Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

-

Hoist Machine Operator (First and Last Name)

-

License Number:

-

Wind Speed ( MPH ):

-

All inspections are to be performed by a competent individual with relevant experience designated by the concrete contractor, except where otherwise noted.

1.0 Weather Conditions

-

Does the Hoist Machine Operator have a wind monitoring system and has the ability and is able to constantly monitor the wind?

-

What Tell-tale device is being used to monitor the wind speed?

- Anemometer

- Weather Station with Mobile Application

- Other

-

What type of Tell-tale device is being used to monitor the wind?

-

Weather Condition for the day:

- Sunny & Clear

- Partly Sunny

- Sunny With Showers

- Cloudy

- Cloudy with Rain

- Cloudy with Heavy Rain

- Thunderstorms

- Overcast sky

- Snowy Conditions

-

Were any operations halted due to weather or wind?

-

Did you notify the Supervisor of the Jobsite?

2.0 Configuration & Controls for Operations

-

Is the Hoist Machine Operator located and configured in accordance with plans?

-

Are Pedestrian and Traffic controls in place Pre, During, and Post operations?

-

Is everyone involved in the Hoist Machine operations qualified?

-

Has the Hoist Machine been inspected prior to lifting operations?

-

As required by Section 3319-01(k)(2) has the operator completed a<br>written record prior to leaving the site?

3.0 Operations

-

Are loads being carried over an occupied building?

-

If yes, are the top two floors vacated, and proper roof protection is in place as required by Section 3319-01(q)(3)(v)?

-

Are there operations near overhead power lines?

-

Are you within compliance with section 3319-01(s)(3)

-

Are you hoisting personnel with Hoist Machine?

-

Are you within compliance with section 3319-01(q)(6)

-

Are all inspections of the Hoist Machine rigging equipment<br>performed prior to start of shift?

-

Is there proper, constant communication between operator, rigging<br>supervisor, and signal persons?

4.0 Pre-Shift Safety Meeting

-

Prior to the start of every shift, the lift director must hold a pre-shift meeting for the following personnel: Hoisting machine operator, rigging supervisor, crane operator, signal persons, and the supervisor of the flag persons and pedestrian traffic managers. Take a photo of the sign in sheet after completion.

-

Did you hold a pre-shift safety meeting with all required parties as stated above in the instructions and covered the following topics:The following topics must be discussed at every meeting:<br>• The day’s planned operations<br>• Pedestrian and traffic controls<br>• Current weather conditions and forecasts<br>• As applicable, signaling/communication protocols for tandem picks<br>• Multiple crane or derrick operations, and operating in the blind<br>• Roles of personnel<br>• Objects to be lifted/lowered, including a review of their weights, lifting points, and any special considerations<br>• Rigging equipment to be used<br>• Site conditions<br>• Pick and landing zones<br>• Fall, crush, electrical, struck by and other hazards<br>• service and out of service wind thresholds for the crane or derrick<br>• Permit validity<br>• Snagged- Wire Ropes, Tag Lines, Rope, Nylon Straps, Chains, Cables

-

Notes:

-

Upload Photo of Rigging Log Checklist

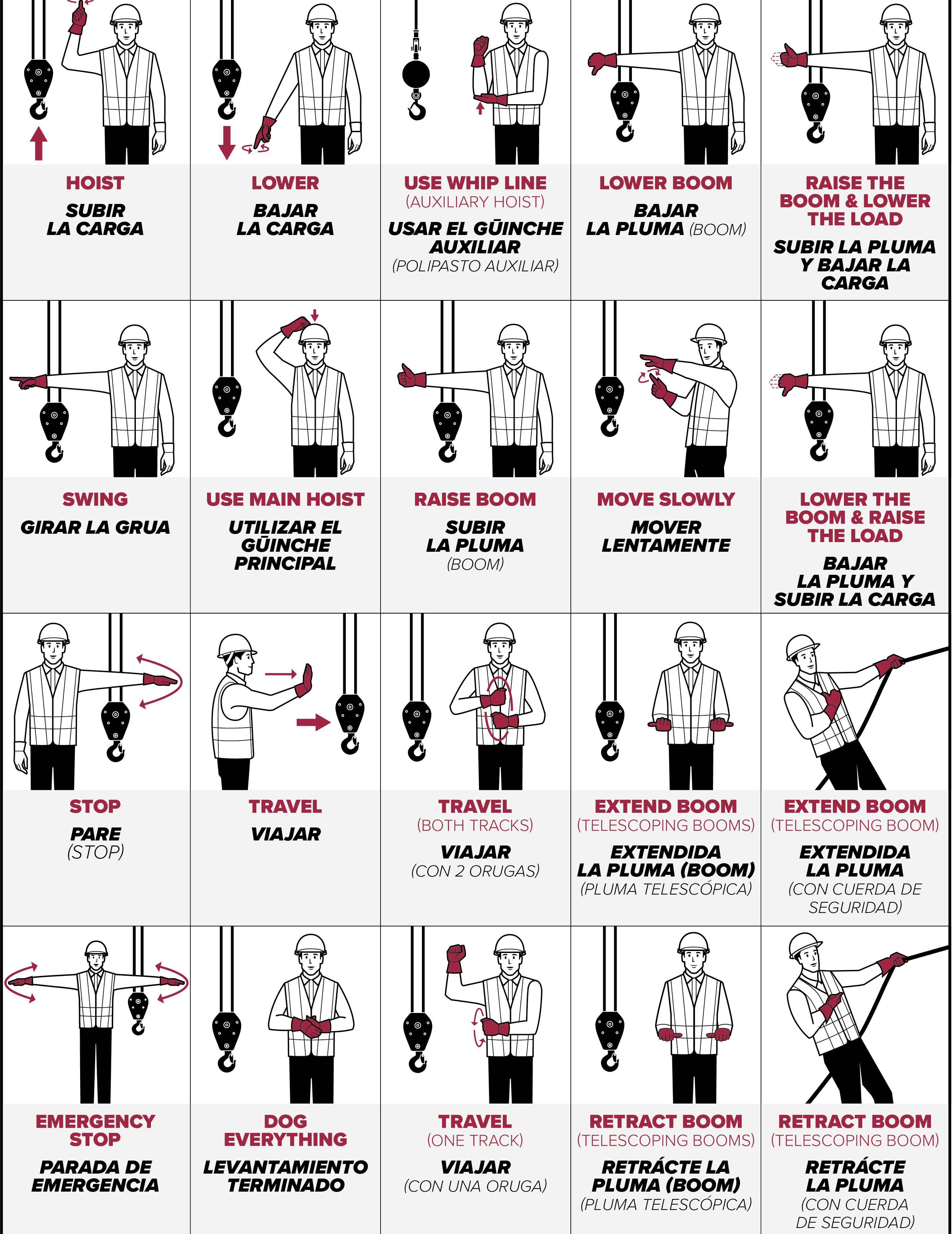

Safety Review of Hand Signals and Lifting Chart

-

Please review the Crane Hand Signals with your crew prior to lifting operations.

-

Please review the load ratings with your crew prior to lifting operations. Scan the QR code below to view hand signals.