Title Page

2.0 Vehicle information

-

VIN NUMBER:

-

BODY NUMBER :

-

FLEET NUMBER:

-

KILOMETRES:

-

INSPECTION LOCATION:

- Volgren

- Rochedale

-

INSPECTED By:

-

FIRST INSPECTION DATE:

-

FINAL ACCEPTANCE DATE:

-

REGO:

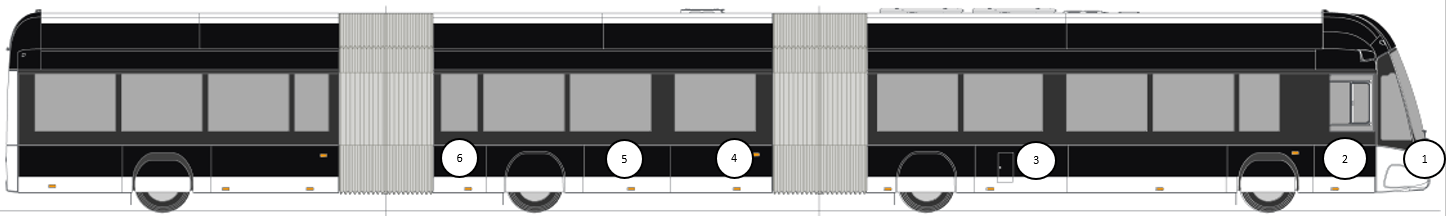

External Inspections

3.1 Paint Work

-

Check colour scheme is as per Council's requirements.

-

Check workmanship, paint free from scratches or damage

3.2 Glazing

-

Check all glass is free from scratches or defects.

-

Check all Sikaflex joints to ensure neat and uniformity appearance.

-

Check all EMG exit decals are located on the correct window ( refer doc : $%#$%#$%).

3.3 Panelling

-

Check all side panels are scratch, dent and defect free .

-

Check alignment of panels against other surfaces.

-

Check opening and closing of each hatch/service compartment for correct latching and operation.

Metro OS Compartments

3.4 (1) Front service hatch

-

Check routing of all harness’ in and out of the compartment for security and contact points.

-

Check routing of all hoses in and out of the compartment for security and contact points.

-

Check general tidiness and condition of the compartment.

-

Washer bottle full / decal fitted

-

Wiper linkages secure and correctly installed

-

Tow pin fitted

-

Air charge point installed

3.5 OS (2) power steering compartment

-

Check routing of all harness’ in and out of the compartment for security and contact points.

-

Check routing of all hoses in and out of the compartment for security and contact points.

-

Check security and attachment of any insulation or fire protection material.

-

Check general tidiness and condition of the compartment.

-

Check fluid level is correct within sight glass.

-

Check routing and attachment of any fire suppression lines.

3.6 OS (3) Slow charge compartment

-

Check routing of all harness’ within the compartments are properly sealed, secured and protected against rubbing.

-

Check security and attachment of any insulation or fire protection material if fitted.

-

Check general tidiness and condition of the compartment.

-

Check reflective tape fitted to back of access door.

3.7 OS (4) Fire suppression compartment

-

Check routing of all harness’ within the compartments are properly sealed, secured and protected against rubbing

-

Check security and attachment of any insulation or fire protection material if fitted.

-

Check general tidiness and condition of the compartment.

-

Check routing and security of fire detection or suppression lines.

-

Check and confirm bottle gauge indicators green.

-

Check and record date of compliance tag.

3.8 OS (3 & 5) Traction motor compartments

-

Check routing of all harness’ within the compartments are properly sealed, secured and protected against rubbing.

-

Check security and attachment of any insulation or fire protection material if fitted.

-

Check general tidiness and condition of the compartment.

-

Check routing and security of fire detection or suppression lines.

3.9 OS (6) 24V battery compartment

-

Check 24V batteries are secure in cradle

-

Check quick release catches on cradle working correctly.

-

Check cradle safety catch is fitted and working.<br>(if the catch is down the compartment door should not close and vehicle shouldn’t be able to move).<br>

-

Check general tidiness and condition of the compartment.

-

Check routing of all harness’ within the compartments are properly sealed, secured and protected against rubbing.

-

Check battery isolation switch works

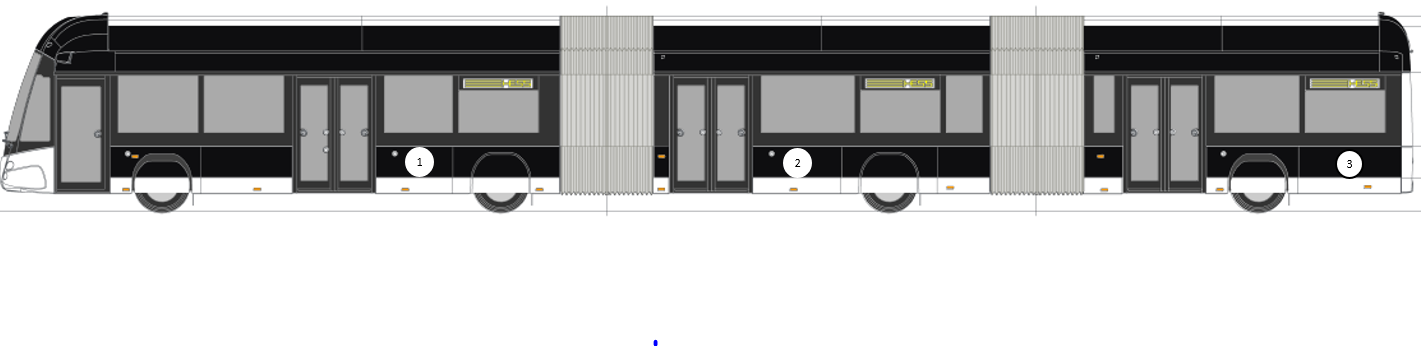

Metro NS Compartments

-

Metro OS Compartments

3.10 NS (1) air compressor compartment

-

•Check routing of all harness’ in and out of the compartment for security and contact points.

-

•Check routing of all hoses in and out of the compartment for security and contact points.

-

•Check security and attachment of any insulation or fire protection material.

-

•Check fluid level is correct within sight glass.

-

•Check routing and attachment of any fire suppression lines.

-

Record current operating hours

3.11 NS (2) heater compartment

-

•Check routing of all harness’ in and out of the compartment for security and contact points.

-

•Check routing of all hoses in and out of the compartment for security and contact points.

-

•Check security and attachment of any insulation or fire protection material.

-

•Check fluid level is correct within sight glass.

-

•Check routing and attachment of any fire suppression lines.

3.12 NS (3) fire extinguisher compartment

-

Check general tidiness and condition of the compartment.

-

Check fire extinguisher is fitted, and compliance plate date is correct.

-

Check and record compliance date

4.0 Tyres

4.0 Check tyre pressures

-

Ensure the tyres are within tolerances using the on board monitoring system

4.0 Check wheel stud tension set at 600 Nm

-

Front axle NS

-

Front axle OS

-

1st drive axle NS

-

1st drive axle OS

-

2nd drive axle NS

-

2nd drive axle OS

-

Rear steer axle NS

-

Rear steer axle OS

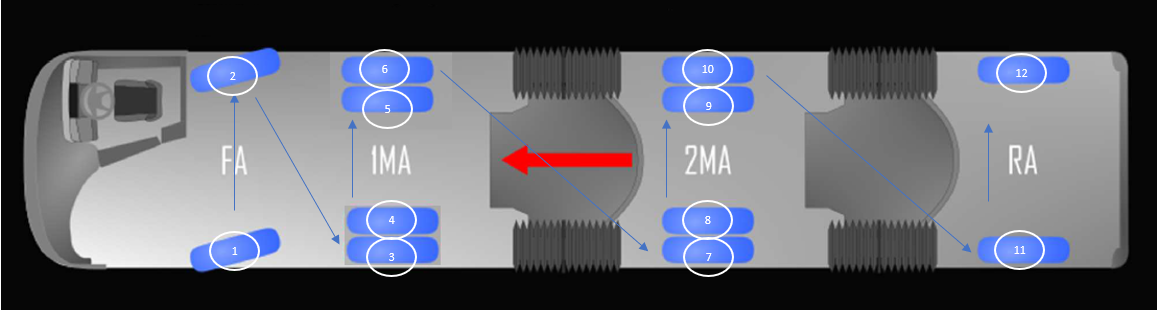

5.1 Underfloor inspection (front carriage)

-

Check routing of all harness and piping are properly sealed, secured and protected against rubbing

-

Check underfloor deadening for any unprotected or exposed areas.

-

Record front steer axle type plate data

-

Check condition of all steering linkages, joints, and threaded connections. Ensure steering components fasteners (steering gear/ angle drive) are fitted securely and are free from damage.

-

Check front axle air bags for leaks and signs of damage

-

Check front axle exhaust ports on any valves are free from paint / masking tape or under body sealer

-

Check front axle suspension levelling sensor is, free from obstructions, damage and that the cable is routed properly.

-

Record front drive axle plate data.

-

Check both axles and axle connections points are secure.

-

Check exhaust ports on any valves are free from paint / masking tape or under body sealer.

5.2 Underfloor inspection (second carriage)

-

Check routing of all harness’ and piping are properly sealed, secured and protected against rubbing

-

Check underfloor deadening for any unprotected or exposed areas.

-

Record 2nd drive axle type plate

-

Check the rear axle and axle connection points are secure

-

Check 2nd drive axle air bags for leaks and signs of damage.

-

Check exhaust ports on any valves are free from paint / masking tape or under body sealer

-

Check condition and mounting of the bellows.

5.3 Underfloor inspection (third carriage)

-

Check routing of all harness’ and piping are properly sealed, secured and protected against rubbing

-

Check underfloor deadening for any unprotected or exposed areas

-

Record rear steer axle type plate.

-

Check the rear steer axle connection points are secure.

-

Check the rear steer axle air bags for leaks and signs of damage.

-

Check any exhaust ports on any valves are free from paint / masking tape or under body sealer

6.1 Roof inspection (front carriage)

-

Check paint work on all surfaces and ensure its free from scratches and damage

-

Check all aerials are secured and free from damage

-

Check routing of all harness’ and piping are properly sealed, secured and protected against rubbing

-

Check that all access panels / hatches are secure and damage free.

-

Check condition and mounting of the bellows.

6.2 Roof inspection (second carriage)

-

Check paint work on all surfaces and ensure Its free from scratches and damage.

-

Check routing of all harness’ and piping are properly sealed, secured and protected against rubbing

-

Check that all access panels / hatches are secure and damage free.

-

Check routing of all harness’ and piping to ETS (operation of ETS is done during road testing.

-

Check condition and mounting of the bellows.

6.3 Roof inspection (third carriage)

-

Check paint work on all surfaces and ensure its free from scratches and damage.

-

Check routing of all harness’ and piping are properly sealed, secured and protected against rubbing.

-

Check that all access panels / hatches are secure and damage free.

7.0 External decal inspection

-

Check that all external decals are fitted in accordance with decal document ########

8.0 Internal inspection / Driver's compartment

8.1 Driver's locker

-

Check general tidiness and condition of the compartment.

8.2 Fire extinguisher compartment

-

Check general tidiness and condition of the compartment.

-

Fire Extinguisher is attached securely

-

Record extinguisher date

8.3 AC / Heater box compartment

-

Check general tidiness and condition of the compartment.

-

Check routing of all harness’ in and out of the compartment for security and pinch points.

-

Check routing of all harness’ and piping are properly sealed, secured and protected against rubbing

8.4 Dash binnacle

-

Check general tidiness and condition of the dash.

-

Check routing of all harness’ in and around dash area for security and pinch points.

-

Check button and switch configuration in accordance with specification.

-

Check installation of ticketing DCU

8.5 Driver's RH side console

-

Check general tidiness and condition of the dash.

-

Check button and switch configuration in accordance with specification.

8.6 Overhead CCTV compartment

-

Check general tidiness and condition of the compartment.

-

Check routing of all harness’ in and out of the compartment for security and pinch points.

-

Check attachment and security of equipment within the compartment

8.7 Rear of main electrical compartment

-

Check routing of all harness’ in and out of the compartment for security and pinch points.

-

Check general tidiness and condition of the compartment.

-

Check component identification decals are fitted

-

Check all circuit breaker and relays are fitted correctly and free from damage

8.8 Driver's seat

-

General condition of the seat cushions.

-

Check seat attachment to floor.

-

Check for full range of movement

-

Check all controls for functionality

-

Check seat belt for smooth easy operation

-

Is the seat belt red?

8.9 Driver's compartment door

-

Check general condition of the door and attaching surfaces

-

Check opening and closing mechanism from both sides

8.10 Manual wheelchair ramp

-

Manual wheelchair ramp fitted, and security attached

8.11 Flooring

-

General inspection of workmanship and compliance to build of the flooring within the driver’s compartment area.

8.12 Driver's compartment decals

-

Check and ensure decals are in accordance with DOC @#$%@#$

8.13 CCTV monitor and system

-

Check operation of CCTV operation via drivers monitor. (more detail required, once configuration has been finalised)

8.14 Driver's INDRA monitor

-

Check operation of Driver’s INDRA monitor (to be re- named and content added)

9.0 Internal Inspection ( Carriage 1)

9.1 Main electrical switchboard (carriage 1)

-

Check routing of all harness’ in and out of the compartment for security and pinch points.

-

Check general tidiness and condition of the compartment.

-

Check component identification decals are fitted

-

Check all circuit breaker and relays are fitted properly and free from damage.

9.2 Seating (carriage 1)

-

Check general condition of seat framing and cushion material

-

Check seat anchor points for correct attachment.

-

Check and ensure no sharp edges or finger traps.

9.3 Flooring (carriage 1)

-

Check floor installation for quality, defects, and compliance

-

Check any step treads for attachment and defects.

9.4 Stanchion (carriage 1)

-

Check all stanchion installations for quality, defects, and compliance.

-

Check anchor points for correct attachment.

-

Check and ensure no sharp edges or finger traps.

-

Check attachment of any bell press to stanchions.

-

Check installation of any modesty panels or parcel rakes.

-

Check installation of the (OBV) ticket readers

9.5 Passenger door 1 (carriage 1)

-

Check door installation for quality, defects, and compliance <br>(Operational checks occur in section #####)

9.6 Side walls (carriage 1)

-

Check side wall installation for quality and any defects

-

Check attachment of bell press and grab handles.

-

Check window capping for quality and any defects.

9.7 Air conditioning ducts (carriage 1)

-

Check the panel installation for quality and any defects.

-

Open each panel to check the routing of all harness’ for quality, security, and pinch points

-

Check installation of light defuses.

9.8 Decals (carriage 1)

-

Check installation of decals and signage for quality and compliance against Doc ####

9.9 Articulation joint (carriage 1)

-

Check bellows installation for quality and defects

-

Check installation of floor plates for quality and defects.

10.0 Internal Inspection ( Carriage 2)

10.1 Seating (carriage 2)

-

Check general condition of seat framing and cushion material

-

Check seat anchor points for correct attachment.

-

Check and ensure no sharp edges or finger traps.

10.2 Flooring (carriage 2)

-

Check floor installation for quality, defects, and compliance

-

Check any step treads for attachment and defects.

10.3 Stanchion (carriage 2)

-

Check all stanchion installations for quality, defects, and compliance.

-

Check anchor points for correct attachment.

-

Check and ensure no sharp edges or finger traps.

-

Check attachment of any bell press to stanchions.

-

Check installation of any modesty panels or parcel rakes.

-

Check installation of the (OBV) ticket readers.

10.4 Passenger door 2 (carriage 2)

-

Check door installation for quality, defects, and compliance <br>(Operational checks occur in section 13)

10.5 Side walls (carriage 2)

-

Check side wall installation for quality and any defects

-

Check attachment of bell press and grab handles.

-

Check window capping for quality and any defects.

10.6 Air conditioning ducts (carriage 2)

-

Check the panel installation for quality and any defects.

-

Open each panel to check the routing of all harness’ for quality, security, and pinch points

-

Check installation of light defuses.

10.7 Decals (carriage 2)

-

Check installation of decals and signage for quality and compliance against Doc ####

10.8 Articulation joint (carriage 2)

-

Check bellows installation for quality and defects

-

Check installation of floor plates for quality and defects.

11.0 Internal Inspection ( Carriage 3)

11.1 Seating (carriage 3)

-

Check general condition of seat framing and cushion material

-

Check seat anchor points for correct attachment.

-

Check and ensure no sharp edges or finger traps.

11.2 Flooring (carriage 3)

-

Check floor installation for quality, defects, and compliance

-

Check any step treads for attachment and defects.

11.3 Stanchion (carriage 3)

-

Check all stanchion installations for quality, defects, and compliance.

-

Check anchor points for correct attachment.

-

Check and ensure no sharp edges or finger traps.

-

Check attachment of any bell press to stanchions.

-

Check installation of any modesty panels or parcel rakes.

-

Check installation of the (OBV) ticket readers.

11.4 Passenger door 3 (carriage 3)

-

Check door installation for quality, defects, and compliance <br>(Operational checks occur in section #####)

11.5 Side walls (carriage 3)

-

Check side wall installation for quality and any defects

-

Check attachment of bell press and grab handles.

-

Check window capping for quality and any defects.

11.6 Air conditioning ducts (carriage 3)

-

Check the panel installation for quality and any defects.

-

Open each panel to check the routing of all harness’ for quality, security, and pinch points

-

Check installation of light defuses.

11.7 Decals (carriage 3)

-

Check installation of decals and signage for quality and compliance against Doc ####

12.0 24V system washers

12.1 Windscreen washers

-

Check operation and coverage of the windscreen washers.

12.2 Windscreen wipers

-

Check operation and coverage of wipers on intermittent, slow, and fast speeds

12.3 Driver's blinds

-

Check operation of drivers front electrical blind (switch 11)

-

Check driver’s manual side blind for defects and smooth operation.

12.4 Driver's partition door

-

Check operation of dimmable partition door (switch 12)

12.5 Driver's compartment light

-

Check operation of driver’s compartment light. (switch 10)

12.6 Mirror heating

-

Check operation of mirror heaters (switch 13)

-

Check for tele-tale on instrument cluster

12.7 Windscreen heating

-

Check operation of windscreen heaters (switch 14)

-

Check for tele-tale on instrument cluster

12.8 Exterior doorstep lighting.

-

Check operation of passenger compartment lighting

12.9 Passenger compartment lighting

-

Check operation of passenger compartment lighting

12.10 Horn

-

Check operation of horn

12.11 Lamp Check

-

Check operation of all external lights

-

Which lights is not working

12.12 Rear vision cameras

-

Check installation of monitor arms and supporting structure

-

Check monitor operation

12.13 Emergency hammers

-

Individually remove each emergency hammer at a time checking for an MP3 message

-

Check that tele-tale appears on the instrument cluster

12.14 2-way radio

-

Check installation of 2-way radio

-

Check communication possible with NCC

12.15.1 Duress alarm

-

Advise NCC before conducting any duress or attack alarm tests

-

Check that once the duress buttons ( ####) are activated there is connection to NCC via 2-way radio

12.15.2 Attack alarm

-

Check that once the attack buttons (###) are activated there is connection to NCC via 2-way radio. The horn, headlights and destination signs are reading “Call police“

12.16 Emergency Evacuation system

-

Detailed to be added at later date

13.0 Doors

13.1 Driver's door / operational test

-

Check opening and closing of the door

-

Check tele-tale on instrument cluster

13.2 Driver's door / safety test 1

-

Whilst closing door place a dowel (35mm diameter) within the safety beam.<br>Door reopens.

-

Check tele-tale on instrument cluster detects fault. 17.

-

Door resets after pressing button 17.

13.3 Driver's door / safety test 2

-

Press door button 17 to close driver’s door. Use force (Force meter) to prevent door closing, once 200N m is reached door should reopen

-

Check tele-tale on instrument cluster detects fault.

-

Door resets after pressing button 17.

14.1 First passenger door / operational test

-

Check opening and closing of the door

-

Check tele-tale on instrument cluster

14.2 First passenger door / safety test 1

-

Whilst closing door place a dowel (35mm diameter) within the safety beam.<br>Door reopens.

-

Check tele-tale on instrument cluster detects fault.

-

Door resets after pressing button 18

14.3 First passenger door / safety test 2

-

Press door button 18 to close driver’s door. Use force (Force meter) to prevent door closing, once 200N m is reached door should reopen

-

Check tele-tale on instrument cluster detects fault.

-

Door resets after pressing button 18.

- Pass

- Major fault

- Minor fault

- Observation

15.1 Second passenger door / operational test

-

Check opening and closing of the door

-

Check tele-tale on instrument cluster

15.2 First passenger door / safety test 1

-

Whilst closing door place a dowel (35mm diameter) within the safety beam.<br>Door reopens.

-

Check tele-tale on instrument cluster detects fault.

-

Door resets after pressing button 19

15.3 First passenger door / safety test 2

-

Press door button 19 to close driver’s door. Use force (Force meter) to prevent door closing, once 200N m is reached door should reopen

-

Check tele-tale on instrument cluster detects fault.

-

Door resets after pressing button 19.

- Pass

- Major fault

- Minor fault

- Observation

16.1 Third passenger door / operational test

-

Check opening and closing of the door

-

Check tele-tale on instrument cluster

16.2 Third passenger door / safety test 1

-

Whilst closing door place a dowel (35mm diameter) within the safety beam.<br>Door reopens.

-

Check tele-tale on instrument cluster detects fault.

-

Door resets after pressing button 20

16.3 Third passenger door / safety test 2

-

Press door button 20 to close driver’s door. Use force (Force meter) to prevent door closing, once 200N m is reached door should reopen

-

Check tele-tale on instrument cluster detects fault.

-

Door resets after pressing button 20.

- Pass

- Major fault

- Minor fault

- Observation

17.0 All door operation / single button

-

Check all doors opening and closing using button 21.

-

Check tele-tale on instrument cluster.

18.0 Wheelchair ramp

18.1 Wheelchair ramp deployment

-

Ensure that something is in place to support the ramp once fully extended

-

Check first passenger doors partially close on ramp request

-

Check MP3 message is heard

-

Check first passenger doors fully open once ramp is deployed

-

Check tele-tale on the dash in present

18.2 Wheelchair ramp retraction

-

Check first passenger doors partially close on ramp request

-

Check MP3 message is heard

-

Check ramp fully retracts and the first passenger doors completely close.

-

Check tele-tale of dash is extinguished

19.0 Road Test

19.0 Road test

-

Before commencing any road test activities verify the vehicle is ready. Ensure all hatches / panels / access doors are closed locked and secured. Any lock out / tag out procedures have been completed.

19.1 Pre-departure checks

-

With the HV slow charge point (CCS2) connected ensure the vehicle cant not be moved.

-

With the HV slow charge point (CCS2) removed ensure the can be moved

19.2 Door interlocks / Haltbrake

-

Open driver’s door / Ensure interlock is activated and tele-tale on dash is present

-

Open first passenger doors / Ensure interlock is activated and tele-tale on dash is present

-

Open second passenger doors / Ensure interlock is activated and tele-tale on dash is present

-

Open third passenger doors / Ensure interlock is activated and tele-tale on dash is present

-

Open each side compartment door / Ensure interlock is activated and tele-tale on dash is present

19.3 Anti-roller away

-

Ensure vehicle is in a control position where these tests can be conducted safety .

Whilst seated in the driver's position , seat belt fastened and vehicle ready to drive .

- Traction on

-Park brake off.

- Forward direction selected. -

Remove seat belt , audible message / buzzer should be heard as well as tele-tale on dash.

-

Repeat the test , this time having seat belt clipped in but not around your body. Lifting off body weight off seat should activate pressure switch in seat base and audible message / buzzer should be heard as well as tele-tale on dash.

19.4 Suspension

-

Check Kneeling function / Ensure interlock is activated and tele-tale on dash is present

-

Raise vehicle / Ensure tele-tale on dash is present

19.5 Departure

-

Dash free of any fault codes or error messages

-

Record codes / issues

-

-

Record kms prior to road test

-

Record state of charge (SOC) prior to road test

-

Record distance to travel ( DTG) prior to road test

-

Move vehicle forward and ensure brakes and steering react accordingly before departing facility.

19.6 AVAS (Acoustic vehicle alerting system)

-

Check that AVAS is working under 20 km/h (button 22)

19.7 Steering / handling

-

Vehicle handles and steers as expected

-

Vehicle bakes smoothly and handles as excepted under brakes

19.8 Acceleration / acceleration test

-

Vehicle is smooth under accelerations

-

Record acceleration time from 0 to 40kms

-

Record acceleration time from 0 to 60kms

-

Record acceleration time from 0 to 80kms

19.9 General inspections

-

Check for any rattles, squeaks or noises that shouldn’t be present

-

Replicate stop /start operation on BUSWAY. Open and close doors at platforms whilst ensuring CCTV images are correct (minimum 5 stops)

-

Check operation of HELP points

-

Check and ensure route maps and displays correspond with vehicles actual location and stops

-

Check PICS and designation signs are working correctly

19.10 HV (EOT) charging

-

Before applying park brake to start recharging , record the following

-

Record kms

-

Record state of charges (SOC)

-

Record time to charge (TTC)

-

Charge completed

19.11 Driver's AC

-

Check driver’s AC is working / adjustable / fan speeds

-

Record cabin Temp

19.12 Passenger carriage AC

-

Record Temperature in carriage 1

-

Record Temperature in carriage 2

-

Record Temperature in carriage 3

20.0 PDI Completed

-

PDI Completed and vehicle accepted for delivery Date:

-

(TFB) PDI conducted by:

-

Signature:

-

(HESS) PDI conducted by:

-

Signature: