Information

-

Site conducted

-

Document No.

-

Audit Title (Employee Name - Payroll Number - Plant Category e.g. Joe Bloggs - 12345 - Bulldozer)

-

Licence Scheme

-

Is this a zonal assessment?

-

Date of Assessment

-

Start Time of Practical Assessment

-

Finish Time of Practical Assessment

-

Outcome of Assessment

Operator Assessment Details

-

Operator Name

-

Is the operator an Tarmac employee

-

Company name

-

National Insurance number

-

Date of Birth

-

Payroll Number

-

Line manager

-

Category of Job

- Maintenance

- Plant

- Process

- SHE

- Technical

- Weighbridge

- Waste

- Other

-

If Other Job Category please state

-

Business Unit

- Aggregates

- Asphalt

- Cement

- Concrete

- National Contracting

- Functions

- Building Products

-

Site

-

Photo (Digital photograph must be supplied)

-

Assessor

- Chris Harrison

- Pete Simpson

- Rick Callinswood

- Gary Cumberbatch

- Lea Woodward

- Phil Antcliffe

- Chris Hill

- David Hines

- Ian Orme

- Martin Stephens

- Mick Spencer

- Ian Robinson

- Tarmac Certora

- Brett Turtle

- Lee Andrews

- Tony Deane

- Mike Rothon

- Alex Lee

- Stewart Anderson

- Edward Young

- Wade French

- Steve Parfitt

- Rich Billing

- James Roles

- Peter Chruch

-

Vehicle Used

- Agricultural Tractor

- All Terrain Utility Vehicle

- Bitumen Boiler

- Bitumen Spraying Machine

- Bulldozer

- Chipping Machine

- Compactor

- Dredge Operations

- Dumptruck

- Face Shovel

- Fixed Plant Crusher

- Fork Lift Truck

- Forward Tipping Dumper

- Hot Box Lorry

- Hydraulic Excavator 360 Degree

- Level Technician (Planer)

- Light Vehicle 4x4

- Loader Compressor

- Lorry Mounted Crane

- Low Loader

- MEWP Boom

- MEWP Scissor

- Mini Digger

- Mobile Crusher

- Mobile Screen

- Motor Grader

- Motor Scraper W

- Paver

- Planer (Tracked CMM)

- Planer (Wheeled CMM)

- Pneumatic Tyred Roadroller

- Processing Operations

- Road Roller (Hand Operated Only)

- Road Roller (Not including Hand Operated)

- Roadsweeper

- Roped Excavator

- Screwman

- Self-Propelled Fuel Bowser

- Self-Propelled Water Bowser

- Site Lorry

- Site Slurry Tanker

- Site Truckmixer

- Skidsteer

- Skip Handler

- Stihl Saw Abrasive Wheels

- Surface Banksman

- Telehandler

- Tracked Loading Shovel

- Wheeled Loading Shovel 180 with Backacter Pecker

- Wheeled Loading Shovel

- Wheeled Excavator

- Mobile Crane (Tarmac Licences only)

-

Categories

-

<10t

-

10-20t

-

20-30t

-

Categories

-

Bucket

-

Push Tractor

-

Scraper Bowl

-

Categories

-

Less than 30T

-

31-50T

-

51-90T

-

More than 90T

-

Categories

-

Up to 30 Tonnes

-

31-60 Tonnes

-

61-100 Tonnes

-

100+ Tonnes

-

Standard Reach

-

Long Reach

-

Categories

-

Tracked

-

Steel Wheeled

-

Rubber Tyred

-

Large

-

Small

-

Categories

-

< 10m

-

< 18m

-

> 18m

-

Self Propelled

-

Lorry Mounted

-

Proof of Training

-

Categories

-

<10m

-

<18m

-

>18m

-

Rough Terrain

-

Standard

-

Platform Extension

-

Proof of Training

-

Categories

-

Up to 5 Tonne

-

5 - 9 Tonne

-

Categories

-

Breaker

-

Categories

-

Tracked

-

Wheeled

-

Categories

-

Under 8 Tonne

-

Over 8 Tonne

-

Categories

-

Up to 0.5m

-

Up to 1.2m

-

Over 1.2m

-

Categories

-

up to 0.5m

-

up to 1.2m

-

Over 1 .2m

-

Categories

-

Crushing/Screening/Washing

-

Drying

-

Asphalt/Coated Materials Production

-

Density/Fluid Separation

-

Chemical Separation

-

Forming

-

Heat Treatment

-

Sawing/Splitting/Shaping

-

Packaging

-

Water Monitoring

-

China Clay Processing

-

Categories

-

Deadweight

-

Vibrating Under 6 Tonne

-

Vibrating Over 6 Tonne

-

Pneumatic Tyre

-

Categories

-

Rigid

-

Articulated

-

Manual

-

Automatic

-

Normal Fill

-

Fast Fill

-

Categories

-

Rigid

-

Articulated

-

Manual

-

Gravity Fed

-

Automatic

-

PTO

-

Static Site Pump

-

Categories

-

Rigid

-

Articulated

-

Manual

-

Automatic

-

Up to 10 Tonne

-

Up to 20 Tonne

-

Between 21-40 Tonne

-

Over 40 Tonne

-

Categories

-

Standard

-

Short

-

Categories

-

Industrial

-

Rough Terrain

-

Rough Terrain Telescopic Handler above 9 metres

-

Rough Terrain Telescopic handler below 9 metres

-

Industrial Telescopic Handler above 9 metres

-

Industrial Telescopic Handler below 9 metres

-

Proof of Training

-

Telehandler Lift Chart Quiz

Telehandler Lift Chart Quiz

-

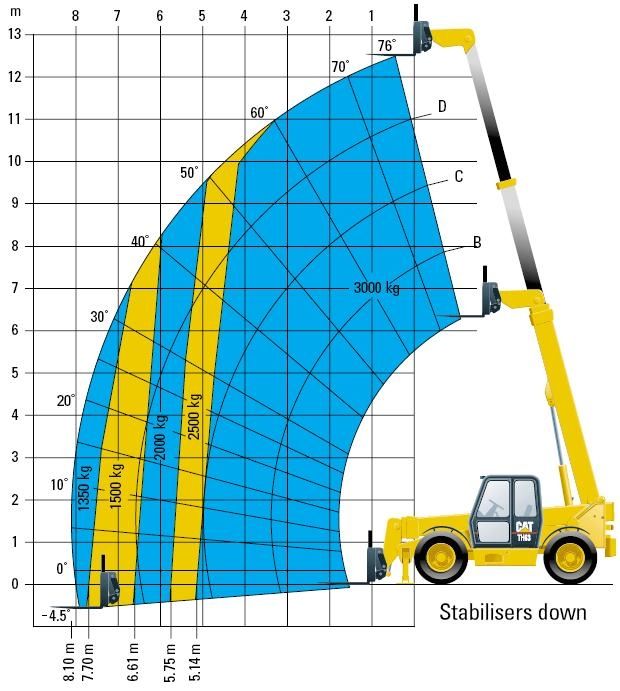

LIFT CHART IMAGE 1

-

1. Lift chart image 1 shows the telehandler with its stabilisers down. What is the maximum lifting capacity at maximum height?

-

TO BE COMPLETED BY THE ASSESSOR - IS THE ANSWER CORRECT?

-

2. Using lift chart image 1 above, what is the maximum lifting capacity with a boom angle of 15° and boom extension at D?

-

TO BE COMPLETED BY THE ASSESSOR - IS THE ANSWER CORRECT?

-

3. Using lift chart image 1 above, what is the further distance (measured from the front tyres) available to place a 2500kg load at a height of 9m?

-

TO BE COMPLETED BY THE ASSESSOR - IS THE ANSWER CORRECT?

-

4. Using lift chart image 1 above, what is the maximum lifting capacity with a boom angle of 50° and boom extension at E?

-

TO BE COMPLETED BY THE ASSESSOR - IS THE ANSWER CORRECT?

-

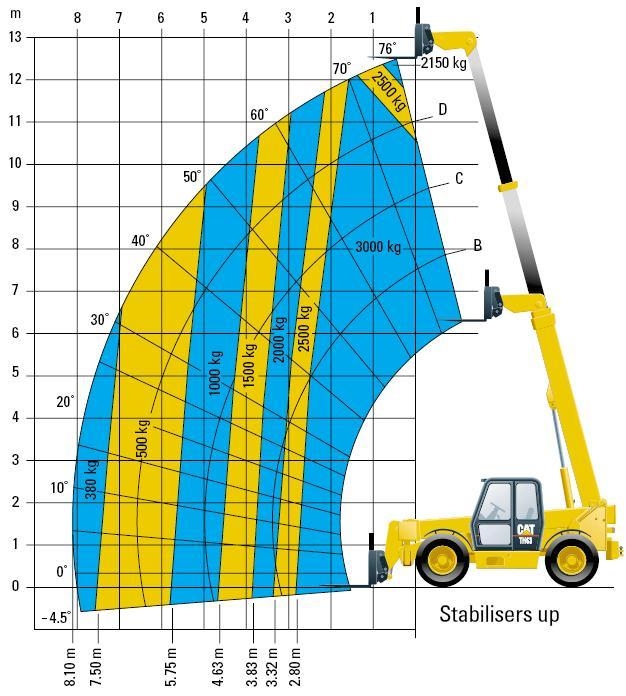

LIFT CHART IMAGE 2

-

5. Using lift chart image 2 for the same telehandler with stabilisers up, what is the maximum lifting capacity at maximum height?

-

TO BE COMPLETED BY THE ASSESSOR - IS THE ANSWER CORRECT?

-

6. Using lift chart image 2 above, what is the maximum lifting capacity with a boom angle of 25° and boom extension at C?

-

TO BE COMPLETED BY THE ASSESSOR - IS THE ANSWER CORRECT?

-

7. Using lift chart image 2 above, what is the furthest distance (measured from the front tyres) available to place a 1500kg load at a height of 8m?

-

TO BE COMPLETED BY THE ASSESSOR - IS THE ANSWER CORRECT?

-

8. Using lift chart image 2 above, what is the furthest distance (measured from the front tyres) available to place a 1000kg at 0°?

-

TO BE COMPLETED BY THE ASSESSOR - IS THE ANSWER CORRECT?

-

Total score for quiz

-

Categories

-

Up to 6 Tonne

-

Above 6 Tonne

-

Backacter

-

Pecker

-

Categories

-

Below 1.5m3

-

Below 3.5m3

-

Below 7.5 m3

-

Below 13 m3

-

13m3 +

-

Categories

-

Blade

-

Wheel

-

Categories

-

Wheeled

-

Bucket

-

Forks

-

Hydraulic Breaker

-

Tracked

-

Auger

-

Sweeper

-

Blade

-

Planer

-

Categories

-

Hydrostatic

-

Mechanical

-

Categories

-

Rigid

-

Articulated

-

Tracked (NOT TO BE USED FOR MPQC LICENCES - TARMAC CARDS ONLY)

-

Up to 10 Tonne (TARMAC CARDS ONLY - NOT MPQC LICENCES)

-

11-20 Tonne (TARMAC CARDS ONLY - NOT MPQC LICENCES)

-

Manual

-

Automatic

-

Up to 20 Tonne

-

21 to 50 Tonne

-

51 to 100 Tonne

-

Over 100 Tonne

-

Categories

-

Counter Balance

-

Rough Terrain

-

Reach Truck

-

Tele Truck

-

Below 5t

-

Between 5t and 10t

-

Above 15t

-

Forks (FB)

-

Fork Extensions (FKE)

-

Bale Clamp (BC)

-

Jib (J)

-

Rotating Forks (RFK)

-

Working Platform - Non Integrated (WPNI)

-

Grad (G)

-

Lifting Beam (LIB)

-

Lifting Forks (LF)

-

Double Forks (DF)

-

Skip

-

Proof of Training

-

Categories

-

Rigid

-

Articulated

-

Up to 6 Tonne

-

6 to 8 Tonne

-

Over 8 Tonne

-

Categories

-

Standard Reach

-

Long Reach

-

Up to 30 Tonnes

-

Between 31-60 Tonnes

-

Between 61-100 Tonnes

-

Over 100 Tonnes

-

Categories

-

Trailer

-

Categories

-

Below 3.5m3

-

Below 7.5m3

-

Below 13m3

-

Above 13m3

-

Loader with Compressor

-

Loader with Backhoe

-

Categories

-

Articulated

-

Rigid

-

Manual

-

Automatic

-

Up to 20 Tonne

-

21 – 50 Tonne

-

51 – 100 Tonne

-

Over 100 Tonne

-

Make/Model

-

Specify Material

- Sand and Gravel

- Fragmented Stone

- Hard Rock

- Powder

- Asphalt

- Liquid

- Roadbuilding

- Waste Recycled

- Other

-

If Other please specify

-

Does the employee have the required qualification to meet the safer by competence initiative?

-

Comments

-

Qualification Name

-

Certificate Number

-

Supplementary Evidence

-

Type of Card

-

This card has been issued as there is no current Vocational Qualification available for this plant type

-

This card has been issued for the purpose of Test & Repair only, NOT for operational use.

-

This card has been issued for Loading and Unloading Plant for transportation

-

Environment Type of Card Applying For

- Plant Operations - Extractives

- Processing Operations - Extractives

- Roadbuilding/Highways Maintenance - Construction

-

Did the employee pass the Health and Safety Test

-

Health and Safety Test Score

Health and Safety

All criteria in this section needs to be met

-

Risk assessment is in place and operator demonstrates knowledge (please attach photo)

-

Operator can demonstrate the following:

- Traffic management plan is explained

- Correct PPE is worn for all tasks carried out

- 3 points of contact used for access / egress

- Complies with site rules & company procedures

- Demonstrates awareness of all hazards, obstructions and services at all times -

Has the criteria in this section been met successfully?

-

Please tick which criteria hasn't been met.

-

Risk Assessment is explained

-

Comments

-

Traffic management plan is explained

-

Comments

-

Correct PPE is worn for all tasks carried out

-

Comments

-

3 points of contact used for access / egress

-

Comments

-

Complies with site rules & company procedures

-

Comments

-

Demonstrates awareness of all hazards, obstructions and services at all times

-

Comments

-

Professional Discussions

-

Comments

Professional Discussions (Has the candidate met the criteria?)

-

What circumstances would you stop using your item of mobile plant?

-

Comments

-

Is there any areas on site that have restricted access?

-

Comments

-

When might you use additional PPE?

-

Comments

-

Has the criteria in this section been met successfully?

-

Assessor comments on the professional conversations

Prepare

Outside Checks

-

Operator can demonstrate the following:

- Assesses ground conditions

- Visual overview of machine for major anomalies

- Visual inspection of wheels / tracks to include where applicable: pressure, defects, nuts, Rim locks, tension and cleanliness

- Checks levels on the following: Engine oil, Transmission oil, Hydraulic oil, Coolant, Autolube

- Operator uses additional items for Pre-start (cloths, PPE etc)

- Checks for any signs of leaks and condition of pipes

- Checks condition of handrails and steps

- Checks general condition of the following: Bucket, Lifting arms, Quick hitch couplers, Cab, Roll over protection structure, Mudguards, Engine cover, Battery cover, Counter balance, Bucket

- Checks condition of the following: Drive belt, Fuel filter, Air filter, Oil filter

- Removes isolator key whilst pre-start checks are carried out -

Has the criteria in this section been met successfully?

-

Please tick which criteria hasn't been met

-

Assesses ground conditions

-

Comments

-

Visual overview of machine for major anomalies

-

Comments

-

Visual inspection of wheels/tracks to include pressure, defects, nuts, Rim locks, tension, cleanliness

-

Comments

-

Checks levels on Engine oil

-

Comments

-

Checks levels on Hydraulic oil

-

Comments

-

Checks levels on Coolant

-

Comments

-

Checks levels on Autolube

-

Comments

-

Operator uses additional items for Pre-start (cloths, PPE etc)

-

Comments

-

Checks for any signs of leaks and condition of pipes

-

Comments

-

Checks condition of handrails and steps

-

Comments

-

Checks general condition of Bucket

-

Comments

-

Checks general condition of Lifting arms

-

Comments

-

Checks general condition of Quick hitch couplers

-

Comments

-

Checks general condition of Cab

-

Comments

-

Checks general condition of Roll over protection structure

-

Comments

-

Checks general condition of Mudguards

-

Comments

-

Checks general condition of Engine cover

-

Comments

-

Checks general condition of Battery cover

-

Comments

-

Checks general condition of Counter balance

-

Comments

-

Checks general condition of Bucket

-

Comments

-

Checks condition of the Drive belt

-

Comments

-

Checks condition of the Fuel filter

-

Comments

-

Checks condition of the Air filter

-

Comments

-

Checks condition of the Oil filter

-

Comments

-

Removes isolator key whilst pre-start checks are carried out

-

Comments

Cab Checks

-

Operator can demonstrate the following:

- Checks condition of cab, Windscreen, Mirrors, Seat, Controls

- Operator explains symbols on cab controls

- Applies seat restraint

- Carries out function checks on the following: Lights, Indicators, All reversing aids, Warning devices, Monitoring devices. -

Has the criteria in this section been met successfully?

-

Please tick which criteria hasn't been met

-

Condition of cab

-

Comments

-

Windscreen

-

Comments

-

Mirrors

-

Comments

-

Seat

-

Comments

-

Controls

-

Comments

-

Operator explains symbols on cab controls

-

Comments

-

Applies seat restraint

-

Comments

-

Carries out function checks on Lights

-

Comments

-

Carries out function checks on Indicators

-

Comments

-

Carries out function checks on All reversing aids

-

Comments

-

Carries out function checks on Warning devices

-

Comments

-

Carries out function checks on Monitoring devices

-

Comments

Start Up

-

Start up (Operator confirms that the following is working correctly)

- Power Unit, Transmission, Steering, Hydraulics, Electrics, Brake test

- VMS checked (all 3 settings)

- Was the pre-start checks carried out in a logical sequence -

Has the criteria in this section been met successfully?

-

Please tick which criteria hasn't been met

-

Start up - Operator confirms that the Power Unit is working correctly

-

Comments

-

Start up - Operator confirms that the Transmission is working correctly

-

Comments

-

Start up - Operator confirms that the Steering is working correctly

-

Comments

-

Start up - Operator confirms that the Hydraulics is working correctly

-

Comments

-

Start up - Operator confirms that the Electrics is working correctly

-

Comments

-

Start up - Operator confirms that the Brakes are working correctly

-

Comments

-

VMS checked (all 3 settings)

-

Comments

-

Was the pre-start checks carried out in a logical sequence

-

Comments

Professional Discussions (Has the candidate met the criteria?)

-

Operator confirms when inspections take place & how defects are reported

-

Comments

-

Photo of defect book

-

What information would you find in the manufacturers operating book

-

Comments

-

How do you ensure all round awareness?

-

Comments

-

What is your responsibilities relating to maintenance on your mobile plant?

-

Comments

-

Has the criteria in this section been met successfully

-

Assessor comments on the professional conversations

Operating

-

Task 1 - Travelling

Task 1 – Travelling

-

Operator demonstrates the following:

- Can explain the sequence of the task

- Demonstrates all round awareness

- Operates to conditions (bucket position, speed, ground etc)

- Keeps vehicle stable at all times

- Demonstrates use of aids (mirrors, camera, indicators etc)

- Controls load that is being carried (If applicable)

- Keeps reversing to a minimum

- Communicates with those in the work area -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met

-

Can explain the sequence of the task

-

Comments

-

Demonstrates all round awareness

-

Comments

-

Operates to conditions (bucket position, speed, ground etc)

-

Comments

-

Keeps vehicle stable at all times

-

Comments

-

Demonstrates use of aids (mirrors, camera, indicators etc)

-

Comments

-

Controls load that is being carried (spillage etc)

-

Comments

-

Keeps reversing to a minimum

-

Comments

-

Communicates with those in the work area

-

Comments

Professional Discussions

-

What action would you take in the event of brake failure?

-

Comments

-

What action do you take when you feel a task is outside your competency?

-

Comments

-

What action do you take when changes occur in the work area?

-

Comments

-

How do you work out what quantity of material goes into the receiving location

-

Comments

-

Has the criteria in this section been met successfully?

-

Assessor comments on the professional conversations

-

Task 2 - Material Handling (working at stockpiles, stacks, bays etc)

Task 2 - Material Handling (working at stockpiles, stacks, bays etc)

-

Operator demonstrates the following:

- Can explain the sequence of the task

- Ensures that the machine is in the correct position when approaching material

- Maintains bucket capacity avoiding spillage

- Displays good use of controls

- Demonstrates good all round awareness

- Avoids contamination

- Demonstrates use of aids (mirrors, camera, indicators etc)

- Ensures work area is clear and good housekeeping maintained

- Keeps vehicle stable at all times

- Communicates with those in the work area -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met

-

Can explain the sequence of the task

-

Comments

-

Ensures that the machine is in the correct position when approaching material

-

Comments

-

Maintains bucket capacity avoiding spillage

-

Comments

-

Displays good use of controls

-

Comments

-

Demonstrates good all round awareness

-

Comments

-

Avoids contamination

-

Comments

-

Demonstrates use of aids (mirrors, camera, indicators etc)

-

Comments

-

Ensures work area is clear and good housekeeping maintained

-

Comments

-

Keeps vehicle stable at all times

-

Comments

-

Communicates with those in the work area

-

Comments

-

Task 3 - Working at the face

Task 3 – Working at the face

-

Rockpad Operations Assessed?

-

Operator can demonstrate the following:

- Can explain the sequence of the task

- Shows awareness of face conditions

- Ensures work area is clear and good housekeeping maintained

- Ensures that the machine is in the correct position whilst carrying out the task

- Maintains bucket capacity avoiding spillage

- Demonstrates good use of controls

- Keeps vehicle stable at all times

- Communicates with those in the work area -

Has the criteria in this section been met successfully?

-

Please tick which criteria hasn't been met

-

Can explain the sequence of the task

-

Comments

-

Shows awareness of face conditions

-

Comments

-

Ensures work area is clear and good housekeeping maintained

-

Comments

-

Ensures that the machine is in the correct position whilst carrying out the task

-

Comments

-

Maintains bucket capacity avoiding spillage

-

Comments

-

Demonstrates good use of controls

-

Comments

-

Keeps vehicle stable at all times

-

Comments

-

Communicates with those in the work area

-

Comments

-

Comments

Professional Discussions

-

Explain the key principles of the design plan for your area of work?

-

Comments

-

How do you report misfires?

-

Comments

-

Has the criteria in this section been met successfully

-

Assessor comments on the professional conversations

-

Task 4 - Working on the highway

Task 4 - Working on the highway

-

Operator can demonstrate the following-

- Can explain the sequence of the task

- Understands the layout of the site

- Works to speed limits that have been put in place

- Ensures the vehicle is fit for purpose -

Has the criteria in this section been met successfully?

-

Please tick which criteria hasn't been met

-

Can explain the sequence of the task

-

Comments

-

Understands the layout of the site

-

Comments

-

Works to speed limits that have been put in place

-

Comments

-

Ensures the vehicle is fit for purpose

-

Comments

-

Comments

-

Task 5 - Working at heights

Task 5 - Working at heights

-

Are the MEWP operating activities part of this assessment

-

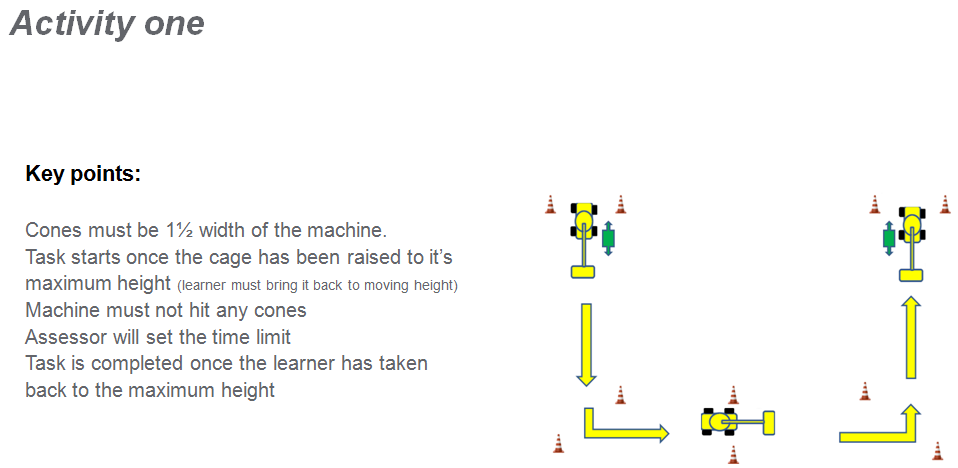

Activity one

-

Comments

-

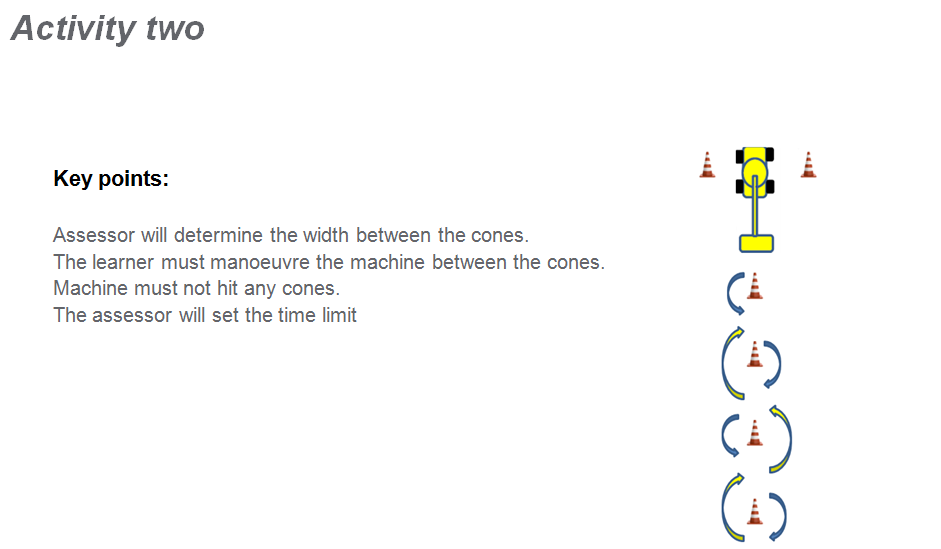

Activity two

-

Comments

-

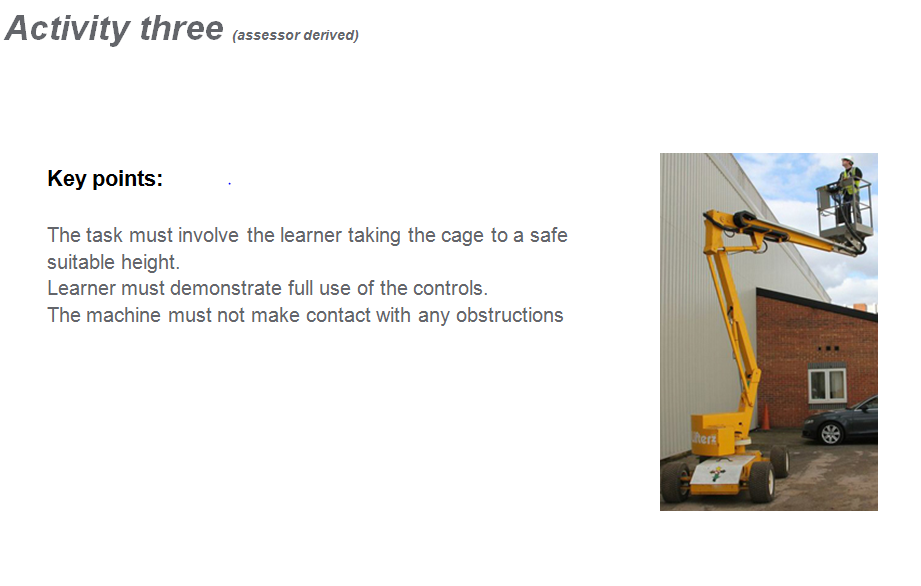

Activity three

-

Comments

-

Details of activity three

-

Photos of task required

-

Operator can demonstrate the following:-

- Can explain the sequence of the task

- Inspection of safety harnesses

- Ensures valid certification for maintenance, inspection and examination

- operates machine within safe working limits, level and angle limits, and wind limits

- safe operation in relation to working conditions and envrionment

- safely accesses and egresses using steps and handrails or access points

- safely attaches safety harness to recognised harness points

- Communicates with those in the work area

- The use of the emergency controls -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met

-

Can explain the sequence of the task

-

Comments

-

Inspection of safety harnesses

-

Comments

-

Ensures valid certification for maintenance, inspection and examination

-

Comments

-

Operates machine within safe working limits, level and angle limits, and wind limits

-

Comments

-

Safe operation in relation to working conditions and envrionment

-

Comments

-

Safely accesses and egresses using steps and handrails or access points

-

Comments

-

Safely attaches safety harness to recognised harness points

-

Comments

-

Communicates with those in the work area

-

Comments

-

Can demonstrate the use of the emergency controls

-

Comments

Professional Discussions

-

Who's permitted to fit guide ropes?

-

Comments

-

Can you explain the rescue plan?

-

Comments

-

Has the criteria in this section been met successfully?

-

Assessor comments on the professional conversations

-

Task 6 - Excavating

Task 6 - Excavating

-

Operator can demonstrate the following:-

- Can explain the sequence of the task

- Sets up and positions machine for safe operation

- employs the correct co-ordination of all hydraulic controls to achieve maximum efficiency of operation

- maintains good working area conditions

- maintains safe area and working environment

- uses machine within manufacturers safe working limits and capabilities

- Communicates with those in the work area -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met

-

Can explain the sequence of the task

-

Comments

-

Sets up and positions machine for safe operation

-

Comments

-

Employs the correct co-ordination of all hydraulic controls to achieve maximum efficiency of operation

-

Comments

-

Maintains good working area conditions

-

Comments

-

Uses machine within manufacturers safe working limits and capabilities

-

Comments

-

Communicates with those in the work area

-

Comments

Professional Discussions

-

What conditions can affect safe operations?

-

Comments

-

Has the criteria in this section been met successfully?

-

Assessor comments on the professional conversations

-

Task 7 - Compacting

Task 7 - Compacting

-

Operator can demonstrate the following:

- Can explain the sequence of the task

- Sets up vehicle in correct position for task

- Maintains safe working to minimise risk from movement of materials

- Maintains efficient/effective operational techniques

- Work to engineers designs (levels/density and compaction specifications)

- Communicates with those in the work area -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met

-

Can explain the sequence of the task

-

Comments

-

Sets up vehicle in correct position for task

-

Comments

-

Maintains safe working to minimise risk from movement of materials

-

Comments

-

Maintains efficient/effective operational techniques

-

Comments

-

Work to engineers designs (levels/density and compaction specifications)

-

Comments

-

Communicates with those in the work area

-

Comments

-

Task 8 - Creating, Forming and processing

Task 8 - Creating, Forming and processing

-

Operator can demonstrate the following:

- Can explain the sequence of the task

- Sets up vehicle in correct position for task

- Works to engineers designs (levels/density and compaction specifications)

- Maintains efficient/effective operational techniques

- Maintains safe working to minimise risk from movement of materials

- Communicates with those in the work area -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met

-

Can explain the sequence of the task

-

Comments

-

Sets up vehicle in correct position for task

-

Comments

-

Maintains efficient/effective operational techniques

-

Comments

-

Works to engineers designs (levels/density and compaction specifications)

-

Comments

-

Maintains safe working to minimise risk from movement of materials

-

Comments

-

Communicates with those in the work area

-

Comments

-

Task 9 - Loading Hoppers

Task 9 – Loading Hoppers

-

Operator can demonstrate the following:

- Can explain the sequence of the task

- Ensures that hopper is clear from contamination

- Approaches hopper at the correct speed and in control of material

- Maintains bucket capacity avoiding spillage

- Controls rate of discharge to minimise spillages, blockages etc

- Demonstrates good all round awareness

- Demonstrates use of aids (mirrors, camera, indicators etc)

- Demonstrates good use of controls

- Ensures work area is clear and good housekeeping maintained

- Keeps vehicle stable at all times

- Communicates with those in the work area -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met.

-

Can explain the sequence of the task

-

Comments

-

Ensures that hopper is clear from contamination

-

Comments

-

Approaches hopper at the correct speed and in control of material

-

Comments

-

Maintains bucket capacity avoiding spillage

-

Comments

-

Controls rate of discharge to minimise spillages, blockages etc

-

Comments

-

Demonstrates good all round awareness

-

Comments

-

Demonstrates use of aids (mirrors, camera, indicators etc)

-

Comments

-

Demonstrates good use of controls

-

Comments

-

Ensures work area is clear and good housekeeping maintained

-

Comments

-

Keeps vehicle stable at all times

-

Comments

-

Communicates with those in the work area

-

Comments

-

Task 10 - Loading road vehicles

Task 10 – Loading road vehicles

-

Operator can demonstrate the following:

- Can explain the sequence of the task

- Ensures that receiving vehicle is in the correct position

- Demonstrates good control when approaching the vehicle

- Maintains bucket capacity avoiding spillage

- Loads vehicle to ensure even distribution and to avoid spillage

- Demonstrates good use of controls

- Demonstrates use of aids (mirrors, camera, weigh loader etc)

- Ensures work area is clear and good housekeeping maintained

- Keeps vehicle stable at all times

- Communicates with those in the work area -

Has the criteria in this section been met successfully

-

Comments

-

Please tick which criteria hasn't been met

-

Communicates with those in the work area

-

Comments

-

Can explain the sequence of the task

-

Comments

-

Ensures that receiving vehicle is in the correct position

-

Comments

-

Demonstrates good control when approaching the vehicle

-

Comments

-

Maintains bucket capacity avoiding spillage

-

Comments

-

Loads vehicle to ensure even distribution and to avoid spillage

-

Comments

-

Demonstrates good use of controls

-

Comments

-

Demonstrates use of aids (mirrors, camera, weigh loader etc)

-

Comments

-

Ensures work area is clear and good housekeeping maintained

-

Comments

-

Keeps vehicle stable at all times

-

Comments

-

Task 11 - Loading site vehicles

Task 11 - Loading site vehicles

-

Operator can demonstrate the following:-

- Can explain the sequence of the task

- Correctly positions the receiving vehicle

- Loads the vehicle safely

- Minimises spillage

- Correctly accesses and egresses the vehicle

- Displays sensitivity of all controls -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met

-

Can explain the sequence of the task

-

Comments

-

Correctly positions the receiving vehicle

-

Comments

-

Loads the vehicle safely

-

Comments

-

Minimises spillage

-

Comments

-

Correctly accesses and egresses the vehicle

-

Comments

-

Displays sensitivity of all controls

-

Comments

-

Task 12 - Loading trains

Task 12 - Loading trains

-

Operator can demonstrate the following:-

- safe working procedures and knowledge of the operation

- selection of correct materials to be loaded

- reduces chance of spillage -

Has the criteria in this section been met successfully?

-

Please tick which criteria hasn't been met

-

safe working procedures and knowledge of the operation

-

Comments

-

selection of correct materials to be loaded

-

Comments

-

reduces chance of spillage

-

Comments

-

Comments

Professional Discussions

-

Can you explain potential hazards that effect loading operations?

-

Comments

-

How do you know what material to load on to the train?

-

Comments

-

Has the criteria in this section been met successfully?

-

Assessor comments on the professional conversations

-

Task 13 - Receiving / Tipping / Discharging

Task 13 - Receiving / Tipping / Discharging

-

Operator demonstrates the following:

- Can explain the sequence of the task

- Checks suitability of ground conditions/stability

- Checks all round vision before moving off

RECEIVING

- Ensures the vehicle is in the correct position for receiving

- Remains in the correct location whilst loading operations take place

- Engages parking brake whilst loading operations take place

- Attaches pipe work using correct manual handling techniques (if applicable)

- Controls the rate of receiving to minimise the risk of spillage (if applicable)

- Checks load security

TIPPING

- Engages parking brake/ tipping brake before commencing tipping procedure

- Controls rate of discharge to avoid damage blockage and spillage

- Move away from discharge point only when body is lowered and the travel position

- Ensure that tailboard is secure before travelling (if applicable)

- Tipping operation is carried out to all company procedures

DISCHARGES

- Controls rate of discharge to avoid damage or blockage

- Receives confirmation that discharging can commence (if applicable)

- Uses ancillary equipment to all company procedures

- Takes consideration to other activities to avoid contamination/soaking

- Discharging operation is carried out to all company procedures -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met.

-

Can explain the sequence of the task

-

Comments

-

Checks suitability of ground conditions/stability

-

Comments

-

Checks all round vision before moving off

-

Comments

-

Ensures the vehicle is in the correct position for receiving

-

Comments

-

Remains in the correct location whilst loading operations take place

-

Comments

-

Engages parking brake whilst loading operations take place

-

Comments

-

Attaches pipe work using correct manual handling techniques (if applicable)

-

Comments

-

Controls the rate of receiving to minimise the risk of spillage (if applicable)

-

Comments

-

Checks load security

-

Comments

-

Engages parking brake/ tipping brake before commencing tipping procedure

-

Comments

-

Controls rate of discharge to avoid damage blockage and spillage

-

Comments

-

Move away from discharge point only when body is lowered and the travel position

-

Comments

-

Ensure that tailboard is secure before travelling (if applicable)

-

Comments

-

Tipping operation is carried out to all company procedures

-

Comments

-

Controls rate of discharge to avoid damage or blockage

-

Comments

-

Receives confirmation that discharging can commence (if applicable)

-

Comments

-

Uses ancillary equipment to all company procedures

-

Comments

-

Takes consideration to other activities to avoid contamination/soaking

-

Comments

-

Discharging operation is carried out to all company procedures

-

Comments

-

Task 14 - Towing / Shunting

Task 14 - Towing / Shunting

-

The operator can demonstrate the following:

Can explain the sequence of the task

Checks the vehicle recommended towing limit (VIN plate)

Ensures that the gross weight does not exceed the capacity of the towing vehicle

Checks all coupling equipment

Inspects the item of equipment that is due to be towed

Securely attaches the equipment to the towing vehicle

Positions the vehicle correctly

Carries out reversing manoeuvres -

Has the criteria in this section been met successfully?

-

Comments

-

Checks the vehicle recommended towing limit (VIN plate)

-

Comments

-

Ensures that the gross weight does not exceed the capacity of the towing vehicle

-

Comments

-

Checks all coupling equipment

-

Comments

-

Inspects the item of equipment that is due to be towed

-

Comments

-

Securely attaches the equipment to the towing vehicle

-

Comments

-

Positions the vehicle correctly

-

Comments

-

Carries out reversing maneuvers

-

Comments

-

Task 15 - Working with attachments

T15 – Working with attachments

-

Please state the quick hitch coupling

-

Please state attachments

- Auger

- Bale Clamp

- Bars

- Breaker

- Bucket

- Bucket 4 in 1

- Bucket 6 in 1

- Clamp

- Coupling Lance

- Crane

- Cutting Wheel

- Digging & Grading

- Double Forks

- Drop Ball

- Flat Edge

- Fork Extensions

- Forks

- Forks with Lifting Equipment

- Front and Rear High Pressure Spray Bars

- Front Tipping Dumper

- Fuel Bowser

- Grab

- Grab Bucket

- Grading Bucket

- Grapple

- Gritter

- High Discharge Skip

- High Pressure Washing Lance

- Jib

- Lifting Beam

- Lifting Forks

- Lifting Hook

- Lifting Jib

- Pecker

- Plough

- Riddle

- Right Hand Brush

- Ripper

- Roadroller

- Rock Hammer

- Rock Hammer/Auger

- Rotating Forks

- Side Tipping Dumper

- Snowplough

- Suction Dredge

- Tipping Trailer

- Trencher

- Vacuum Gully Sucker

- Vehicle Tank Grab

- Waste Grab

- Water Bowser

- Working Platform – Integrated

- Working Platform – Non Integrated

- Compactor

- Platform Extension

- Sweeper

- Hydraulic Breaker

- Blade

- Wheel

- Grab or Bucket Dredge

- Planer

-

Operator can demonstrate the following:

- Explain the sequence of the task

- Ensure machine is parked in correct location

- Detach the attachment ensuring it’s left in a safe manner

- Attach attachment ensuring its securely attached

- Communicates with those in the work area

- Carry out function checks -

Has the criteria in this section been met successfully

-

Comments

-

Please tick which criteria hasn't been met

-

Explain the sequence of the task

-

Comments

-

Ensure machine is parked in correct location

-

Comments

-

Detach the attachment ensuring it’s left in a safe manner

-

Comments

-

Attach attachment ensuring its securely attached

-

Comments

-

Communicates with those in the work area

-

Comments

-

Carry out function checks

-

Comments

-

Task 16 - Drilling

Task 16 - Drilling

-

Operator demonstrates the following:

- Can explain the sequence of the task

- Confirms drill specification requirements and correct face identified

- Confirms edge protection in place

- Sets up rig in correct/safe position for task

- Collars off correctly and clears any loose material

- Checks drill beam and realigns if necessary

- Good drilling rate, no snatching

- Lifts hammer or drill bit off hole bottom to change rod or tube

- Ensures threads are greased and dirt free

- Ensures rods/tubes are clear

- Does not apply rotation whilst holding spanner on rods/tubes

- Monitor ground and hole condition whilst drilling

- Monitor and adjust dust control system

- Operator positions himself safely at all times during task

- On completion checks hole for depth and straightness, protects from ingress of material if necessary

- Records hole position/angle/depth/anomalies -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met.

-

Does not apply rotation whilst holding spanner on rods/tubes

-

Comments

-

Monitor ground and hole condition whilst drilling

-

Comments

-

Monitor and adjust dust control system

-

Comments

-

Operator positions himself safely at all times during task

-

Comments

-

On completion checks hole for depth and straightness, protects from ingress of material if necessary

-

Comments

-

Records hole position/angle/depth/anomalies

-

Comments

-

Can Explain the sequence of the task

-

Comments

-

Confirms drill specification requirements and correct face identified

-

Comments

-

Confirms edge protection in place

-

Comments

-

Sets up rig in correct/safe position for task

-

Comments

-

Collars off correctly and clears any loose material

-

Comments

-

Checks drill beam and realigns if necessary

-

Comments

-

Good drilling rate, no snatching

-

Comments

-

Lifts hammer or drill bit off hole bottom to change rod or tube

-

Comments

-

Ensures threads are greased and dirt free

-

Comments

-

Ensures rods/tubes are clear

-

Comments

-

Task 17 - Loader / Securing

Task 17 - Loader / Securing

-

Operator demonstrates the following:

- Can explain the sequence of the task

- Identifies the area where the loading operation will take place

- Considers all hazards in the proximity

- Checks height and dimensions of the load prior to loading

- Ensures that the load is prepared for transport

- Selects and uses the correct load restraint equipment

- Safely maneuvers the load onto the transport

- Checks balance / stability of load before securing -

Has the criteria in this section been met successfully?

-

Comments

-

Please tick which criteria hasn't been met.

-

Can explain the sequence of the task

-

Comments

-

Identifies the area where the loading operation will take place

-

Comments

-

Considers all hazards in the proximity

-

Comments

-

Checks height and dimensions of the load prior to loading

-

Comments

-

Ensures that the load is prepared for transport

-

Comments

-

Selects and uses the correct load restraint equipment

-

Comments

-

Safely maneuvers the load onto the transport

-

Comments

-

Checks balance / stability of load before securing

-

Comments

Professional Discussion

-

What are the differences between directing and guiding operations

-

Comments

-

What are the differences between a slinger and signaller

-

Comments

-

What are the differences between load restraint and lifting equipment

-

Comments

-

Task 18 - Lifting operations

Task 18 - Lifting operations

-

Operator can demonstrate the following:

Explain the sequence of the task

Confirm all specific lifting equipment has been tested and checked

Ensure all safety devices are operational

All relevant risk assessments, SSOW/SOP, Permits, lift plans etc are in place and adequate

A suitable exclusion zone has been established

If lifting people, necessary PPE (harness, chin strap) is worn

Confirm weight, size, centre of gravity and distance travelled of load

Any slinging conducted by competent person

Conduct a test lift

Assess area before conducting and during lift

Agree suitable communication methods

Conducts lift demonstrating correct coordination of all hydraulic controls

At end of lift all lifting equipment to be checked and stored securely -

Was this task carried out successfully?

-

Comments

-

Confirms all specific lifting equipment has been tested and checked

-

Comments

-

Ensure all safety devices are operational

-

Comments

-

All relevant risk assessments, SSOW/SOP, Permits, lift plans etc are in place and adequate

-

Comments

-

A suitable exclusion zone has been established

-

Comments

-

If lifting people, necessary PPE (harness, chin strap) is worn

-

Comments

-

Confirm weight, size, centre of gravity and distance travelled of load

-

Comments

-

Any slinging conducted by competent person

-

Comments

-

Conducts a test lift

-

Comments

-

Assess area before conducting and during lift

-

Comments

-

Conducts lift demonstrating correct coordination of all hydraulic controls

-

Comments

-

At end of lift all lifting equipment to be checked and stored securely

-

Comments

-

Agree suitable communication methods

-

Comments

-

Can explain the sequence of the task

-

Comments

Professional Discussions

-

Describe the de-rating equipment

-

Comments

-

Task 20 - Variable

Task 20 - Variable (please confirm this task with the operational competence team)

-

What was the task being carried out?

-

Please give detail of the observation criteria.

-

Was this task carried out successfully?

Shut Down / Security

-

Operator can demonstrate the following:

- Machine is parked is the designated parking area (preferred first move forward)

- Engages hydraulic safety control device

- Bucket in correct position

- Parking brake applied

- Engine off, ignition & isolator key removed

- Drains air tank (if applicable)

- Checks equipment is secured

- Walks round the machine to check for any damages / changes

- Ensures keys are left in secure place -

Has the criteria in this section been met successfully?

-

Please tick which criteria hasn't been met.

-

Machine is parked is the designated parking area (preferred first move forward)

-

Comments

-

Engages hydraulic safety control device

-

Comments

-

Bucket in correct position

-

Comments

-

Parking brake applied

-

Comments

-

Engine off, ignition & isolator key removed

-

Comments

-

Drains air tank (if applicable)

-

Comments

-

Checks equipment is secured

-

Comments

-

Walks round the machine to check for any damages / changes

-

Comments

-

Ensures keys are left in secure place

-

Comments

Professional discussions

-

How do you maintain good housekeeping standards on your machine?

-

Comments

-

When do you remove the isolator key from your mobile plant?

-

Comments

-

When are you allowed to leave mobile plant unattended?

-

Comments

-

Has the criteria in this section been met successfully?

-

Can the operator explain the 'Regeneration System'?

-

Comments

-

Assessor comments on the professional conversations

Signatures

-

PRIVACY NOTICE

How will Tarmac use your personal information?

Tarmac will use your personal information for the purpose of providing your Mobile Plant Licence Assessment. As this is part of an accredited service, your information will be shared with MPAwards, our awarding body. To view a copy of their GDPR policy please search for MPQC Plant Scheme Data Protection Policy on the Vault. -

Candidate's Signature

-

Assessor's Signature

-

Line Manager's Signature

-

Additional comments Operator / Assessor / Line manager

-

undefined

-

Any additional media

-

Add media