Title Page

-

Prepared By?

-

Equipment being worked on:

-

Machine Serial Number:

-

Conducted on

-

Job Site Location

-

Briefly describe the work being done today.

Safety First

Safety & Job Pause

-

I will perform this risk assessment of the job to the best of my ability. I will follow the procedures that are outlined within this assessment and pause the job if something should occur that isn't planned. If I'm unable to correct a job pause with the resources on site, I'll contact my Manager immediately.

-

Any failed response (noted in red) should trigger a PAUSE THE JOB and your Manager should be notified.

-

Safety Saves Lives

Job Site

Work Environment

-

Are the ground/site conditions suitable to safely perform my job?

-

Am I aware of the site specific procedures and safety rules?

-

Do I know where to go in the event of a facility emergency?

-

Is my work area clear of any obstructions? (power lines, extension cords, air hoses etc.)

-

Do I have sufficient space around my work area?

-

Can I position myself in a safe location in relation to moving equipment and other equipment in the area?

-

Can I stand clear of the dander zone from unstable and/or suspended loads?

-

Can I work safely in the current weather conditions? (heat, wind, ice etc.)

Job Details

Task

-

I wear my seatbelt when operating any equipment?

-

Do I have suitable PPE to perform the job safely?

-

Has my PPE been inspected and is in good condition before use?

-

Do I have the proper tools/equipment to perform the job safely?

-

Have my tools/equipment been inspected and are in good condition before use?

-

Is there another person on site to provide me assistance with the job?

-

PAUSE THE JOB! Working Alone must be approved by your Manager. Working Alone is defined as “not having anyone assigned to work directly with you”. An assigned person can include an operator, dealer or customer technician, or any other willing and able person. This person must be immediately available for assistance.

-

Does the job require working at heights? (work performed above 6ft)

-

Can fall prevention controls be put in place including avoiding/eliminating the need for work at height, the use of edge protection/railings, use of aerial work platforms, or use of fall protection equipment?

-

PAUSE THE JOB! Working at heights with no fall prevention controls in place is prohibited. Please contact your Manager immediately.

-

Do I have a working at heights rescue plan in place?

-

Does the job require rigging of any parts/equipment?

-

Inspect all rigging equipment and straps to unsure they are in good condition and follow your lifting plan.

-

Does the job require the use of a torch, welder, grinder or anything else that can cause a fire?

-

Ensure that you have a fire extinguisher on hand and that you have all necessary equipment to prevent a fire.

-

Does the job require entering a confined space? (Definition: A confined space has a limited or restricted means for entry or exit, is a space that is not designed for continuous occupancy, and is a space large enough for you to enter and conduct work)

-

PAUSE THE JOB! Confined Space entries are not allowed. Please contact your Manager immediately.

Hazardous Energy

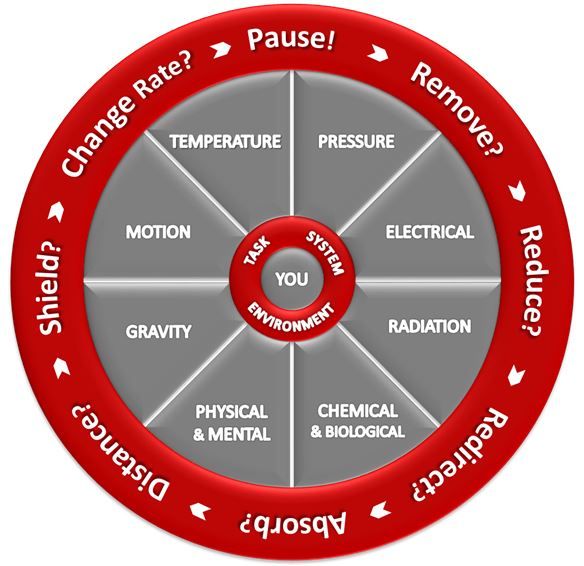

Energy Wheel

-

Starting from the inside out; evaluate the environment, tasks, and systems involved with the job. Next, identify the hazardous energies that need to be controlled within the environment, task and systems. Keep in mind that some systems or tasks can fall into multiple sections of the energy wheel. The outside of the wheel describes the controls to be used. If the hazards cannot be controlled, PAUSE THE JOB!

-

What ENERGY sources are being worked on?

- Electrical

- Hydraulic

- Mechanical

- Pneumatic

- N/A

-

Identify all HAZARDOUS energy.

- Pressure

- Electrical

- Radiation

- Chemical & Biological

- Physical & Mental

- Gravity

- Motion

- Temperature

-

How will the HAZARDOUS energy be CONTROLLED?

- Remove

- Reduce

- Redirect

- Absorb

- Distance

- Shield

- Change Rate

-

Briefly explain how you will control the hazardous energies.