Title Page

-

Site conducted

-

Date of Despatch

-

Load Number

-

Number of Pallets

-

Checked By

-

Location

-

All items marked 'No' must be corrected pre-despatch

Pallet Checks

-

-

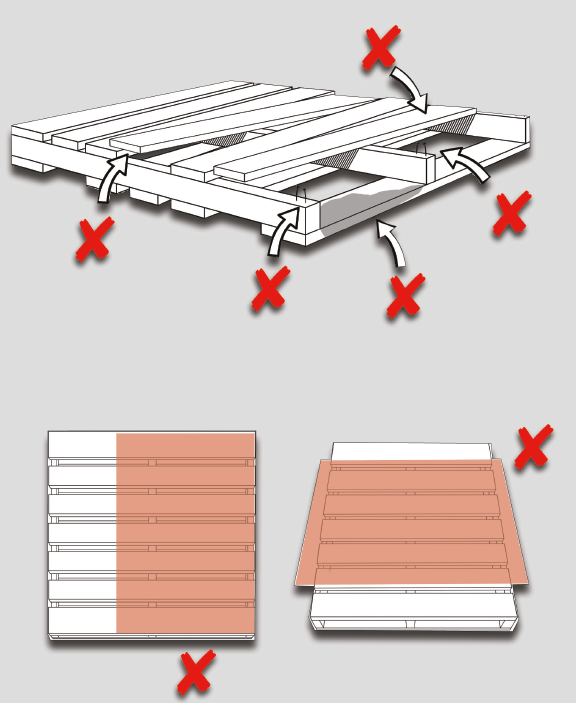

All boards and bearers are within tolerances of pallet quality specifications

-

Lead boards are square with bearer, or at no greater than 15mnn pushback?

-

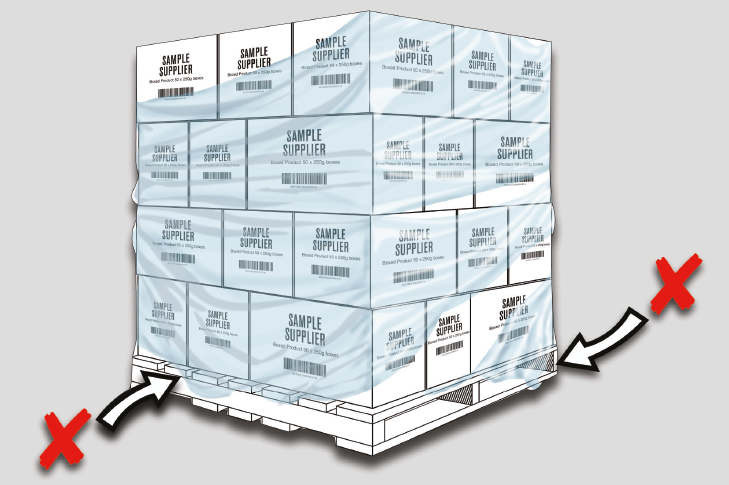

All stock is centred on the pallets and no product or slipsheets overhang the pallet edge

-

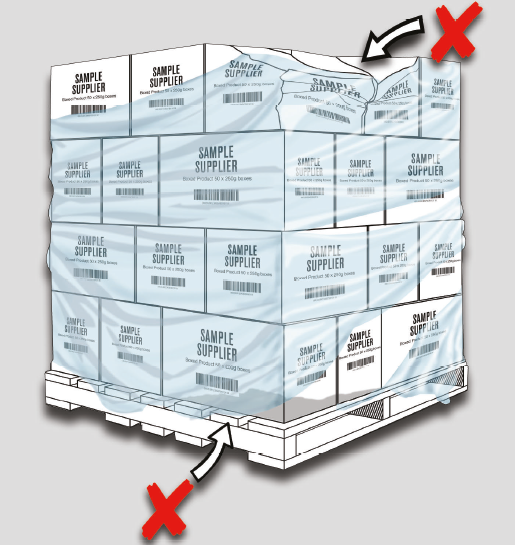

All pallets are wrapped securely with sufficient passes to maintain load stability in transit

-

Stretch wrap is securely bound to the top 30-50% of the wooden pallet

-

Stretch wrap is applied neatly, with no"tails"or"dags" at risk of becoming loose

-

No loose sheets of paper have been placed between wrap and product

Carton Checks

-

-

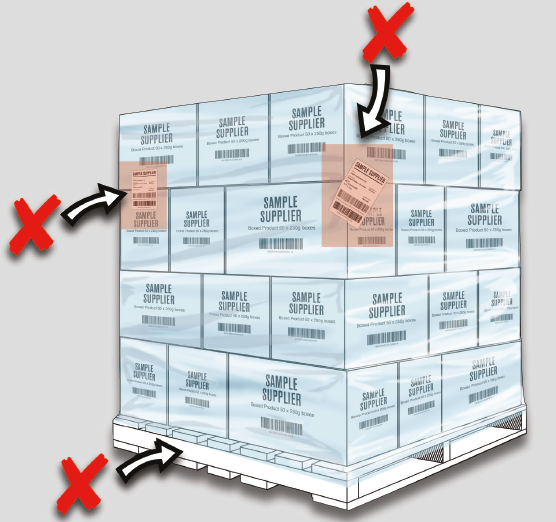

GTIN barcodes are visible on fork-entry sides of the pallet (for at least some cartons)

-

No cartons are damaged, crushed, leaking, moisture-affected or spilling product

SSCC Label Checks

-

-

-

SSCC labels are in place on both of the pallet's fork-entry sides

-

SSCC labels are on the right hand side of the pallet face, at 400-800mm from ground level Both

-

SSCC labels - on the front and back fork-entry sides of each pallet - are identical Both

-

SSCC labels on each pallet match the actual product contained within that pallet Both

-

SSCC labels are clearly visible, are not wrinkled, damaged, dirty or poorly printed

Sign Off

-

Checked By Team Leader (Name, Signature & Sign Date)

-

Other Issues Identified