Title Page

-

Conducted on

-

Prepared by

Linde Combi Fleet Familiarisation 2018

-

Employee Familiarised

-

Department

- Distribution Centre

- Extrusion

- Small Stores

- Link

- Mixing Plant

- Mould Shop

- SHEQ

- Engineering

- Transport

-

There is now a black pressure pad on the floor of the Combi FLT cab that requires the operator to be standing on it to operate the hydraulic controls and to allow the Combi FLT to travel.

-

Check box when a demonstration has been given and an understanding has been achieved by the MHE operator

-

The fork arm extension sensor will not allow the Combi FLT to travel if forks and carriage are extended or not fully retracted, the propose of this sensor is to eliminate the risk of operator error that may cause damage or injury

-

Check box when a demonstration has been given and an understanding has been achieved by the MHE operator

-

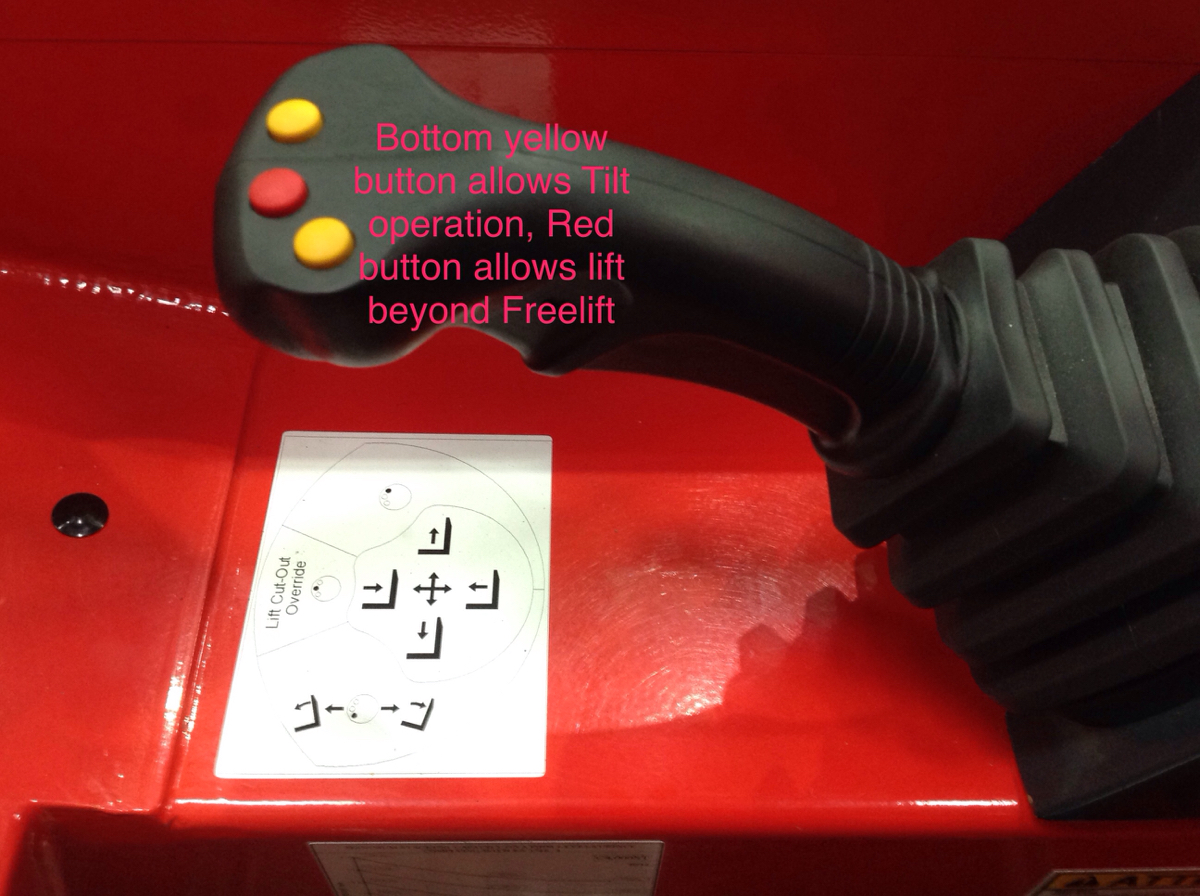

Hydraulic Control Joystick design change - Tilt function is allowed when the left YELLOW button is held down and the Joystick is moved left and right. There is now also a RED Lift override button that should be held down to allow the forks and carriage to raise beyond free-lift, when the auxiliary booms come into operation

-

Check box when a demonstration has been given and an understanding has been achieved by the MHE operator

-

LPG cylinder has been removed from the top of the Combi FLT and has been rehoused in a lock away compartment below the engine. The door can be opened for refuelling and also the cylinder in fixed onto runners so that it can be easily pulled out of the compartment for cylinder change or refuelling purposes and then stowed away with ease. This design change greatly improves operator visibility and therefore safety.

-

Check box when a demonstration has been given and an understanding has been achieved by the MHE operator

-

Exhaust system has been redesigned to allow greater visibility to the operator and reduce damage to the exhaust system itself.

-

Check box when a demonstration has been given and an understanding has been achieved by the MHE operator

-

Floor pedals are now more central to the footplate in the Combi FLT cab; this allows good Contact with the Pressure Pad and encourages good posture thus reducing chance of strains and injuries.

-

Check box when a demonstration has been given and an understanding has been achieved by the MHE operator

-

Stillage Guards have been positioned rising virtually from both sides of the Combi FLT bed to reduces the chance of damage to the hydraulic system and Combi cad glass windows.

-

Check box when a demonstration has been given and an understanding has been achieved by the MHE operator

-

Power Isolation Switch is now located adjacent to the steps into the Combi FLT cab, this gives the operator quicker access in an emergency situation.

-

Check box when a demonstration has been given and an understanding has been achieved by the MHE operator

-

The new Fleet of Combi FLT's are dimensionally similar to the previous Fleet - They can travel down narrow aisles and through all cargo doors within DC1 and DC2.

- All operators should exercise extra caution when using new MHE.

- Operators should keep good observations at all times before, during and after all manoeuvres.

- Operators should ALWAYS look in the direction of travel.

- Operators should NEVER attempt to lift or move an unsafe or unstable load.

- Operators should always make their intentions known when loading/unloading vehicles and insist that the driver stays in the cab, engine off, park brake on, keys removed and where possible driver sitting in the passenger seat.

- Hydraulic controls and functions should never be operated when the Combi FLT in motion. The park brake should be applied prior to all Lift operations. -

Check box when a demonstration has been given and an understanding has been achieved by the MHE operator

-

Trainee Name

-

Training facilitator