Title Page

-

Site conducted

-

Location

-

Conducted on

-

Prepared by

- Jessyca Tyler

- Kendi Smith

Record Keeping

1. Food Cost Reporting, Production Records, and Backsheets

-

1.1 Food Cost Reports are complete, accurate, and submitted on time each week by the facility food service authority (or their designee).

-

Inspection Method:

-

Inspection Method:

-

1.1.a The facility food service authority (or their designee) completes and submits the food cost report on time each week, using the template provided by the Dietary Services Manager.

-

1.1.b The food cost reports are complete and accurate.

-

1.2 The daily production records are complete and accurately reflect what is served on a daily basis, including holidays (i.e., the number of portions prepared and served are recorded for mainline, selective, and medical diets, temperatures are recorded for TCS foods, and substitutions are documented correctly, including holidays).

-

Inspection Method:

-

Inspection Method:

-

1.2.a Substitutions are documented correctly on the daily production record.

-

1.2.b Holiday meals are accurately recorded on the production record to reflect what was served.

-

1.2.c Staff accurately record on the daily production records the food items and number of portions prepared and served for each medical meal/snack.

-

1.2.d Staff completely and accurately record on the daily production record the food items and number of portions prepared and served for each standard meal.

-

1.2.e Staff completely and accurately record on the daily production record the service temperature of each food item served that requires "Time and/or Temperature Control for Safety".

-

1.3 Daily "back sheets" are complete, accurate, and include signatures (printed or electronic) of the morning, afternoon, or evening staff responsible for completing the daily inspections (i.e., inspection of residents and serving areas, inspection of equipment and storage areas, and thermometers are calibrated 2x/week).

-

Inspection Method:

-

Inspection Method:

-

1.3.a Inspections of resident workers for appropriate hygiene and signs of illness is completed prior to the start of preparation of each meal and is documented on the daily "back sheet".

-

1.3.b Inspection of the serving line for appropriate head coverings, glove use, serving utensils, and menu items (all completed prior to the start of service of each meal), is recorded on the daily "back sheet".

-

1.3.c Inspection of all food storage areas is conducted each morning and afternoon/evening and is documented on the daily "back sheet".

-

1.3.d Inspection of all dish washing sinks and machines is conducted each morning and afternoon/evening and is documented on the daily "back sheet".

-

1.3.e All thermometers are calibrated at a minimum of twice per week and more frequently as needed. Calibration testing is recorded on the daily "back sheet".

-

1.3.f The daily "back sheets" include signatures (printed or electronic) of the morning and afternoon or evening staff responsible for completing the inspections.

-

1.4 The current level of inventory on hand is appropriate for the facility population and location and includes a minimum quantity of RTE foods sufficient to sustain the population for 72 hours in the event of an emergency.

-

Inspection Method:

-

Inspection Method:

-

1.4.a The current level of inventory on hand is appropriate for the facility population (approximately 2-3 weeks worth of food, based on inventory dollar and average weekly food cost).

-

1.4.b There is a minimum quantity of RTE/shelf-stable foods to sustain the entire population for 72 hours in the event of an emergency.

-

1.5 Only those with an approved background check deliver food/supplies to IDOC facilities on behalf of the contractor. The food service authority notifies the facility shift commander and the Dietary Services Manager when an unauthorized contract employee makes a delivery.

-

Inspection Method:

2. Staff and Resident Workers

-

2.1 All food service staff receive training specific to their job role and function upon initial hire, have completed a state approved sanitation training course (if designated as the person in charge), and sign a food borne illness reporting agreement prior to commencing work in the food service department.

-

Inspection Method:

-

Inspection Method:

-

2.1.a All IDOC staff persons who may be designated by the Idaho Food Code as the 'person in charge' have completed a state approved sanitation training course. This includes all IDOC food service staff, as well as any IDOC security staff that participate in the oversight of food preparation or service, and all community reentry center (CRC) staff.

-

2.1.b In addition to the state-mandated sanitation training, all food service staff members receive training on each of the standards addressed in this SOP upon initial hire. Staff members who have transferred from a food service position from one IDOC facility to another receive facility-specific food service training.

-

2.1.c All food service staff, as well as any security staff who may provide food service relief duties, sign a food borne illness reporting agreement prior to commencing work in the food service department. The facility food service authority retains this agreement at all times while the person is employed in an IDOC food service or relief position.

-

2.2 The facility food service authority maintains a resident worker file that clearly documents that workers have received training specific to their job role and function upon initial hire and prior to assignment of kitchen duties. This file also contains a signed food borne illness reporting agreement that is retained at all times while the worker is employed in a food service position.

-

Inspection Method:

-

Inspection Method:

-

2.2.a Prior to assignment of kitchen duties, resident workers receive training on: proper use of gloves and hair coverings; required hand washing procedures; food borne illness; cross contamination; appropriate food storage; safe chemical and equipment use; IDOC menus, recipes, and basic food preparation. This is clearly documented with the residents hire date, training topics covered, and a signature from the resident indicating their comprehension of the material and agreement to comply with all standards taught at all times while working in food service.

-

2.2.b All resident workers sign a food borne illness reporting agreement prior to commencing work in the food service department. The food service authority retains this agreement at all times while the resident is employed in a food service position.

-

2.3 The facility food service authority maintains a daily resident worker schedule that includes each resident's name, IDOC ID number, job role/position title, and the daily shifts starting and ending times.

-

Inspection Method:

-

2.4 The lead food service staff member at each facility personally oversees the preparation and service of a minimum of 15 meals each month, to include a minimum of 2 breakfast meals, 4 dinner meals, and 1 weekend meal.

-

Inspection Method:

-

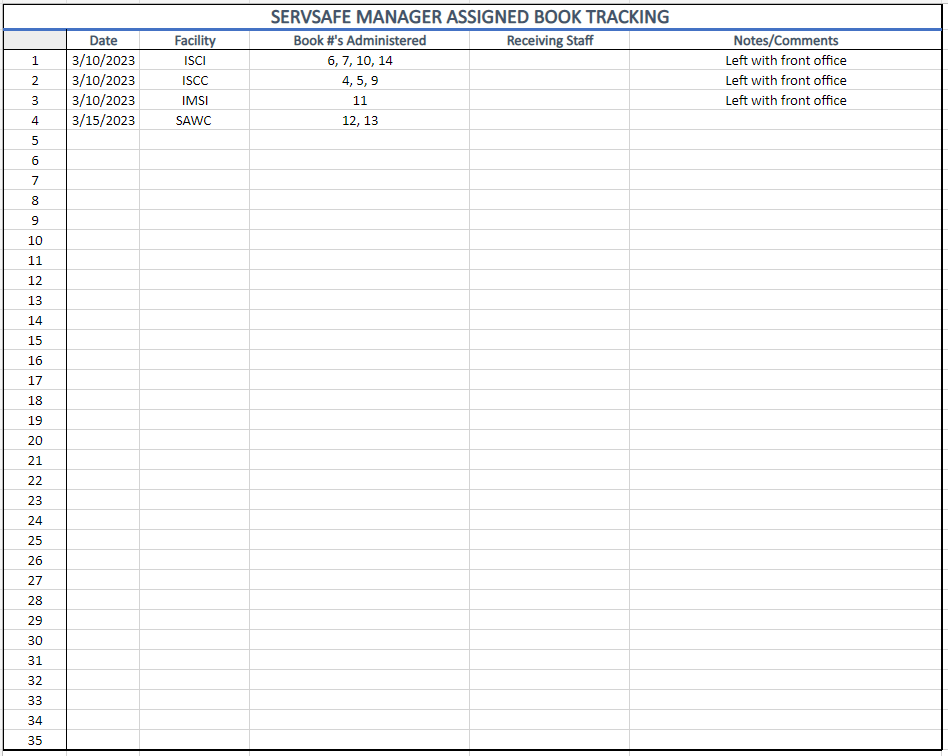

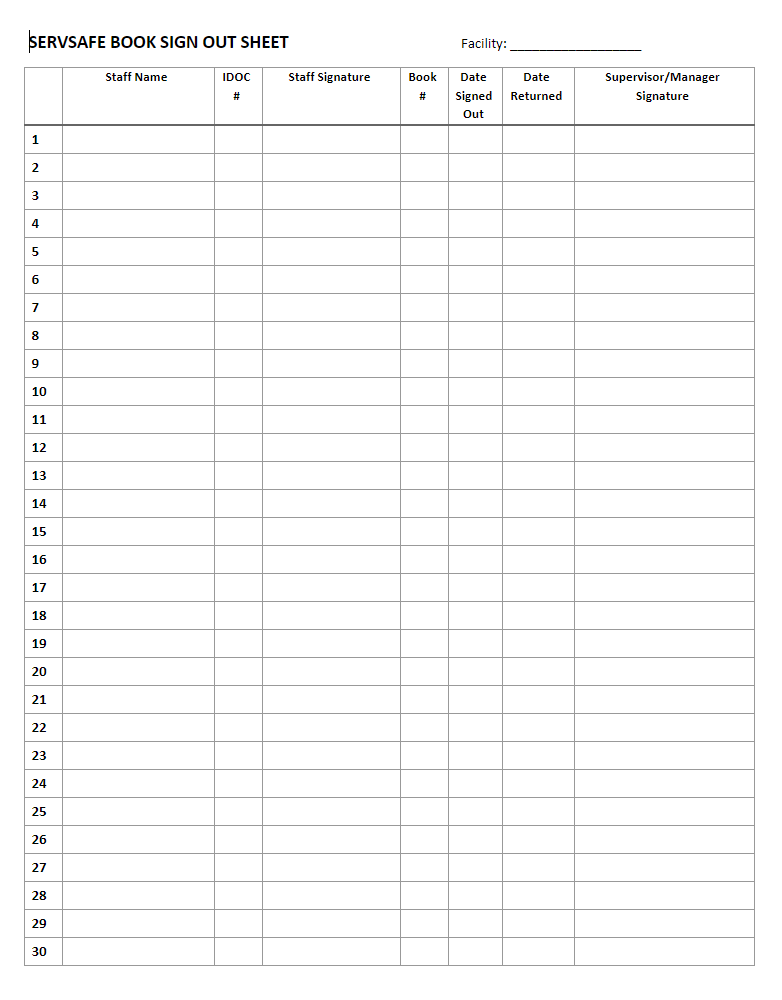

2.5 Staff maintain record of the IDOC administered ServSafe Manager training books (via the ServSafe book sign out sheet) provided from Central Office and are aware of who has each book at all times.

-

Inspection Method:

-

Inspection Method:

-

2.5.a The facility maintains the appropriate number of ServSafe books as assigned by Central Office Dietary Service at all times.

-

2.5.b The facility utilizes the ServSafe book sign out sheet to document who has which book at all times.

3. State Health Inspection and Field Memorandum

-

3.1 The food service operation meets annual license requirements for food establishments. Findings from the most recent state health inspection, if any, are corrected in a timely manner.

-

Inspection Method:

-

Inspection Method:

-

3.1.a The food service operation meets annual license requirements for food establishments.

-

3.1.b If there were any findings with the most recent state health inspection, they were corrected in a timely manner.

-

3.2 There is an up-to-date facility field memorandum, approved by the applicable division chief, which outlines the process for counting meals. The process is adhered to.

-

Inspection Method:

Operations

1. Staff and Resident Workers

-

1.1 Staff and resident workers are appropriately dressed for the work environment (i.e., wearing clean and appropriately sized uniforms and free from jewelry except for a plain ring/wedding band without stones).

-

Inspection Method:

-

Inspection Method:

-

1.1.a Staff and resident workers wear clean uniforms that are appropriate for the work environment (i.e., no overly large shirts that drape into food).

-

1.1.b Staff and resident workers are free from jewelry except for small/non dangling earrings and/or a plain ring/wedding band, without stones.

-

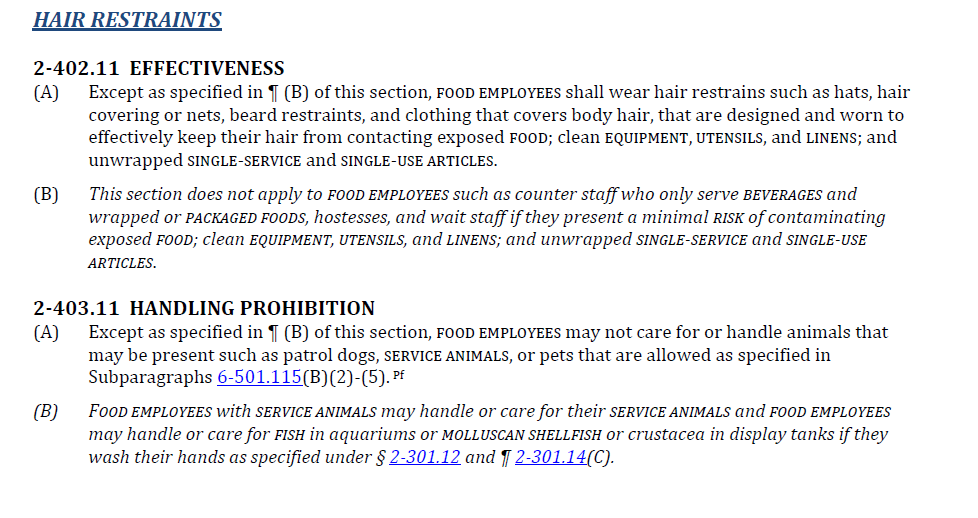

1.2 Staff and resident worker head and facial hair is secured and covered by a hat/hair net/beard net, unless trimmed 1/4" or less, at all times that food is being prepared and/or served.

-

Inspection method:

-

Inspection Method:

-

1.2.a Long hair is pulled back tightly in such a way as to minimize hair falling into food.

-

1.2.b Head or facial hair is trimmed short (such as 1/4" or less), or covered by a hat/hair net/beard net at all times that food is being prepared and/or served.

-

1.3 Staff and resident workers are free from observable signs of poor hygiene.

-

Inspection method:

-

Inspection Method:

-

1.3.a Staff and resident workers are free from observable signs of poor hygiene (visible dirt on face, arms, or body, dirty fingernails, etc.).

-

1.3.b Staff and resident workers appear to be free from observable signs of illness (i.e., diarrhea, fever, vomiting, jaundice, sore throat with fever, lesions/pus on exposed body parts, excessive coughing or sneezing, runny nose, etc.).

2. Hand Hygiene

-

2.1.Signs describing the required procedures for when and how to wash hands, as well as reminders, are placed in strategic locations throughout the kitchen.

-

Inspection Method:

-

Inspection Method:

-

2.1.a Signs that describe the required procedures for when and how to wash hands are placed near handwashing sinks.

-

2.1.b Handwashing signs reminding staff and workers to wash their hands are placed in strategic locations throughout the kitchen (such as upon entering the kitchen, after using the restroom, when entering a production area, after touching their face/body/clothing, etc.).

-

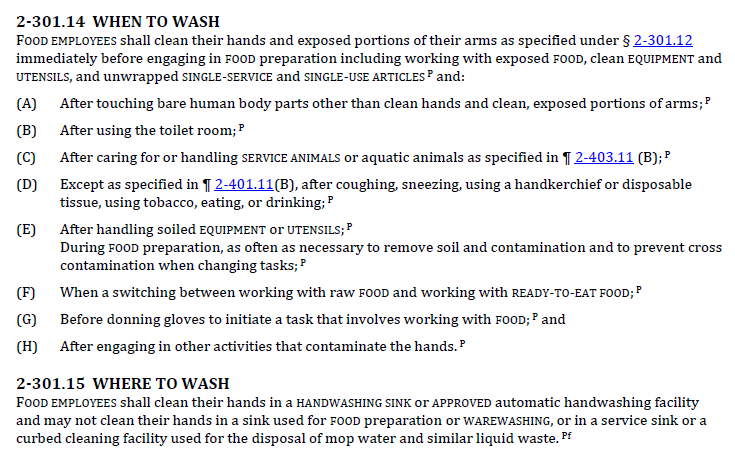

2.2. All staff and resident workers wash their hands in accordance with Idaho Food Code guidelines including required frequency and procedure.

-

Inspection Method:

-

Inspection Method:

-

2.2.a All staff and resident workers wash their hands upon entering the kitchen and at other times as indicated necessary by the Idaho Food Code.

-

2.2.b All food service staff and resident kitchen workers use the correct procedure when washing their hands (see appendix).

-

2.3 The Idaho requirement for glove use is adhered to when handling food: all kitchen workers wear single-use, disposable food service gloves when handling ready-to-eat foods. The gloves are used for only one task, are used for no other purpose, and are discarded when damaged, soiled, when the glove comes into contact with a potentially contaminated surface, or when interruptions occur in the task being executed.

-

Inspection Method:

-

Inspection Method:

-

2.3.a Staff and resident workers wear single-use, disposable food service gloves at all times while handling ready-to-eat foods.

-

2.3.b Staff and resident workers change gloves at the frequency and occurrence required by ID Food Code and food safety best practices (i.e., the gloves are used for only one task, are used for no other purpose, and are discarded when damaged, soiled, when the glove comes into contact with a potentially contaminated surface, or when interruptions occur in the task being executed).

3. Non-Food Contact Surfaces

-

3.1 The kitchen floor is cleaned regularly (at the end of each production period at a minimum), and wet or slippery spills are cleaned immediately (or the area is cleared of foot traffic while waiting for cleaning). The floors are largely free of visible signs of grime, grease, dust, dirt, and food debris.

-

Inspection Method:

-

Inspection Method:

-

3.1.a The kitchen floor is largely free of visible signs of grime, grease, food, dust, or dirt build-up.

-

3.1.b Food debris on the floor is observed to be cleaned up at the end of each production time, at a minimum, and more often as needed to prevent hazardous conditions.

-

3.1.c Wet or slippery spills are cleaned immediately, and/or the area is cleared of foot traffic while waiting for cleaning.

-

3.2 Ventilation hoods are current on their most recent inspection (within 6 months) and are clean and free of dust/debris that may contaminate food.

-

Inspection Method:

-

Inspection Method:

-

3.2.a Ventilation hoods are clean and free of debris or dust that might contaminate the food or preparation areas or cause a fire hazard.

-

3.2.b The ventilation hoods are current on their most recent inspection (within the last 6 months).

-

3.3 The kitchen walls, ceiling and light fixtures, and windows are largely clean and free of visible dirt, dust, grime, or paint chips that may contaminate food or preparation areas.

-

Inspection Method:

-

Inspection Method:

-

3.3.a The kitchen walls are clean and free of paint chips, dust, etc., that might contaminate the food or preparation areas.

-

3.3.b The kitchen ceiling, overhead pipes, and light fixtures are clean and free of paint chips, dust, etc., that might contaminate the food or preparation areas.

-

3.3.c The kitchen windows and frames are largely free of visible signs of grime, grease, dust, and dirt.

-

3.4 Trash canisters are thoroughly clean and emptied at the end of each production period at a minimum.

-

Inspection Method:

-

Inspection Method:

-

3.4.a Trash canisters are thoroughly clean inside and out.

-

3.4.b Trash canisters are emptied promptly following the day's production at a minimum, and more often as needed to minimize the development of objectionable odors or other conditions that attract or harbor pests.

-

3.5 A professional or in-house pest control program is utilized to ensure sanitary food service conditions in accordance with Idaho Food Code requirements. No visible signs of pest control problems are found in the kitchen, dining, or storage areas.

-

Inspection Method:

-

Inspection Method:

-

3.5.a A professional or in-house pest control program is utilized and sufficient to control pests and ensure sanitary food service conditions in accordance with Idaho Food Code requirements.

-

3.5.b There are no visible signs of pest control problems.

4. Food Contact Surfaces

-

4.1 Food preparation tables and equipment (including mixers, ovens, griddles, stovetops, etc.) are clean and free of food debris, dirt, grease, and grime build-up (including inside the microwave, warming units, ovens, in the blade housing of cutters, in the rotators of stand mixers, etc.), and are observed to be cleaned (and protected if necessary) after each use.

-

Inspection Method:

-

Inspection Method:

-

4.1.a The food preparation tables are cleaned and sanitized after each use.

-

4.1.b Food preparation equipment (including mixers, ovens, stovetops, griddles, etc.) is observed to be cleaned and sanitized by kitchen workers after each use.

-

4.1.c Food-contact surfaces of food preparation equipment are free of excessive food debris, dirt, grease, and grime build-up (including inside the microwave, warming units, ovens, in the blade housing of cutters, in the rotators of stand mixers, etc.).

-

4.1.d Food preparation equipment is protected from contamination when not in use (sheet pans or similar equipment are utilized to protect griddles, warmer doors are kept closed, stand mixer bowls are covered, etc.).

-

4.2 The serving lines are clean and free from food debris, grease, grime, and excessive hard water build-up and are observed to be cleaned and sanitized after each use.

-

Inspection Method:

-

Inspection Method:

-

4.2.a The serving lines are observed to be cleaned and sanitized by kitchen workers after each use.

-

4.2.b The serving lines (including countertop, sneeze guard/pass through, steam table, holding wells, etc.) are free from food debris, dirt, grease, grime, and excessive hard water build-up.

-

4.3 Food transport equipment is clean and free from food debris, dirt, grease, and grime build-up and is observed to be cleaned and sanitized after each use.

-

Inspection Method:

-

Inspection Method:

-

4.3.a Food transport equipment is observed to be cleaned and sanitized between uses.

-

4.3.b Food transport equipment is free from food debris, dirt, grease, and grime build-up.

-

4.4 Dishes, pots, pans, silverware, glassware, and serving utensils are properly stored when not in use and in accordance with Idaho Food Code Guidelines.

-

Inspection Method:

-

4.5 All ice machines stored in the kitchen and dining areas are clean and appropriately used (ice is dispensed using a clean plastic or metal scoop with a handle and the ice machine scoop is stored correctly in a clean location outside of the ice well).

-

Inspection Method:

-

Inspection Method:

-

4.5.a All ice machines stored in the kitchen and/or dining room are clean (there is not visible debris in the ice wells, excessive hard water build-up, mold, or slimy coating on the interior walls/lid).

-

4.5.b Ice is dispensed using only a clean plastic or metal scoop with a handle.

-

4.5.c The ice machine scoops are stored correctly in a clean location outside of the ice well.

-

4.6 Staff and resident workers appropriately handle beverage cups in food preparation areas, or eating and drinking is limited to designated areas away from food preparation, storage, and serving areas.

-

Inspection Method:

-

Inspection Method:

-

4.6.a Employee beverage cups used in food preparation areas are covered and the container is handled in such a way as to prevent contamination of the employee's hands and exposed food and clean equipment and utensils.

-

4.6.b Staff and residents do not store or consume personal food items in areas of facility food preparation, storage, or service.

-

4.7 Separate sinks are used to wash hands, prepare foods, and clean dishes. The sinks are not used for other than their intended purpose (i.e., a handwashing sink is not used to fill pitchers of water for food preparation).

-

Inspection Method:

-

4.8 Sanitizer is used appropriately, to include sanitizer buckets accessible in preparation and service areas, the sanitizer buckets are clean and frequently changed, clean wipe cloths are available in all areas, in good condition, and stored appropriately in the sanitizing solution between uses.

-

Inspection Method:

-

Inspection Method:

-

4.8.a Buckets of sanitizing solution are accessible in all areas of food production and service.

-

4.8.b The sanitizer buckets are clean, the solution is clean and changed as frequently as needed to maintain dilution rate, as well as when becoming excessively cloudy or contaminated with food debris.

-

4.8.c Clean wipe cloths are available in all work areas.

-

4.8.d The wipe cloths are properly stored in clean sanitizing solution between uses.

-

4.8.e The rags used are in good condition, not excessively tattered, and changed with clean rags when becoming excessively soiled.

5. Chemicals

-

5.1 Chemicals are stored and used appropriately in accordance with Idaho Food Code guidelines.

-

Inspection Method:

-

Inspection Method:

-

5.1.a Chemicals are stored in an area that is not adjacent to or above food or food equipment or utensils.

-

5.1.b All containers used for dispensing chemicals (such as cleaner and sanitizer spray bottles) are clearly and individually identified with the common name of the material (i.e., a bottle of glass cleaner must be labeled as glass cleaner, although it may also include the label of "ammonia").

-

5.1.c Chemical containers are not used for food, and food containers are not used for chemicals.

-

5.1.d The appropriate chemicals are used for cleaning and sanitizing. All kitchen workers who utilize chemicals for cleaning use the appropriate chemical for the intended purpose (i.e., Spic Span is not used on food prep equipment or tables or surfaces that come into direct contact with food [unless rinsed with water afterwards], floor cleaner is not used to clean the inside of a steam kettle, etc.).

6. Dining Room

-

6.1 The dining room is largely clean and free of wet or slippery spills, as well as visible grime, grease, dust, and dirt in areas to include the walls, floor, overhead pipes and light fixtures, and windows and frames. Any spills observed are cleaned immediately and/or the area is cleared of foot traffic while waiting for cleaning.

-

Inspection Method:

-

Inspection Method:

-

6.1.a The dining room walls are largely free of visible grime, grease, dust, and dirt.

-

6.1.b The dining room floor is largely free of visible signs of grime, grease, dust, and dirt.

-

6.1.c The overhead pipes and light fixtures in the dining room are largely free of visible signs of grime, grease, dust, and dirt.

-

6.1.d The dining room windows and frames are largely free of visible signs of grime, grease, dust, and dirt.

-

6.1.e Wet or slippery spills are cleaned immediately; and/or the area is cleared of foot traffic while waiting for cleaning.

-

6.2 Dining tables and chairs are cleaned and sanitized between uses.

-

Inspection Method:

-

6.3 The dining room is not used for any purpose that may contaminate food when food is being served or consumed.

-

Inspection Method:

7. Dry Storage

-

Storage area name (if applicable):

-

7.1 The dry storage area is clean and primarily free of grease, grime, dust, food debris, and wet spills.

-

Inspection Method:

-

Inspection Method:

-

7.1.a Dry storage cleanliness - shelving.

-

7.1.b Dry storage cleanliness - walls.

-

7.1.c Dry storage cleanliness - floors.

-

7.1.d Dry storage cleanliness - ceiling, overhead pipes and fixtures, etc.

-

7.2 The dry storage area is well-organized and goods are stocked and stored with the oldest-dated items most accessible.

-

Inspection Method:

-

Inspection Method:

-

7.2.a The dry storage area is well-organized and with a system that allows for easy locating of products and efficient inventory.

-

7.2.b The FIFO (first-in, first-out) system is adhered to when storing goods in the dry storage areas; foods are stocked and stored with the oldest-dated items most accessible.

-

7.3 Food items in the dry storage area are labeled appropriately to include the identifying name and the date of receipt, preparation, or the manufacturer's use-by date.

-

Inspection Method:

-

Inspection Method:

-

7.3.a Foods stored in the dry storage area are labeled with their identifying name.

-

7.3.b Foods stored in the dry storage area are dated (with the date of receipt, preparation, or manufacturer's use-by date).

-

7.4 Food items in the dry storage area are held appropriately (i.e., held in such a way as to prevent contamination, repackaged into clean food-grade containers when removed from their original packaging, held in a storage area that maintains a temperature of 45-85 degrees F).

-

Inspection Method:

-

Inspection Method:

-

7.4.a Foods in the dry storage area that are removed from their original packaging are repackaged in clean food-grade containers.

-

7.4.b Food items in the dry storage area are covered and held in such a way as to prevent contamination.

-

7.4.c The dry storage areas are observed to maintain a temperature of 45-85 degrees F.

8. Cold Storage

-

Storage area name (if applicable):

-

8.1 The cold storage area is clean and primarily free of grease, grime, dust, food debris, and wet spills.

-

Inspection Method:

-

Inspection Method:

-

8.1.a Cold storage cleanliness - shelving.

-

8.1.b Cold storage cleanliness - walls.

-

8.1.c Cold storage cleanliness - floors.

-

8.1.d Cold storage cleanliness - ceiling, overhead pipes and fixtures, etc.

-

8.2 The cold storage area is well-organized and goods are stocked and stored with the oldest-dated items most accessible.

-

Inspection Method:

-

Inspection Method:

-

8.2.a The cold storage area is well-organized and with a system that allows for easy locating of products and efficient inventory.

-

8.2.b The FIFO (first-in, first-out) system is adhered to when storing goods in the cold storage areas; foods are stocked and stored with the oldest-dated items most accessible.

-

8.3 Food items in the cold storage area are labeled appropriately to include the identifying name and the date of receipt, preparation, or the manufacturer's use-by date.

-

Inspection Method:

-

Inspection Method:

-

8.3.a Foods stored in the cold storage area are labeled with their identifying name.

-

8.3.b Foods stored in the cold storage area are dated (with the date of receipt, preparation, or manufacturer's use-by date).

-

8.4 Food items in the cold storage area are held appropriately (i.e., held in such a way as to prevent contamination, repackaged into clean food-grade containers when removed from their original packaging, held in a storage area that maintains a temperature of 33-41 degrees F).

-

Inspection Method:

-

Inspection Method:

-

8.4.a Foods in the cold storage area that are removed from their original packaging are repackaged in clean food-grade containers.

-

8.4.b Food items in the cold storage area are covered and held in such a way as to prevent contamination.

-

8.4.c The cold storage areas are observed to maintain a temperature of 33-41 degrees F.

9. Frozen Storage

-

Storage area name (if applicable):

-

9.1 The frozen storage area is clean and primarily free of grime, dust, food debris, and ice build-up.

-

Inspection Method:

-

Inspection Method:

-

9.1.a Frozen storage cleanliness - shelving.

-

9.1.b Frozen storage cleanliness - walls.

-

9.1.c Frozen storage cleanliness - floors.

-

9.1.d Frozen storage cleanliness - ceiling, overhead pipes and fixtures, etc.

-

9.1.e Frozen storage cleanliness - excessive ice build-up (indicative of possible equipment malfunction).

-

9.2 The frozen storage area is well-organized and goods are stocked and stored with the oldest-dated items most accessible.

-

Inspection Method:

-

Inspection Method:

-

9.2.a The frozen storage area is well-organized and with a system that allows for easy locating of products and efficient inventory.

-

9.2.b The FIFO (first-in, first-out) system is adhered to when storing goods in the frozen storage areas; foods are stocked and stored with the oldest-dated items most accessible.

-

9.3 Food items in the frozen storage area are labeled appropriately to include the identifying name and the date of receipt, preparation, or the manufacturer's use-by date.

-

Inspection Method:

-

Inspection Method:

-

9.3.a Foods stored in the frozen storage area are labeled with their identifying name.

-

9.3.b Foods stored in the frozen storage area are dated (with the date of receipt, preparation, or manufacturer's use-by date).

-

9.4 Food items in the frozen storage area are held appropriately (i.e., held in such a way as to prevent contamination, repackaged into clean food-grade containers when removed from their original packaging, held in a storage area that maintains a temperature of 0 degrees F or below).

-

Inspection Method:

-

Inspection Method:

-

9.4.a Foods in the frozen storage area that are removed from their original packaging are repackaged in clean food-grade containers.

-

9.4.b Food items in the frozen storage area are covered and held in such a way as to prevent contamination.

-

9.4.c The frozen storage areas are observed to maintain a temperature of 0 degrees F or below.

10. Facility Maintenance

-

10.1 The flooring is largely well maintained in all areas (i.e., free of unevenness/projections that render it difficult to clean, there are no visible signs of mold/mildew, etc.).

-

Inspection Method:

-

Inspection Method:

-

10.1.a Kitchen - Floors are an even or level surface with no roughness or projections that render it difficult to clean (including large areas of broken tiles, missing grout, pitted epoxy, unsealed concrete, etc.).

-

10.1.b Kitchen - There are no visible signs of mold/mildew growth on the floor.

-

10.1.c Dining room - Floors are an even or level surface with no roughness or projections that render it difficult to clean (including large areas of broken tiles, missing grout, pitted epoxy, unsealed concrete, etc.).

-

10.1.d Dining room - There are no visible signs of mold/mildew growth on the floor.

- Compliant

- Non Compliant

- N/A/Not Observed

- Pending

-

10.1.e Storage areas - Floors are an even or level surface with no roughness or projections that render it difficult to clean (including large areas of broken tiles, missing grout, pitted epoxy, unsealed concrete, etc.).

-

10.1.f Storage areas - There are no visible signs of mold/mildew growth on the floor.

-

10.2 Walls, light fixtures, overhead pipes, windows, and other surfaces are well maintained (i.e., free of unevenness/projections that render it difficult to clean, free from damage/chips/cracks in surfaces that could contaminate food and/or food preparation areas or injure staff or resident workers, etc.).

-

Inspection Method:

-

Inspection Method:

-

10.2.a Walls - Well maintained and free of unevenness/projections that render it difficult to clean, free from damage/chips/cracks in surfaces that could contaminate food and/or food preparation areas or injure staff or resident workers, etc.

-

10.2.b Light fixtures - Well maintained and free of unevenness/projections that render it difficult to clean, free from damage/chips/cracks in surfaces that could contaminate food and/or food preparation areas or injure staff or resident workers, etc.

-

10.2.c Overhead pipes - Well maintained and free of unevenness/projections that render it difficult to clean, free from damage/chips/cracks in surfaces that could contaminate food and/or food preparation areas or injure staff or resident workers, etc.

-

10.2.d Windows - Well maintained and free of unevenness/projections that render it difficult to clean, free from damage/chips/cracks in surfaces that could contaminate food and/or food preparation areas or injure staff or resident workers, etc.

-

10.2.e Other surfaces as indicated - Well maintained and free of unevenness/projections that render it difficult to clean, free from damage/chips/cracks in surfaces that could contaminate food and/or food preparation areas or injure staff or resident workers, etc.

-

10.3 When issues with flooring, walls, light fixtures, overhead pipes, windows, and other surfaces arise, staff notify facility maintenance and promptly submit a work order for correction.

-

Inspection Method:

-

Inspection Method:

-

10.3.a Floors - A work order has been submitted, noting issues with the flooring.

-

10.3.b Walls - A work order has been submitted, noting issues with the walls.

-

10.3.c Light fixtures - A work order has been submitted, noting issues with the light fixtures.

-

10.3.d Overhead pipes - A work order has been submitted, noting issues with the overhead pipes.

-

10.3.e Windows - A work order has been submitted, noting issues with the windows.

-

10.3.f Other surfaces as indicated - A work order has been submitted.

-

10.4 Staff monitor food preparation equipment to ensure it is in good working order and submit work orders promptly when issues arise.

-

Inspection Method:

-

Inspection Method:

-

10.4.a Staff monitor food preparation equipment to ensure it is in good working order.

-

10.4.b Staff submit work order promptly when issues arise.

11. Dish-washing

-

11.1 The dish machine maintains appropriate temperatures (see appendix 10.1).

-

Inspection Method:

-

11.2 The appropriate process and wash temperatures are used when handwashing dishes (see appendix 10.1 and 10.2.a)

-

Inspection Method:

-

Inspection Method:

-

11.2.a During the wash process, the washing and sanitizing liquids are maintained clean and fresh, without a build-up of grease and food debris.

-

11.2.b The correct process is used when hand-washing dishes (washed in clean soapy water at least 110-degree F, the dishes are rinsed and then sanitized in quat sanitizer [150-400 ppm, 75-1000-degree F, minimum 30-second soak] or chlorine bleach [50-200 ppm, 75-100-degree F, minimum 2-minute soak]).

-

11.3 Clean dishes, pots, pans, silverware, glassware, and serving utensils are handled and stored appropriately in accordance with Idaho Food Code guidelines (see appendix 10.3).

-

Inspection Method:

-

Inspection Method:

-

11.3.a Dishes, pots, pans, silverware, glassware, and serving utensils are completely air-dried before stacking and reuse.

-

11.3b Cleaned dishes are not handled by hands contaminated from handling dirty dishes.

12. Staff Oversight

-

12.1 Food service staff provide direct oversight and monitoring of all activities occurring within the kitchen, to include monitoring of food storage areas, preparation and service of every meal, acting as the final authority when making decisions, and promptly taking appropriate corrective action when errors do occur.

-

Inspection Method:

-

Inspection Method:

-

12.1.a Food storage areas are directly monitored by staff at all times during food pulls and restocking and remain locked at all other times (indirect monitoring is acceptable at CRCs).

-

12.1.b Food service staff members (and/or appropriately trained security staff at CRCs) provide direct oversight of the preparation and service of every meal, with only limited reliance on secondary methods of oversight (viewing from an office window, security cameras, etc.). Monitoring must be continuous at prison facilities and may be intermittent at CRC facilities.

-

12.1.c Food service staff act as the final authority when making decisions regarding the preparation and troubleshooting of recipes, quantities of food items needed for each recipe, etc., by investigating issues themselves and providing direction (without relinquishing decision-making authority to resident workers).

-

12.1.d When errors in meal preparation and/or service do occur, staff promptly take appropriate corrective action.

-

12.2 Food service staff ensure that residents receive the correct mainline, selective, or medical diet trays and that residents do not take more than one meal per serving period.

-

Inspection Method:

-

Inspection Method:

-

12.2.a Food service staff ensure that residents receive the correct mainline or selective diet tray that they are signed up for.

-

12.2.b When applicable, food service staff ensure that residents receive the correct type of medical diet.

-

12.2.c Food service staff ensure that residents do not take more than one meal per serving period (except for any additional meals/snacks provided due to work requirements).

13. Food Pulls

-

13.1 Food service staff appropriate plan food pulls in advance, according to needed items and quantities, and in order to minimize waste or over-production only the necessary quantities of each ingredient are pulled and set aside for production.

-

Inspection Method:

-

Inspection Method:

-

13.1.a Food pulls are completed in advance, allowing adequate time to identify and correct any supply shortages.

-

13.1.b Food service staff plan food pulls according to needed items and quantities, utilizing sized recipe cards (or another pull sheet template approved by the dietary service manager).

-

13.1.c To minimize waste or over-production, only the necessary quantities of each ingredient are pulled in advance and set aside for production (with cases opened and the required quantities separated).

14. Food Production and Service

-

14.1 All foods provided by the facility's food service operation are prepared in accordance with Idaho Food Code guidelines for thawing, cooking, and minimizing time in the "Temperature Danger Zone".

-

Inspection Method:

-

Inspection Method:

-

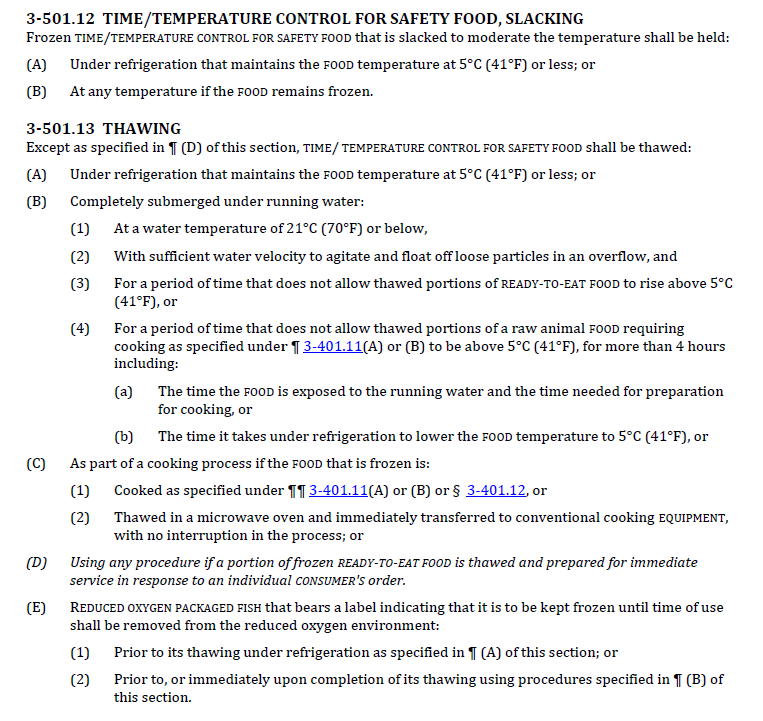

14.1.a All foods are thawed in accordance with Idaho Food Code guidelines (thawed under refrigeration, or under cold running water when there isn't sufficient time for refrigerator thawing), or they are thawed as part of the cooking process. Foods are not thawed at room temperature or in warm or stagnant water.

-

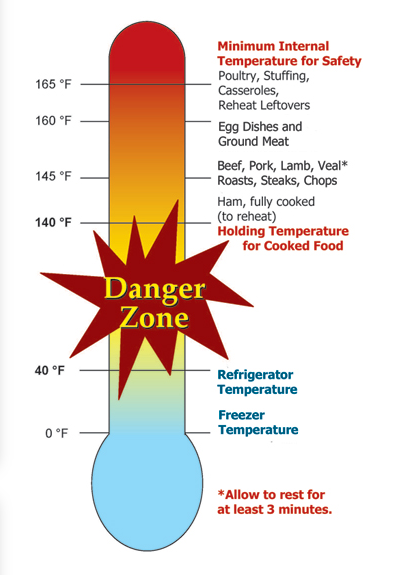

14.1.b All food provided by the facility's food service operation is prepared in such a way as to minimize the time in the "Temperature Danger Zone" (such as keeping foods in iced trays at the prep tables, preparing only small batches at a time and keeping the remaining ingredients in coolers, etc.).

-

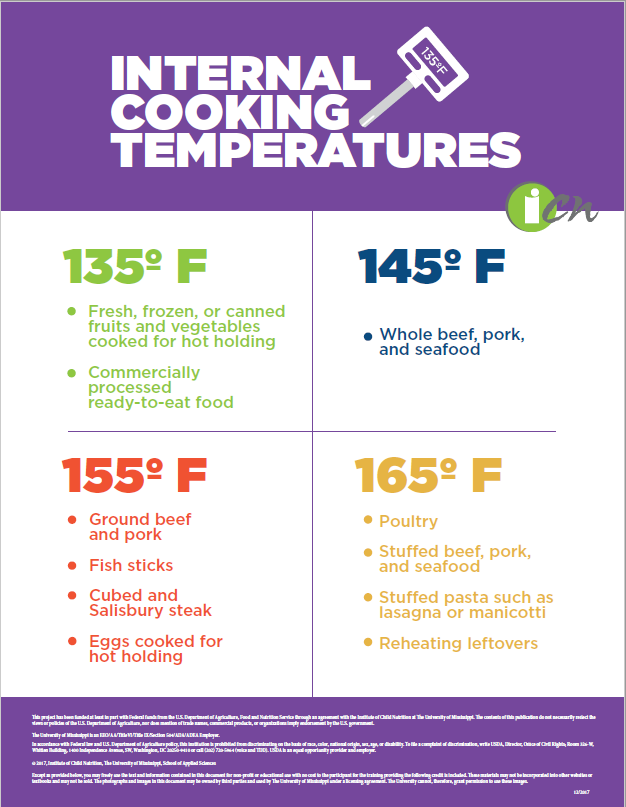

14.1.c All hot food provided by the facility's food service operation is cooked to the minimum allowable temperature as required by the Idaho Food Code.

-

14.2. All foods provided by the facility's food service operation are washed (if applicable) and prepared correctly using appropriate production techniques.

-

Inspection Method:

-

Inspection Method:

-

14.2.a Per staff and/or resident workers, fruit with an edible peel is always thoroughly washed/rinsed with water prior to service.

-

14.2.b Cooks use the correct ingredients and calculated quantities, as determined by approved, sized recipe cards, when preparing food (or if the recipe cannot be prepared as written due to recipe card error, staff notify the dietary services manager promptly).

-

14.2.c Appropriate production techniques are followed, as dictated by approved recipe cards (or standard food service "best practices" in the absence of specific instruction) to ensure the best possible food quality.

-

14.3 Staff test the just-cooked and ready-to-be served temperatures of each food item that requires "Time and/or Temperature Control for Safety". These foods are served within allowable temperature ranges as determined by the Idaho Food Code.

-

Inspection Method:

-

Inspection Method:

-

14.3.a Staff test the just-cooked and/or ready-to-be served temperatures of each food item served that requires "Time and/or Temperature Control for Safety".

-

14.3.b All food provided by the facility's food service operation is served within allowable temperature ranges as described by the Idaho Food Code (i.e., all hot foods are served at the minimum required temperature or within 4-hours of reaching the minimum temperature. All cold foods are served at or below 41-degree F, or within 2-hours of being removed from refrigeration [only 2-hours is allotted for cold foods due to the presumed time out of refrigeration during preparation]).

-

14.4. Food items are arranged in an appealing manner on the trays (foods are served in layers when appropriate [i.e., chili is ladled over noodles on the trays rather than all mixed together prior to service], there is not major spillage from one compartment to the next, vegetables are well-drained prior to plating, etc.).

-

Inspection Method:

15. Menu and Diet Compliance

-

15.1 The current IDOC cycle menu and nutritional profile are posted or published for residents, including for residents who don't have access to the dining hall. This includes the mainline and selective diet menus.

-

Inspection Method:

-

15.2. The correct food items, recipes, and portion sizes, as outlined by the master food service menu, are observed to be served for each mainline, selective and medical diets (if applicable).

-

Inspection Method:

-

Inspection Method:

-

15.2.a The correct food items, recipes, and portion sizes, as outlined by the master food service menu, are observed to be served for each mainline and selective diet.

-

15.2.b The correct food items, recipes, and portion sizes, as outlined by the master food service menu, are observed to be served for each medical diet type.

- Compliant

- Non Compliant

- N/A/Not Observed

- Pending

-

15.3. No more than 14 hours pass between the service of any two consecutive meals.

-

Inspection Method:

-

Breakfast and dinner serving times:

-

15.4. Substitutions or changes to the master menu are made only with prior approval by the dietary services manager (or approval by the facility head in the case of emergency).

-

Inspection Method:

-

15.5 Residents participating in a selective diet are permitted to eat mainline holiday meals, in lieu of their selective diet, without being deemed "non-compliant". In addition, special diet holiday meals are made available to residents who prefer to continue their selective diet on days when a holiday meal is offered.

-

Inspection Method:

16. Other Observations

-

16.1 Use the note function to document any observations that were not captured within the previous audit questions.

-

Inspection Method:

Administration

1. Biohazard Cleaning

-

1.1 Food service staff are able to access and locate an adequately stocked biohazard cleaning kit and procedure document in the kitchen and/or food service office.

-

Inspection Method:

-

Inspection Method:

-

1.1.a A procedure outlining the specific actions that staff must take to minimize the spread of contamination and the exposure of staff, residents, food, and surfaces to vomitus and/or fecal matter is posted in the kitchen or food service office.

-

1.1.b An appropriately stocked contamination event cleaning kit is available and readily accessible (i.e., not locked in a closet or office that only one person has a key to).

-

1.1.c Staff are able to locate the contamination event cleaning kit and procedures document.

2. Inventory and Ordering

-

2.1 The facility food service authority (or designee) accurately counts and records their facility's complete food inventory each Tuesday following the dinner meal.

-

Inspection Method:

-

2.2 The facility food service authority (or their designees) prepare and submit weekly food orders from approved contractors in accordance with approved food supply lists, menu requirements, and contractually obligated ordering schedules.

-

Inspection Method:

-

Inspection Method:

-

2.2.a Facility food service authorities (or their designees) prepare weekly food orders in accordance with approved food supply lists and menu requirements. The facility food service authority ensures that the correct food items in the required quantities are ordered weekly.

-

2.2.b Food orders are made according to contractually obligated ordering schedules (standing orders may be established at the vendors' discretion).

-

2.2.c Food purchases are made only from approved contractors.

3. Goods Receiving

-

3.1. At the time of delivery, staff inspect the goods delivered to ensure they are of sound quality and free from storage temperature abuse. Staff reject any items that are not of sound quality or acceptable temperature.

-

Inspection Method:

-

Inspection Method:

-

3.1.a At the time of delivery, staff inspect the goods delivered to ensure they are of sound quality.

-

3.1.b At the time of delivery, staff inspect the goods for signs of improper storage or temperature abuse (water stains or ice build-up on the boxes of frozen goods, for example).

-

3.1.c At the time of delivery, staff reject any items that are not of sound quality or acceptable temperature.

-

3.2 At the time of delivery, staff verify that the products delivered match what was ordered, that the invoice matches the items and quantities delivered, and that the prices charged match the contract bid prices. Staff notify the driver of any issues in quality, quantity, or price and notate as such on the delivery invoice.

-

Inspection Method:

-

Inspection Method:

-

3.2.a At the time of delivery, staff verify that the products delivered match what was ordered.

-

3.2.b At the time of delivery, staff verify that the invoice matches the items and quantities delivered.

-

3.2.c Staff verify that the prices charged match the contract bid prices.

-

3.2.d At the time of delivery, staff notify the driver of any quality, quantity, or pricing issues and notate as such on the delivery invoice.

-

3.3 At the time of delivery, goods are quickly moved to the appropriate storage locations following inspection and acceptance of the delivery, in a manner that prevents residents from entering any part of a delivery truck.

-

Inspection Method:

-

Inspection Method:

-

3.3.a Delivered goods are quickly moved to the appropriate storage locations following inspection and acceptance of the delivery.

-

3.3.b No residents are permitted to enter any part of a delivery truck.

Notes

- Questions for Follow-up

-

Use this section to document any questions or concerns requiring follow-up.

Appendix

Record Keeping

-

2.5.a Assigned ServSafe Books

-

2.5.b Assigned ServSafe Book Sign Out Sheet

Operations

-

1.2 Idaho Food Code Guidelines: Hair Restraints

-

2.2a Idaho Food Code Guidelines: When to Wash Hands

-

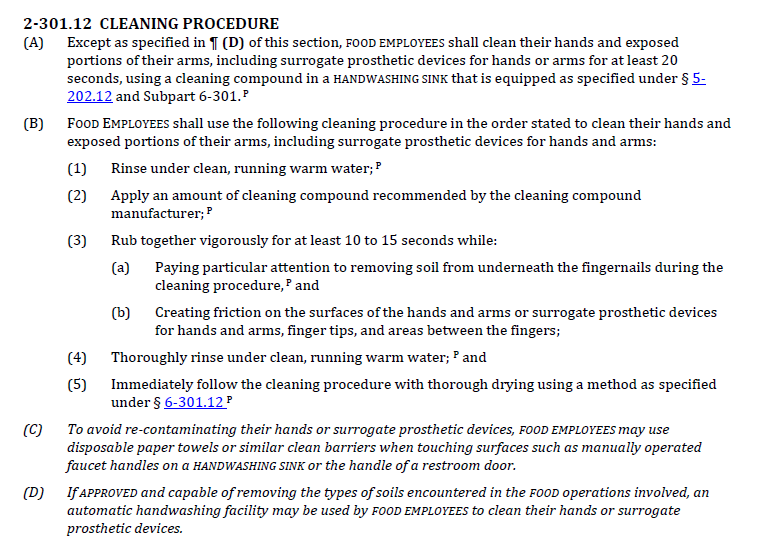

2.2.b Idaho Food Code Guidelines: How to Wash Hands

-

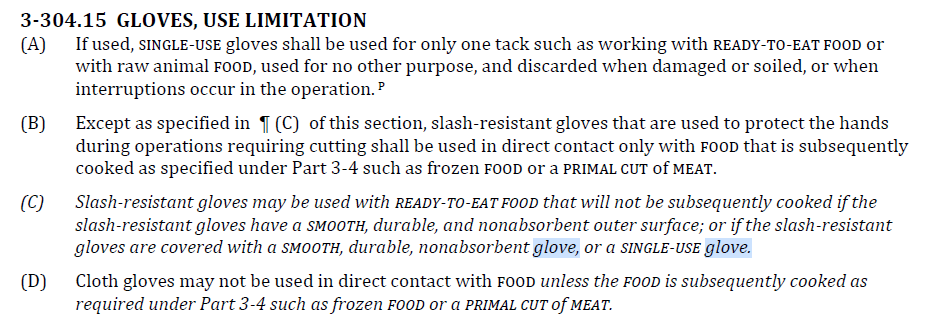

2.3 Idaho Food Code Guidelines: Glove Use

-

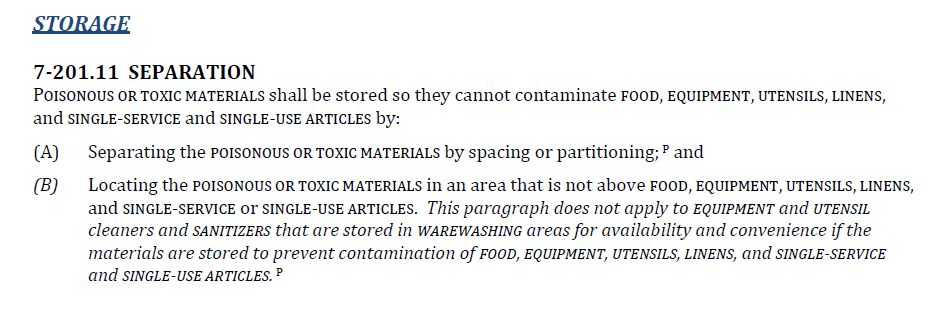

5.1.a Idaho Food Code Guidelines: Chemical Storage

-

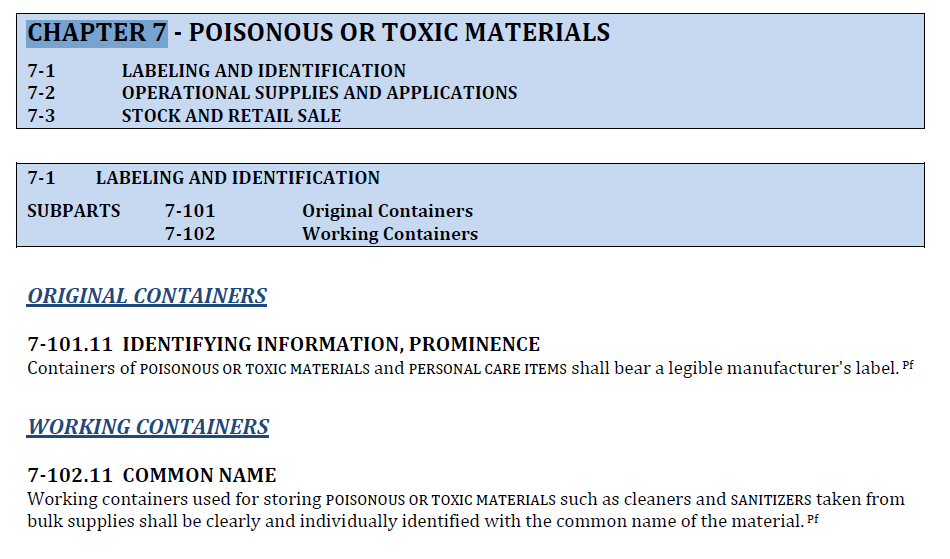

5.1.b Idaho Food Code Guidelines: Labeling of Chemical Containers

-

5.1.c Idaho Food Code Guidelines: Chemical Containers Restrictions

-

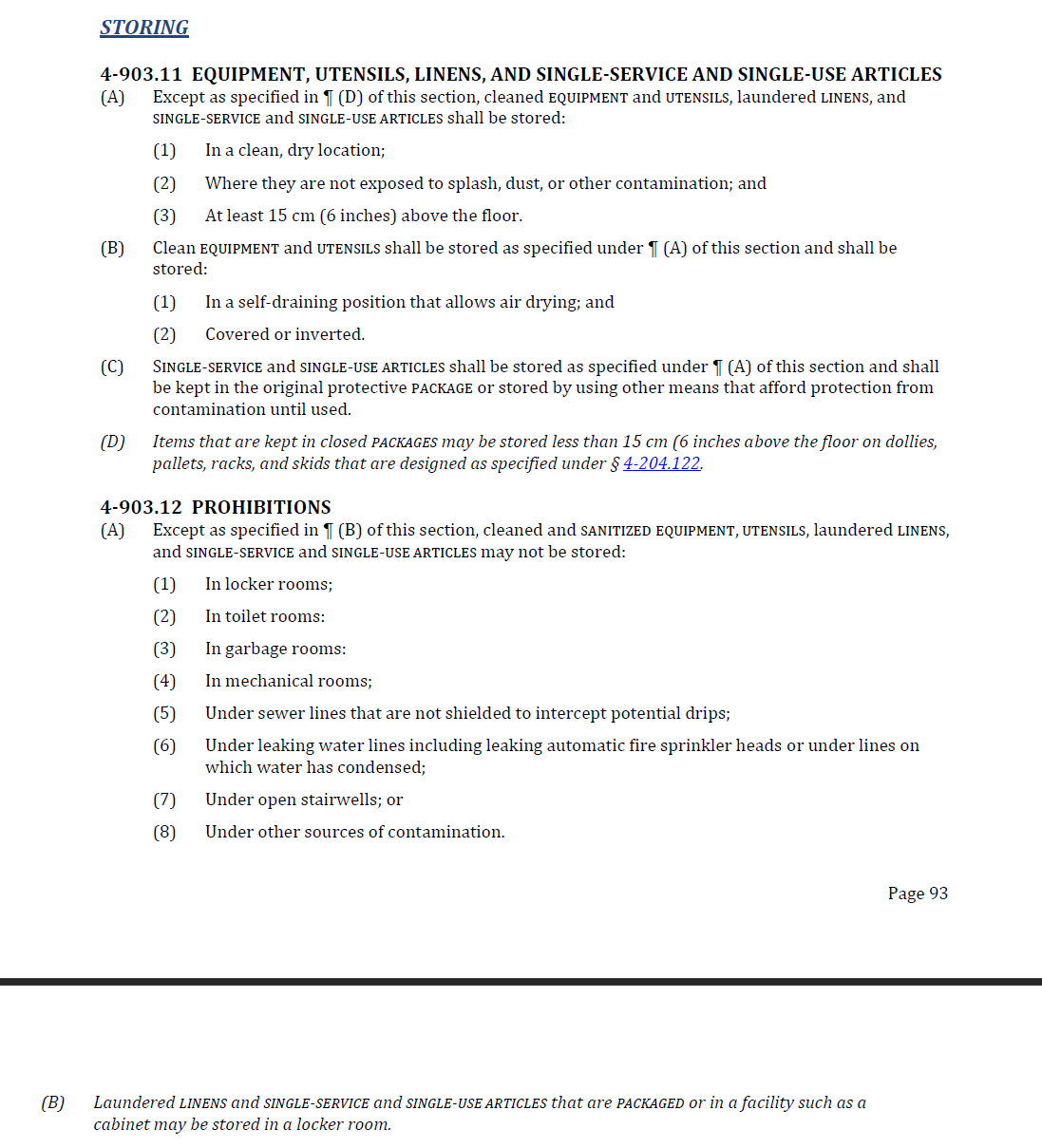

5.4 Idaho Food Code Guidelines: Storing Equipment, Utensils, and Single Use Items

-

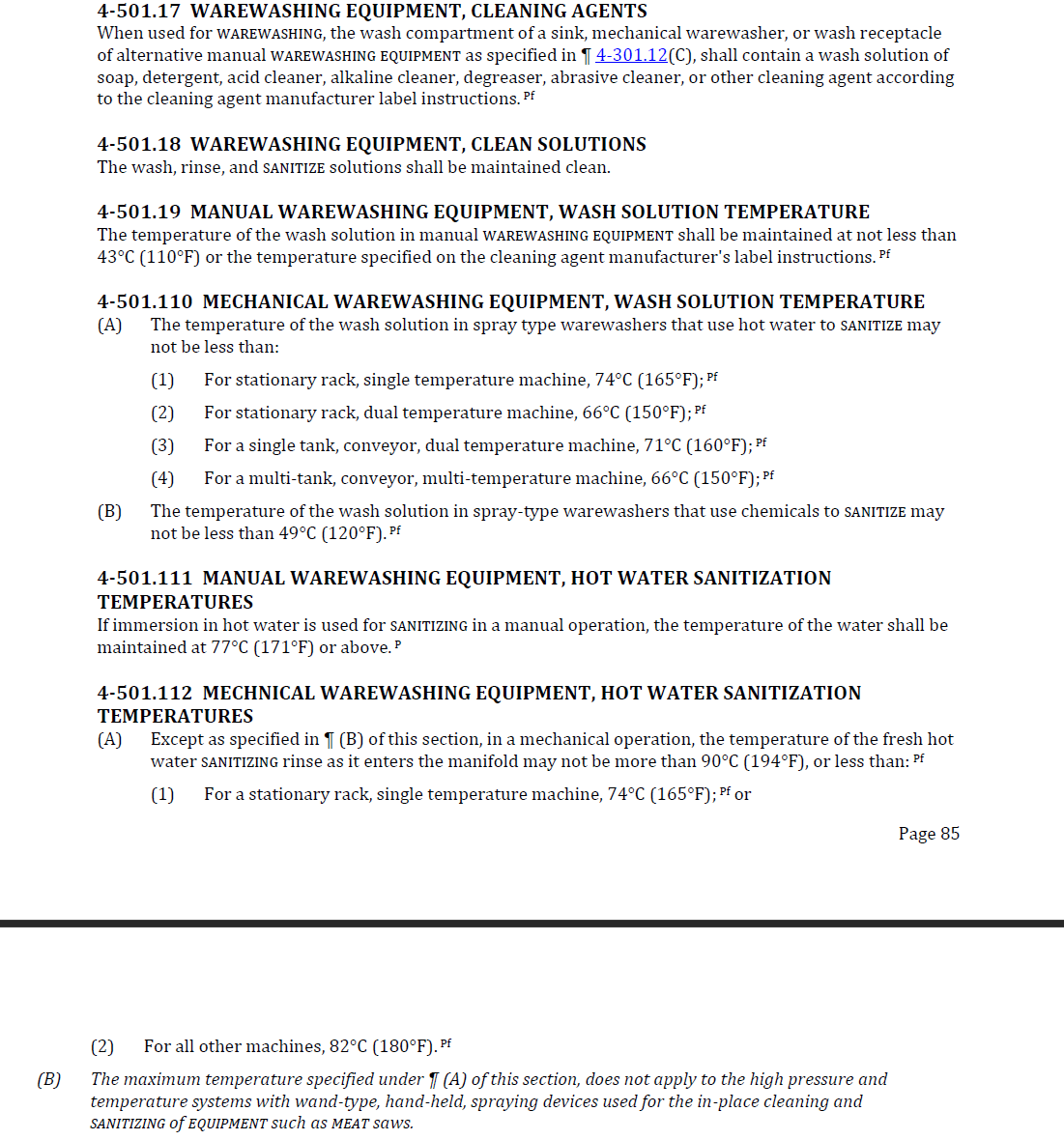

10.1 Idaho Food Code Guidelines: Dish Washing Process and Temperature

-

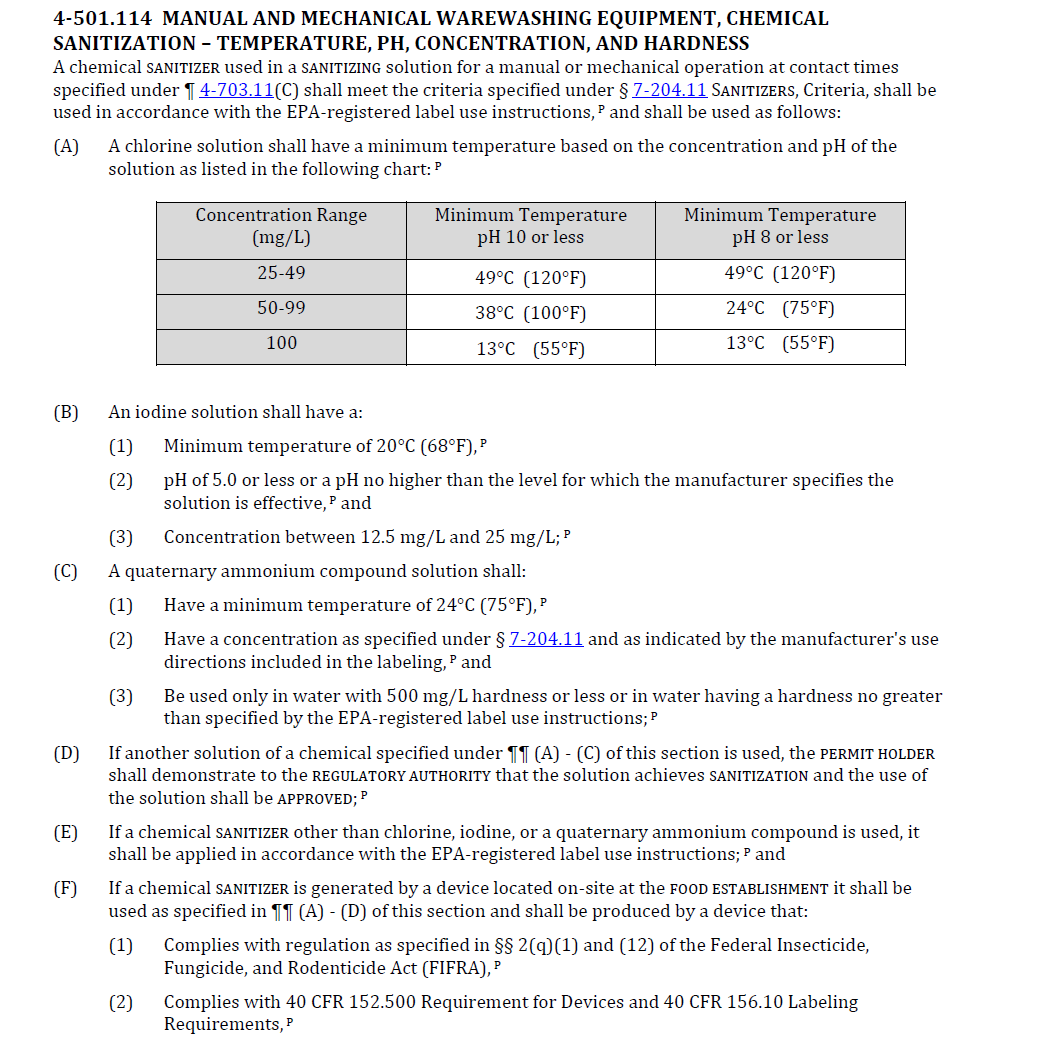

10.2.a Idaho Food Code Guidelines: Chemical Sanitizer Requirements

-

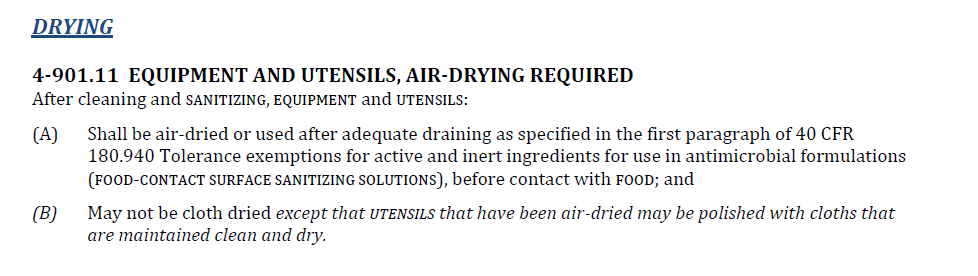

10.3. Idaho Food Code Guidelines: Equipment Storage

-

13.1.a Idaho Food Code Guidelines: Thawing

-

13.1.b: Temperature Danger Zone: 40 F -140 F

-

13.1.c: Internal Cooking Temperatures

Administration

-

1.1 Idaho Food Code Guideline: Biohazard Cleaning