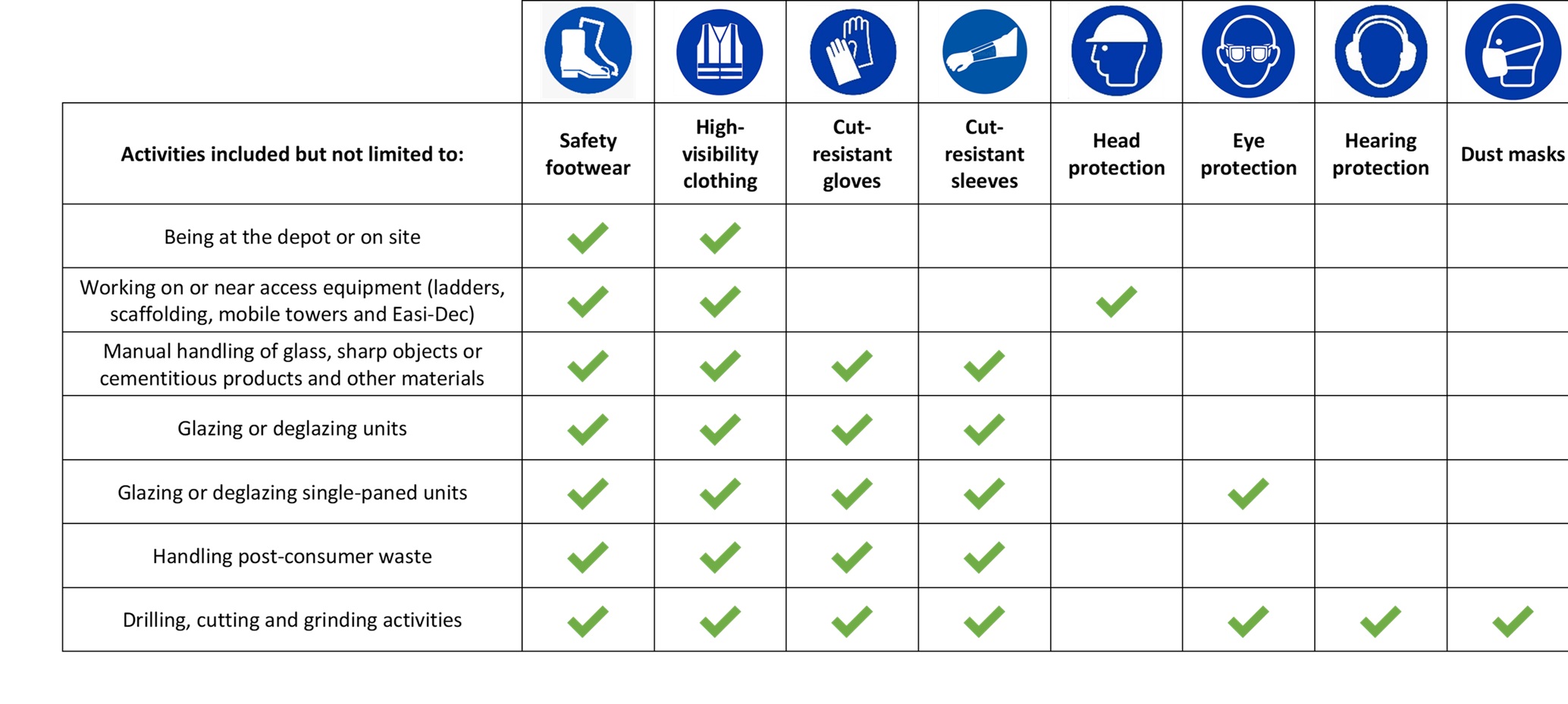

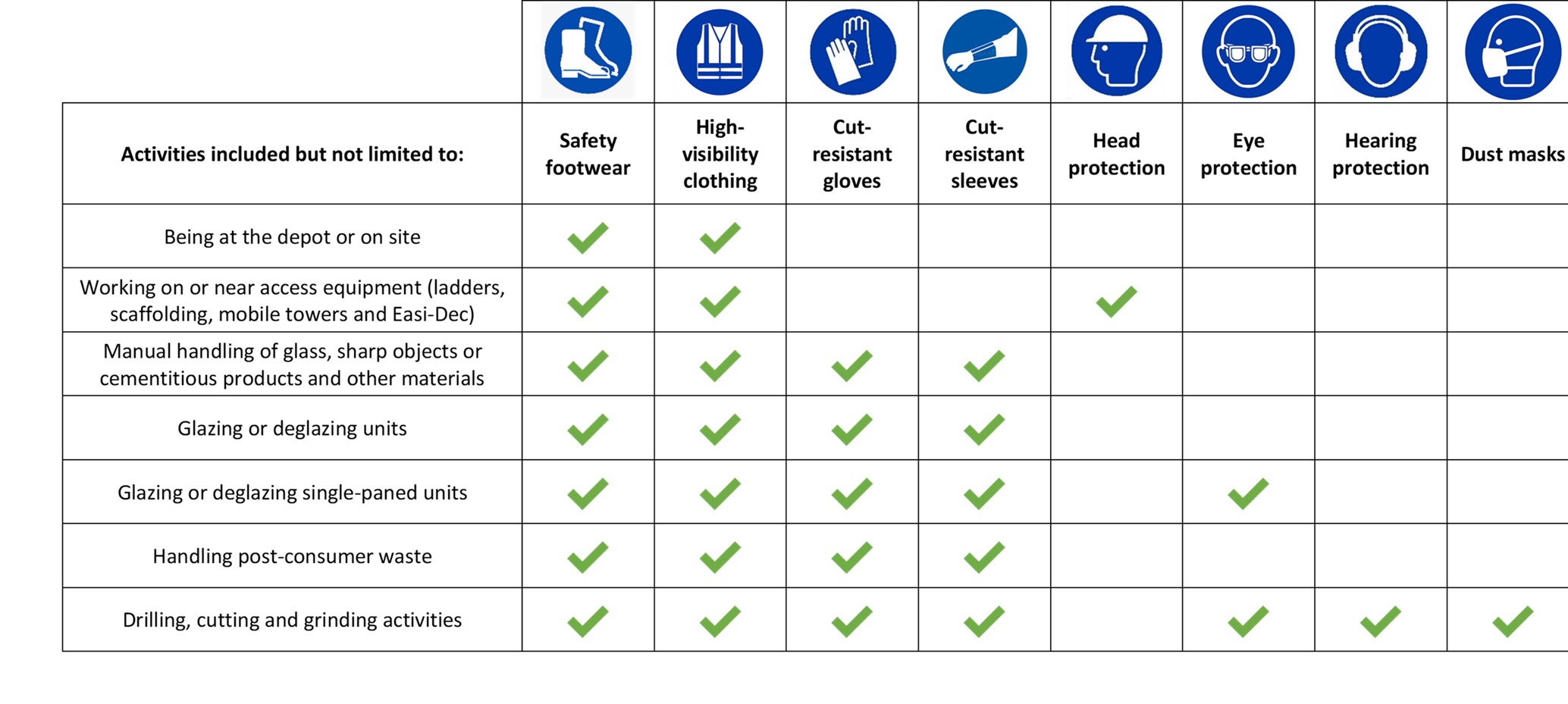

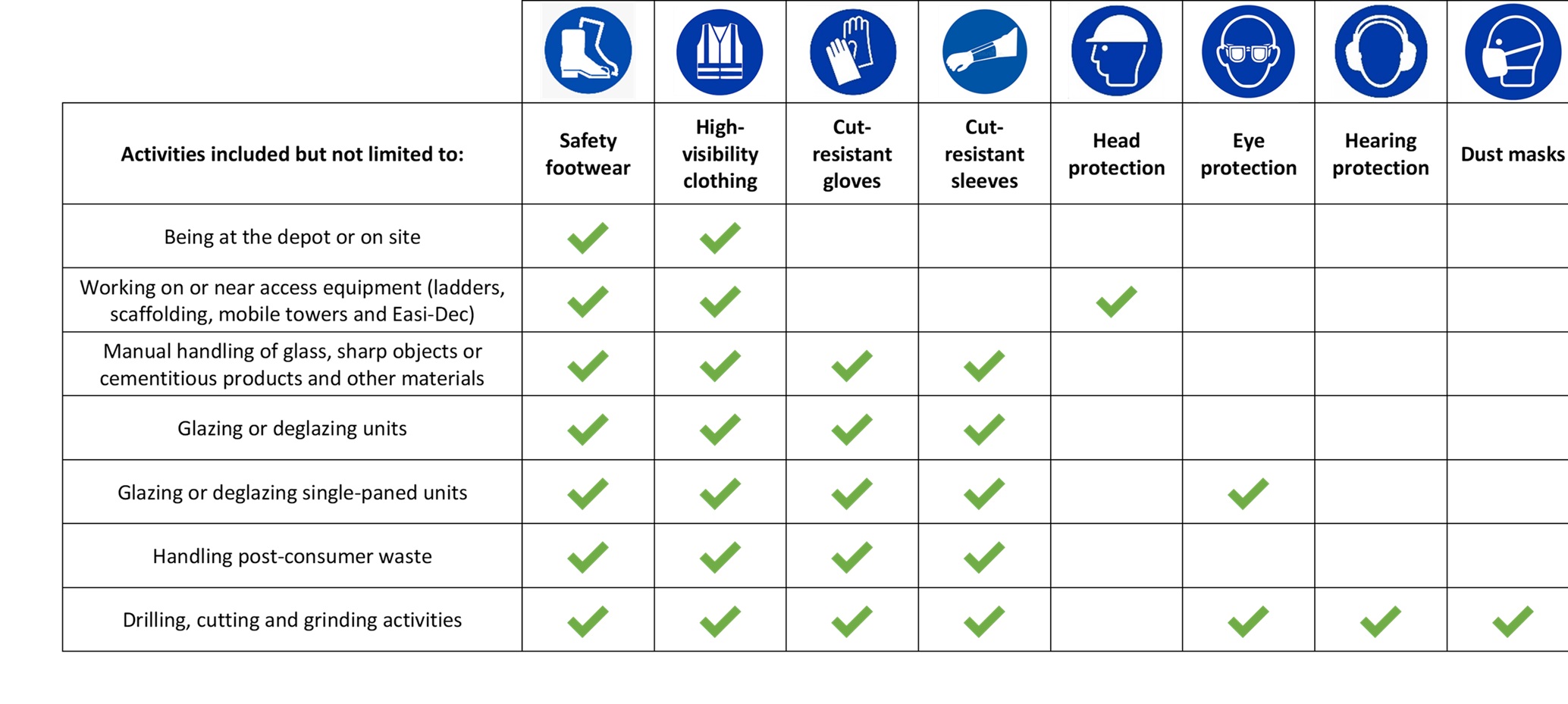

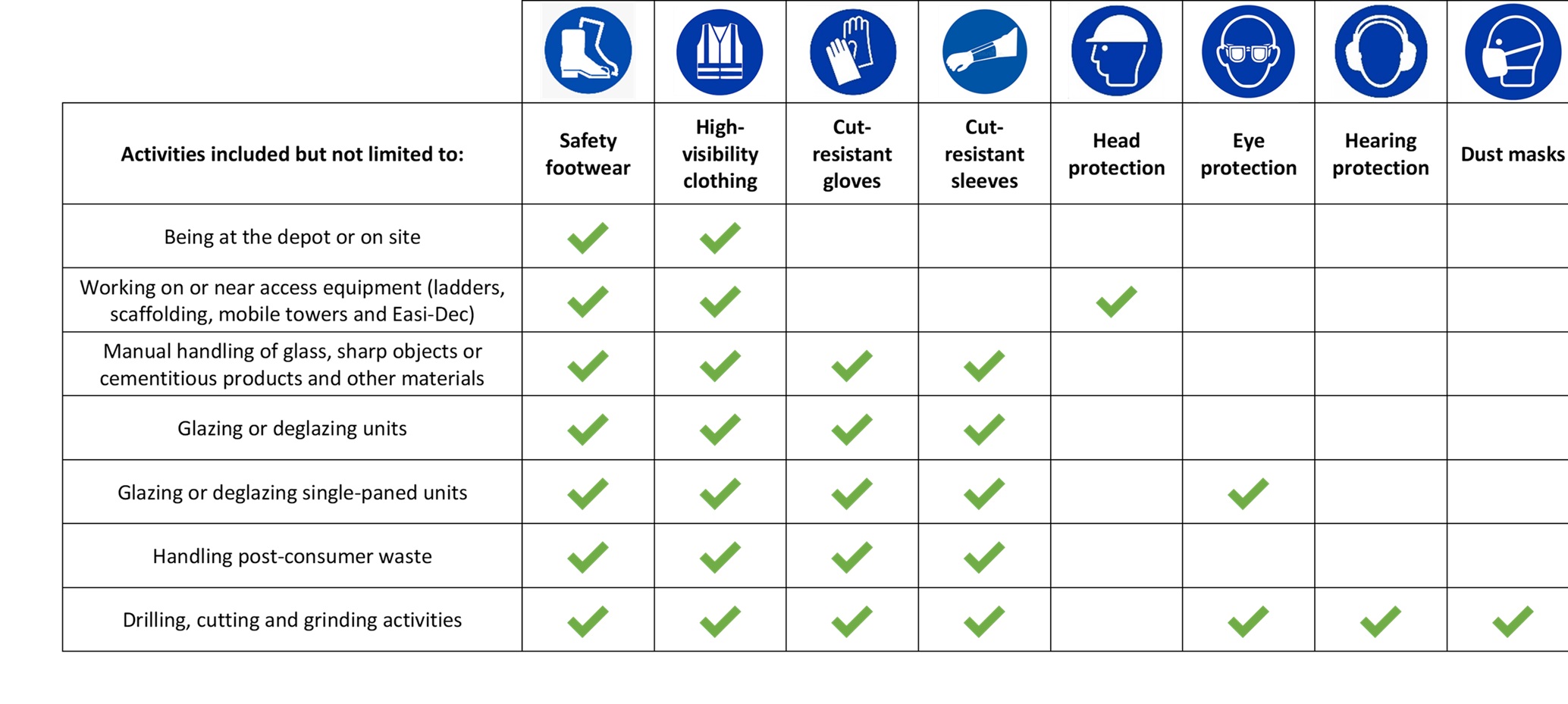

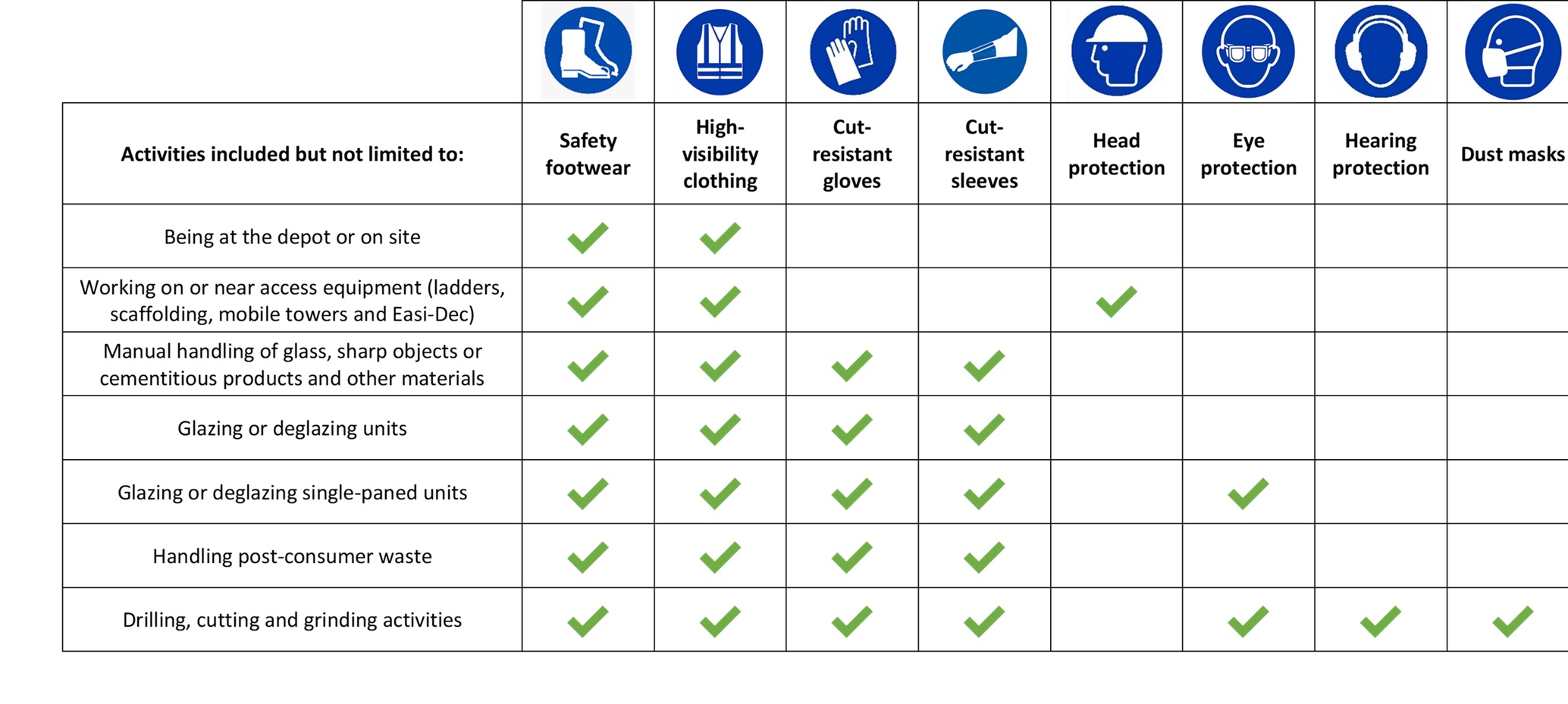

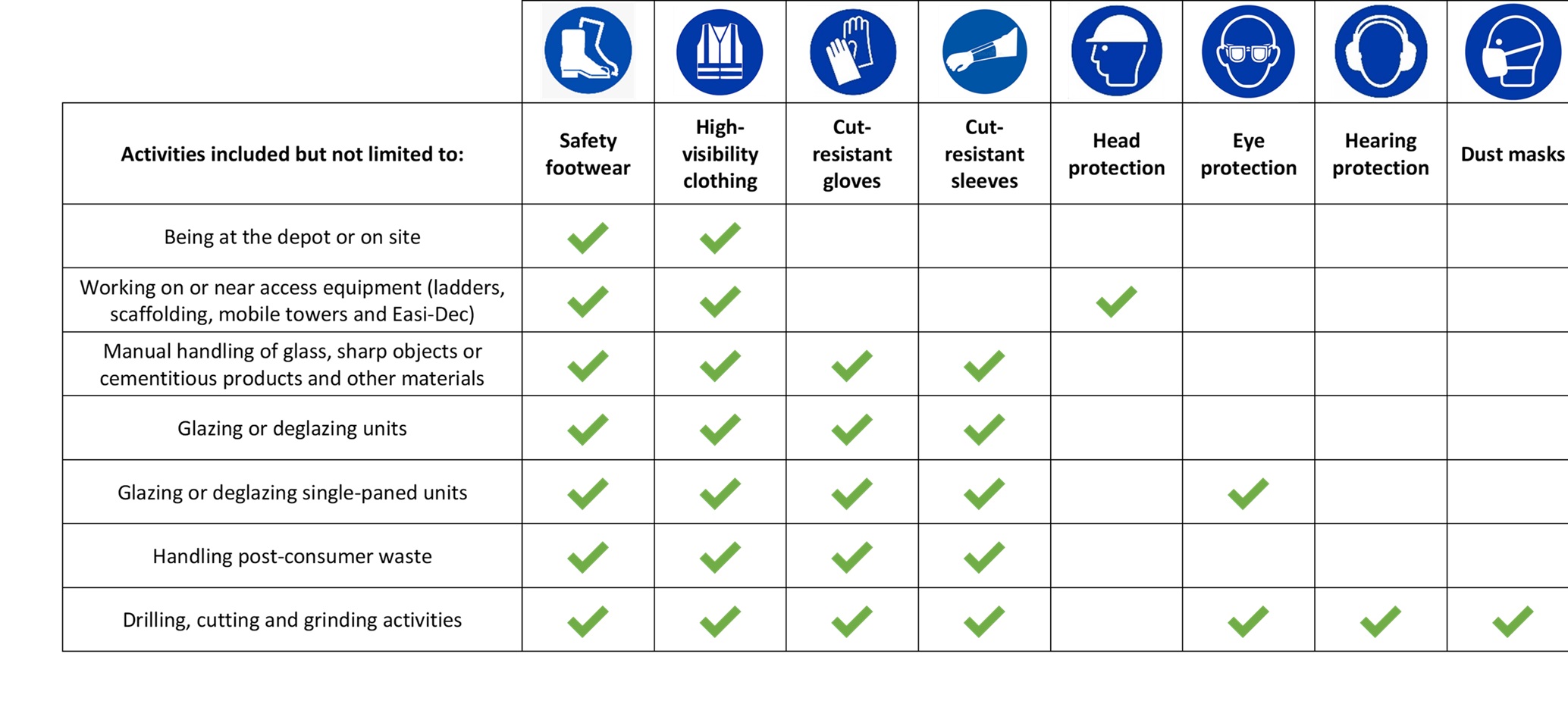

Is the Lead installer wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Lead installer: Items of PPE not being worn

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Lead installer: Reason for not wearing PPE?

-

Comment

MTC card

-

Does the lead installer have their MTC card?

Installer(s)

-

Please indicate the number of ADDITIONAL installers working on site besides the lead installer within this team

-

Team 1 Installer 1 name

-

Is Team 1 Installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 1)

-

Team 1 Installer 1 name

-

Is Team 1 Installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 1)

-

Team 1 Installer 2 name

-

Is Team 1 Installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 2)

-

Team 1 Installer 1 name

-

Is Team 1 Installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 1)

-

Team 1 Installer 2 name

-

Is Team 1 Installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 2)

-

Team 1 Installer 3 name

-

Is Team 1 Installer 3 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 3)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 3)

Team 1 Information

-

Team 1 Lead installer name

-

Is the Team 1 Lead installer wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Team 1 Lead installer: Items of PPE not being worn

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Team 1 Lead installer: Reason for not wearing PPE?

-

Comment

MTC card

-

Does the Team 1 Lead Installer have their MTC card?

-

Please select a reason why

- The card is lost

- Forgot to bring it

- They are currently undergoing the programme

- Have not enrolled onto programme yet

- Other

-

Please provide a reason why

Installer(s)

-

Please indicate the number of ADDITIONAL installers working on site besides the lead installer within Team 1

-

Team 1 Installer 1 name

-

Is installer 1 from Team 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 1 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 1 installer 1)

-

Team 1 Installer 1 name

-

Is Team 1 Installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 1)

-

Team 1 Installer 2 name

-

Is Team 1 Installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 2)

-

Installer 1 name

-

Is installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (installer 1)

-

Installer 2 name

-

Is installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (installer 2)

-

Installer 3 name

-

Is installer 3 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (installer 3)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (installer 3)

Team 2 Information

-

Team 2 Lead installer name

-

Is the Team 2 Lead installer wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Team 2 Lead installer: Items of PPE not being worn

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Team 2 Lead installer: Reason for not wearing PPE?

-

Comment

MTC card

-

Does the Team 2 lead installer have their MTC card?

-

Please select a reason why

- The card is lost

- Forgot to bring it

- They are currently undergoing the programme

- Have not enrolled onto programme yet

- Other

-

Please provide a reason why

Team 2 Installer(s)

-

Please indicate the number of ADDITIONAL installers working on site besides the lead installer within this team

-

Team 2 Installer 1 name

-

Is team 2 installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 1)

-

Team 2 Installer 1 name

-

Is team 2 installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 1)

-

Team 2 Installer 2 name

-

Is team 2 installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 2)

-

Team 2 Installer 1 name

-

Is Team 2 installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 1)

-

Team 2 Installer 2 name

-

Is team 2 installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 2)

-

Team 2 Installer 3 name

-

Is Team 2 installer 3 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 2 Installer 3)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 2 Installer 3)

Team 1 Information

-

Team 1 Lead installer name

-

Is the Team 1 Lead installer wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Team 1 Lead installer: Items of PPE not being worn

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Team 1 Lead installer: Reason for not wearing PPE?

-

Comment

MTC card

-

Does the Team 1 Lead Installer have their MTC card?

-

Please select a reason why

- The card is lost

- Forgot to bring it

- They are currently undergoing the programme

- Have not enrolled onto programme yet

- Other

-

Please provide a reason why

Installer(s)

-

Please indicate the number of ADDITIONAL installers working on site besides the lead installer within Team 1

-

Team 1 Installer 1 name

-

Is installer 1 from Team 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 1 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 1 installer 1)

-

Team 1 Installer 1 name

-

Is Team 1 Installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 1)

-

Team 1 Installer 2 name

-

Is Team 1 Installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 1 Installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 1 Installer 2)

-

Installer 1 name

-

Is installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (installer 1)

-

Installer 2 name

-

Is installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (installer 2)

-

Installer 3 name

-

Is installer 3 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (installer 3)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (installer 3)

Team 2 Information

-

Team 2 Lead installer name

-

Is the Team 2 Lead installer wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Team 2 Lead installer: Items of PPE not being worn

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Team 2 Lead installer: Reason for not wearing PPE?

-

Comment

MTC card

-

Does the Team 2 lead installer have their MTC card?

-

Please select a reason why

- The card is lost

- Forgot to bring it

- They are currently undergoing the programme

- Have not enrolled onto programme yet

- Other

-

Please provide a reason why

Team 2 Installer(s)

-

Please indicate the number of ADDITIONAL installers working on site besides the lead installer within team 2

-

Team 2 Installer 1 name

-

Is team 2 installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 1)

-

Team 2 Installer 1 name

-

Is team 2 installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 1)

-

Team 2 Installer 2 name

-

Is team 2 installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 2)

-

Team 2 Installer 1 name

-

Is Team 2 installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 1)

-

Team 2 Installer 2 name

-

Is team 2 installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 2 installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 2 installer 2)

-

Team 2 Installer 3 name

-

Is Team 2 installer 3 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 2 Installer 3)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 2 Installer 3)

Team 3 Information

-

Team 3 Lead installer name

-

Is the Team 3 Lead installer wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Team 3 Lead installer: Items of PPE not being worn

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Team 3 Lead installer: Reason for not wearing PPE?

-

Comment

MTC card

-

Does the Team 3 lead installer have their MTC card?

-

Please select a reason why

- The card is lost

- Forgot to bring it

- They are currently undergoing the programme

- Have not enrolled onto programme yet

- Other

-

Please provide a reason why

Team 3 Installer(s)

-

Please indicate the number of ADDITIONAL installers working on site besides the lead installer within team 3

-

Team 3 Installer 1 name

-

Is team 3 installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 3 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 3 installer 1)

-

Team 3 Installer 1 name

-

Is team 3 installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 3 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 3 installer 1)

-

Team 3 Installer 2 name

-

Is team 3 installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 3 installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 3 installer 2)

-

Team 3 Installer 1 name

-

Is Team 3 installer 1 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 3 installer 1)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 3 installer 1)

-

Team 3 Installer 2 name

-

Is team 3 installer 2 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (team 3 installer 2)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (team 3 installer 2)

-

Team 3 Installer 3 name

-

Is Team 3 installer 3 wearing suitable PPE appropriate to the task being undertaken?

-

STOP WORK IMMEDIATELY: Speak with personnel not wearing the necessary PPE to identify reasons for not complying with the PPE requirements and advise that work must not commence until the correct PPE is worn.

-

Items of PPE not being worn (Team 3 Installer 3)

- Hi-visibility clothing

- Head Protection

- Gloves

- Wrist Protection

- Eye Protection

- Hearing Protection

- Safety Footwear

- Safety Harness

- RPE

-

Reason for not wearing PPE? (Team 3 Installer 3)

Site housekeeping

-

Is the site a construction site, new build or under re-furbishment?

-

Are dust sheets in use?

-

Are the floors protected?

-

Are the furnishings protected?

-

Are the stair or walkway runners in use?

-

Are all walkways clear internally?

-

Are all walkways clear externally?

Survey Issues

-

Is the work at height solution adequate for the works?

-

Comment

-

Have any of the frames been mis-measured at survey?

-

Please select the action completed

-

Please select how this issue is/was being resolved

- Resolved on site

- Contacted depot who are dealing with it

- Remake ordered

- Survey hazards missed to add

- Cables on frame

- Pipes attached to frame

- Water

- Access issues

- Distance to site

- Size of frame

- Parking

- Boundaries

-

Have any significant hazards not been identified at survey?

-

Please select all hazards that apply

- Cables on frame

- Pipes attached to frame

- Water

- Access issues

- Distance to site

- Size of frame

- Parking

- Boundaries

-

Comment

-

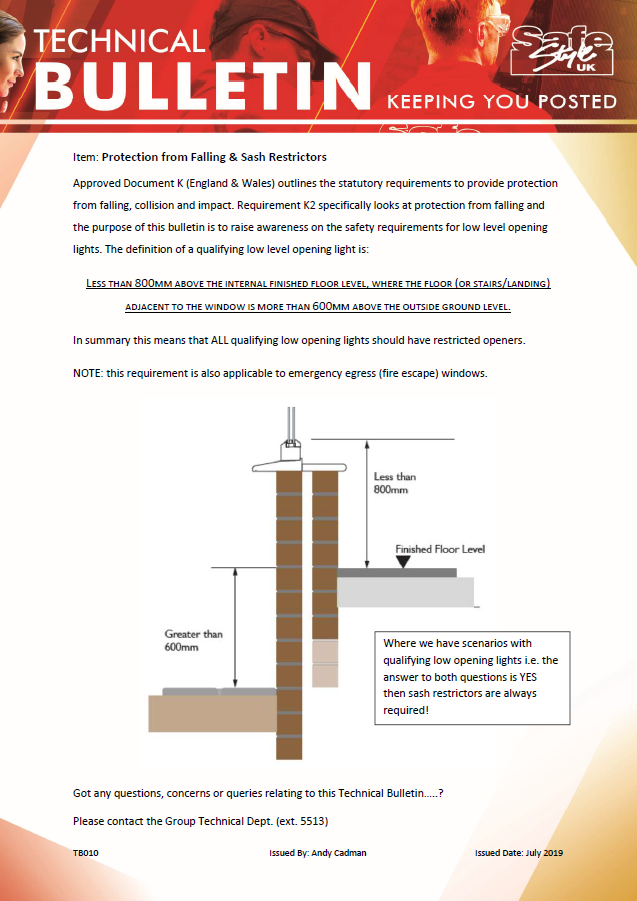

Has the requirement for sash restrictors been identified by the surveyor?

-

Have these been installed as per the survey requirements at the time of inspection?

-

ACTION REQUIRED: Services department to be informed of the need to arrange an appointment to install the required sash restrictors and branch management to be informed of non-conformance.

-

Review the attached guidance to determine whether sash restrictors are required for the works

-

Based on the guidance provided, are additional sash restrictors required for the works?

-

Provide details of locations requiring restrictors

-

ACTION REQUIRED: Services department to be informed of the need to arrange an appointment to install the required sash restrictors and survey management to be informed of non-conformance.

Quality of Installation

-

Have frames been installed?

-

Have they been fitted from the inside?

-

Is the window board height from the floor covering 950mm or more?

-

Frames sealed between the cill and the outer frame?

-

Frames fixed correctly?

-

Frames glazed correctly?

-

Frames foamed around the perimeter?

-

If no, please provide more details

- Too tight

- Sash bay

- Porch

- Fascia

- Conservatory

-

Please provide more details

-

Have the frames been finished off?

-

Have the frames been taped?

-

Is the quality of the external finish of good quality?

-

If 'other', please select from the following options

-

Please select which aspect of the external finish was of poor quality

- Render

- Mortar

- Spa

- Dash

- Other (please comment)

-

Please provide further details

-

Is the quality of the internal finish of good quality?

-

Please select which aspect of the internal finish was of poor quality

- Silicone overload

- Untidy sealant

- Untidy trims

- Untidy linings

- Poor plaster finish

-

Quality of frames acceptable?

-

Please select the quality issue

- Frames

- Frame bedded on silicone

- Door slab

- External cill

- Internal cill

- Timber window board

- Stone cill

- Existing cill

- Face drain

- Not fitted

-

Please provide further details

-

Additional materials required / ordered?

-

Please state what further materials are required

-

Is there a bay being installed at this current time?

-

Please select the type being installed

- Bow bay

- Wedges

- Stone pillar

- Box sash

- Full roof construction

- Other (please comment)

- Square bay

- Splayed bay

-

undefined

-

Is the bay pole assembly (jacks, shims sealed) acceptable?

Quality of products

-

Are the following products in good quality?

-

Foil

-

Please provide details

-

Slab

-

Please provide details

-

Welds

-

Please provide details

-

Routing out

-

Please provide details

-

Glass

-

Please provide details

-

Lock mech

-

Please provide details

-

Frame out of square

-

Please provide details

Asbestos

-

Have any asbestos issues been discovered during the installation?

-

How was this discovered?

- Asbestos missed on survey

- Asbestos hidden behind existing frames

- Asbestos hidden in cavity

- Suspect material

-

Resolution

- Reported to DM

- Action created

- Clean up team to attend site

- Clean up team attended site

- Sampling testing arranged

- Awaiting test results

Completion Declaration

-

Does the installer(s) have any issues or concerns they would like to bring to the attention of the SHEQ team?

-

Please state their concerns or comments

-

Inspector comments

-

Inspector signature

-

Lead installer signature