Information

-

Job Reference

-

Customer

-

Conducted on

-

Prepared by

-

Location

-

What 3 Words https://what3words.com/pretty.needed.chill

Introduction

-

Please provide an overview of the scope of works detailed in this survey document.

-

Please provide details of any enabling works to be completed or arranged by the customer.

-

Please detail any assumptions and exclusions

-

We recommend a fire risk assessment is carried out by the customer and any recommendations complied with in relation to RC59 guidance.

-

The Works shall comply with all relevant Statutory and other Instruments, Regulations, and European and British Standards current at the date of Tender, which shall include but may not be limited to the following:-

CDM

CDM Checklist

-

Will any intrusive works be required on a building?

-

Was the building constructed pre 2000

-

Has asbestos survey been provided on salesforce?

-

Are suitable welfare facilities available for use during the works? (Confirm with customer)

-

Is there a flood risk in the area? https://flood-map-for-planning.service.gov.uk/

-

LSBUD detail in job folder on SharePoint

-

Work at height required

-

Will any special lifting equipment be required? (EG: Hi-Ab or Cable puller) ** Hi-Ab will be required for DC units**

Origin Detail

Origin Details

-

Will EVCs be supplied via a new DNO point of connection?

-

Incoming Supply Cut Out Rating (AMPS)

-

Earthing System

-

Relevant DNO

-

Conductor size from DNO Cut-Out to meter

-

MPAN

-

Agreed Capacity

-

Is the supply CT metered?

-

Picture of Meter

-

Rating of Meter

-

Is the metering adequate for the proposed total load?

-

Proposed Additional Load (Amps)

-

Rating & type of new supply

-

Location of feeder pillar

-

Any other information

Surge Protection

-

Does the building have a lightning protection system installed?

-

Is a type 1 surge protection device present?

-

Advise customer of the need to have this installed and ascertain whether or not we need to build this in to our design.

Maximum Demand

Maximum Demand

-

Has maximum demand data been provided pre survey by the customer?

-

Maximum Demand data from customer

-

Clamp Meter Reading L1

-

Clamp Meter Reading L2

-

Clamp Meter Reading L3

-

Photographs of maximum demand data on meter display

-

Can data be obtained via clamp meter readings and meter display data?

-

Clamp Meter Reading L1

-

Clamp Meter Reading L2

-

Clamp Meter Reading L3

-

Photographs of maximum demand data on meter display

-

Given the information available , is it feasible to potentially install the proposed additional load on the existing supply pending ENA information at a later date?

-

Where Agreed Capacity & / Or Maximum demand data has not been provided and is not available at site survey stage. We will make an assessment based on our experience as to whether or not the proposed extra load can potentially be connected to the existing supply or not. For any works to proceed this will need to be confirmed via ENA application to the DNO which requires ASC & MD data. Where this data cannot be provided or obtained at survey we may be required to fit load monitoring equipment to the supply at a cost to be confirmed.

-

New connection to be provided for EVCPs. No ENA required.

Existing EVCPs

-

Please detail any existing EVCPs on site

Proposed Installation 1

Charger requirements & location

-

Type and rating of EVCPs (Please specify wall or floor mount)

-

Google map & Street view image

-

Picture of charger location

-

Is the proposed area in an indoor car park or basement?

-

Has the customer been notified that hey must have a fire risk assessment completed and comply with any recommendations in this?

-

Are there any fuel system components or combustible material storage areas on site?

-

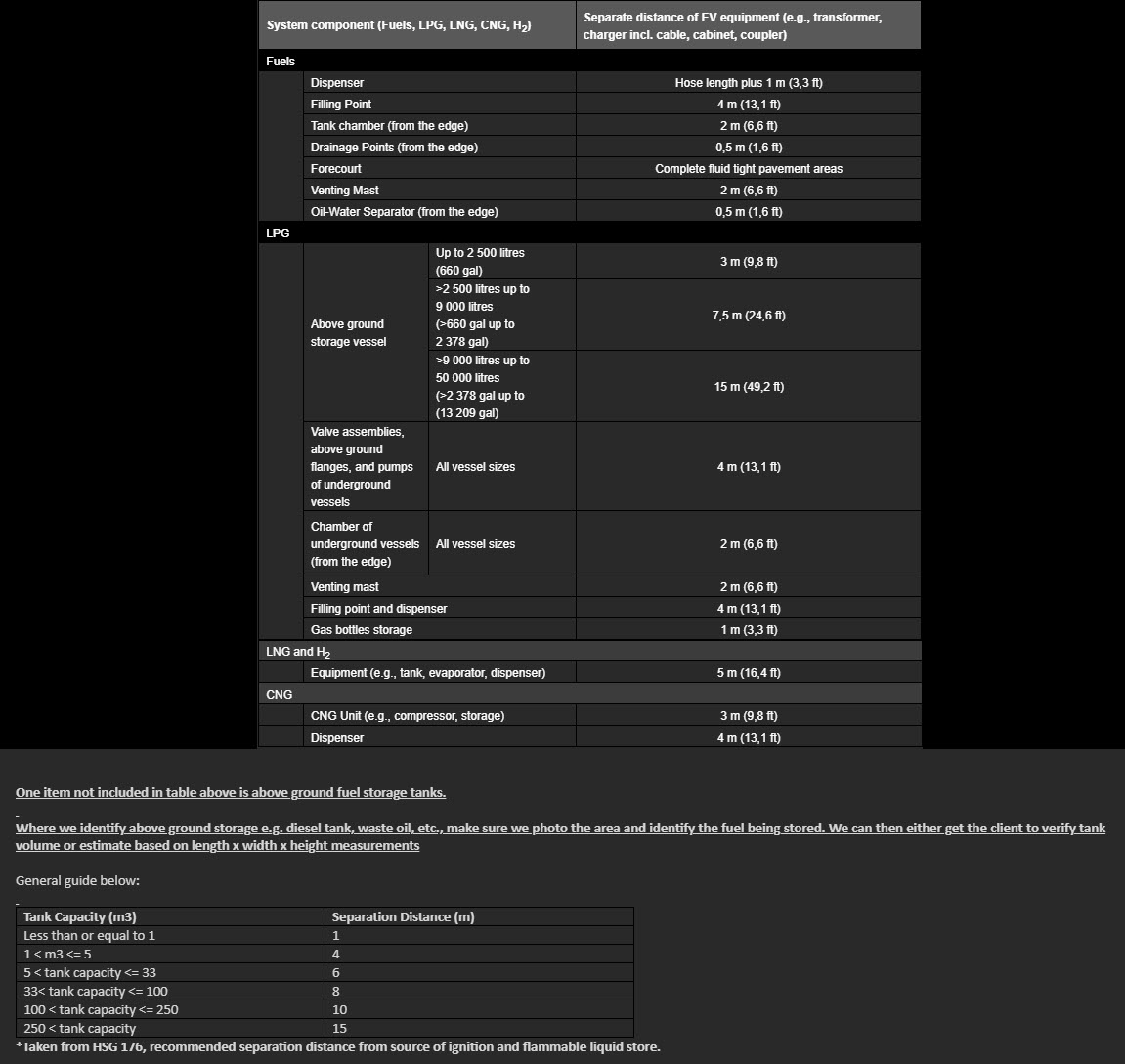

Refer to the attached separation distances for fuel systems componants

-

Can EVCs be sited in line the recommended separation distances shown above?

-

Abort survey and advise customer that EVCs cannot be installed due to proximity to fuel system components

-

Is the area used for HGVs?

-

Is there a risk of collision with EVCs?

-

Existing bay size

-

Are EVCs to be fully or partially sited within parking bays?

-

Do bay sizes need altering to allow for EVC position within it?

-

If bays are to be extended to allow for EVC positions, will any roads or walkways be encroached on.

-

Will there be adequate clearance around EVCs for maintenance to be carried out?

Signal Test Detail

-

Signal strength test Pass / Fail (min -78db)

-

Can a router be fitted to enable a network connection?

-

Electrical Installation

-

Are EVCs being supplied via new POC?

-

Detail & photographs of existing switchgear

-

Detail & photograph of existing Surge Protection Devices

-

Is type 1 surge protection required within EVC switchgear (> 10m from type 1 at origin)

-

Detail any feeder pillar requirements

-

Provide a clear picture and measurment of the area where new switch gear is to be installed.

-

Detail proposed installation to new EV switch gear from existing switch gear

-

Detail proposed electrical installation to EV charge points from new EV switch gear position

-

Containment detail

-

Recommended earthing system for EVCs

-

Any other notes or pictures

-

Detail new feeder pillar & switchgear requirements

-

Detail proposed electrical installation to EV charge points from new EV switch gear position

-

Recommended cable type & size

-

Measured cable distances

-

Recommended earthing system for EVCs

-

Any other notes or pictures

-

Civils Installation

-

Detail trenching required to EVC positions

-

Detail concrete base requirements for chargers & any feeder pillars

-

Surface details

-

Any other notes or pictures

Bay Marking & Signage

-

Is bay marking required?

-

Number of bays?

-

Surface type?

-

Is signage required?

Crash Protection & Barriers

-

Specify crash protection barriers required for each EVC and any feeder pillars

-

Are wheel stops required?

-

Is there adequate space within the existing bay for wheel stops?

-

Any other notes or pictures

Proposed Installation 2

Charger requirements & location

-

Type and rating of EVCPs (Please specify wall or floor mount)

-

Google map & Street view image

-

Picture of charger location

-

Is the proposed area in an indoor car park or basement?

-

Has the customer been notified that hey must have a fire risk assessment completed and comply with any recommendations in this?

-

Are there any fuel or combustible material storage areas within 15m of proposed EVCs?

-

Is the area used for HGVs?

-

Is there a risk of collision with EVCs?

-

Existing bay size

-

Are EVCs to be fully or partially sited within parking bays?

-

Do bay sizes need altering to allow for EVC position within it?

-

If bays are to be extended to allow for EVC positions, will any roads or walkways be encroached on.

-

Will there be adequate clearance around EVCs for maintenance to be carried out?

Signal Test Detail

-

Signal stregnth test Pass / Fail (min -78db)

-

Can a router be fitted to enable a network connection?

Electrical Installation

-

Are EVCs being supplied via new POC?

-

Provide detail and photos of existing switchgear

-

Detail any feeder pillar requirements

-

Provide a clear picture and measurment of the area where new switch gear is to be installed.

-

Detail proposed installation to new EV switch gear from existing switch gear

-

Detail proposed electrical installation to EV charge points from new EV switch gear position

-

Containment detail

-

Recommended earthing system for EVCs

-

Any other notes or pictures

-

Detail new feeder pillar & switchgear requirements

-

Detail proposed electrical installation to EV charge points from new EV switch gear position

-

Recommended cable type & size

-

Measured cable distances

-

Recommended earthing system for EVCs

-

Any other notes or pictures

-

Civils Installation

-

Detail trenching required to EVC positions

-

Detail concrete base requirements for chargers & any feeder pillars

-

Surface details

-

Any other notes or pictures

Bay Marking & Signage

-

Is bay marking required?

-

Number of bays?

-

Surface type?

-

Is signage required?

Crash Protection & Barriers

-

Specify crash protection barriers required for each EVC and any feeder pillars

-

Are wheel stops required?

-

Is there adequate space within the existing bay for wheel stops?

-

Any other notes or pictures

Proposed Installation 3

Charger requirements & location

-

Type and rating of EVCPs (Please specify wall or floor mount)

-

Google map & Street view image

-

Picture of charger location

-

Is the proposed area in an indoor car park or basement?

-

Has the customer been notified that hey must have a fire risk assessment completed and comply with any recommendations in this?

-

Are there any fuel or combustible material storage areas within 15m of proposed EVCs?

-

Is the area used for HGVs?

-

Is there a risk of collision with EVCs?

-

Existing bay size

-

Are EVCs to be fully or partially sited within parking bays?

-

Do bay sizes need altering to allow for EVC position within it?

-

If bays are to be extended to allow for EVC positions, will any roads or walkways be encroached on.

-

Will there be adequate clearance around EVCs for maintenance to be carried out?

Signal Test Detail

-

Signal stregnth test Pass / Fail (min -78db)

-

Can a router be fitted to enable a network connection?

Electrical Installation

-

Are EVCs being supplied via new POC?

-

Provide detail and photos of existing switchgear

-

Detail any feeder pillar requirements

-

Provide a clear picture and measurment of the area where new switch gear is to be installed.

-

Detail proposed installation to new EV switch gear from existing switch gear

-

Detail proposed electrical installation to EV charge points from new EV switch gear position

-

Containment detail

-

Recommended earthing system for EVCs

-

Any other notes or pictures

-

Detail new feeder pillar & switchgear requirements

-

Detail proposed electrical installation to EV charge points from new EV switch gear position

-

Recommended cable type & size

-

Measured cable distances

-

Recommended earthing system for EVCs

-

Any other notes or pictures

-

Civils Installation

-

Detail trenching required to EVC positions

-

Detail concrete base requirements for chargers & any feeder pillars

-

Surface details

-

Any other notes or pictures

Bay Marking & Signage

-

Is bay marking required?

-

Number of bays?

-

Surface type?

-

Is signage required?

Crash Protection & Barriers

-

Specify crash protection barriers required for each EVC and any feeder pillars

-

Are wheel stops required?

-

Is there adequate space within the existing bay for wheel stops?

-

Any other notes or pictures

Proposed Installation 4

Charger requirements & location

-

Type and rating of EVCPs (Please specify wall or floor mount)

-

Google map & Street view image

-

Picture of charger location

-

Is the proposed area in an indoor car park or basement?

-

Has the customer been notified that hey must have a fire risk assessment completed and comply with any recommendations in this?

-

Are there any fuel or combustible material storage areas within 15m of proposed EVCs?

-

Is the area used for HGVs?

-

Is there a risk of collision with EVCs?

-

Existing bay size

-

Are EVCs to be fully or partially sited within parking bays?

-

Do bay sizes need altering to allow for EVC position within it?

-

If bays are to be extended to allow for EVC positions, will any roads or walkways be encroached on.

-

Will there be adequate clearance around EVCs for maintenance to be carried out?

Signal Test Detail

-

Signal stregnth test Pass / Fail (min -78db)

-

Can a router be fitted to enable a network connection?

Electrical Installation

-

Are EVCs being supplied via new POC?

-

Provide detail and photos of existing switchgear

-

Detail any feeder pillar requirements

-

Provide a clear picture and measurment of the area where new switch gear is to be installed.

-

Detail proposed installation to new EV switch gear from existing switch gear

-

Detail proposed electrical installation to EV charge points from new EV switch gear position

-

Containment detail

-

Recommended earthing system for EVCs

-

Any other notes or pictures

-

Detail new feeder pillar & switchgear requirements

-

Detail proposed electrical installation to EV charge points from new EV switch gear position

-

Recommended cable type & size

-

Measured cable distances

-

Recommended earthing system for EVCs

-

Any other notes or pictures

-

Civils Installation

-

Detail trenching required to EVC positions

-

Detail concrete base requirements for chargers & any feeder pillars

-

Surface details

-

Any other notes or pictures

Bay Marking & Signage

-

Is bay marking required?

-

Number of bays?

-

Surface type?

-

Is signage required?

Crash Protection & Barriers

-

Specify crash protection barriers required for each EVC and any feeder pillars

-

Are wheel stops required?

-

Is there adequate space within the existing bay for wheel stops?

-

Any other notes or pictures

Additional Comments or Pictures

-

Any additional comments or pictures

Annex D Checklist

-

Are there any hazardous zones where flammable/combustible gases may be present?

-

Have the boundaries of any hazardous zones been identified?

-

Can the installation be carried out so that the charged vehicle, cable and connections are outside the hazardous area when charging?

-

CoP Ref 3.1 - Is the metering adequate for the intended use and billing model?

-

CoP Ref 3.2 - Is the existing supply adequate for the additional demand?

-

CoP Ref 8 - Has the earthing arrangement for the incoming power supply been established?

-

CoP Ref 8.2.1 - If a TT earthing system is being provided for the charging equipment, has a simultaneous contact risk assessment been carried out?

-

CoP Ref 8.2.3 - Are the existing earthing and bonding arrangements compliant with BS 7671.

-

CoP Ref 8.2.3 - Is the supply PME (TN-C-S) or a TN-S public supply?

-

CoP Ref 8.2.3 If PME (TN-C-S) have precautions necessary to prevent danger in the event of an open-circuit neutral fault been identified and addressed?

-

CoP Ref 3.5 - "Has GPRS coverage of the proposed installation location been checked?<br>Note: some EVSE manufacturers require a minimum of 3G coverage."<br>

-

CoP Ref 3.6 - Has the installer reviewed the installation instructions provided by the charging equipment manufacturer?

-

CoP Ref 3.7 - Has planning permission been granted for the charging equipment installation?

-

CoP Ref 3.9 - Have the details of the proposed installation been discussed and agreed with the client?

-

CoP Ref 3.9 - Have any necessary repairs to the existing installation been agreed with the client?

<br>D1 IET Risk Assessment Form - Installations with PME supply and vehicle charging equipment to be installed outdoors where a TT system is proposed to be adopted for charging equipment only<br>

Installation Detail

-

Installation address

-

Supply taken from e.g. Main intake, office unit, store

-

Location of electric vehicle charging equipment considered in this risk assessment (approximate distance to reference points)

Identify the hazards

-

(a) Does the building from which the charging equipment supply is to be obtained have a PME supply?

-

(b) Is the vehicle charging equipment to be installed outdoors?

-

(a) Is a TT system to be adopted for the main installation and vehicle charging equipment?

Step 2 - Decide who might be harmed and how: Any person who can simultaneously touch any conductive-parts or conductor that might be connected to the main PME earth terminal of the building, e.g. a water tap, or metallic gas/water or fuel pipe, or metallic conduit, or item of Class I electrical equipment such as an outside light, switch or socket-outlet, or boiler flue, or structural steel work, etc. AND the vehicle being charged OR any other conductive-parts or conductor that might be directly or indirectly or otherwise connected to the TT earth terminal of the vehicle charging equipment.

Step 3 - Evaluate the risk and decide on precautions

-

(Question 1) Is it possible to simultaneously touch any conductive-parts or conductor that might be connected to the main PME earthing terminal AND the vehicle being charged OR any conductive-parts or conductor that might be connected to the TT earth terminal of the vehicle charging equipment? NB: All possible locations and positions of the vehicle on charge, and the charging lead and connector, must be considered here.

Customer Sign Off

-

Customer Sgnature

-

Date

-

Customer Comments